Siemens SG-3118 Owner's manual

Other Siemens Industrial Electrical manuals

Siemens

Siemens SIRIUS 3RA132.-8XB30 User manual

Siemens

Siemens SIRIUS 8WD44 User manual

Siemens

Siemens 3KF1-B Series User manual

Siemens

Siemens 8UC6 Series User manual

Siemens

Siemens SIMOTION D45 Series User manual

Siemens

Siemens 38-3AH3-GTD User manual

Siemens

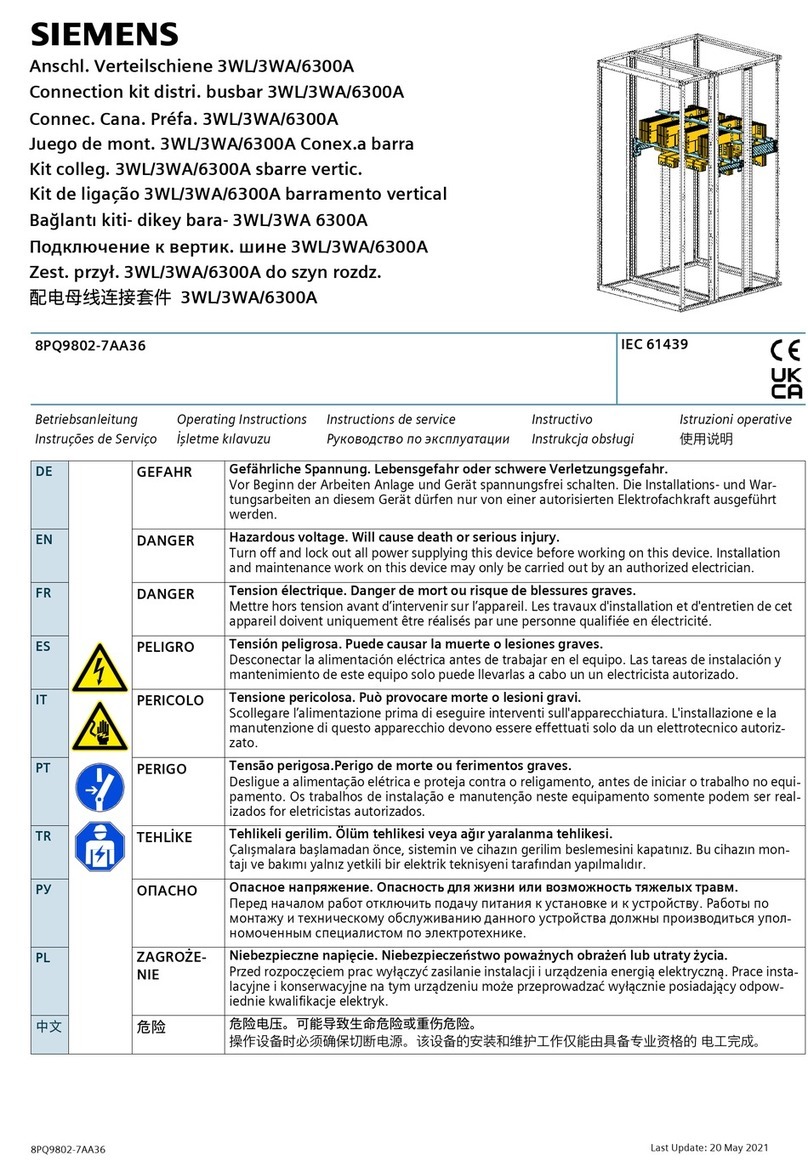

Siemens 6300A User manual

Siemens

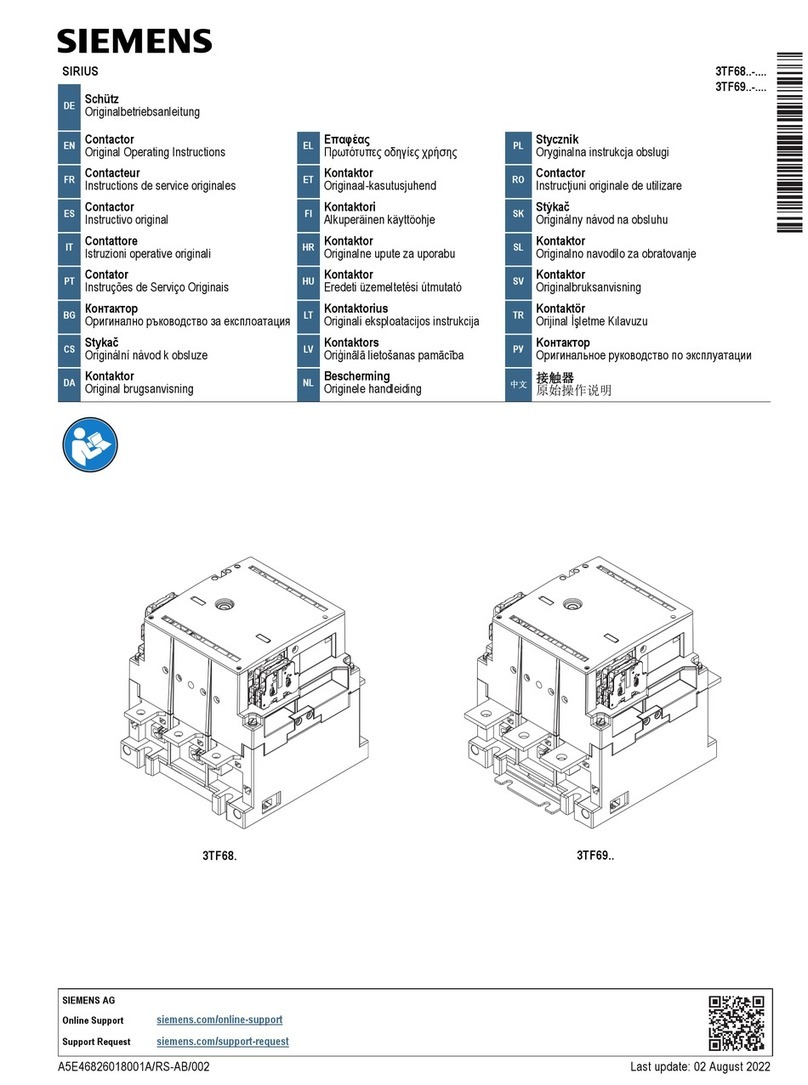

Siemens SIRIUS 3TF68 Series User manual

Siemens

Siemens SIVACON 8PS BD2 Series User manual

Siemens

