1

EntelliGuard R Circuit Breaker Retrofill AKD-5/6 Installation Manual DEH 524 R 1

Table of Contents

Preface .............................................................................................................................................................. 3

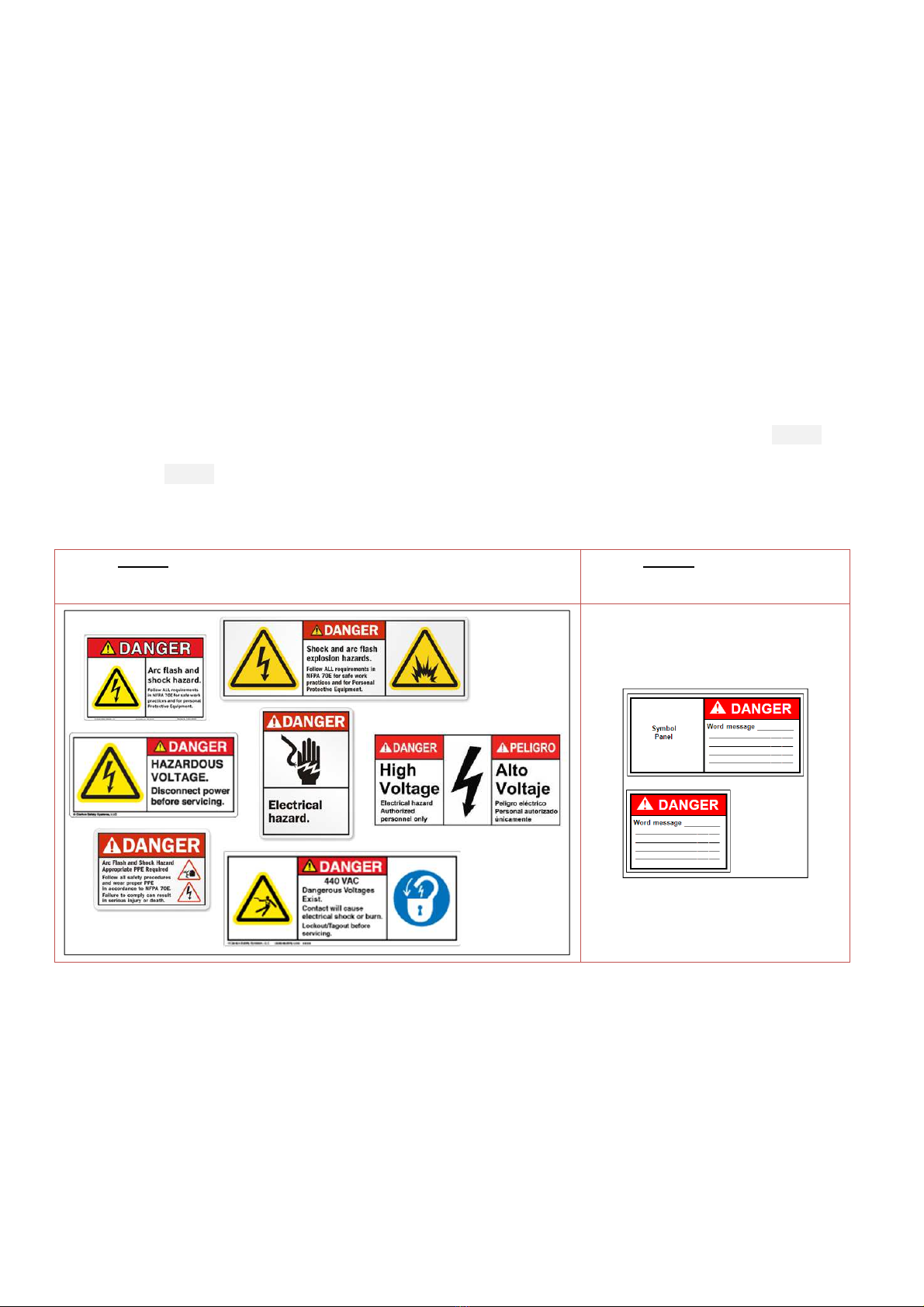

Hazards .................................................................................................................................................................................................... 3

Danger ...................................................................................................................................................................................................... 3

Warning ................................................................................................................................................................................................... 4

Caution ..................................................................................................................................................................................................... 4

Notice or Note ....................................................................................................................................................................................... 5

