Siemens 81000 series User manual

Other Siemens Controllers manuals

Siemens

Siemens Sinamics S120M User manual

Siemens

Siemens SITRANS VP300 User manual

Siemens

Siemens SIMATIC NET CP 1613 A2 User manual

Siemens

Siemens Simatic S7-1500 Parts list manual

Siemens

Siemens Desigo RXC39.5 User manual

Siemens

Siemens SINAMICS S120 User manual

Siemens

Siemens SQL36E series User manual

Siemens

Siemens LGA41.153A27 User manual

Siemens

Siemens DESIGO PX Series User manual

Siemens

Siemens SINAMICS S120 Quick start guide

Siemens

Siemens Simatic S7-1500 User manual

Siemens

Siemens SSA911.01ZB User manual

Siemens

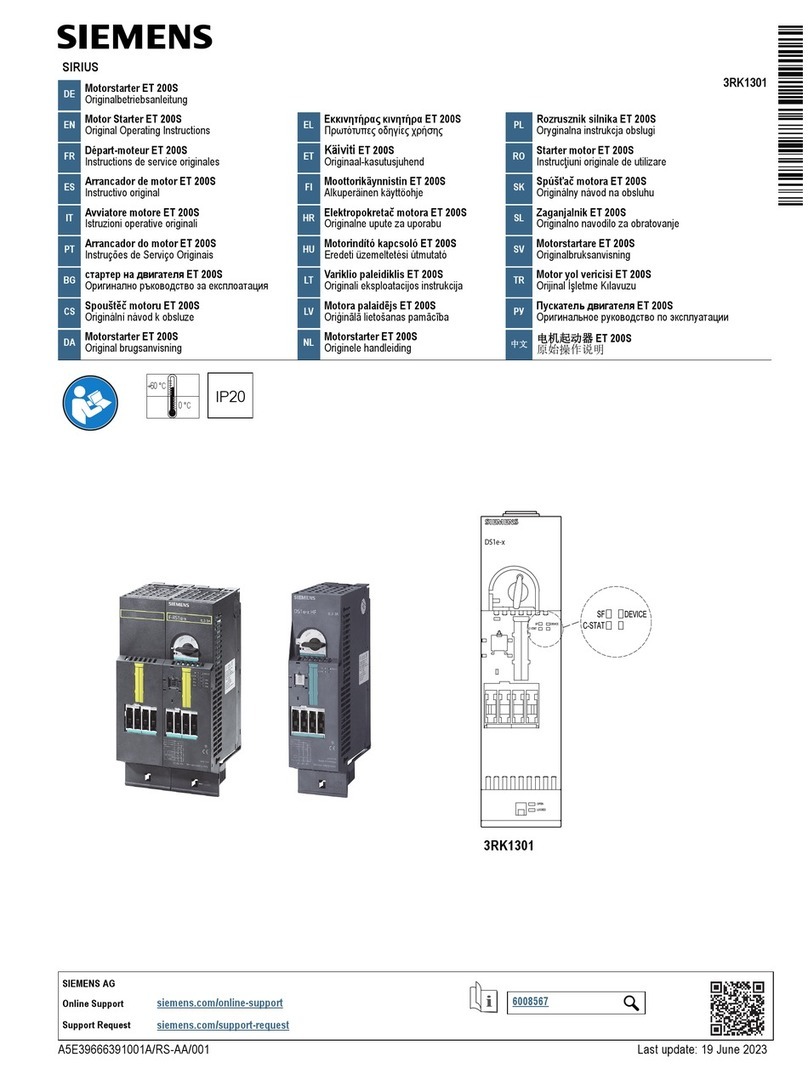

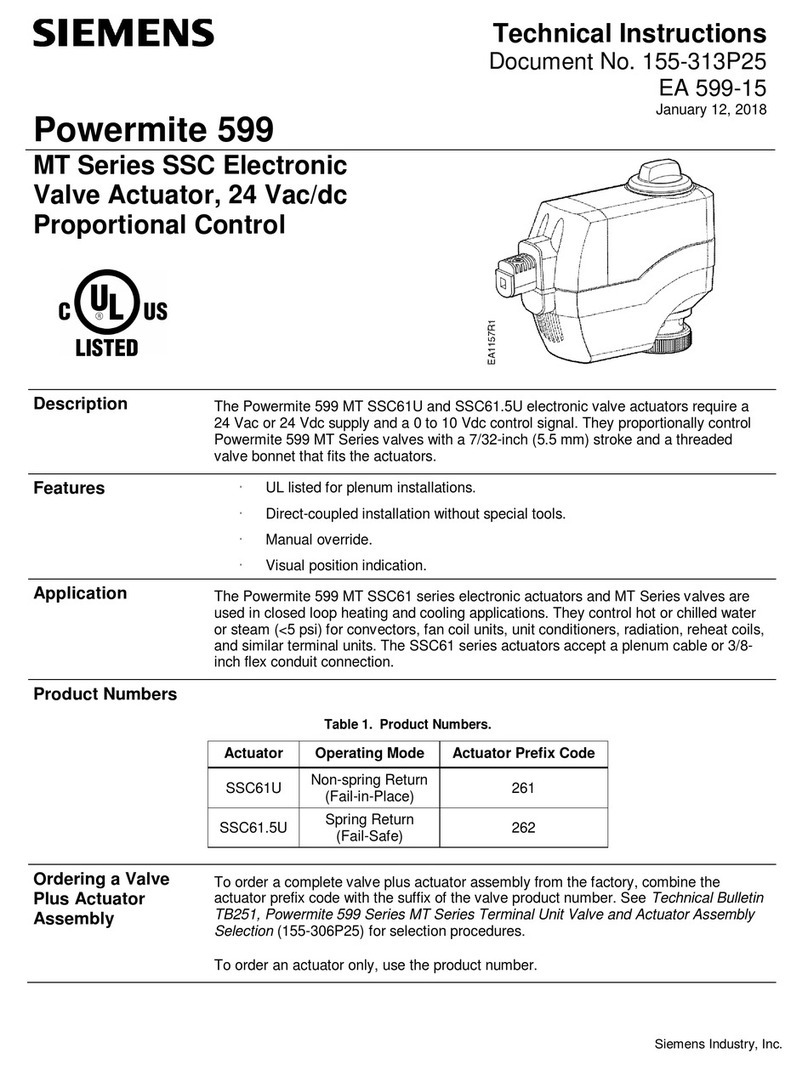

Siemens Powermite 599 MT Series Owner's manual

Siemens

Siemens 5WG1 513-1AB11 User manual

Siemens

Siemens GHT336.1A/35 User manual

Siemens

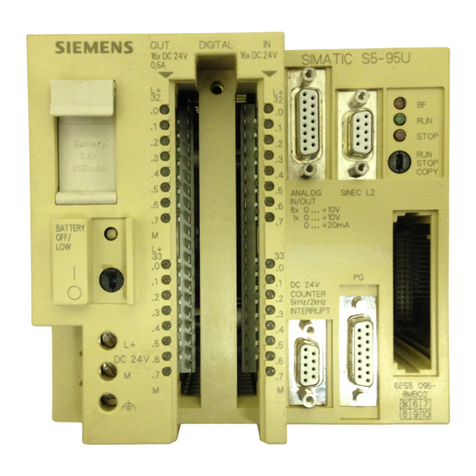

Siemens SIMATIC S5 User manual

Siemens

Siemens 5WG1 523-1AB04 User manual

Siemens

Siemens ACVATIX SAX319.03 User manual

Siemens

Siemens SINUMERIK 840D sl User manual

Siemens

Siemens BACnet User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions