s

Overload Relay with Phase-Failure Sensitivity 3UA50,3UA52

GB14048.4,DIN VDE0660,Part 102,IEC 60947-4-1

Q/SMS 001,XK06-201 0023

Instructions Order No.:4NEB 601 1482-30 *5 English

A001253

!Limited protection against contact with live parts.

Degree of protection IP 20 to IEC 60529.

Safe from finger touch to DIN VDE 0106,Part 100.

Commissioning and maintenance by qualified personnel only.

Follow the operating Instructions!

!WARNING

Hazardous voltage can cause electrical

shock and burns.

Disconnect power before proceeding with

any work on this equipment.

Fig. I 3UA50: For mounting on contactors 3TD40/41, 3TE40, 3TF30/31/40/41,

3TW10/12/40/41;

Individual mounting possible with assembly kit 3UX14 18.

3UA52: For mounting on contactors 3TD42/43, 3TE42, 3TF32/33/42/43,

3TW13/42/43;

Individual mounting possible with assembly kit 3UX14 20.

Installation

Dimension drawings (dimensions in mm): Fig. II

a 3UA50: for individual mounting with assembly kit 3UX14 18

3UA52: for individual mounting with assembly kit 3UX14 20

b 3UA50: for mounting on contactor 3TF30/31

c 3UA50: for mounting on contactor 3TF40/41

I=contactor with 1 NO or 1 NC

II=contactor with 1NO + 1NC or 2NO + 2NC

d 3UA52: for mounting in contactor 3TF32/33

e 3UA52: for mounting in contactor 3TF42/43

1) Minimum distance from earthed components

2) For snap-on mounting on a standard sectional rail to DIN EN 50022.

3) Dimension for square OFF button (stoke 3mm).

4) Dimension for round RESET button (stroke 2.5mm) dimension minus 2.5mm.

