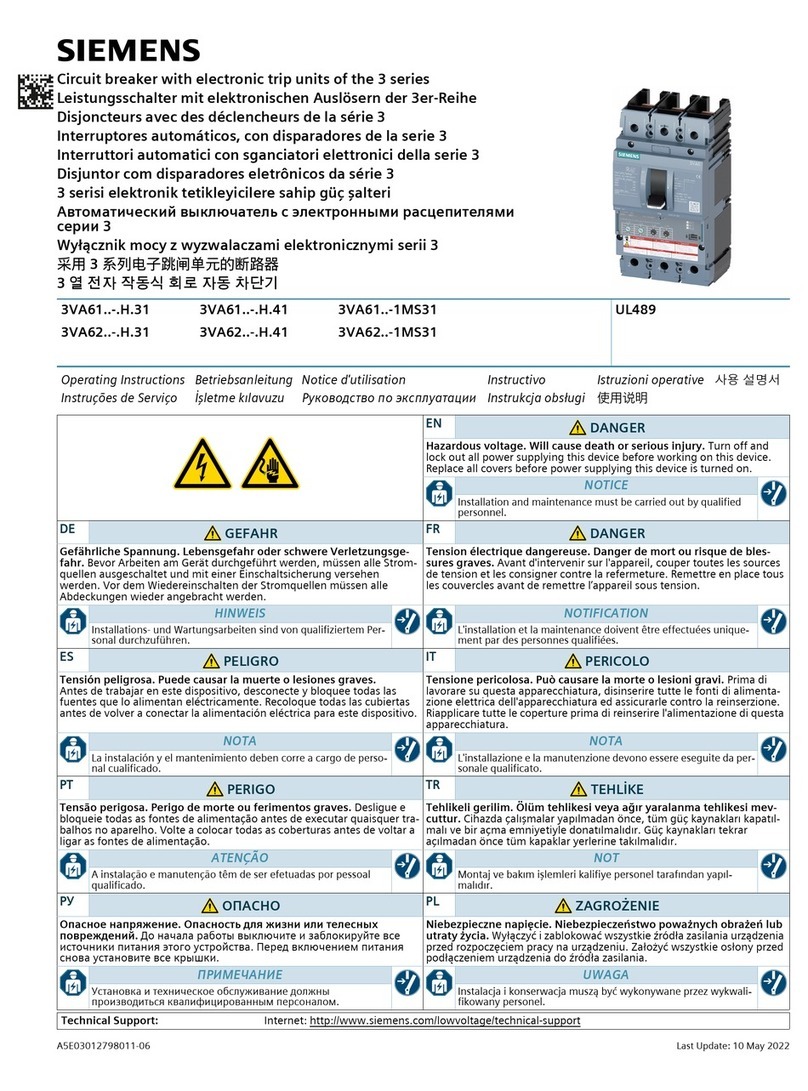

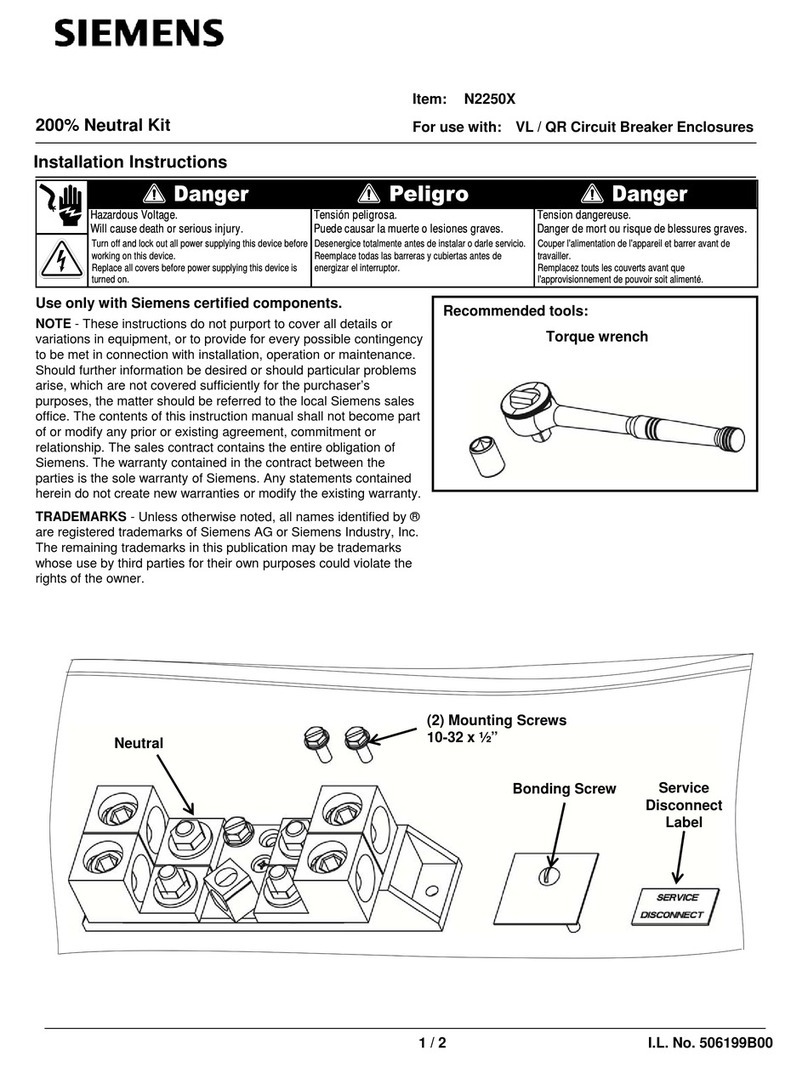

Installation Instructions

Peligro

Tensión peligrosa que puede

causar daños serio o la

muerte, desenergice

totalmente antes de instalar

o darle servicio. Reemplace

todas las barreras y

cubiertas antes de energizar

el interruptor.

Instructivo de Instalación y Operación

4. Inspection and FieldTesting

ED-frame circuit breakers are designed to provide years of

maintanance free service. The following procedure outlines

how to inspect and test a circuit breaker in service.

Inspection and Maintenance

Circuit breakers in service should be inspected periodically.

The inspection should include the following steps:

A. Turn off and lock out power before inspecting or

servicing. Special attention should be paid to reverse

feed applications to ensure no voltage is present.

B. Remove dust, soot, grease or moisture from the

surface of the circuit breaker using a lint free cloth

brush or vacuum cleaner. DO NOT blow debris into

the circuit breakers. If contamination is found, eliminate

the source of the problem.

NOTE: Do not spray or allow any petroleum based

chemicals, solvents or paints to contact the inside or

outside of breaker or electrical connections.

C. Switch the circuit breaker to the ON and OFF positions

several times to be sure the mechanical linkages are

free and do not bind. If mechanical linkages are not

free, replace the circuit breaker.

D. Press the PUSH-TO-TRIP button to mechanically trip

