3 On safety

This chapter deals with your own safety and the safety of the equipment operators.

bPlease read this chapter carefully before working with the safety switch or with the

machine protected by the safety switch.

The national/international rules and regulations apply to the installation, commission‐

ing, use and periodic technical inspections of the safety switch, in particular the work

safety regulations and safety rules.

3.1 Qualified safety personnel

The switch must be mounted, installed and commissioned only by qualified safety per‐

sonnel. Qualified safety personnel are defined as persons who …

•have undergone the appropriate technical training

and

•who have been instructed by the responsible machine operator in the operation of

the machine and the current valid safety guidelines

and

•who have access to the operating instructions.

3.2 Application

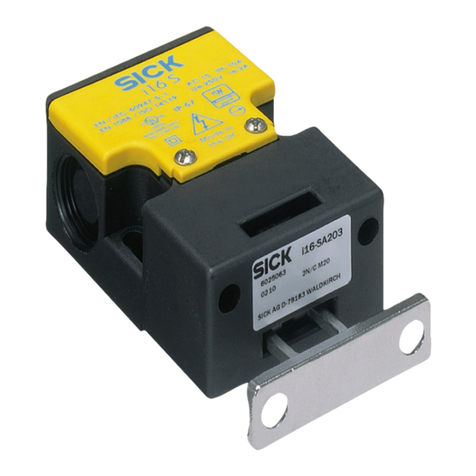

The safety switch is a magnetically operated, non-contact safety switch. In combination

with a suitable safety-related evaluation unit, they protect movable guards in the follow‐

ing way:

•The dangerous state of the machine can only be switched on when the guard is

closed.

•If the guard is opened while the machine is running, a stop command is triggered.

For the control this means:

•Activation commands that result in dangerous states are only allowed to become

effective if the guard is in the protective position.

•Dangerous states must have been terminated before the protective position is left.

Prior to the use of safety switches, a risk assessment must be performed on the

machine.

3.3 Correct use

The safety switch must be used only as defined in section "Application", page 5. The

safety switch must be used only on the machine where it has been mounted, installed

and initialized by qualified safety personnel in accordance with these operating instruc‐

tions.

All warranty claims against SICK AG are forfeited in the case of any other use, or alter‐

ations being made to the safety switch, even as part of its mounting or installation.

Correct use includes also regular inspection of the guard by qualified safety personnel

in accordance with chapter 7.2.

3.4 General safety notes and protective measures

Safety switches provide a protection function for persons. Incorrect installation or

manipulation can result in serious injuries.

ON SAFETY 3

8022165/2017-11-14 | SICK O P E R A T I N G I N S T R U C T I O N S | RE1 5

Subject to change without notice