Removerequiredlengthof

insulationandusingthe

hardwareconnectedatthe

contactorterminals,fixthe

incomingandoutgoing

cables.

c. Incase,thepowerandcontrol

circuitsareofdifferent

voltages,connectthedesired

supplytothecontrolcircuit,

usingtheconnector.Follow

theinstructionsgivenon

wiringdiagramlabelstuckon

innersideoffrontcover.

d. Tightenthescrewsfirmly.

e. Checkthatthelineandmotor

connectionsaredoneexactly

asperwiringdiagrampasted

insidethefrontcover.

f. Removeanywirecutting

fallenintothestarter.

• Connectearthingconductorto

terminalsmarked

Commissioning:

Read the caution

note carefully before

commissioning.

• Removethefrontcover.

• BeforeswitchingON,re-check

externalconnections.

• Setoverloadrelayto0.58

timestheratedmotorcurrent.

• Setthedialofthetimer(fig.

7)toanapprox.valueof

startingtimeofyourmotor

(preferablymorethan6sec.).

• Star-DeltaTimersetting(for

ASDonly):

a. Firststartthemotorby

pressingthe‘ON’buttonas

indicatedinfig.8.

b. Measuretimetakenforitto

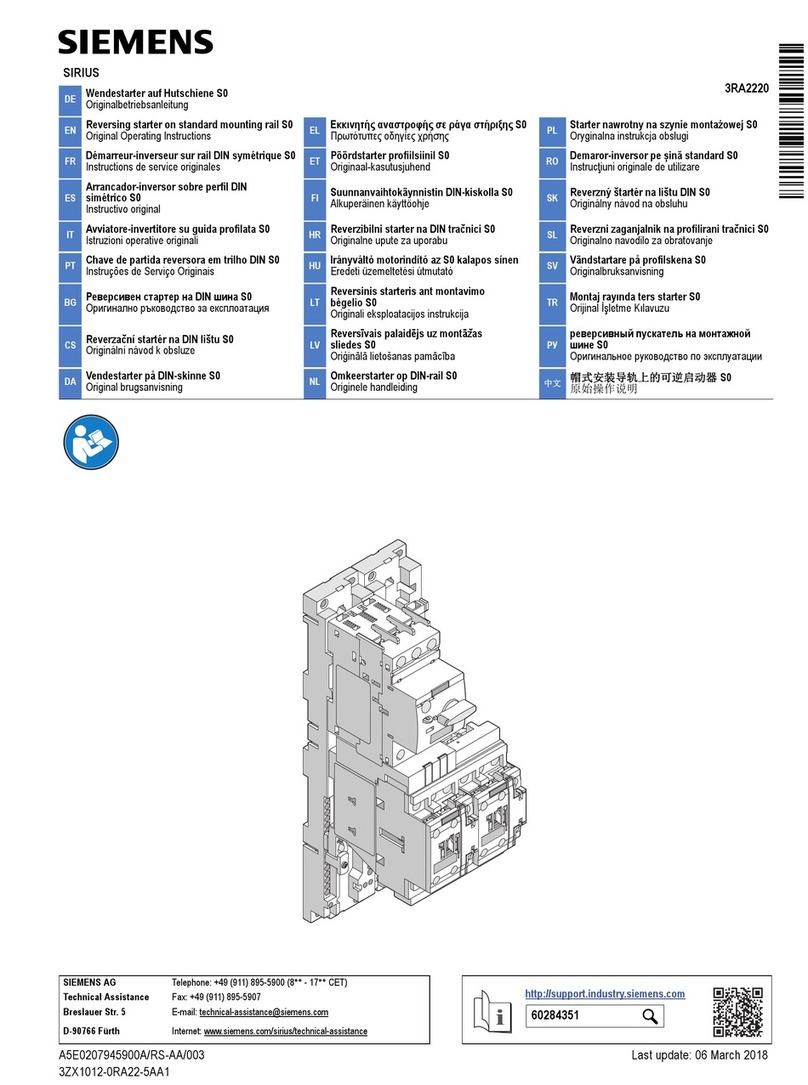

• Mountstarteronavertical

wall/platefreefrom

vibrations,withpropernuts

andbolts.Referfig.11for

mountingdimensions,and

alsofig.5forpermissible

displacement.

Fig.5 Maximumpermissible

displacementfromverticalplane

Fig.6Cableconnections

Fig.4ResetCordconnections

'Reset'

Cord

reachnearlyratedspeedor

steadystatecurrent(indicated

whenmotorhumreachesa

steadypitch).

c. Stopthemotor.Settimertothis

measuredvalue,byrotatingthe

dialshowning.7.

• Overloadrelaysetting:

a. Forcloserprotectionsetthe

overloadrelaytoactualline

current(DOL)oractualphase

current(ASD)asmeasuredby

anAmmeter.

• IntheabsenceofanAmmeter,

useprocedureasgivenbelow:

a. Startthemotorandletitrun

for½anhour.Thengradually

reducerelaysettingtillittrips.

Setrelayataslightlyhigher

valueofthissetting.

b.Allowresettimeofapprox.

4min.Presstheblueknobon

therelaycompletelytoreset

therelay.

c.Re-startmotoraftersome

time.Iftherelaydoesnottrip,

considerittobeproperlyset.

Ifittrips,followstepbwith

settingatalittlehighervalue

andrecheck.

d. Overloadrelaycharacteristics

giveninfig.10canbeusedto

estimatetheaveragetripping

timeatdifferentmultiplesof

setcurrent.

Caution:

• Switch off the starter and

disconnect the main supply

by switching off the main

switch before doing any

maintenance.

Screw for

adjustment

2

Fig.7TimerAdjustment

Dial

• Selectcorrectsizesofcableas

specifiedinselectionTable1

and2.

• Dependinguponlocation

ofincomingandoutgoing

cablesremovecorresponding

rubbergrommets.Ensuredust

proofingbyusingpropercable

gland.(fig.6)

a. Forcontactorsupto3TS36,

removeapprox.10mmof

insulationoftheconductor,

loosenterminalscrews

andpushcableendunder

theSIGUTterminalofthe

contactor.

b. Forcontactorsabove

3TS36,selectproperlugs

forconductortermination

dependinguponcablesize

specifiedinTable1and2.