Contents

1Approval...................................................................................................5

2Safety regulations and warnings...........................................................5

3General notes ..........................................................................................6

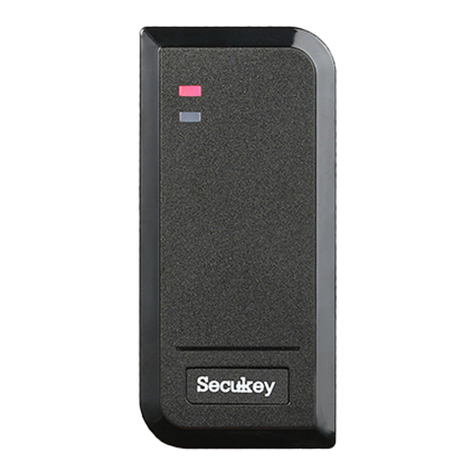

4Delivery volume.......................................................................................6

5Technical specifications ........................................................................7

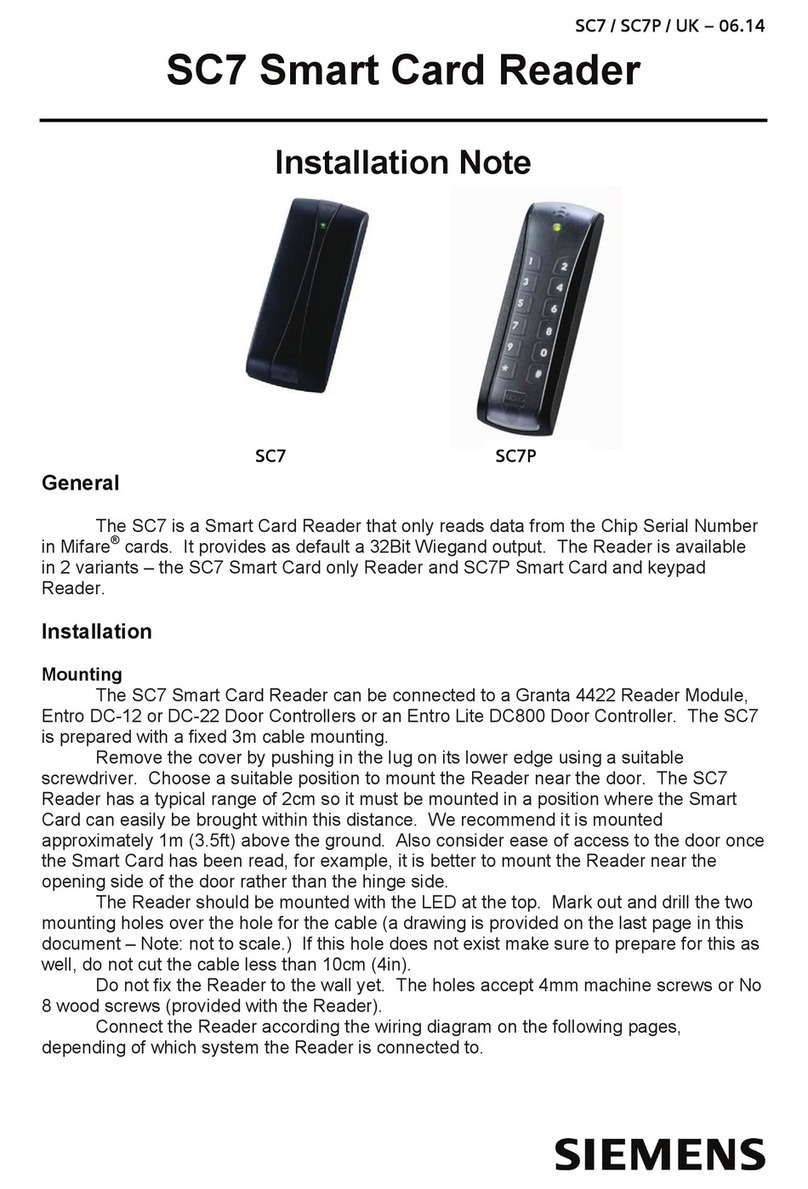

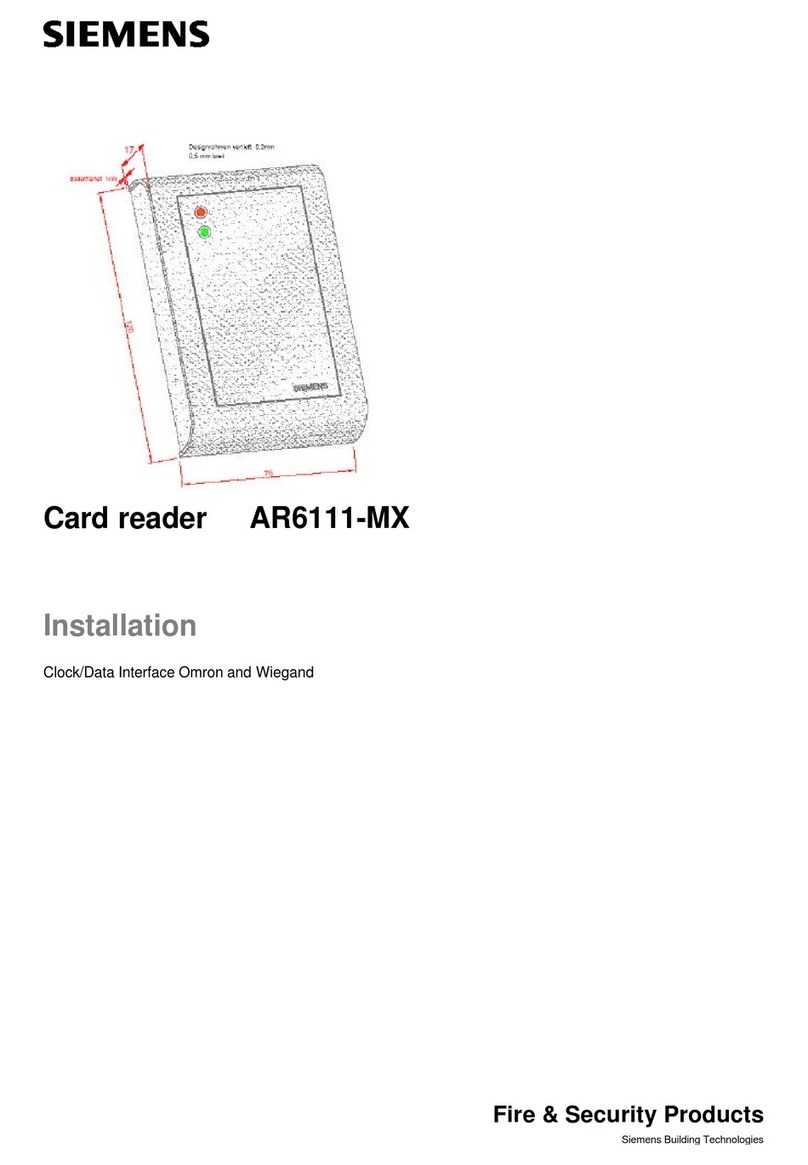

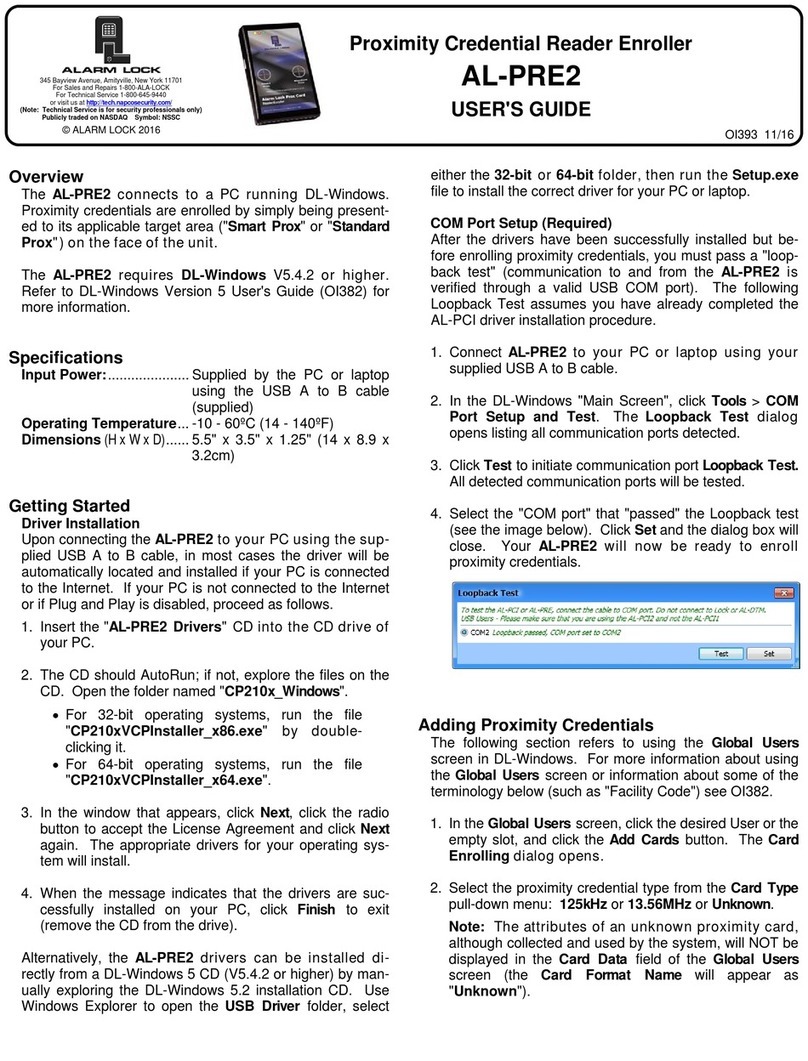

6Installation ...............................................................................................8

6.1 Opening the housing.................................................................................8

6.2 Flush mounting..........................................................................................9

6.3 Surface mounting....................................................................................10

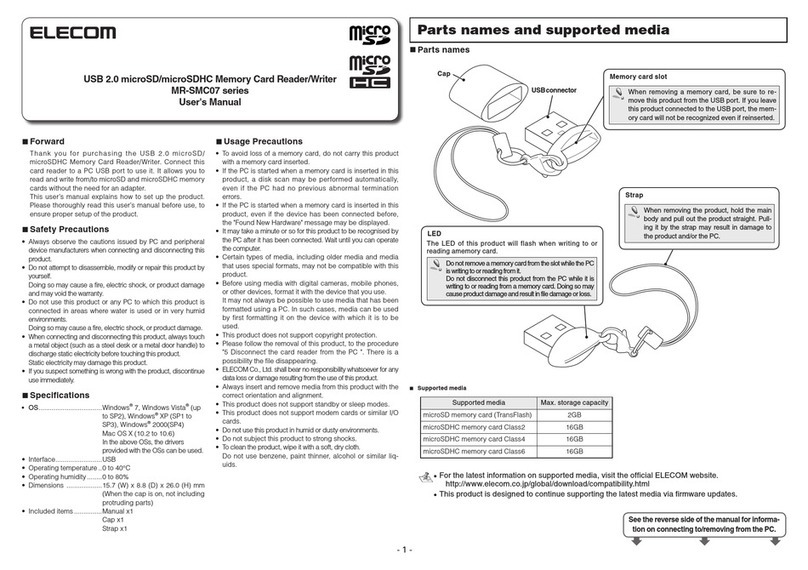

6.4 Connecting the reader, display elements ...............................................12

6.4.1 Power supply...........................................................................................13

6.4.2 RS485 interface ......................................................................................13

6.4.3 Clock/Data interface................................................................................13

7DIP switch settings ...............................................................................14