Warranty ................................................................................................................................................................................................. 5

Trademarks and Patents ................................................................................................................................................................. 5

Standards ................................................................................................................................................................................................ 5

Document Conventions ................................................................................................................................................................... 5

Related Publications .......................................................................................................................................................................... 6

Service and Support ........................................................................................................................................................................... 6

Estimated Time to Complete Tasks ............................................................................................................................................ 6

Weight (LBS) ........................................................................................................................................................................................... 6

Description ....................................................................................................................................................... 7

Product Specs ....................................................................................................................................................................................... 7

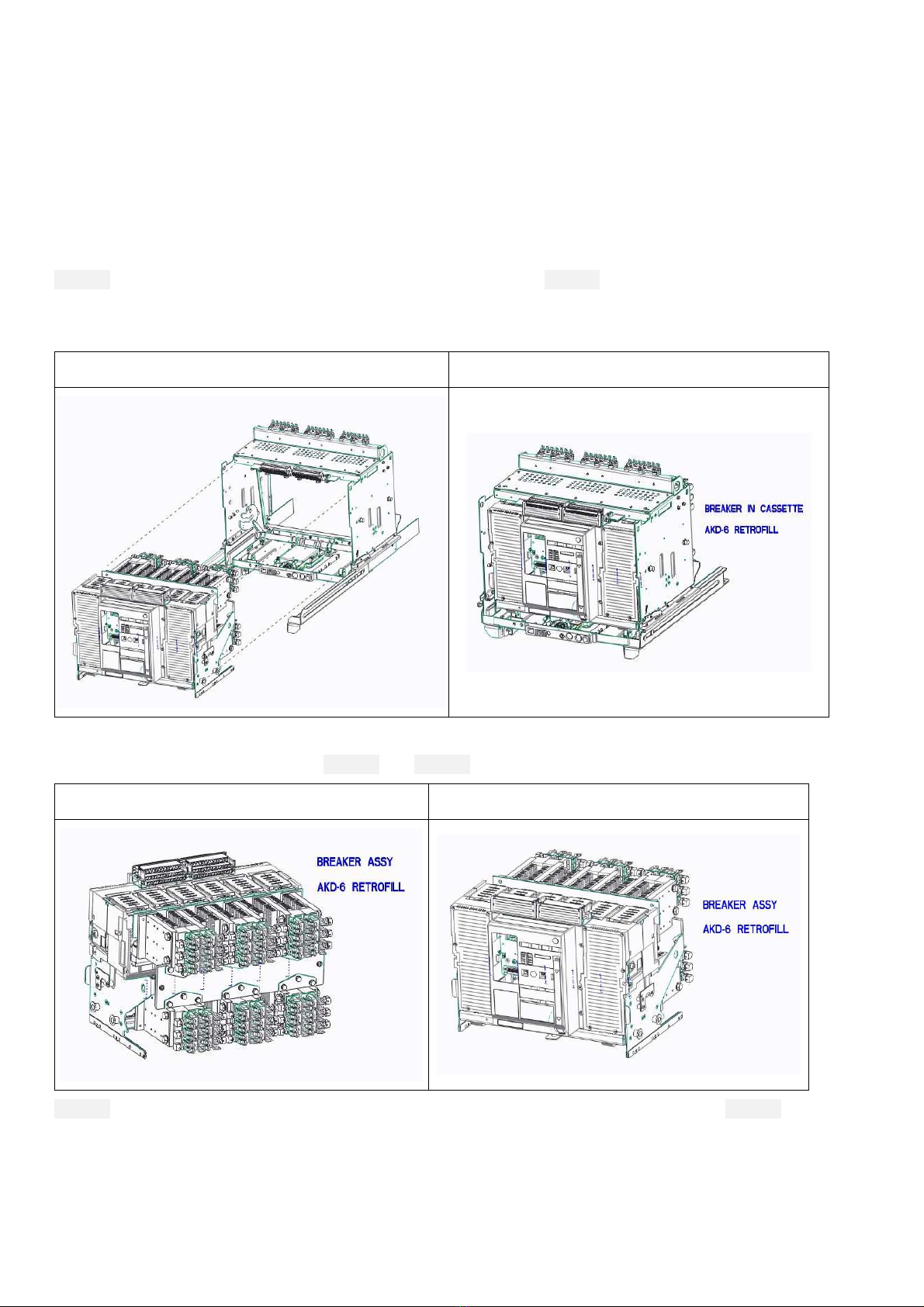

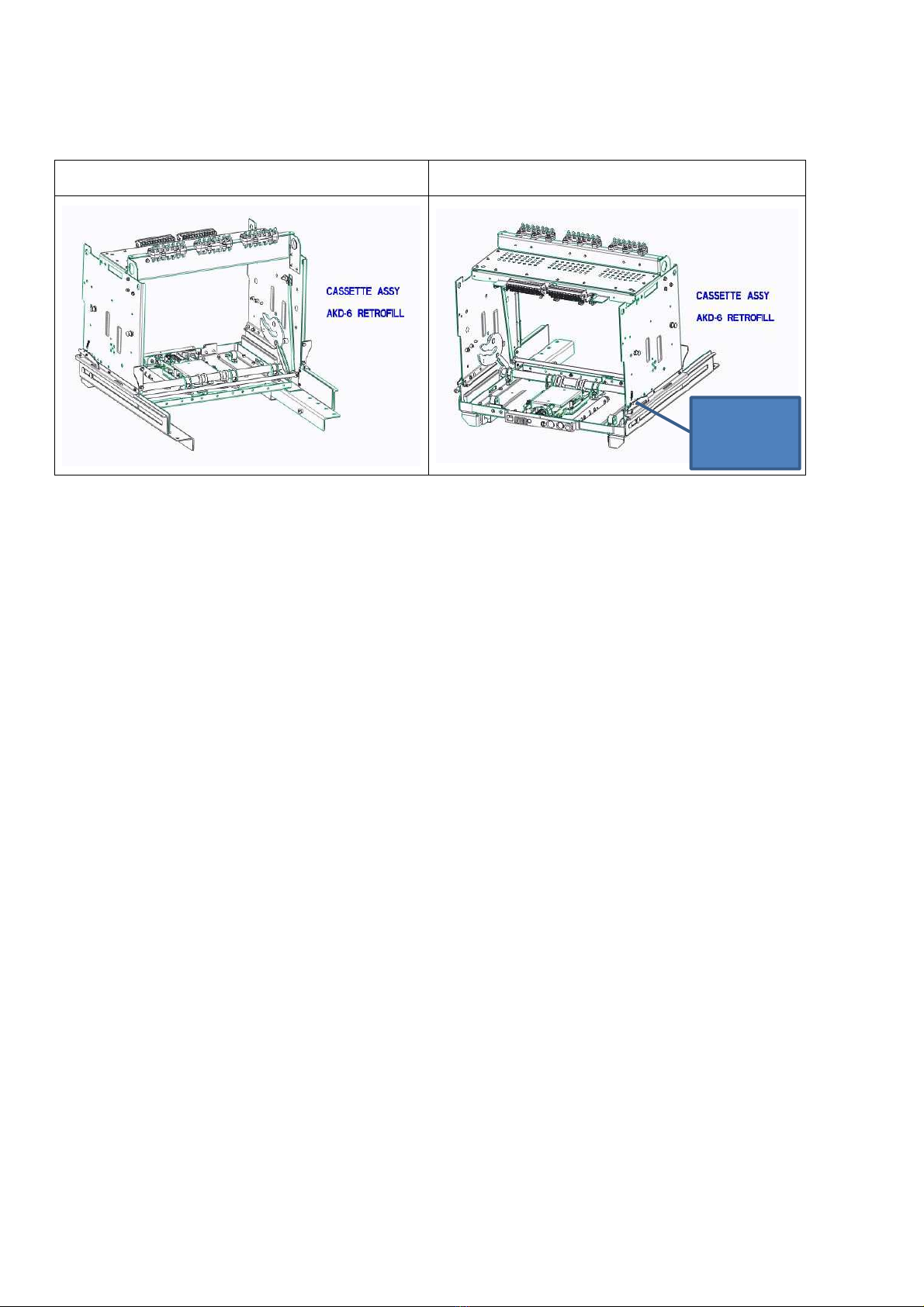

History and Types ............................................................................................................................................

