2614 6 22 019

-

SH 360

DECLARATION OF CONFORMITY

Sleipner Motor AS

P.O. Box 519, Arne Svendsensgt. 6-8

N-1612 Fredrikstad, Norway

Declare that this product with accompanying standard control systems complies with

the essential health and safety requirements according to:

DIRECTIVE 2013/53/EU

DIRECTIVE 2014/30/EU

DIRECTIVE 2014/35/EU

MC_0020

Installation instructions

Planning Considerations and Precautions................................. 3

Thruster Measurements ........................................................... 4

Thruster Specications ............................................................. 5

Technical Specications ........................................................... 5

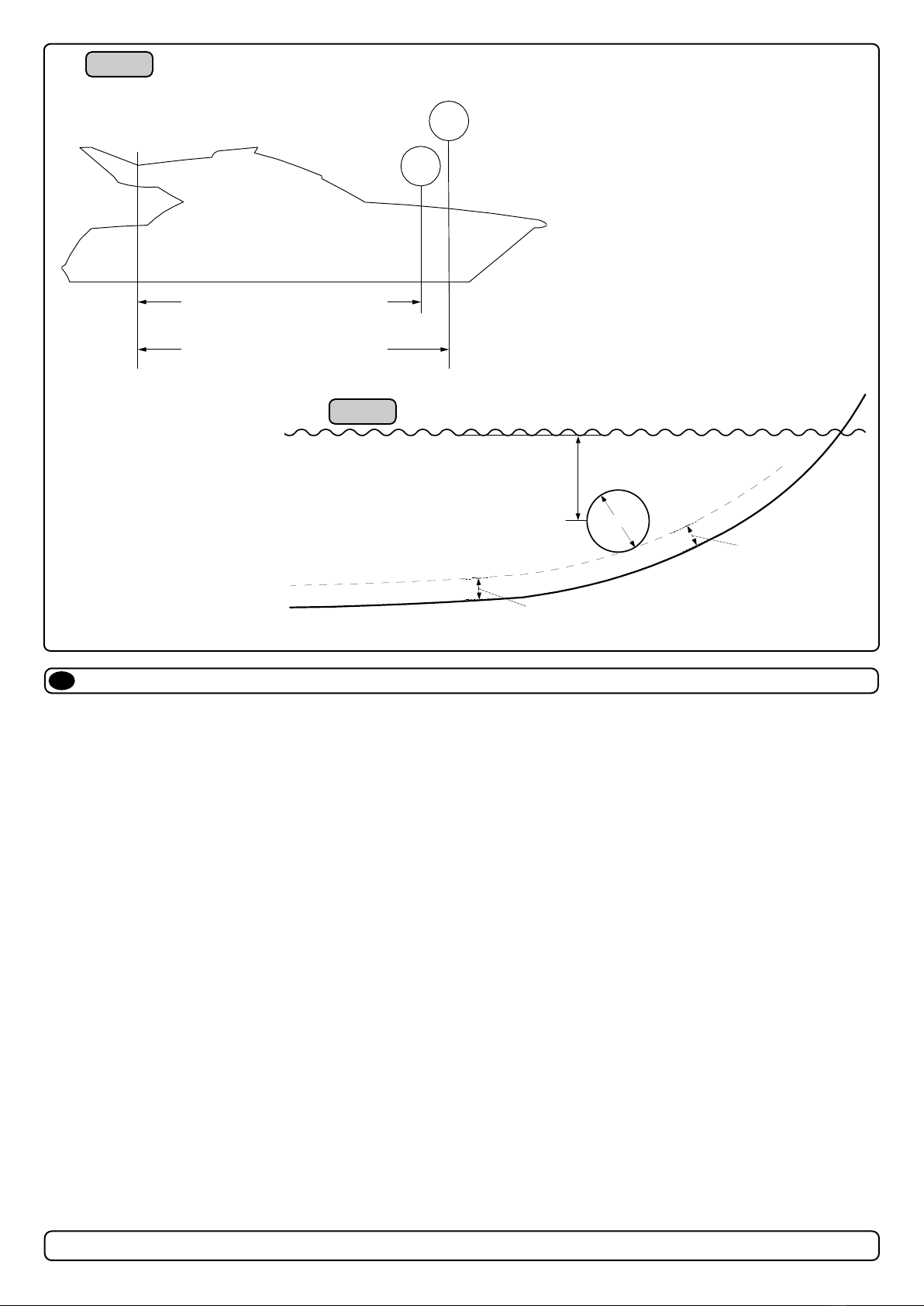

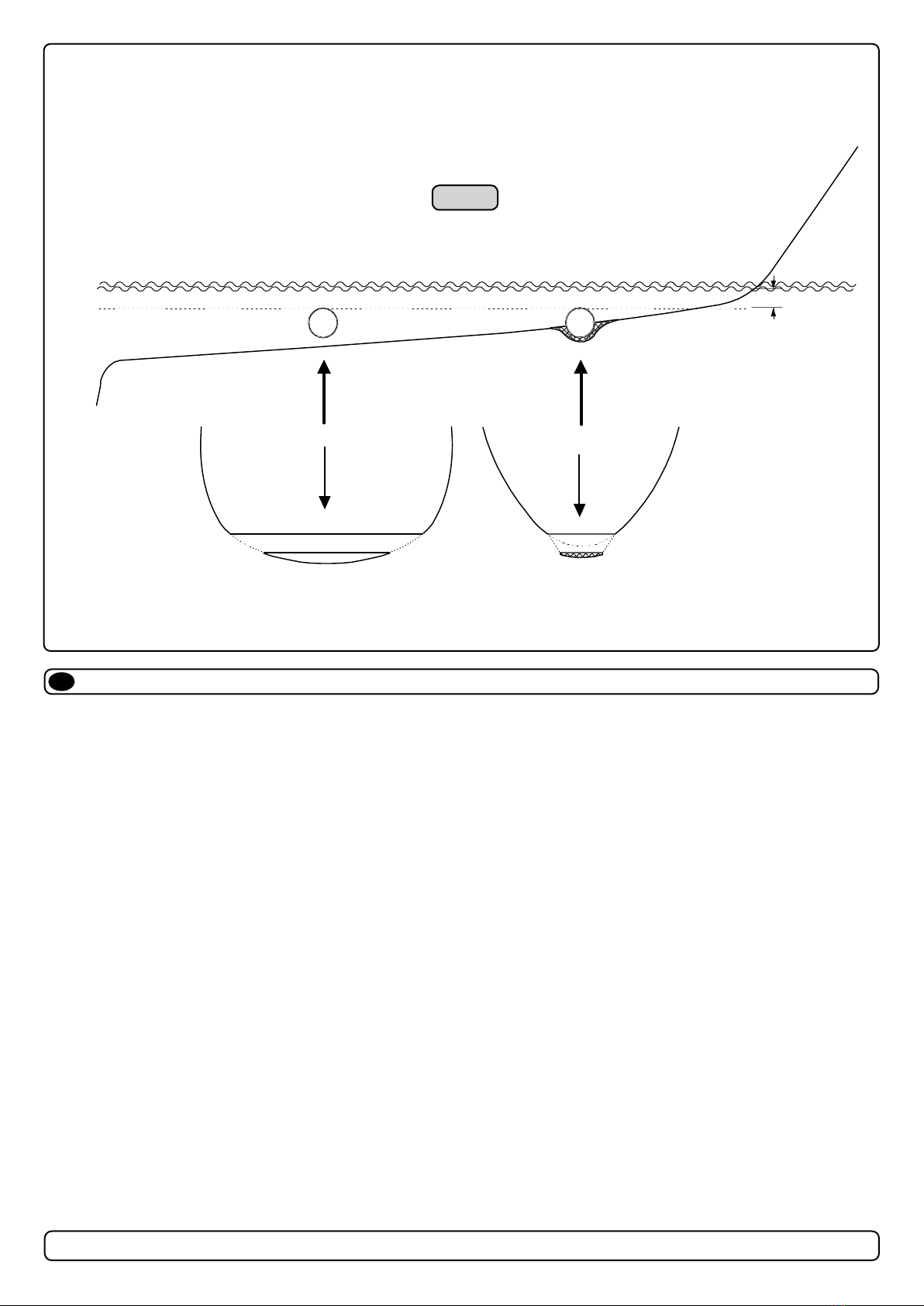

Positioning of the tunnel/ thruster.............................................. 6

