3

SE 80/185 T - SE 100/185 T - SE 130/250T 1.0.1- 2008

Motor: Spesialutviklet reversibel DC-motor.

Girhus: Sjøvannsbestandig bronsje. Kulelagre på pro-

pellaksel. Kule og glidelager komb. på drivaksel.

Motorbraket: Sjøvannsbestandig aluminium.

Galvanisk isolert fra motor

Tunnel: Kryssvevet glassber.

Aluminium og ståltunnel på forespørsel.

Propell: 5-llads skew "Q"-propell i kompositmateriale.

Batterier: Minimum anbefalt batteri størrelse.

(Kaldstart kapasitet etter DIN/SAE std.)

SE 80/185T 12V : 550 CCA DIN/1045 CCA SAE

SE 80/185T 24V : 300 CCA DIN/570 CCA SAE

SE 100/185T 12V : 750 CCA DIN/1425 CCA SAE

SE 100/185T 24V : 400 CCA DIN/760 CCA SAE

SE 130/250T 12V : 750 CCA DIN/1425 CCA SAE

SE 130/250T 24V : 400 CCA DIN/760 CCA SAE

Drift tid: S2 = 3 min. Eller gjennomsnittlig 7-10% innen

en begrenset tidsperiode.

Sikkerhet: Elektronisk tidsforsinkelse forhindrer motorskade

ved rask retningsendring.

Motoren stanser automatisk ved overopphetning

(slår seg automatisk på etter nedkjøling).

Brytepinne mellom drivaksel og motor beskytter

gir hvis propell blir blokkert.

Om orginalt Side-Power panel blir brukt så vil

dette slås av automatisk etter 6 minutter etter

siste gang trøsteren ble brukt.

Integrerte microprossessor føler hele tiden på

releet, reduserer slitasje og risk for ”heng” på

relé. Trøsteren vil stoppe automatisk etter 3

minutter om det oppstår ”heng” på relé, eller

om trøsteren går kontinuerlig i 3 minutter.

Tekniske spesikasjoner

N

Motor: Custom made reversible DC-motor.

Gearhouse: Seawater resistant bronze. Ballbearing at

propellershaft and combination of ballbearing

and slide bearing at driveshaft.

Motor bracket: Seawaterresistant aluminium,

galvanicly insulated from motor

Tunnel: Cross spun with rowing G.R.P tunnel

Steel & aluminum tunnels available at request.

Propeller: 5 blade skew "Q"-propeller,

breglass reinforced composite.

Batteries:

Minimum recommended battery capacity

(cold crank capacity by DIN/SAE standard)

SE 80/185T 12V : 550 CCA DIN/1045 CCA SAE

SE 80/185T 24V : 300 CCA DIN/570 CCA SAE

SE 100/185T 12V : 750 CCA DIN/1425 CCA SAE

SE 100/185T 24V : 400 CCA DIN/760 CCA SAE

SE 130/250T 12V : 750 CCA DIN/1425 CCA SAE

SE 130/250T 24V : 400 CCA DIN/760 CCA SAE

Max. use: S2 = 3 min. or appr. 7-10% within a limited time

frame.

Safety

:

Electronic time-lapse device protects against

sudden change of drive direction. Electric thermal

cut-off switch in electromotor protects against

over heating (auto reset when electro motor cools

down).

Flexible coupling between electro-motor and

driveshaft protects electromotor and gearsystem

if propeller gets jammed.

If original Sidepower panel is used, the panel

shuts off automatically 6 minutes after last use.

