induQ®- Series VMM

- 2 - © SIKA •Ba_VMM_us •09/2018

Table of contents page

0About this operating manual.........................................................................................4

1Device description .........................................................................................................5

1.1 Delivery, unpacking and accessories .........................................................................6

1.2 Intended use................................................................................................................7

1.3 Exclusion of liability ....................................................................................................7

2Safety instructions.........................................................................................................8

3Construction and function.............................................................................................9

3.1 Construction................................................................................................................9

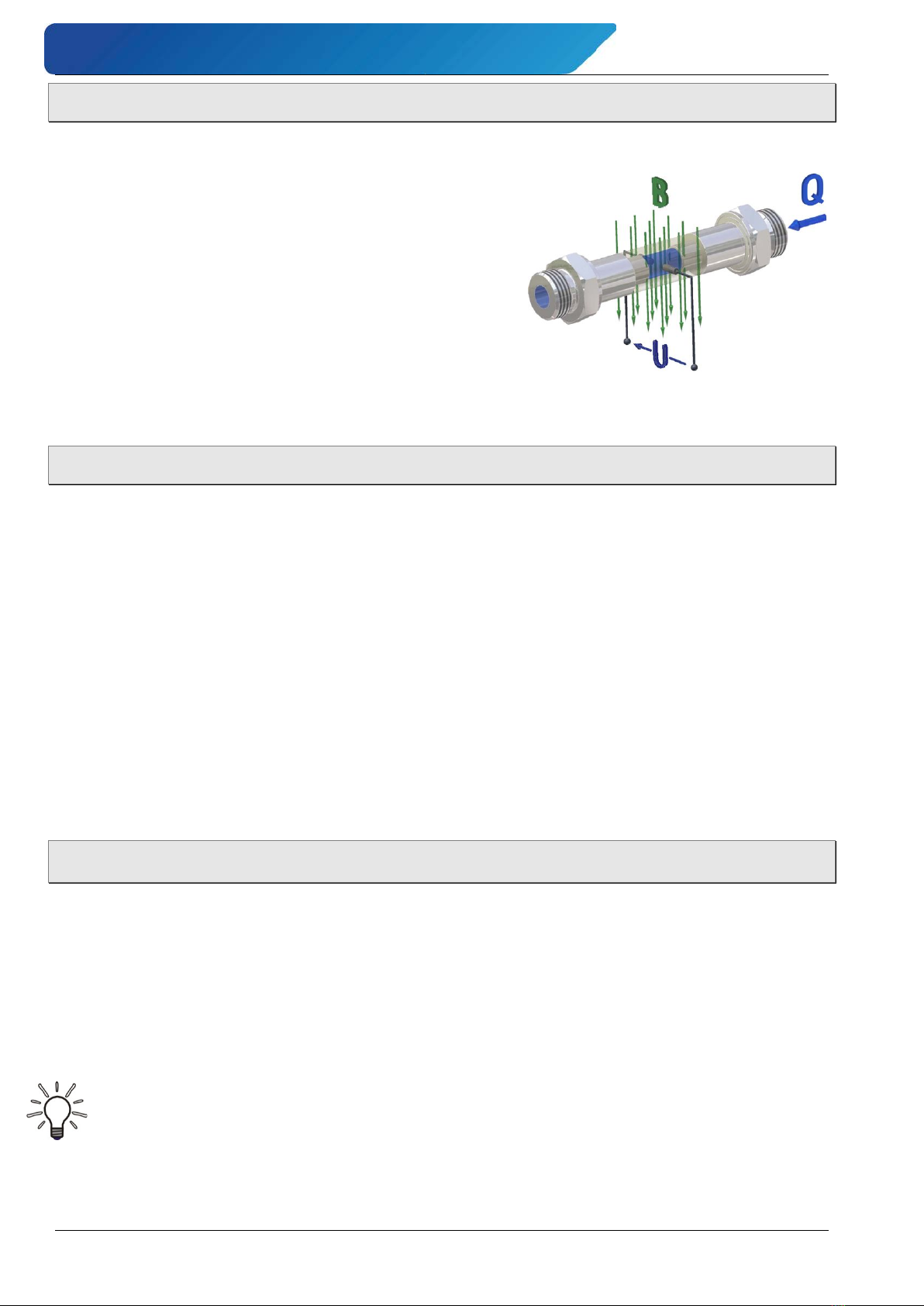

3.2 Measuring principle ..................................................................................................10

3.3 Functions...................................................................................................................10

4Installation of VMM......................................................................................................10

4.1 Installation instructions display electronics ............................................................11

4.2 Instructions on potential equalization and cathode protection................................12

4.2.1 Potential equalization ...........................................................................................12

4.2.2 Cathodic protectives .............................................................................................13

4.3 Sensor installation instructions................................................................................14

4.4 Mounting....................................................................................................................16

5Electrical connection...................................................................................................17

5.1 Mains and signal cable..............................................................................................17

5.2 Electrode and magnetic current line........................................................................19

6Commissioning............................................................................................................19

7Operation .....................................................................................................................21

7.1 Functional classes (main menu)...............................................................................24

7.1.1 Measured values...................................................................................................25

7.1.2 Password ..............................................................................................................27

7.1.3 Totalizer ................................................................................................................29

7.1.4 Measurement processing.....................................................................................30

7.1.5 Flow.......................................................................................................................31

7.1.6 Pulse output..........................................................................................................34

7.1.7 Status output.........................................................................................................36

7.1.8 Current output ......................................................................................................37

7.1.9 Simulation .............................................................................................................38

7.1.10 Self-test ................................................................................................................40

7.1.11 Settings Sensor.....................................................................................................42

8Errors and returns ......................................................................................................46

8.1 System errors............................................................................................................46

8.2 Self-test errors .........................................................................................................47

8.3 Return shipment to the manufacturer .....................................................................48