Siemens Simatic S7-1500 User manual

Siemens

Siemens 3TF68 Q Series User manual

Siemens

Siemens 3VA1 Series User manual

Siemens

Siemens 3VA9117-0HB 0 Series User manual

Siemens

Siemens IP Viewer N151 Service manual

Siemens

Siemens SIVACON 8PS User manual

Siemens

Siemens SINAMICS G120P User manual

Siemens

Siemens SWT-3000 Technical Document

Siemens

Siemens 3VA9157-0PK11 User manual

Siemens

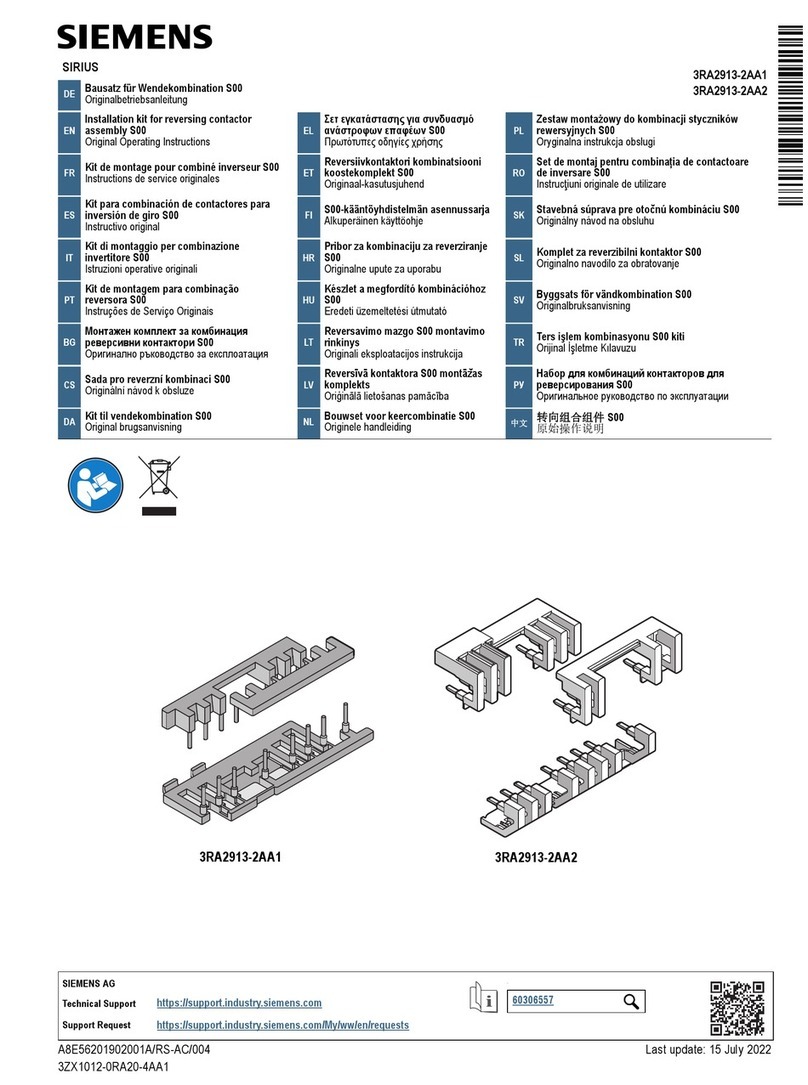

Siemens SIRIUS S00 User manual

Siemens

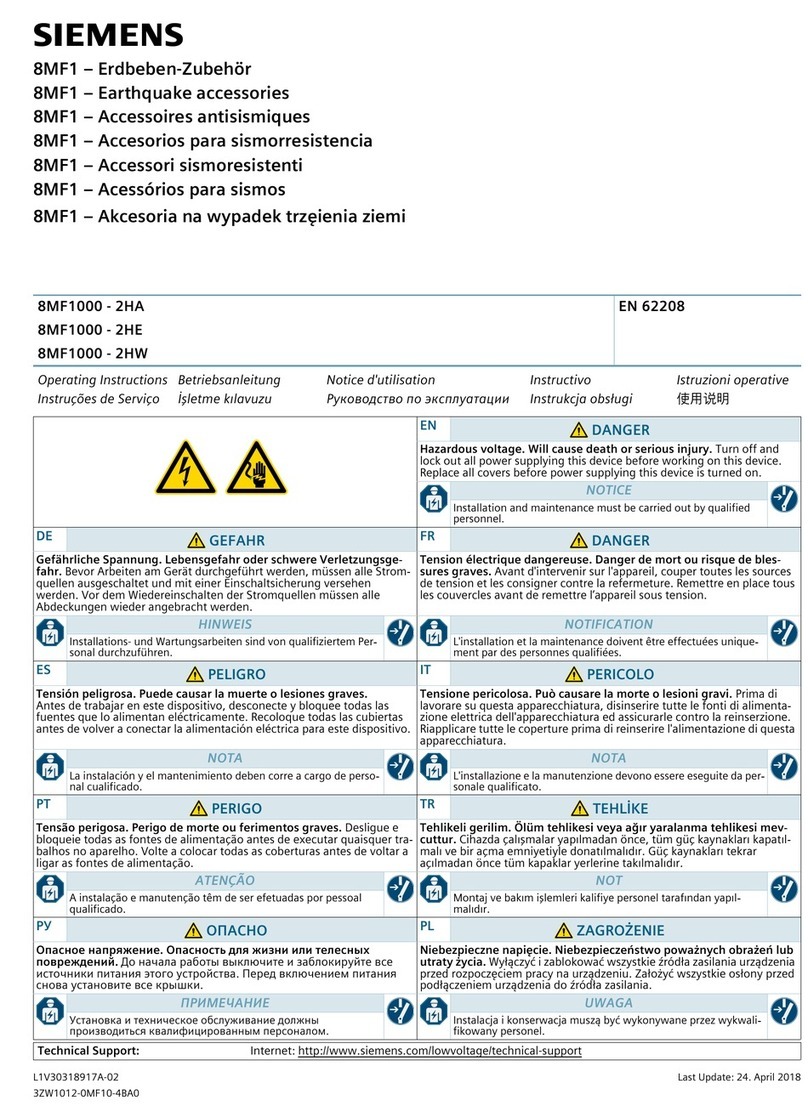

Siemens 8MF1000-2HA User manual