the circuit breaker. Trip, reset, and switch the breaker

on several times. If the circuit breaker cannot be turned

on replace the circuit breaker.

E. Check circuit breaker housing and handle for cracks,

chipping and discoloration. Circuit breakers should

be replaced if cracks or severe discoloration is found.

F. Check terminals and wire connectors for looseness

or signs of overheating. Overheating will show as discol-

oration, melting or blistering of conductor insulation, or

as pitting or melting of conductor surfaces due to arcing.

If there is no evidence of overheating or looseness,

do not disturb or tighten the connections. If there is

evidence of overheating, terminations should be

replaced. Before re-energizing the circuit breaker, all

wire connectors and cable should be refurbished to

the original installed condition.

IMPORTANT: Refer to instructions on page 2, Item 6.

G. Check circuit breaker mounting hardware. Tighten if

necessary.

H. Check area where circuit breaker is installed for any

safety hazards, including personal safety and fire

hazards. Exposure to certain types of chemicals can

cause deterioration of electrical connections.

Field Testing

Any field testing should be conducted in accordance

with NEMA Standards Publication AB2.

Revisión.

Los interruptores ya montados deben reviarse periódicamente.

La revisión se realiza de la siguiente forma:

A. Desenergice totalmente el interruptor antes de revisar a darla

servicio, prestando especial atención a la ausencia de cual;quier

votaje inverso.

