z

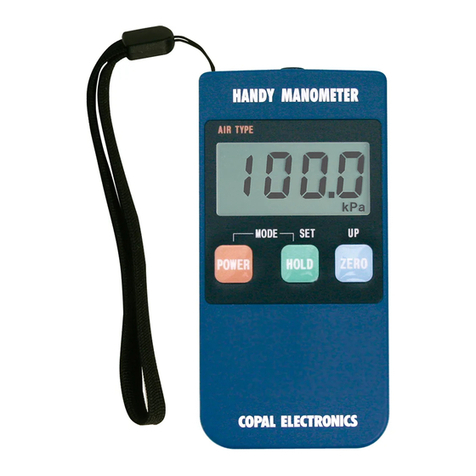

The Shimpo Model PT-120 Contact Tachometer is a simple to use,

ergonomic, rugged test instrument for rotational speed applica-

tions. This velocity analyzing and measuring device is ideal for

rotational machine inspection and process speed analysis. The

PT-120 possesses a large backlit LCD screen that provides clear

viewing in any environment. With a simple selection switch users

can obtain readings in either RPM, meters, meters per minute in

metric models or RPM, feet and feet per minute in imperial mod-

els. During testing, the unit automatically saves maximum, min-

imum, last recorded values and up to 96 logged data readings.

The compact, lightweight PT-120 Tachometer comes standard

with 3 AAA batteries, protective carrying case, plus several con-

tact adapters and contact wheel.

PT-120 Contact Tachometer

Operation Manual

Be careful of clothing or appendages getting too

close to moving machinery when taking readings.

Do not leave the device close to water or any other

liquid to avoid damage.

If not using this instrument for extended periods of

time, remove the batteries to prevent potential battery

leakage from causing product damage.

Do not attempt to open housing or do maintenance.

SPECIFICATIONS

Range: PT-122: 0.5-19,999 RPM, 0.05-1999.9 m/min,

0.05-99,999 m; PT-121: 0.5-19,999 RPM, 0.16-6559.6 ft/min, 0.16-

99999 ft

Resolution: 0.1 RPM (0.5-999.9 RPM), 1 RPM (above 1000 RPM);

0.01 m/min (0.05-99.99 m/min), 0.1 m/min (100+ up m/min);

0.02 m (0.05-99,999 m); 0.03 ft/min (0.16-99.99 ft/min), 0.3 ft/min

(100 ft/min and up); 0.04 ft (0.16-99,999 ft)

Display: 5 digit, 0.7” (18 mm) LCD

Accuracy: +/-0.05% + 1 digit

Sampling Time: 0.8 second (over 60 RPM)

Memory: Automatically stores Maximum (UP), Minimum (dn), last

value (LA) and up to 96 readings for review. Maximum speed for

reading storage is every 0.8 seconds.

Dimensions: 6.7 x 2.8 x 1.4 (170 x 70 x 35 mm)

Power: 3 x 1.5V AAA battery

Enclosure: ABS plastic housing

Product Weight: 0.45 lb (0.20 kg)

Package Weight: 1.00 lb (0.45 kg)

Certification: CE

Warranty: 1 Year

Included Accessories: 3 AAA batteries, protective carrying case.

Large & small cone adapter, surface wheel, 3.87” ( 98.3 mm) cir.