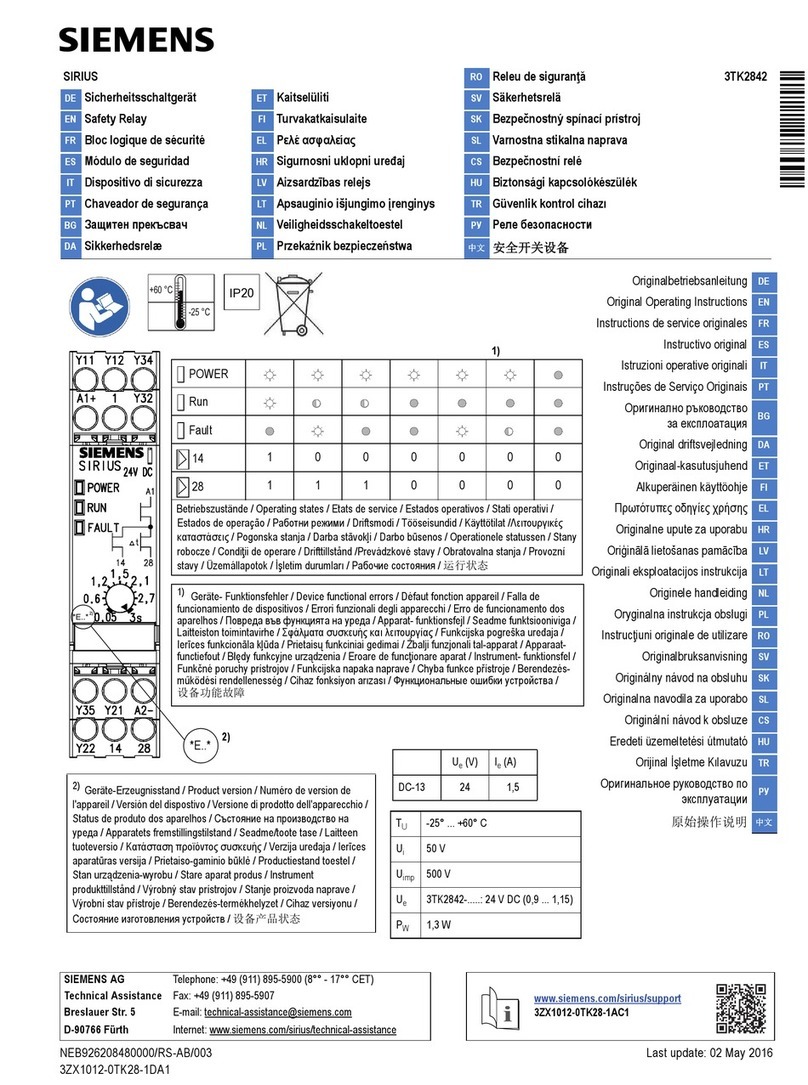

Permissible installed positions: Fig. III

a Overload relay with contactor

b Overload relay for individual mounting

Do not subject to sudden shocks or long-term vibrations.

Mounting:

Snap-on mounting on a standard sectional rail (35mm) to EN 50 022 or bolting on a plane

surface by two bolts to be secured by washers and spring washers.

Connection

Equipment circuit diagram: Fig. IV

Permissible cable cross-sections: Fig. V

In the case of several single-phase loads, the three main circuits must be connected in series.

Commissioning

Instructions: Fig. VI

①Set the scale to the rated current of load.

② Reset button (blue)

Push this button before commissioning and after tripping to make relay ready for

operation.

In the as-delivered condition, the auxiliary contact is set to H=Manual resetting.

To change from H=Manual to A=Automatic, press and turn the button counter-

clockwise from H to A.

③ Test button (red)

When this button is actuated, the NC contact opens and the NO contact closes, i.e.

a test function for NC and NO contacts (simulation of overload tripping).

In the “Manual” position, the relay is reset when the blue button is pressed.

In the “Automatic” position, the relay is reset automatically when the red button is

released.

④ TRIPPED indication (green)

In the H setting, a green pin protrudes from the front plate to indicate the TRIPPED

condition. In the A setting, this condition is not indicated.

⑤Terminal for contactor coil, A2.

Tripping characteristics: Fig. VII

The characteristics conform to VDE0165, VDE 0170/0171 for machines with type of

protection E Ex e.

Tripping times are shown for a three-phase load from the cold state (ambient temperature

+20 ℃). In the case of hot relays, preloaded with 1×IE, the tripping times decrease by

approx. 25%.

IE Current setting

tATripping time in seconds (±20% )

① Setting range

(I= lowest value of current setting IE, II= highest value of current setting IE)

②Type designation/Order No.

③PTB (Federal testing Laboratories) Test Report No.

Technical data

Main circuit

Rated insulation voltage 690V

Rated operational current 3UA50: 0.1~14.5 A

3UA52: 0.1~25 A

Permissible ambient air temperature -25 ℃to +55 ℃

Short-circuit protection see nameplate

Auxiliary circuit

Rated operational currents

AC-15/Ue V 24 60 125 230 400 500 690

AC-15/Ie A 2 1.5 1.25 1.15 1.1 1 0.8

DC-13/Ue V 24 60 110 220

DC-13/Ie A 2 0.5 0.3 0.2

Rated insulation voltage:

400V 690V

differing potential same potential

Short-circuit protection:

NH, NEOZED or DIAZED fuses 6A gG or 10A, fast

Miniature circuit-breaker 3A (C-characteristic)

Operating conditions at ambient temperatures>55 ℃

At ambient temperatures > 55 ℃, you must

1. Reduce the current loading for the overload relay

2. Upwardly correct the setting current to prevent tripping at motor rated current.

Correction factors:

Ambient

temperature

Perm. current loading referred

to end-of-scale value

Setting current

correction

55℃1 1

60℃0.94 1.08

65℃0.88 1.09

70℃0.82 1.1

Calculation example:

Motor rated current: 10 A

Ambient temperature: 70 ℃

Overload relay fitted: 8~12.5 A

1st Step: Determine the permissible current loading:

Max. Current loading: 12.5 A ×0.82 =10.25 A

Loading with motor rated current 10 A at 70 ℃ambient temperature is permissible.

2nd Step: Calculate the setting current:

Motor rated current: 10 A

Setting current correction: 10 A ×1.1=11 A

You must set the overload relay to 11 A.

For further information and accessories, see Catalog.

Siemens Electrical Apparatus Ltd., Suzhou

2