9

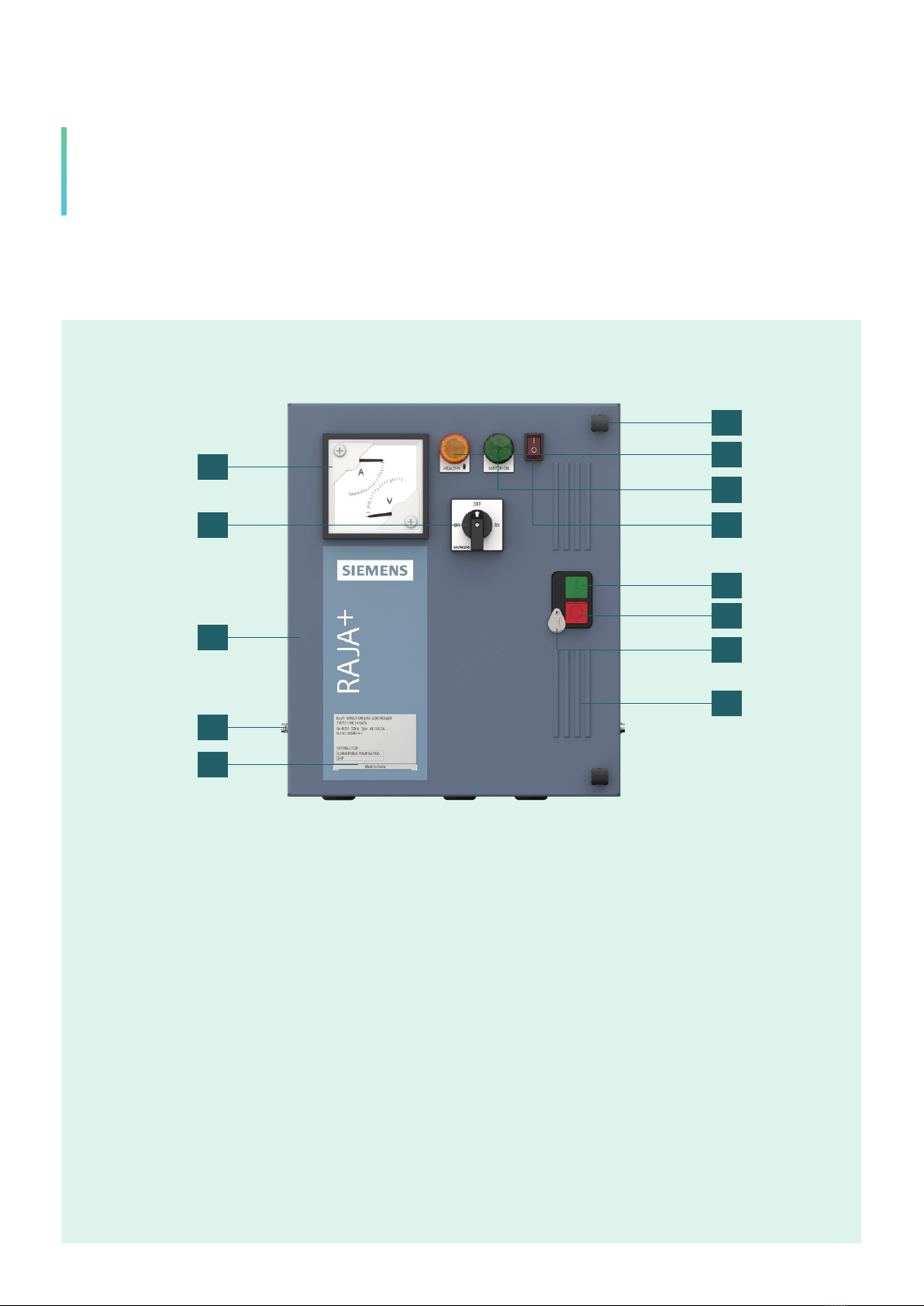

3.4: Installation

• Open the door by rotating the door lock anticlockwise.

• Mount the starter on a vertical wall/ plate free from vibrations with proper nuts and bolts.

Refer operating instruction for mounting dimensions.