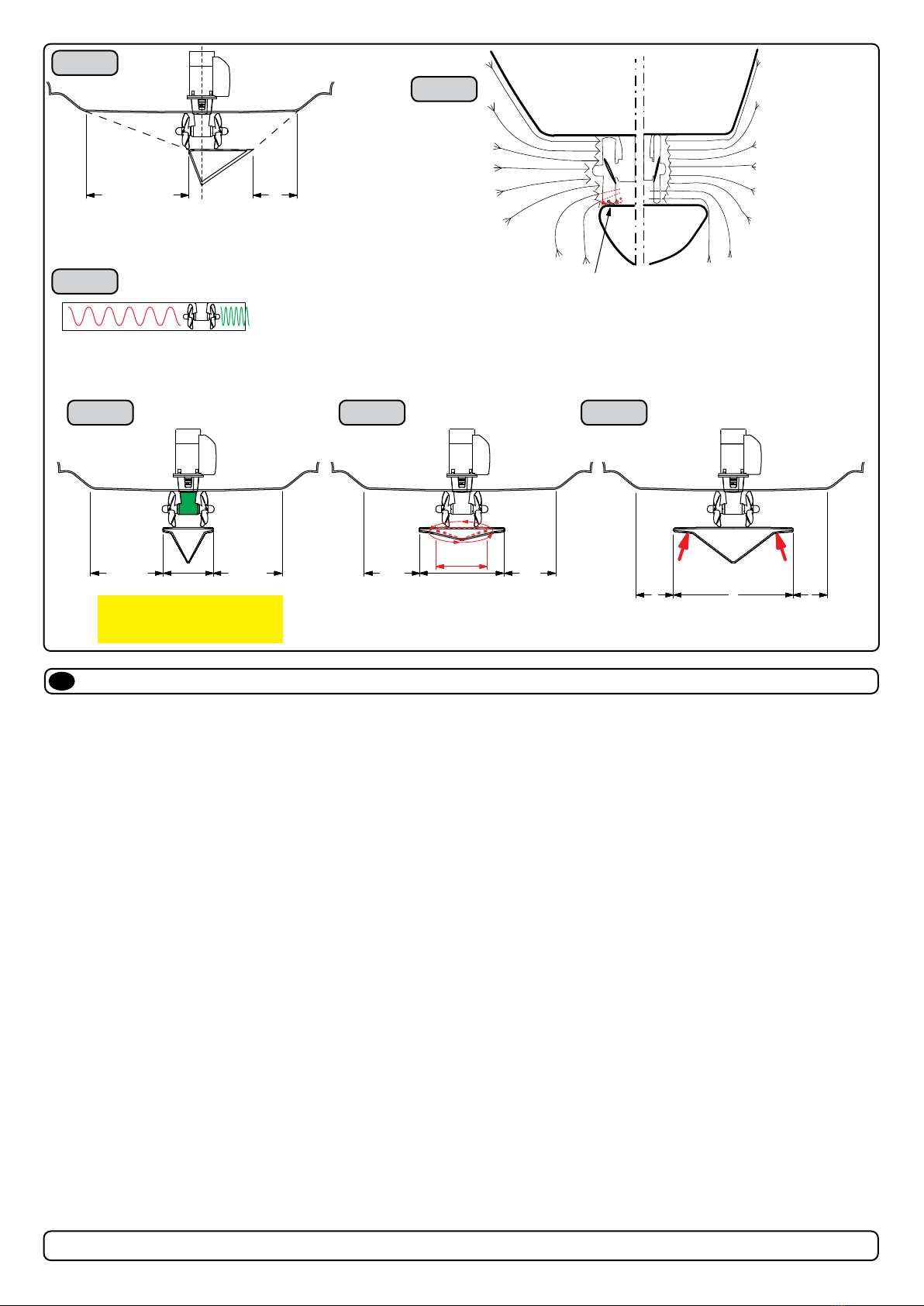

Tunnel Length............................................................................ 7

Tunnel Installation in Sailboats.................................................. 8

Water Deection ........................................................................ 9

Tunnel ends............................................................................. 10

Tunnel Installation ............................................................ 11 - 12

Stern Tunnel Installation.......................................................... 13

Thruster installation

Hydraulic Thruster Installation Considerations and Precautions..

................................................................................................. 14

Technical Specications .......................................................... 15

Technical Requirements / Hydraulic hose connections to motor..

................................................................................................. 16

Gear Leg & Motor Bracket Installation .................................... 17

Propeller Installation.................................................................18

Motor Installation ......................................................................19

Oil Tank Installation ................................................................. 20

S-link Planning & Precautions ................................................ 21

Control Panel Installation..........................................................22

Checklist for Hydraulic Thrusters............................................. 23

Spare Parts............................................................................. 24

Warranty statement ............................................................... 24

Contents

EN

It is the installers responsibility

When installing Side-Power equipment to follow the outlined regulations/ classi cation rules (electrical/ mechanical) according to

international or special national regulations. Instructions in this guide cannot be guaranteed to comply with global electric/ mechanic

regulations/ classi cation rules.

It is the installers responsibility

To follow all health and safety laws in accordance with their local outlined regulations/ classi cation rules.

Before installation, it is important that the installer reads this guide to ensure necessary acquaintance with this product.

The recommendations made in this manual are guidelines ONLY, and Sleipner Motor AS (Side-Power) strongly recommend that

before installation, advice is obtained from a naval architect familiar with the particular vessel and regulations/ classi cations.

This manual is intended to support educated/ experienced staff and is therefore not suffi cient in all details for professional

installation. (NB: These instructions are only general instruction. If you are not skilled to do this work, please contact professional

installers for assistance.)

All electrical work must be done by a licensed professional.

IMPORTANT

Faulty installation of the tunnel, thruster or panel will render all warranty given by Sleipner Motor AS void. MC_0038