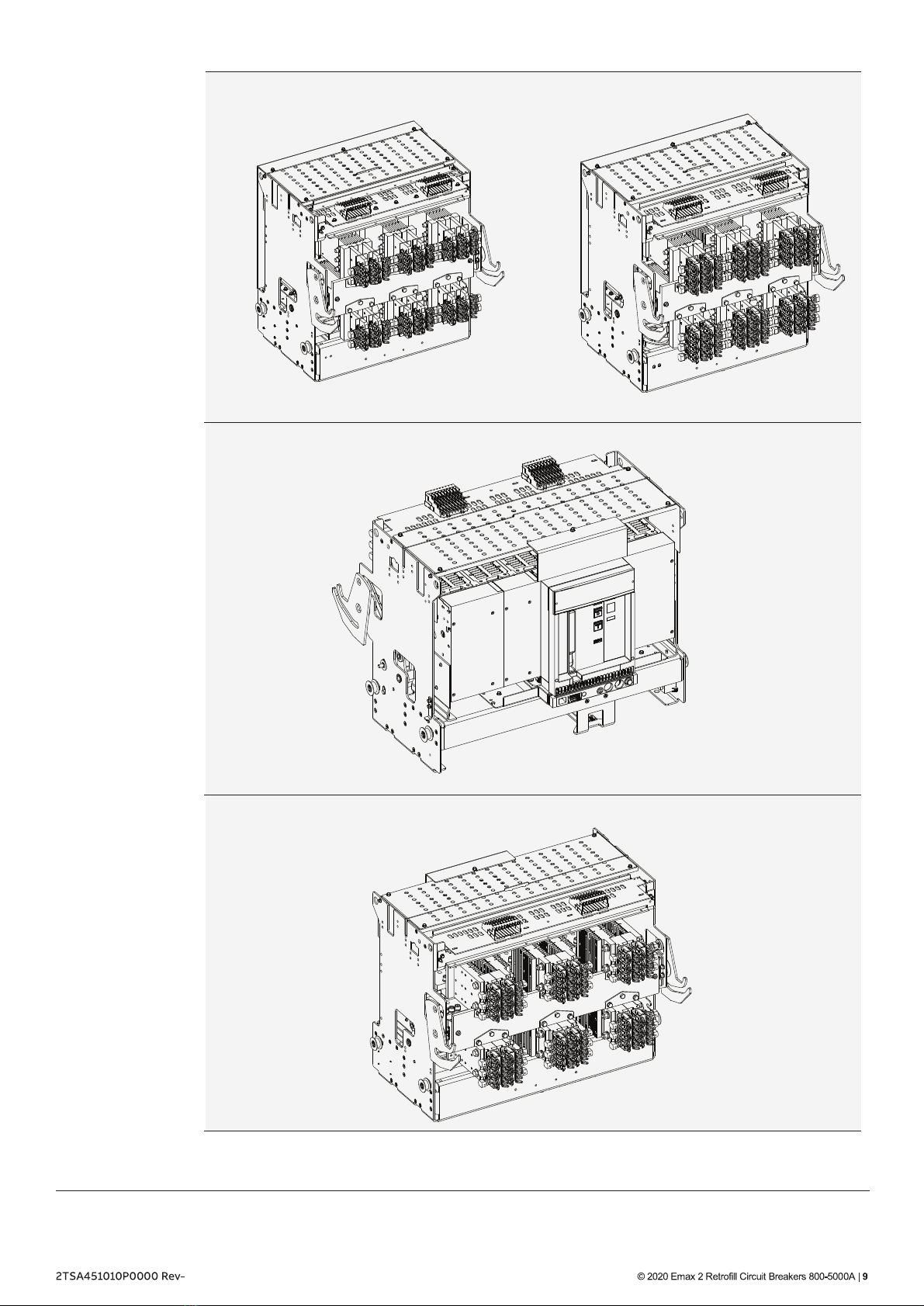

History and Types

10 - History of AKD

AK - Power Circuit Breaker Equipment

D - Drawout circuit breaker construction

Manufactured from 1951 to 1975, all bolted, copper bus design, all drawout breakers AK- 1,2,3,-15 /25 /

50 /75 / 100; the 4000A-max bus rating. Breakers had a ratcheting drawout mechanism, with an

open-door drawout. Breakers were painted ANSI61, light gray,manufactured in Philadelphia

from 1951 to the mid-60s and in Burlington, lowa from the mid-60s to 1975.

The breaker compartment was a welded assembly, and the equipment frame was bolted.

Breaker boxes were stacked to make a vertical section with equipment frame around the

breaker boxes. There were no bus compartment barriers, just an open bus design. Ring

silver-plating was applied to bolted connections.

AKD - 5 Manufactured from 1960 until 1977, the aluminum bus had copper that was “flash-butt

welded’ to the aluminum at bolted connections. During that time, AK-2A, 3A -25 / 50 /T50/75 / 100

(“A” signifies AKD-5 drawout) were produced. Breakers up to 2000A had primary finger

clusters. 3000 & 4000A breakers had a circular primary finger cluster arrangement in

the switchgear compartment. Pull-lanyard drawout mechanism in the switchgear on early

designs was replaced by a single jackscrew mechanism and then later replaced by a double

jack-screw mechanism. Featured is a closed-door, drawout with inner house breaker compartment,

where door moves with the breaker as it is racked in or out. Two bus levels are available with a ring

bus used at 4000A. Particulars include: welded/riveted frame, bus compartment barriers,

line/load separation barriers on mains and ties, isolation barriers on transformer transitions,

copper runbacks on feeder breakers, ring silver-plating on copper, and aluminum bus un-

plated (welded connections). The switchgear is painted sand-gray (beige), with some

instrument doors painted blue. AKR-30/50 in 22"-wide sections were introduced in AKD-5

construction, early 70s. AK25s and AK50s were also available as substructure kits for OEMs to

build around customer gear.

Note: All legacy AK & AKR breakers have a draw out letter code “A”.

AKD-6 was manufactured in Salisbury, NC from 1977 to 1981. Some AKD-5s, which were built

in Salisbury from 1975 until 1977, got name-plated as AKD-6. There is no “flash-butt” welded

aluminum to copper. Aluminum bus is tin-plated and bolted at shipping splits (but welded

everywhere else). Copper bus design has ring silver plating at bolted joints. AKR-75 / 100s

were introduced during this time. Stab-and-finger connections on 3200A and 4000A

breakers were improvements, versus the round the primary disconnects on the AKD-5, The

4000A breaker was also narrowed to same width and phase-phase spacing as the 3200A.

The AKD-6 uses inner-house drawout breaker compartments on the 800 - 2000A breaker

compartments. They are painted ANSI 61 light gray and breakers have ECS or SST trip units.

AKD-6 should mark a shift away from all AK breakers and to AKR breakers. The AKR-

30/50/50H/T50 breakers used in AKD6 have a shallow 1” steel front escutcheon are drawout

letter code “A” i.e. AKR-4A-30. The AKR-30/50/50H/T50/75/100 breakers sold to OEMs for

their switchgear have a 5” deep plastic front escutcheon & spring loaded sliding “picture

frame”.

These are draw out letter code “B” i.e. AKR-4B-30.The AKR-75/100 breakers used in AKD-6

have a shallow 1” steel front escutcheon and vertical primary fingers. They are drawout letter

code”C” i.e. AKR-4C-75.

AKD - 6

C