Integrated microprocessor monitors solenoids,

reducing wear and risk of solenoid lock-in. Auto-

stop of thruster in case of accidental solenoid

lock-in or if run signal is continous for more than

3 minutes

Technical specications

GB

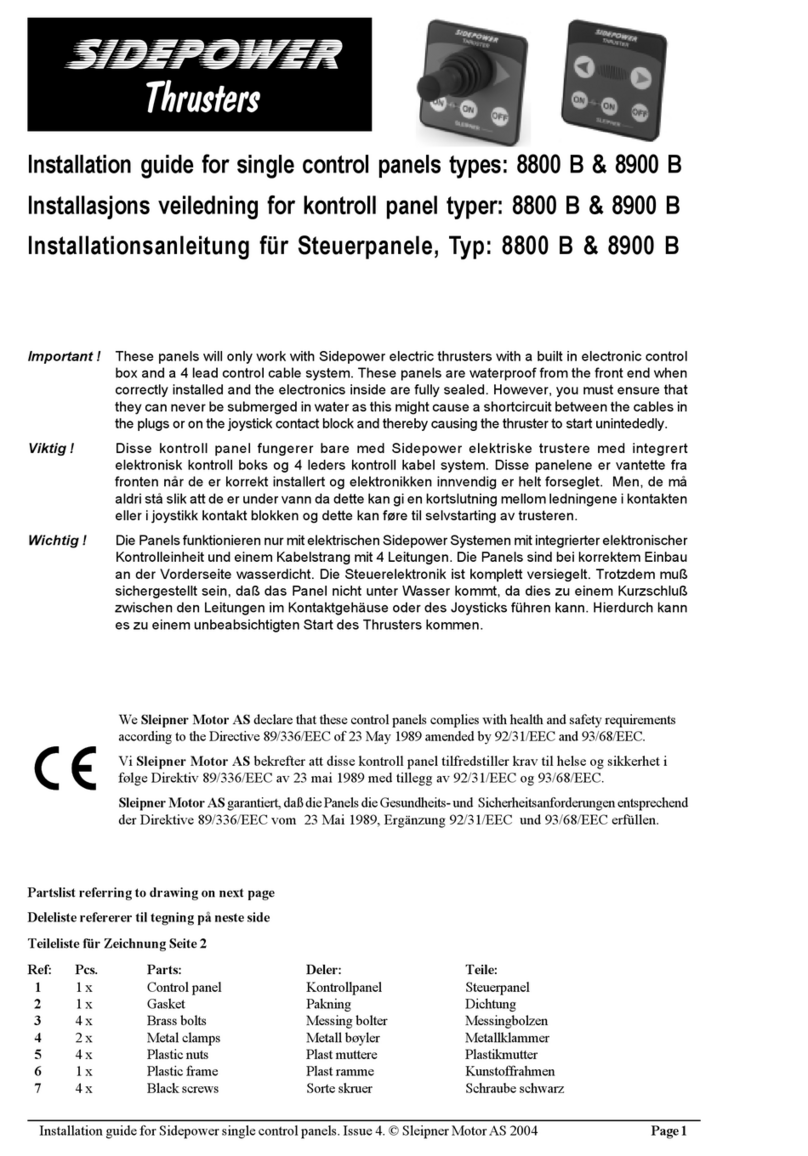

SE80/185T SE100/185T SE130/250T

Thrust [lbs] 176 212 284

A [in] 7,28 7,28 9,84

B [in] 13,9 15,3 15,7

Cmin. [in] 7,87 7,87 9,0