B. Remueva polvo, suciedad, grasa o cochambre de la superficie

del interruptor, con una franela libre de pelusas, brocha o

asperadora.

Nota: No use aire a presión, pues pueden introducirse

particulas al interior. Si se encuentra contaminación elimine la

fuente de esta problema. No use aerosoles, ni permita que

derivados químicos del petróleo, solventes o pinturas, se pongan

en contacto con las conexiones eléctricas dentro o fuera del

interruptor.

C. Accione la manjia varias veces, conectando y desconectando,

para asegurarse que los elementos mecánicos están libres y no

presentan trabazón, si nota que los mecánismos no actúan

libremente, sustituya el interruptor.

D. Oprima el botón de disparo ‘trip’ restablezca y accione la

manija varias veces. Si no se consigue que la manija retorne a la

posición conectado ‘ON’, sustituya el interruptor.

E. Revise exteriormente el interruptor, observe que la caja y la

manija no presentan roturas, despostillado o decoloración. El

interruptor debe ser sustituido si presenta fuerte decoloración o

cualquierea de las anomalias mencionadas.

F. Revise las terminales los conectores de los cables, observando

cualquier indicación de falsos contactos o sobrecalentamientos.

Los sobrecalentamientos muestran decoloración, fusión o

rugosidades del aislamiento del conductor, los falsos contactos,

escoreaduras o fusión de las superficies del conductor ocasionadas

por arqueos. Si no hay evidencia de sobrecalentamientos o falsos

contactos, no altere ni apriete las conexiones. Si hay evidencia de

sobrecalentamiento las terminales deben reemplazarse.Antes de

reenergizar el interruptor, todos los conectores de cable y cables

deben ser colocados en las condiciones originales del interruptor.

G. Revise los elementos de conexión, apriete si es necesario.

H. Revise que el área donde se instalará el interruptor, este libre

de riesgos, inclusive para seguirdad del personal y para evitar

riesgos de incendio. La exposición a ciertos tipos de productos

quimicos, pueden causar deterioro de las conexiones eléctricas.

Page 4 of 4

Pc. No. 75822A04© Siemens Energy & Automation, Inc. 1993

Manufactured Under One or More of the Following

U.S. Patents: 4,594,567; 4,595,896; 4,675,640; 4,680,564.

