Contents

1 About this document........................................................................ 5

1.1 Function of this document....................................................................... 5

1.2 Scope......................................................................................................... 5

1.3 Target groups and structure of these operating instructions................ 5

1.4 Further information................................................................................... 5

1.5 Symbols and document conventions...................................................... 6

2 Safety information............................................................................ 8

2.1 General safety notes................................................................................ 8

2.2 Intended use............................................................................................. 8

2.3 Requirements for the qualification of personnel.................................... 8

3 Product description........................................................................... 10

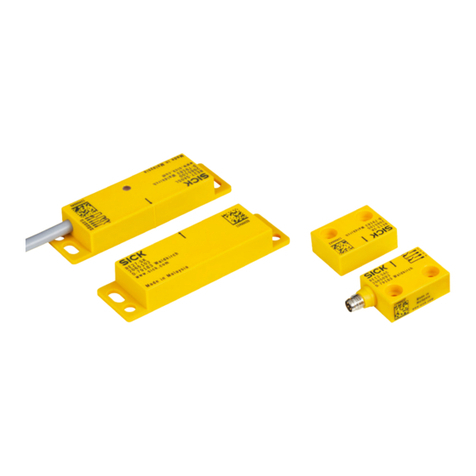

3.1 Structure and function............................................................................. 10

3.2 Product characteristics............................................................................ 11

4 Project planning................................................................................ 13

4.1 Manufacturer of the machine.................................................................. 13

4.2 Operating entity of the machine.............................................................. 13

4.3 Design........................................................................................................ 14

4.4 Integration into the electrical control...................................................... 14

4.5 Thorough check concept.......................................................................... 14

5 Mounting............................................................................................. 16

5.1 Safety......................................................................................................... 16

5.2 Unpacking.................................................................................................. 16

5.3 Mounting................................................................................................... 16

5.4 Changing the approach direction............................................................ 18

6 Electrical installation........................................................................ 20

6.1 Safety......................................................................................................... 20

6.2 Failsafety................................................................................................... 20

6.3 Protection of the voltage supply.............................................................. 21

6.4 Notes on cULus......................................................................................... 21

6.5 Device connection M12×8....................................................................... 21

6.6 Connecting cables.................................................................................... 22

6.7 Y-distribution and end connector............................................................. 24

6.8 Connection................................................................................................ 25

7 Commissioning.................................................................................. 30

7.1 Safety......................................................................................................... 30

7.2 Switching on.............................................................................................. 30

7.3 Teach-in..................................................................................................... 30

7.4 Thorough check........................................................................................ 32

CONTENTS

8022738/2019-05-07 | SICK O P E R A T I N G I N S T R U C T I O N S | T4000 Direct 3

Subject to change without notice