IVI

g,

Handlin and Sto

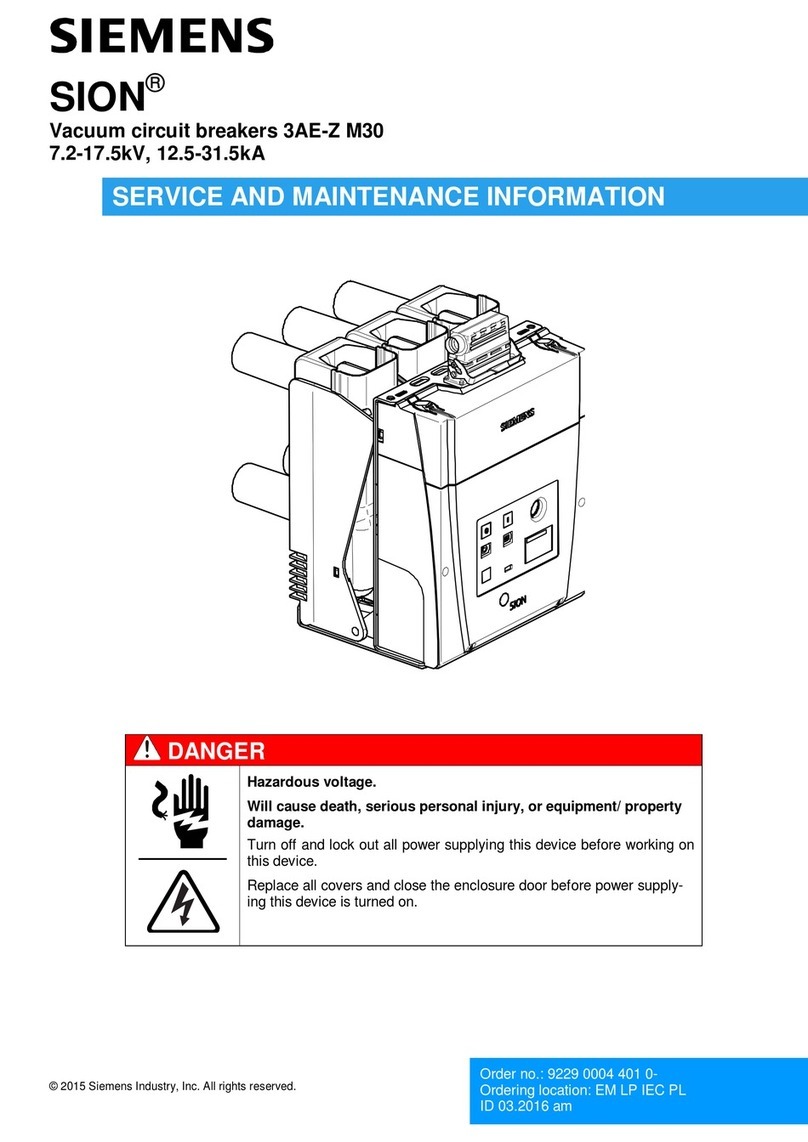

Introduction

Type GM! Vacuum Interrupter Circuit Breakers are normally

installed

in

assembled metal-clad switchgear, and the Switch-

gear Instruction Manual (SG-3258) contains the Receiving,

Handling and Storage instructions for assembled metal-clad

switchgear.

This manual covers the Receiving, Handling and Storage

instructions for Type GM! circuit breakers shipped separately

from the switchgear. This section of the manual

is

intended to

help the user identify, inspect and protect the circuit breaker

prior to its installation.

Receiving Procedure

Make a physical inspection of the shipping container before

removing orunpacking thecircuitbreaker. Checkfor shipment

damageor indicationsofrough handling bythe carrier. Check

each item against the manifest to identify any shortages.

Accessories such as the manual charging lever, the racking

crank and the plug jumper are shipped separately.

Shipping Claims (When Applicable) -Follow nor-

mal shipment damage procedures, which should include:

1.

Check for visible damage upon arrival.

2.

Visible damage must be noted

on

delivery receipt. and

acknowledged with driver's signature. Notation, "Possible

internal damage, subject to inspection" must be

on

delivery

receipt.

3.

Notify Siemens Sales office immediately of any shipment

damage.

4.

Arrange for carrier's inspection. Do not move the unit from

its unloading point.

Handling Procedure

1.

Carefullyremovethe shipping cartonfromthecircuitbreaker.

Keep the shipping pallet for later use if the breaker

is

to be

stored prior to its installation.

2.

Inspect for concealed damage. Notification to carrier must

take place within

15

days to assure prompt resolution of

claims.

3.

Each circuit breaker should be appropriately lifted to avoid

crushing the side panels of the breaker, or damaging the

primary disconnect subassemblies.

Heavy Weight

Can cause death,

serious

injury,

or

property

damage.

Obtain the services of a qualified rigger prior to

hoisting the circuit breaker to assure adequate

safety margins

1n

the hoisting equipment and

procedures to avoid damage.

TypeGM! circuitbreakersweigh between385to 575 pounds

(175to

261

kg). See Table A-4, Technical Data

in

Appendix.

4.

The palleted circuit breaker can also be moved using a

properly rated fork-lift vehicle. The pallets are designed for

movement by a standard fork-lift vehicle.

s""'""'"

..

Procedure

1.

Whenever possible, install circuit breakers

in

their assigned

switchgear enclosures for storage. Follow instructions con-

tained

in

the Switchgear Instruction Manual.

2.

When the breaker will be placed

on

its pallet for storage, be

surethe unit

is

securelybolted to the palletand covered with

polyethylene film at least

10

mils thick.

Indoor -Whenever possible, store the circuit breaker

indoors. The storage environment must be clean, dryand free

of such items as construction dust, corrosive atmosphere,

mechanical abuse and rapid temperature variations.

Outdoor -Outdoor storage

is

not recommended.

When no other option

is

available, the circuit breaker must be

completelycovered and protected from rain, snow, dirtand all

other contaminants.

Space -Space heating must be used for both indoor

and

outdoorstorage to prevent condensation and corrosion.

When stored outdoors. between 150 to 200 watts per breaker

of space heating

is

recommended. If the circuit breakers are

stored insidethe switchgearenclosures, and the switchgear

is

equipped with space heaters, energize the space heaters.

3

Courtesy of NationalSwitchgear.com