7.1 Address setting for RS485 bus operation, 2-wire ...................................14

7.2 Setting the address (Clock/Data)............................................................15

7.3 Communication interface and protocol selection ....................................15

7.4 Information to be read out of cards.........................................................16

8Transponders / ID cards.......................................................................18

8.1 Qualified transponder types (ID cards) ...................................................19

8.1.1 ISO14443A Proximity read range ...........................................................19

8.1.2 ISO14443A+B Proximity read range.......................................................19

8.1.3 ISO15693 Vicinity read range.................................................................20

8.2 Information on transponder.....................................................................20

8.2.1 Serial number..........................................................................................21

8.2.2 ID number ...............................................................................................21

8.3 Data formats of the Transponder............................................................22

8.3.1 BCD format .............................................................................................22

8.3.2 ASCII format............................................................................................23

8.3.3 Wiegand format.......................................................................................23

9Card reader configuration....................................................................24

9.1 Defining parameters................................................................................25

9.2 Launching the terminal program .............................................................25

9.3 Configuration mode of the Terminal program .........................................27

9.3.1 Commands..............................................................................................29

9.3.1.1 Firmware, new load.................................................................................29

9.4 Reader interface......................................................................................32

9.5 Output data formats ................................................................................32

10 Configuration parameters ....................................................................33

10.1 Config or ConfigCard parameters...........................................................33

10.2 Combination options ...............................................................................37

10.2.1 Serial number RS485 – CerPass reader protocol .................................37

10.2.2 Serial number RS485 – UCI reader protocol .........................................37

10.2.3 Serial number Clock / Data – Omron interface ......................................37

10.2.4 Serial number Clock / Data – Wiegand interface...................................38

10.2.5 ID number – ASCII format RS485 – CerPass reader protocol ..............38

10.2.6 ID number – ASCII format RS485 – UCI reader protocol......................38

10.2.7 ID number – BCD format RS485 – CerPass reader protocol .................39

3

Siemens Building Technologies

Fire & Security Products 12.2004