• Remove the rubber grommets for the incoming and outgoing cable connections. (Refer Fig. 8)

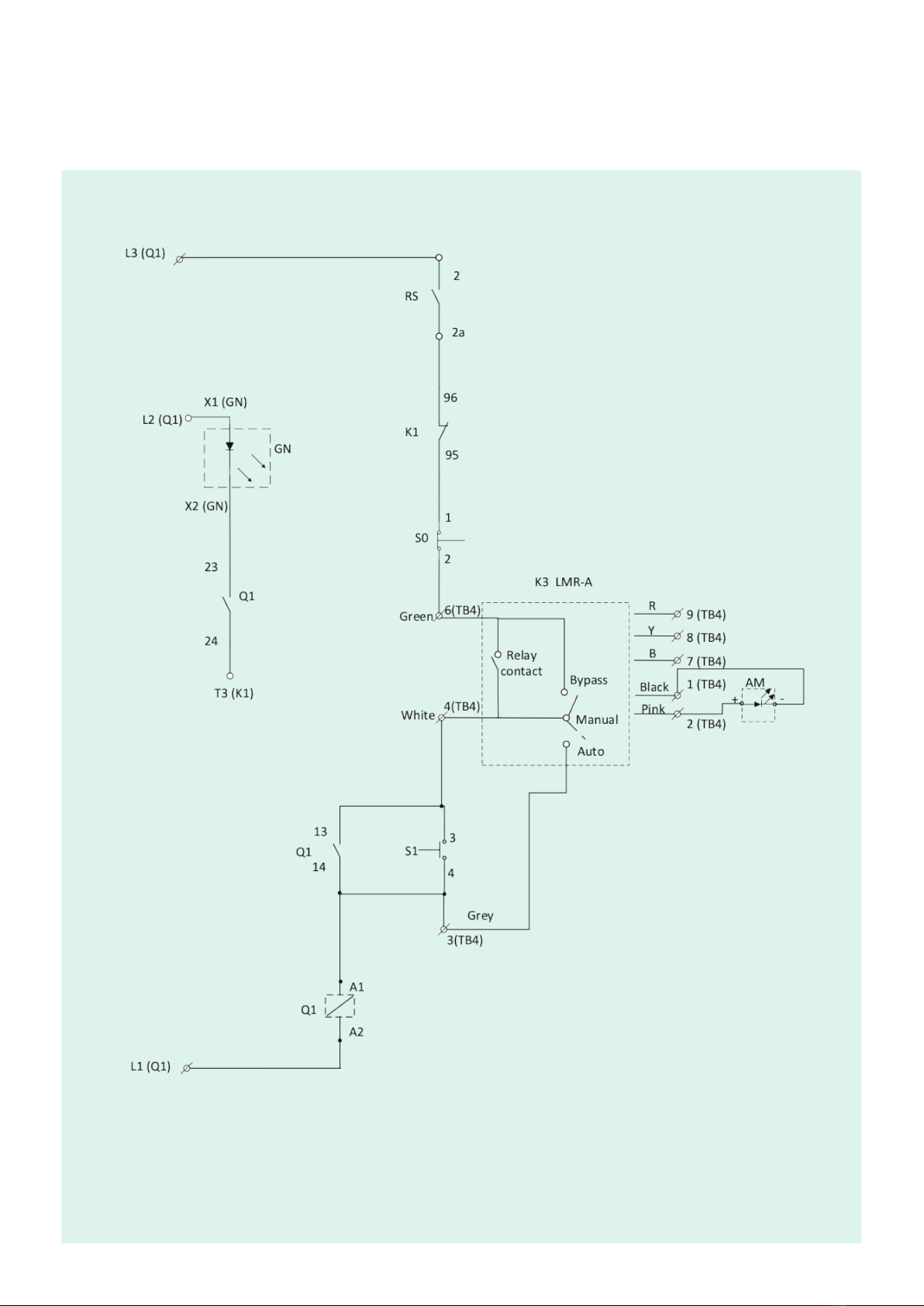

• Connect incoming and outgoing cables as follows (Refer Fig. 8):

- Use proper cable glands to ensure dust proofing. For conduit entry use packed washers.