D [in] 6,7 6,7 11,2

D recommended [in] 13,4 13,4 22

Emin. [in] 0,24 0,24 0,28

Emax. [in] 0,31 0,31 0,39

Motor output [Hp] 6 8 8,7

Voltage [V] 12/24 12/24 12/24

Weight [lbs] 44 68 77

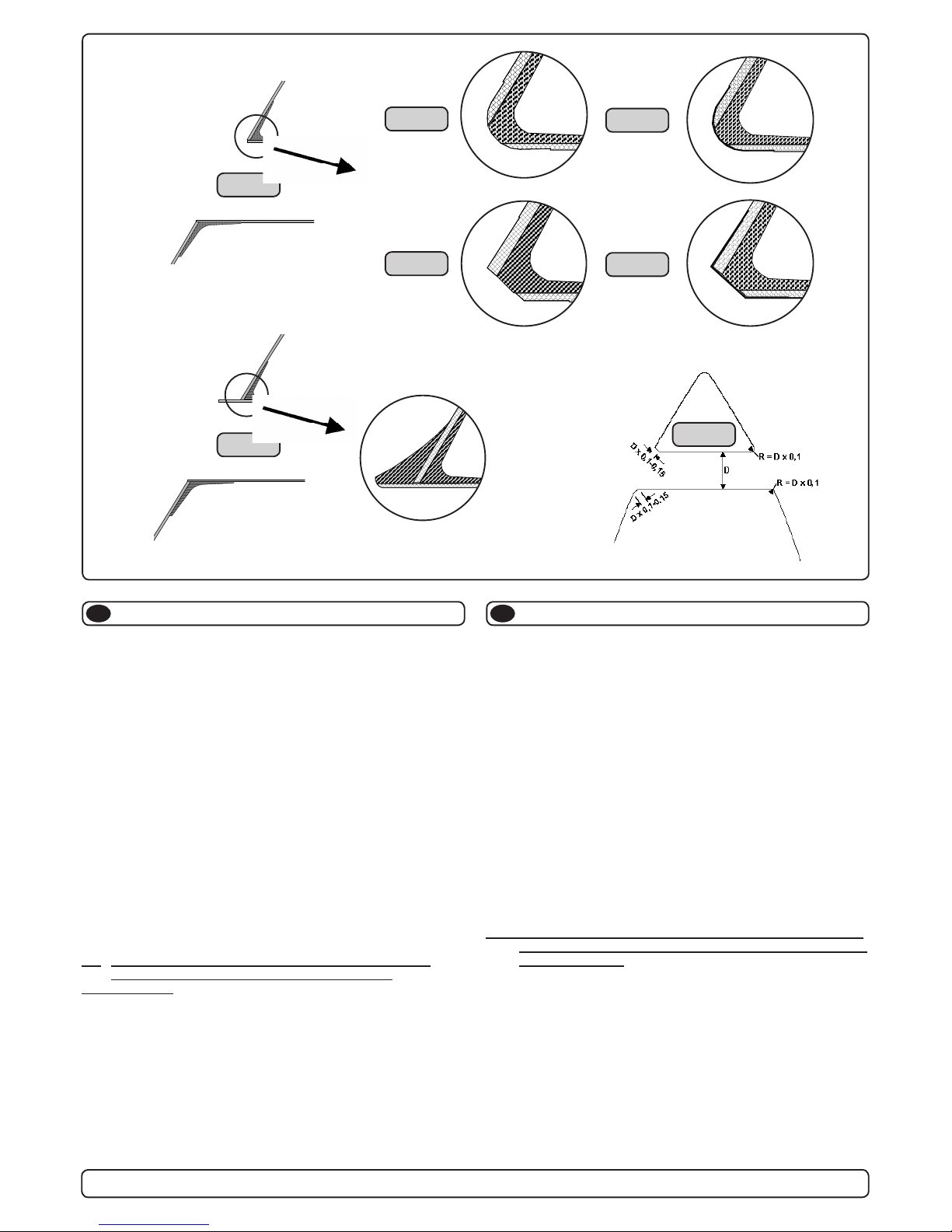

Note: Emin.: wall thickness of a standard Sidepower tunnel

Emax.: maximum wall thickness when using other GRP,

steel or aluminium tunnels

SE80/185T SE100/185T SE130/250T

Thrust [kg] 80 100 130