Popular Industrial Electrical manuals by other brands

Rexroth Indramat

Rexroth Indramat DURADRIVE SYSTEM200 Project planning manual

Abtech

Abtech HVJB Series Installation, operation & maintenance instructions

Murata

Murata GRM0335C1H8R1DA01 Series Reference sheet

SAF-HOLLAND

SAF-HOLLAND CBX 5415.5 Installation and operation manual

Eaton

Eaton Ulusoy HMH24-04 user manual

Murata

Murata GJM0335C1E4R4BB01 Series Reference sheet

Newlong

Newlong NP-7H NSTRUCTION MANUAL/PARTS LIST

Stahl

Stahl 8575/12 operating instructions

SI

SI Pegasus installation instructions

Murata

Murata GRM1555C1H2R7CA01 Seies Reference sheet

Murata

Murata GRM0225C1E6R4BA03 Series Reference sheet

Cooper Power Systems

Cooper Power Systems VXE15 Installation and operation instructions

S&C

S&C Vista SD manual

Murata

Murata GRM0335C2A7R3CA01 Series Reference sheet

Murata

Murata GRM32ER60G227ME05 Series Reference sheet

Rockwell Automation

Rockwell Automation Allen-Bradley MP-Series installation instructions

Phasemation

Phasemation DG-100 owner's manual

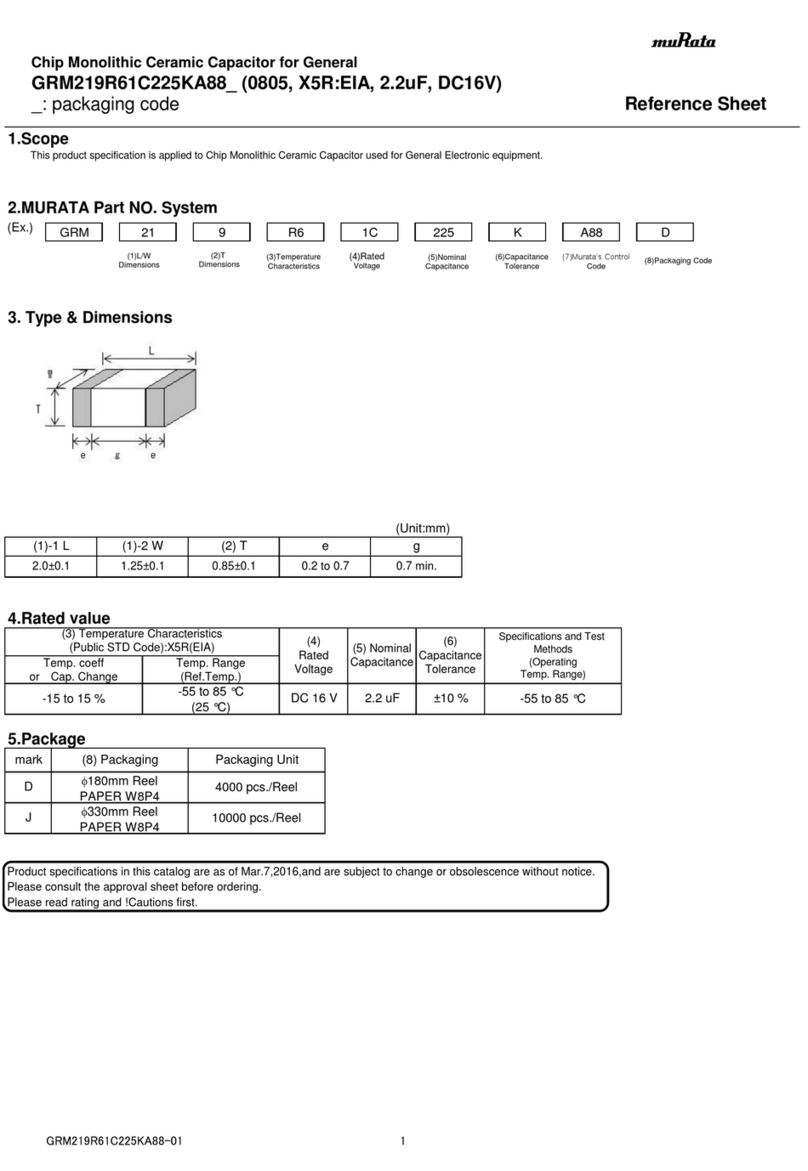

Murata

Murata GRM219R61C225KA88 Series Reference sheet