AKD ............................................................................................................................................................................................................. 8

AKD-5—AK-25, AK-50, AKT-50, AK-75, AK-100 ..................................................................................................................... 8

AKD-6—AKR-30/30H, AKR-50/50H/T50H, AKR-75/75H, AKR-100 ............................................................................... 9

AKD-8—AKR-30/30H/30L, AKR-50/50H/T50H, AKR-75/75H, AKR-100, AKR125 .................................................. 9

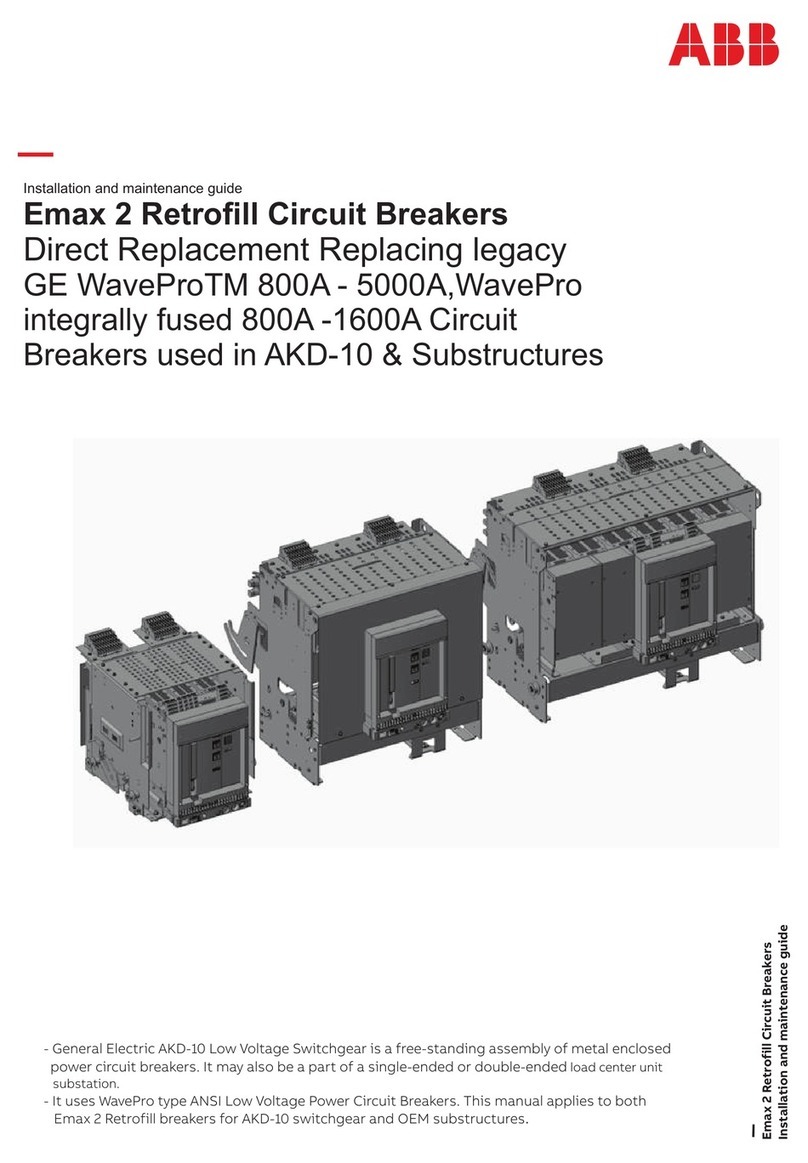

AKD-10—WPS-08, WPH-08, WPX-08, WPS-16, WPH-16, WPS-20, WPS-32, WPH-32 WPX-32, WPS-40,

WPX-40, WPS-50, WPX-50 ........................................................................................................................................................... 10

Unpack Retrofill Circuit Breaker .................................................................................................................. 10

Quality .................................................................................................................................................................................................... 11

nformation Label ............................................................................................................................................................................. 11

Product and Catalog Serial Numbers ..................................................................................................................................... 11

Remove Circuit Breaker from Container ..................................................................................................... 11

nspect ................................................................................................................................................................................................... 11

Use Lifting Truck ............................................................................................................................................................................... 12

Store Circuit Breaker ..................................................................................................................................... 14

Clean and Grease Breaker ............................................................................................................................ 15

Customize Retrofill Secondary Wiring ......................................................................................................... 15

Modify AKD-5 Switchgear Compartment .................................................................................................... 16

Turn OFF/ OPEN the Legacy Circuit Breaker ....................................................................................................................... 16