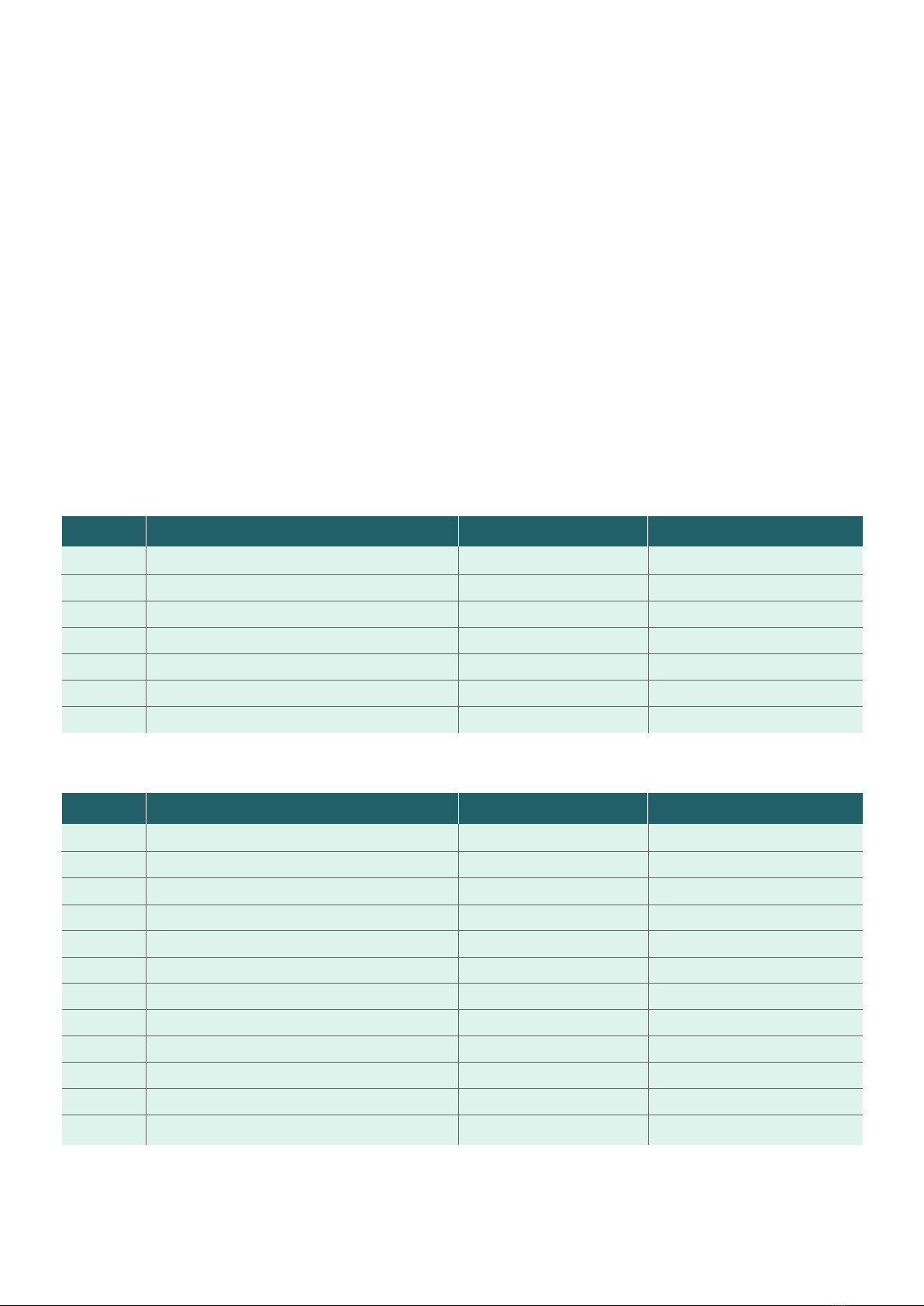

- Select correct size of cables from Table 15

- Connect line and motor leads exactly as per wiring diagram pasted inside the cover of the starter.

- Terminate the incoming supply cables on terminal block TB1 & outgoing cables to motor on terminal block

TB2,(Tightening torque -Refer table 15B)

NOTE: LMRA is set in Manual mode (Factory setting)

- Connect the earthing conductor to terminals marked (earth) on the starter body with torque 1.2 to 1.6Nm.

The Starter is now ready for commissioning.

Commissioning :

Installation, Maintenance & Troubleshooting guide | Version 03

Operating Characteristics:

The given characteristics (Fig. 6) are average values of all ranges and sizes of bimetal relays and are mainly intended to indicate

the inverse time current characteristics & tripping times of the same. The tripping times shown are for relays starting from the cold

state. At operating temperatures (heated at rated current) these are reduced to about 25% of the value obtained from the

characteristics.

Caution

• During commissioning or maintenance always ensure that the main supply is disconnected by switching

off the main switch & Rocker switch.

• If the relay trips even when set at rated motor current the suitability of the starter/relay for the particular application

should be checked with the nearest Siemens office.

For exact setting of overload relay, follow the instruction given below:

Before switching ON recheck all external connections.

• Overload relay setting:

- For closer protection set the overload relay to actual phase current as measured by an ammeter. In the absence

of an ammeter, use the procedure given below:

- Start the motor and let it run for 30 mins. Then gradually reduce the relay settings till it trips. Set the relay at a

slightly higher value than this setting. Overload relay characteristics shown in Fig. 6 can be used to estimate the

average tripping time at different multiples of set current.

- Allow a reset time of approx. 4 min. before pressing the blue knob on the relay to reset it.

- Restart the motor after some time. If the relay does not trip then consider it to be properly set. If the relay trips,

set at a little higher value than before and recheck.

• Close the front door.