Siemens Milltronics Process Instruments Inc.

1954 Technology Drive, P.O. Box 4225

Peterborough, Ontario

K9J 7B1 / Canada

Tel.: (705) 745-2431

Fax: (705) 741-0466

www.siemens.com/processautomation

AG080910

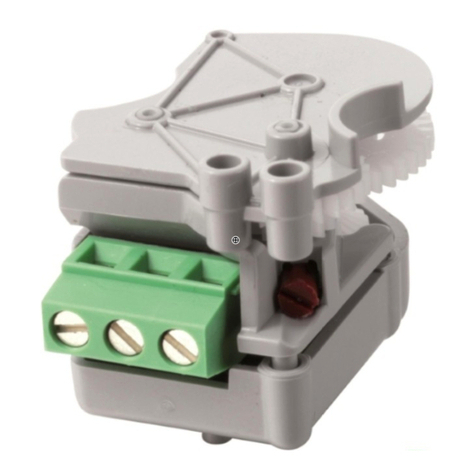

Pointek CLS300 Capacitance Switch (Standard Electronics Version)

Configuration of CLS300 Standard Models Manufactured After January 26, 2011

Objective: Set up and calibrate the Pointek CLS300 (Standard Electronics Version). This app guide applies to any

models manufactured after January 26, 2011.

Equipment: Pointek CLS300 (Standard Electronics Version) Capacitance Switch

While every effort was made to verify the following information, no warranty of accuracy or usability is expressed or implied.

Overview

This application guide is an addition to the operating instructions. Please review CLS300 (Standard Electronics Version) operating

instructions to ensure that the device is properly mounted.

This application guide provides a basic procedure for setting the switch point for correct operation of the CLS300 (Standard

Electronics Version) in either covered or uncovered states. Please note that the guide applies only to hardware manufact

ured after January 26, 2011 as indicated by a serial number of PBD/B127xxxx or higher. (For example, PBD/C9xxxxxx or

PBD/B128xxxx.)

Included in the guide are the appropriate start up procedures to quickly and effectively set up the Pointek CLS300 (Standard

Electronics Version) capacitance switch for general applications, demanding applications and interface detection. It also contains

instructions for adjusting the setpoint and alarm delay.

For more detailed information, please consult the operating manual (7ML19985JH04).

Adjusting the Setpoint

Before adjusting the setpoint or alarm delay the cover must be removed.

Prior to removing the cover, please ensure that power is removed, and that the application and installation allow for removal of

the cover. (This may not be permitted in some Hazardous Areas.)

Once the cover has been removed, apply power to the unit. The green power LED (L3) will glow indicating that the unit is powered

and operational. If L3 is not on, please consult the Specifications and Troubleshooting sections of the operating instructions.

APPLICATION GUIDE