A [mm] 185 185 250

B [mm] 352 389 398

Cmin. [mm] 200 200 230

D [mm] 170 170 285

D recommended [mm] 340 340 560

Emin. [mm] 6 6 7

Emax. [mm] 8 8 10

Motor output [kW] 4,4 6 6,5

Voltage [V] 12/24 12/24 12/24

Weight [kg] 20 31 37

Note: Emin.: wall thickness of a standard Sidepower tunnel

Emax.: maximum wall thickness when using other GRP,

steel or aluminium tunnels

METRIC

IMPERIAL

4

SP 75 Ti / SP 95 Ti / SP 125 Ti

2.5.1- 2007

Technische Daten

D

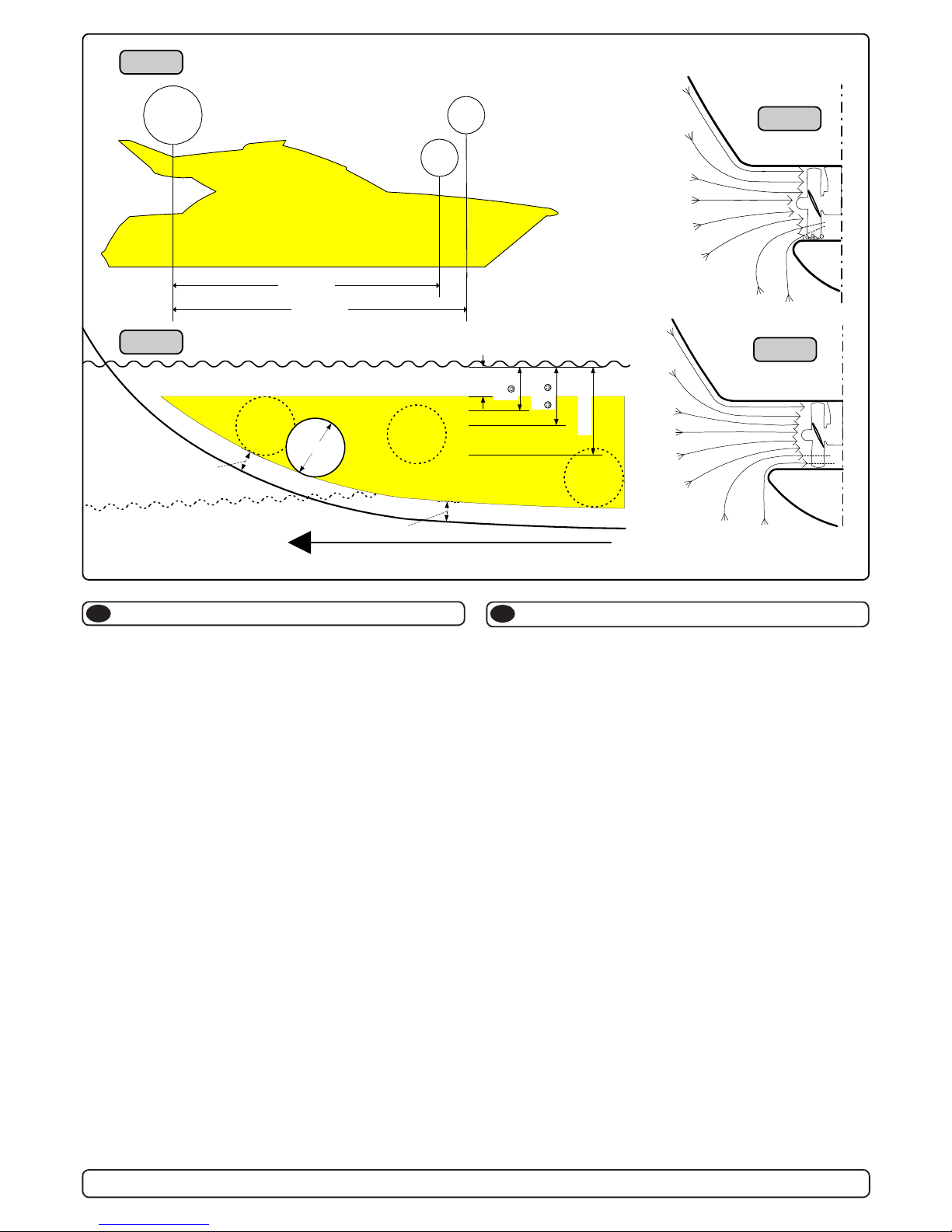

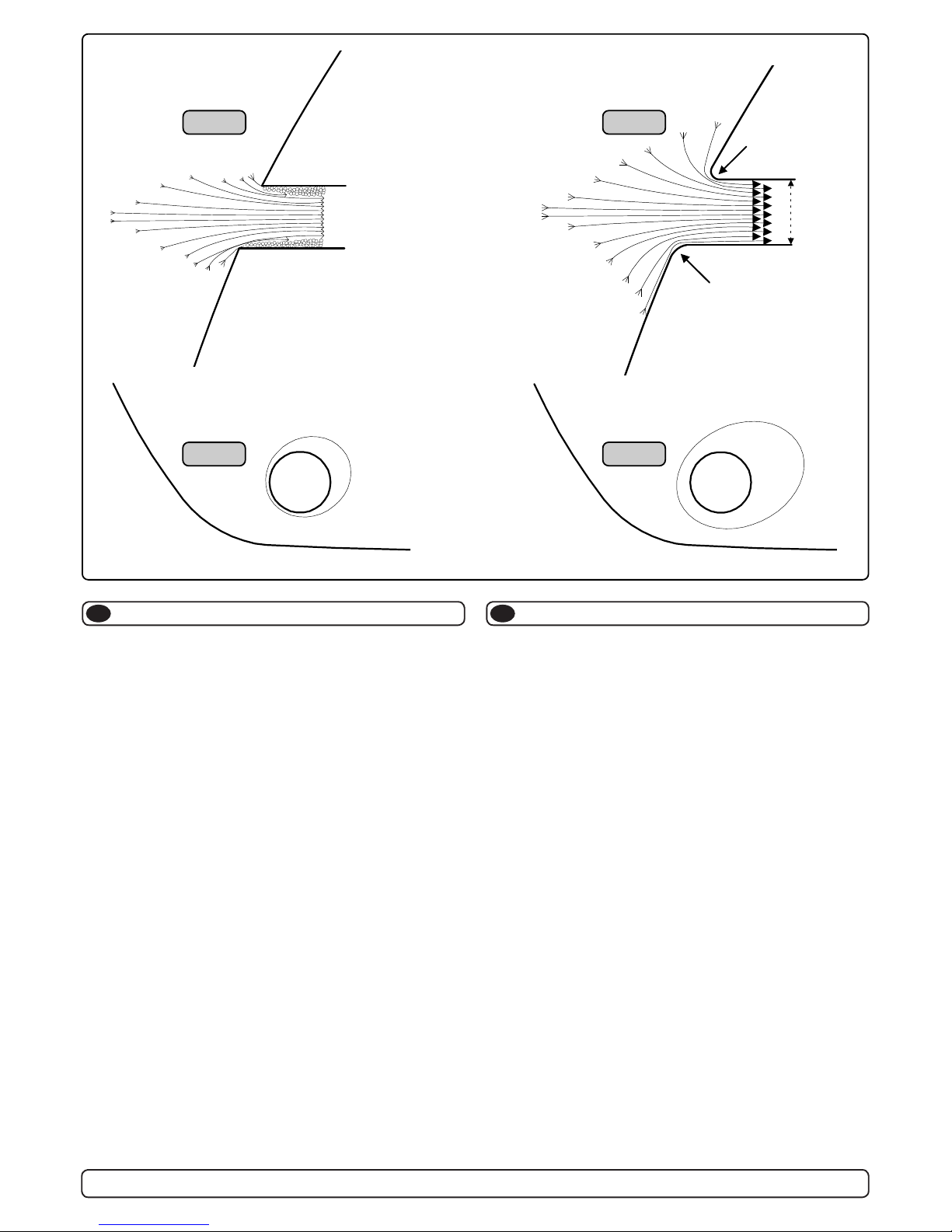

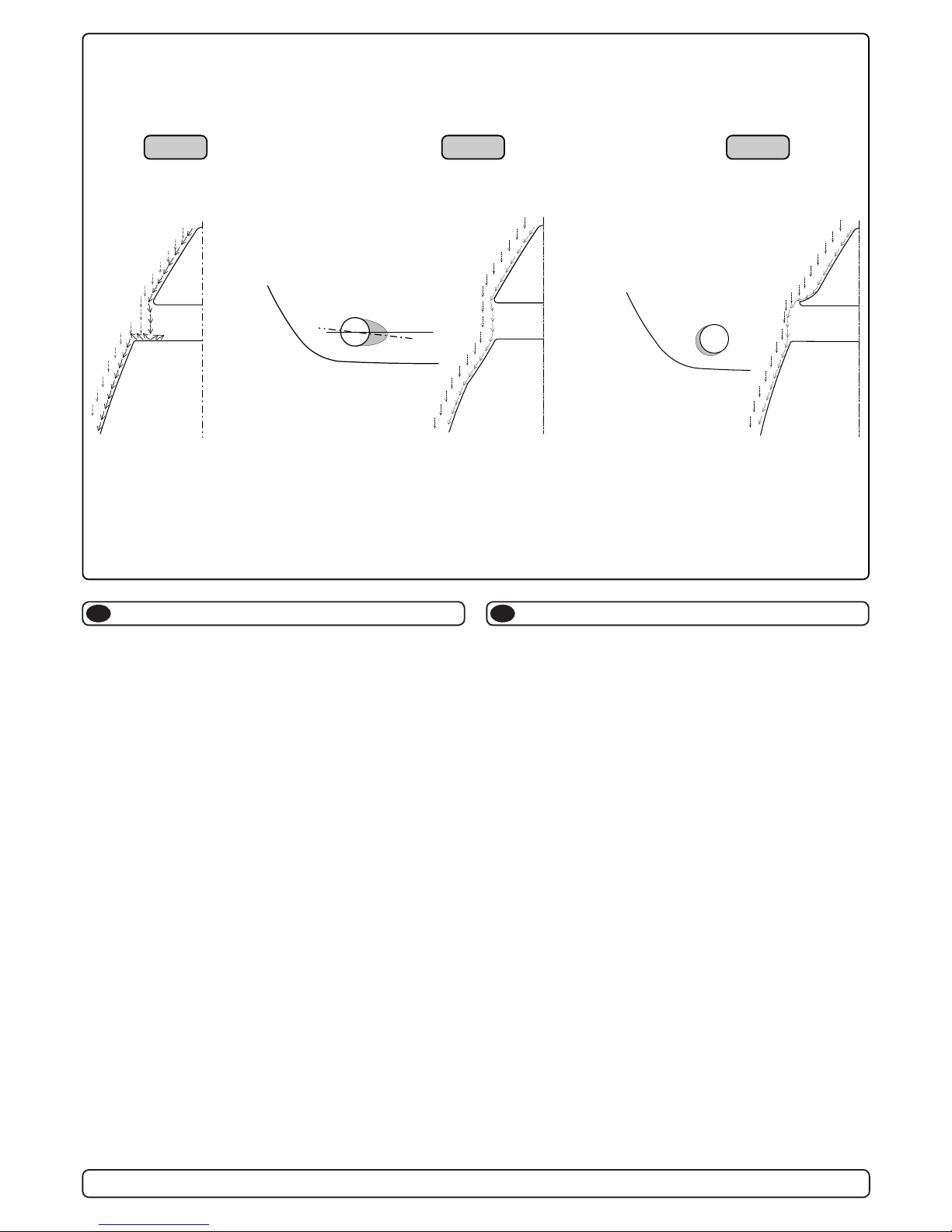

C

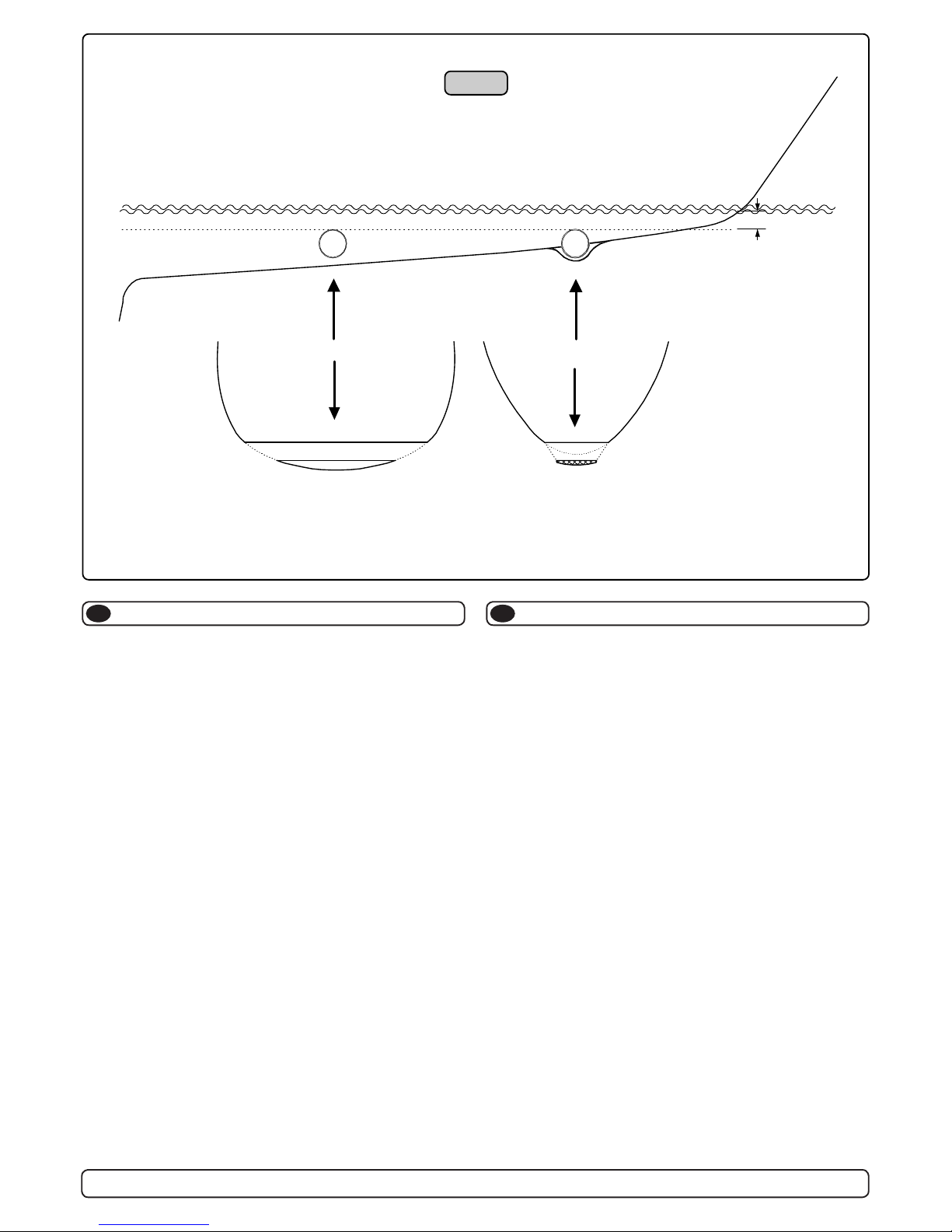

Waterline

A

F

Motor: Custom made reversible DC-motor.

Gearhouse: Seawater resistant bronze. Ballbearing at

propellershaft and combination of ballbearing

and slide bearing at driveshaft.

Motor bracket: SP 75 Ti / SP 95 Ti / SP 125 Ti:

Seawaterresistant aluminium

Tunnel: Cross spun with rowing G.R.P tunnel

Steel & aluminum tunnels available at request.

Propeller: Symmetrical 4 blade propeller, fibreglass reinforced

composite.

Batteries:

Minimum recommended battery capacity

(cold crank capacity by DIN/SAE standard)

SP75Ti 12V : 550 CCA DIN/1045 CCA SAE

24V : 300 CCA DIN/570 CCA SAE

SP95Ti 12V : 750 CCA DIN/1425 CCA SAE

24V : 400 CCA DIN/760 CCA SAE

SP125Ti 12V : 750 CCA DIN/1425 CCA SAE

24V : 400 CCA DIN/760 CCA SAE

Max. use: S2 = 3 min. or appr. 7-10% within a limited time

frame.

Safety

:

Electronic time-lapse device protects against

sudden change of drive direction. Electric thermal

cut-off switch in electromotor protects against over

heating (auto reset when electro motor cools down).