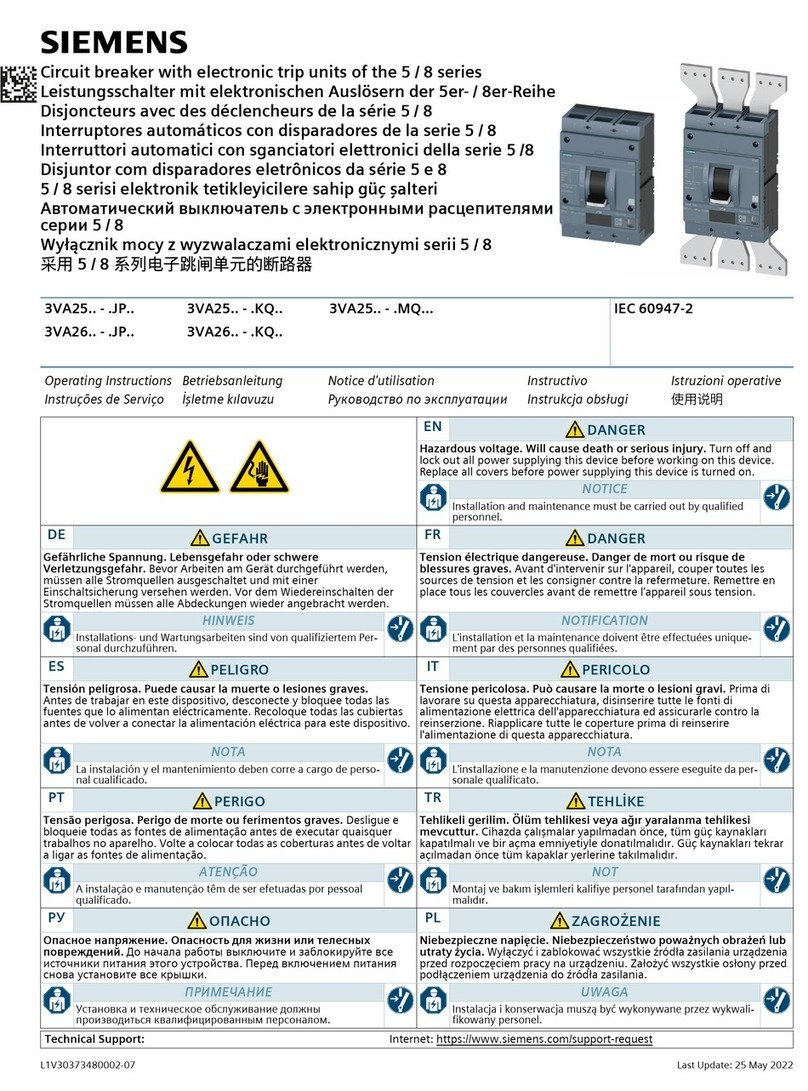

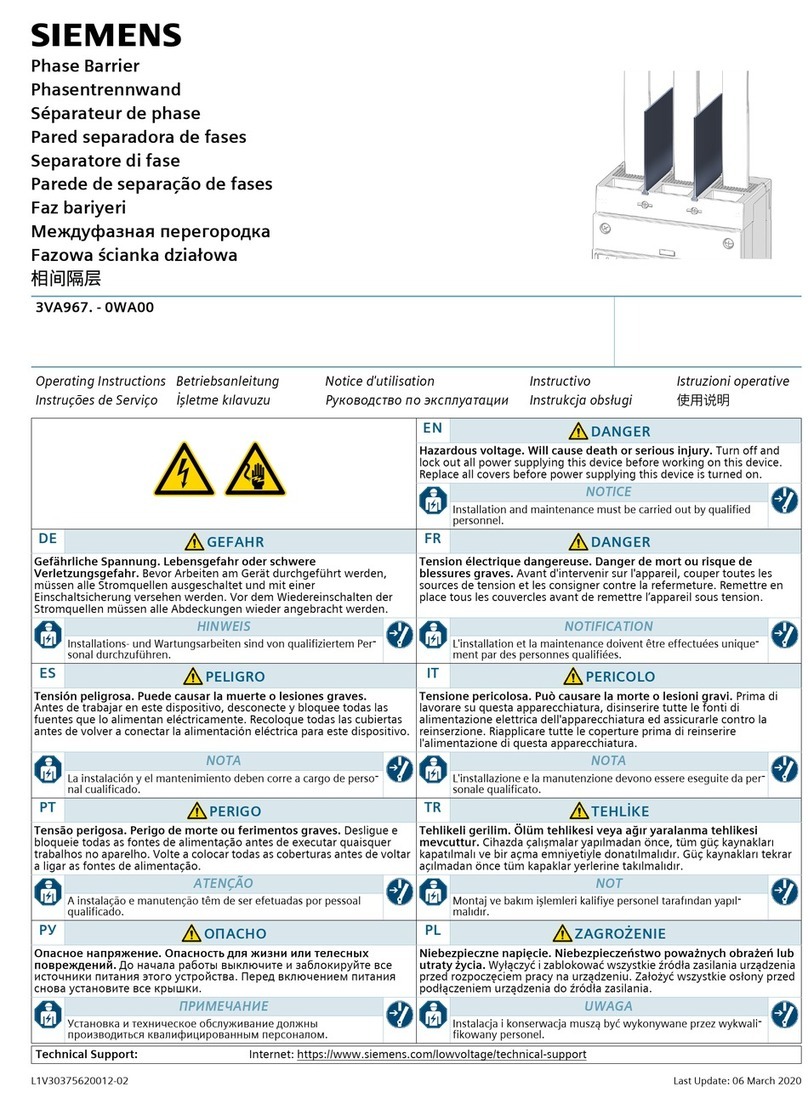

Hazardous voltage.

Will cause death or serious

injury.

Turn off and lock out all power

supplying this device before

removing cover or device and

while cover is removed.

Replace the cover before power

supplying this device is turned on.