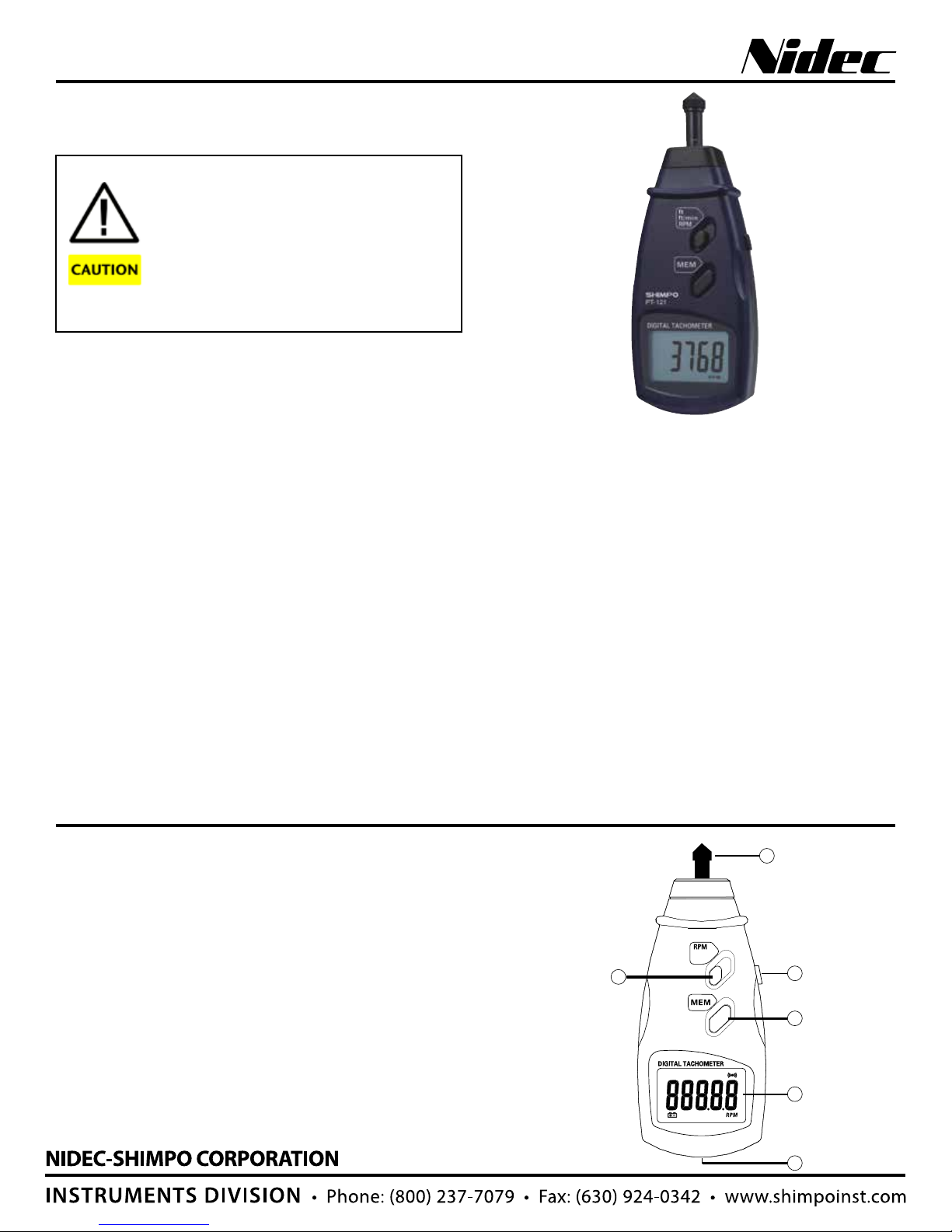

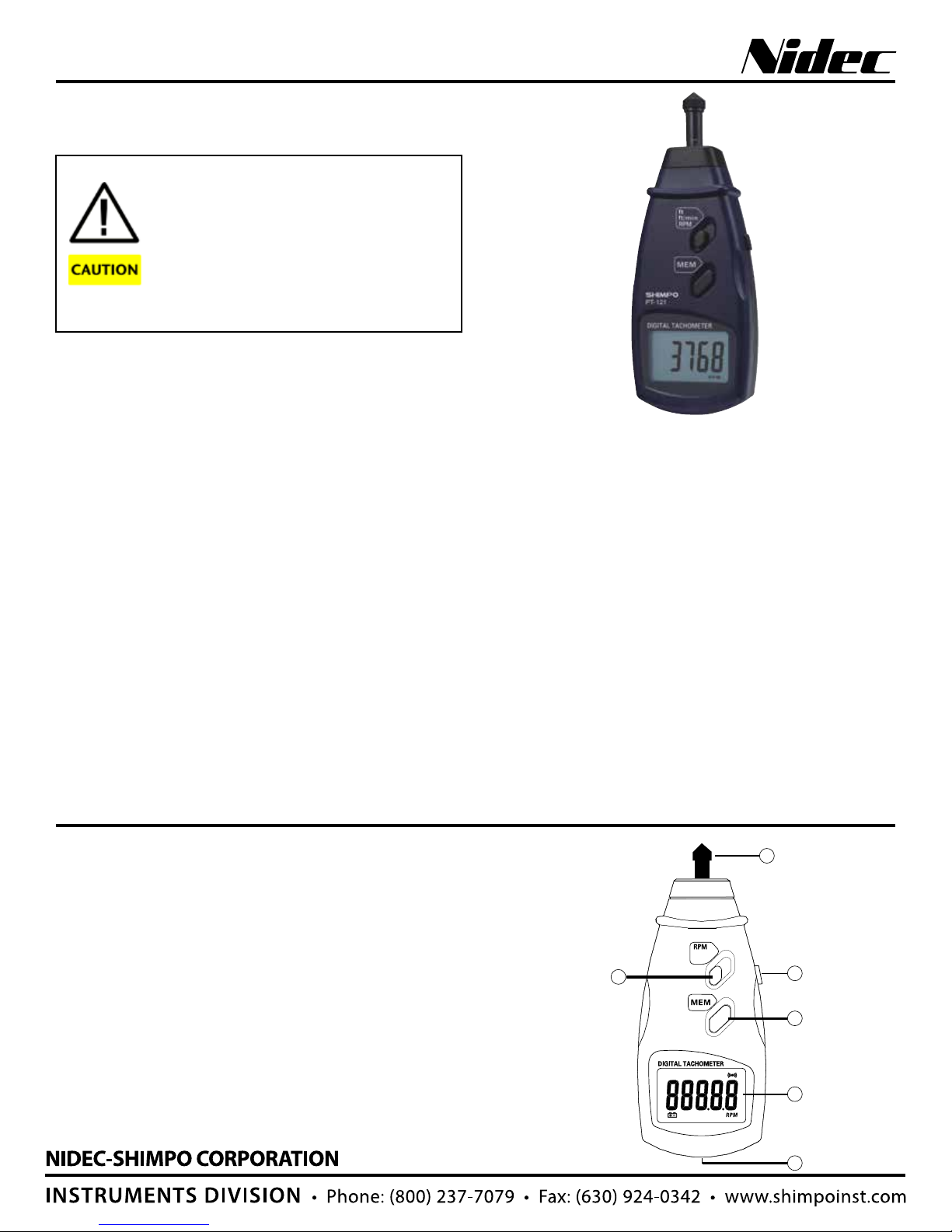

PRODUCT DIAGRAM

1. Measurement Button

2. Function Select Switch

3. Memory Button

4. LCD Display

5. Battery Cover (On Back)

6. Contact Adapter

1

2

3

4

5

6