Flexible coupling between electro-motor and

driveshaft protects electromotor and gearsystem

if propeller gets jammed.

If original Sidepower panel is used, the panel

shuts off automatically 6 minutes after last use.

Integrated microprocessor monitors solenoids,

reducing wear and risk of solenoid lock-in. Auto-

stop of thruster in case of accidental solenoid

lock-in or if run signal is continous for more than

3 minutes

Technical specifications

GB

SP 75 Ti SP 95 Ti SP 125 Ti

Thrust [lbs] 165 209 275

A [in] 7,28 7,28 9,84

B [in] 13,9 15,3 15,7

Cmin. [in] 7,87 7,87 9,0

D [in] 6,7 6,7 11,0

D recommended [in] 13,4 13,4 22,0

Emin. [in] 0,24 0,24 0,28

Emax. [in] 0,31 0,31 0,39

Motor output [Hp] 6 8 8,7

Voltage [V] 12/24 12/24 12/24

Weight [lbs] 44 68 77

Gear oil capacity [fl.oz]2.367 2.367 6,736

Note: Emin.: wall thickness of a standard Sidepower tunnel

Emax.: maximum wall thickness when using other GRP,

steel or aluminium tunnels

SP 75 Ti SP 95 Ti SP 125 Ti

Thrust [kg] 75 95 125

A [mm] 185 185 250

B [mm] 352 389 398

Cmin. [mm] 200 200 230

D [mm] 170 170 280

D recommended [mm] 340 340 560

Emin. [mm] 6 6 7

Emax. [mm] 8 8 10

Motor output [kW] 4,4 6 6,5

Voltage [V] 12/24 12/24 12/24

Weight [kg] 20 31 37

Gear oil capacity [ml] 70 70 200

Note: Emin.: wall thickness of a standard Sidepower tunnel

Emax.: maximum wall thickness when using other GRP,

steel or aluminium tunnels

METRICMETRIC

METRICMETRIC

METRIC

IMPERIALIMPERIAL

IMPERIALIMPERIAL

IMPERIAL

Motor: Gleichstrommotor

Getriebegeh.: Seewasserbeständige Bronze. Kugellager an

der Propellerachse, Kombination von Kugel-

und Gleitlager an der Antriebsachse.

Motorhalterung: SP 75 Ti / SP 95 Ti / SP 125 Ti:

Seewasserbeständiges Aluminium

Tunnel: Glasfibertunnel (Kreuzgewebe)

Stahl- & Aluminiumtunnel auf Anfrage.

Propeller: Symmetrischer, 4 flügeliger Kaplanpropeller aus

Glasfiberverbundmaterial.

Batterie:

Empfohlene mind. Batteriekapazität

(Kaltstartkapazität nach DIN/SAE)

SP75Ti 12V : 550 CCA DIN/1045 CCA SAE

24V : 300 CCA DIN/570 CCA SAE

SP95Ti 12V : 750 CCA DIN/1425 CCA SAE

24V : 400 CCA DIN/760 CCA SAE

SP125Ti 12V : 750 CCA DIN/1425 CCA SAE

24V : 400 CCA DIN/760 CCA SAE

Betriebszeit: S2 = 3 min. oder ca. 7-10% innerhalb eines

beliebigen Zeitraumes.

Sicherheit

:

Elektronische Zeitverzögerung zum Schutz des

Getriebes bei plötzlichem Wechsel der Drehrich-

tung. Elektrischer Thermoschalter zum Schutz

des Motors gegen Überhitzung (erneute Betriebs-

bereitschaft nach Abkühlung).

Scherstift zwischen Elektromotor und Getriebe-

achse als Schutz, wenn der Propeller blockiert

ist. Nach der letzten Benutzung schaltet das

Original Side-Power Panel automatisch nach 6

Minuten ab. Der integrierte Mikroprozessor

überwacht das Relais und reduziert sowohl

Verschleiß, als auch Relaisblockade. Das

Bustrahlruder stoppt automatisch bei Relais-

Blockade, oder bei Betrieb des Bugstrahlruders

von mehr als 3 Minuten.