3

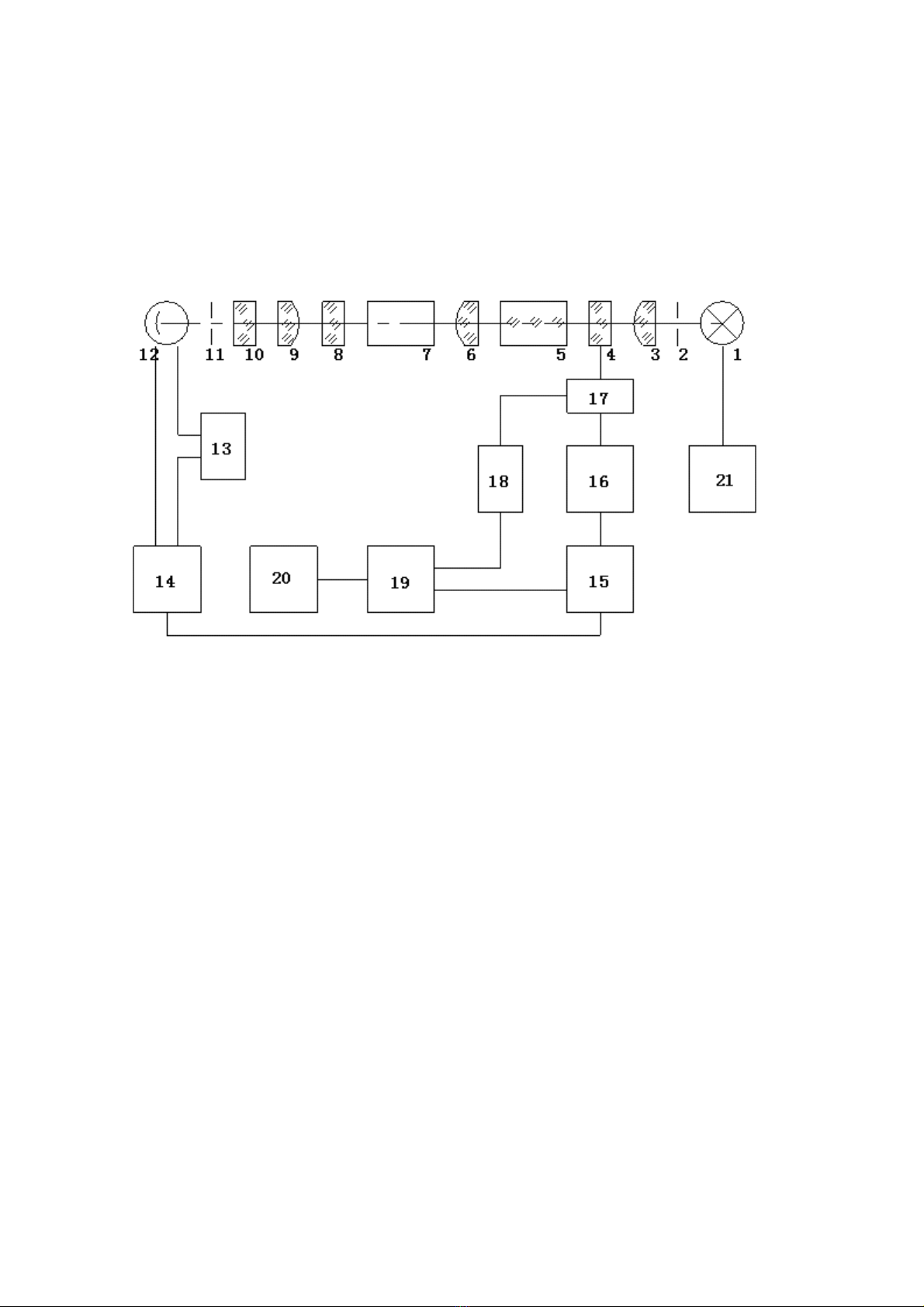

III. Structure and Basic Principles

3.1 Basic principles of application

As we all know, the visible light is a kind of electromagnetic wave with a wavelength of

380nm~780nm. In the statistical law, the corresponding light vibrations happens in possible

directions in the direction perpendicular to the light propagation direction, and the corresponding

amplitude of light vector (light intensity) in all possible directions are the same, usually called the

natural light. With certain devices (e.g., a polarizer), the vibration direction can be fixed in a

direction perpendicular to the light propagation direction, to form a so-called plane-polarized light.

When plane polarized light goes through a substance, the vibration direction of polarized light will

turn an angle, the substance is called optical material, and the angle that polarized light turned is

called optical rotation. If the plane polarized light goes through the optically puresubstance, and

the optical rotation is determined by the following three factors:

(a) The wavelength (λ) of the plane polarized light: for different wavelengths,the optical rotation

is different.

(b) The temperature (t) of the optically active substance: for different temperatures, the optical

rotation is different.

(c) The kind of an optically active substance: for different optically active substances, the optical

rotation is different.

The specific rotation [α]tλrepresents the rotation capacity of a substance.

Typically, the predetermined length of the optical tube is 1dm (100mm), the concentration of the

test substance solution is 1g/mL, and the temperature t℃. When the plane polarized light is at the

wavelength λ, the measured optical rotation is called the specific rotation of the substance, [α]tλ.

The specific rotation is only determined by the structure of substance. Therefore, the specific

rotation is the substance-specific physical constant.

αtλ=[α]tλ·L·C (1)