TP17 / TPM

- 2 - © SIKA • Ba_TP17-TPM_en • 01/2016

Table of contents page

0About this operating manual.........................................................................................4

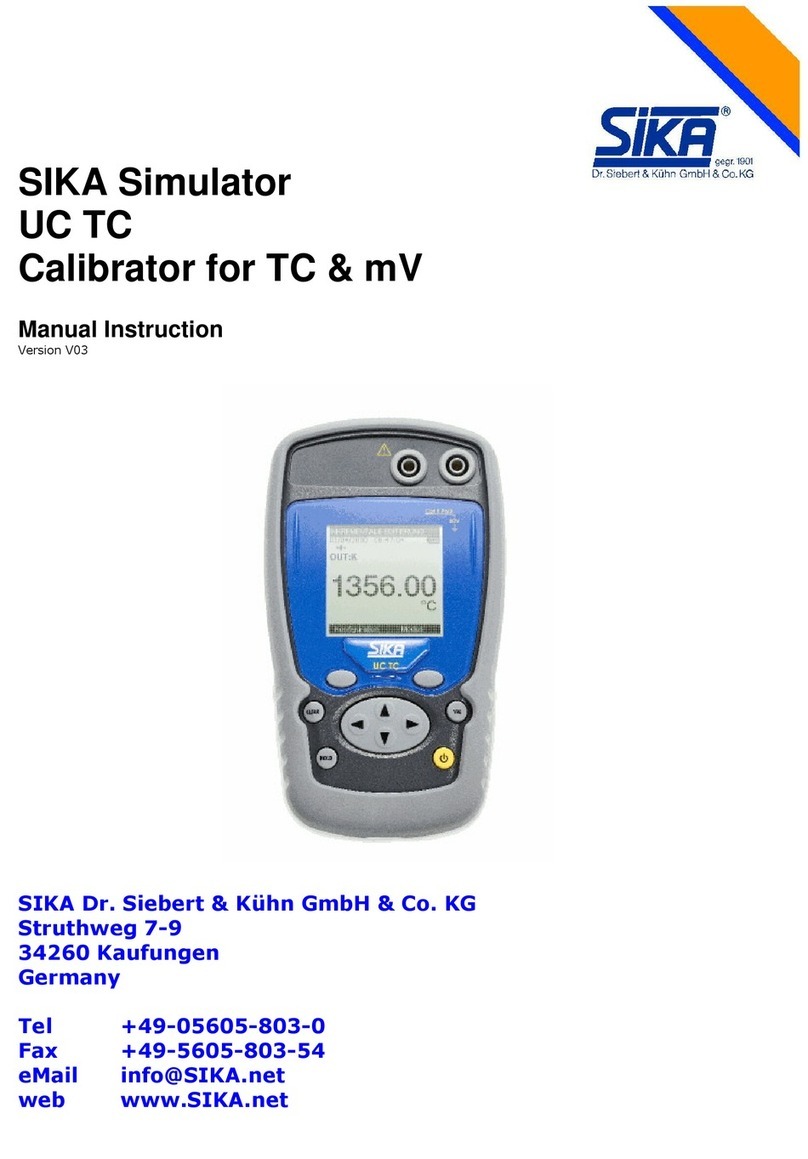

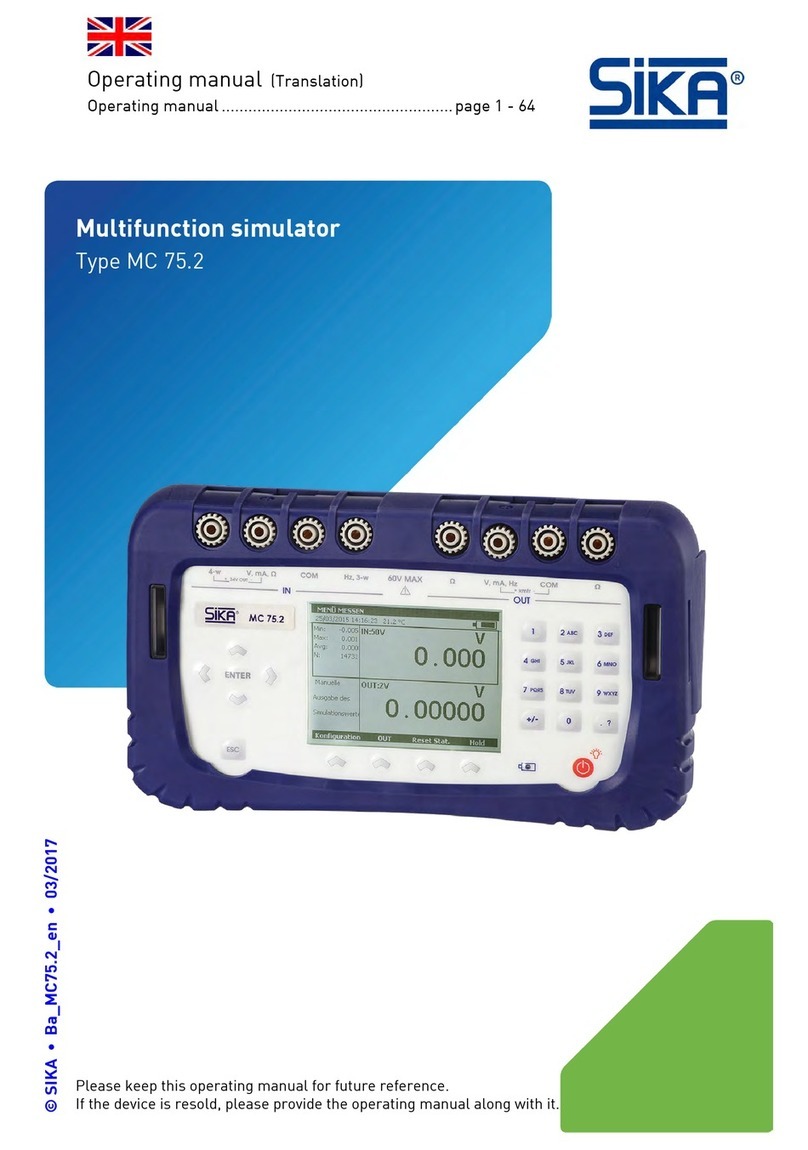

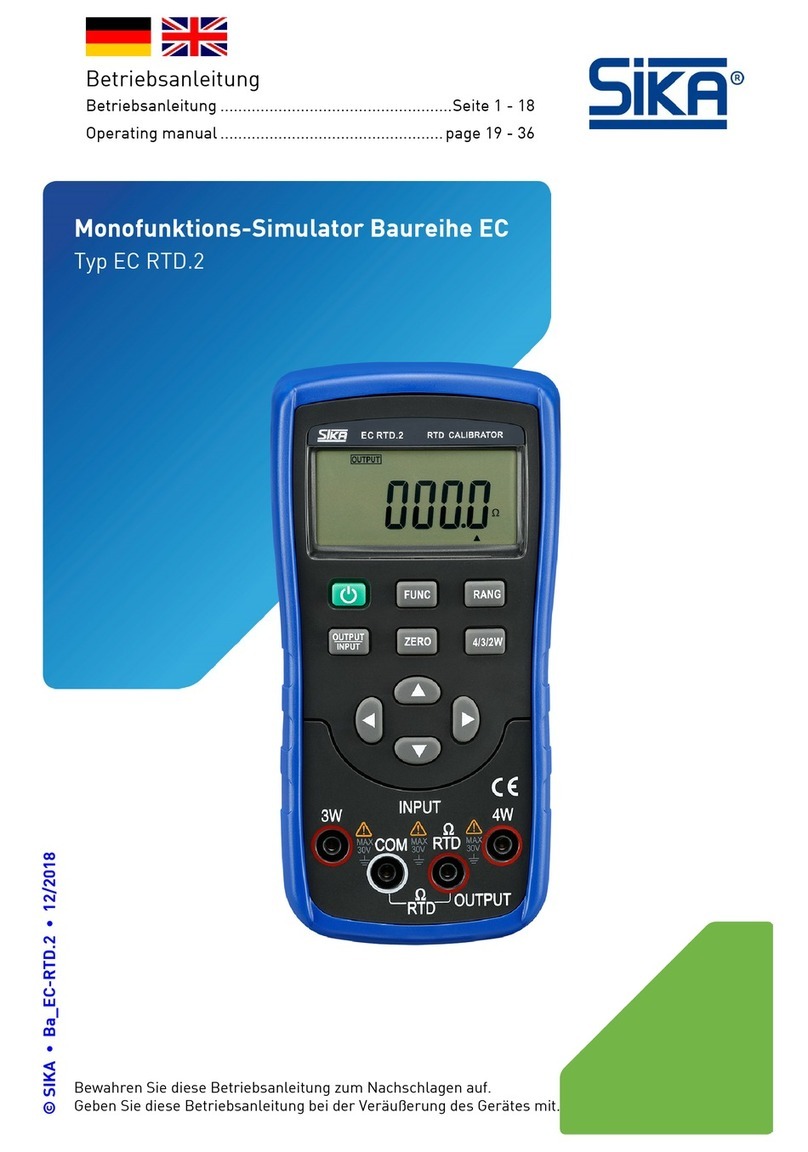

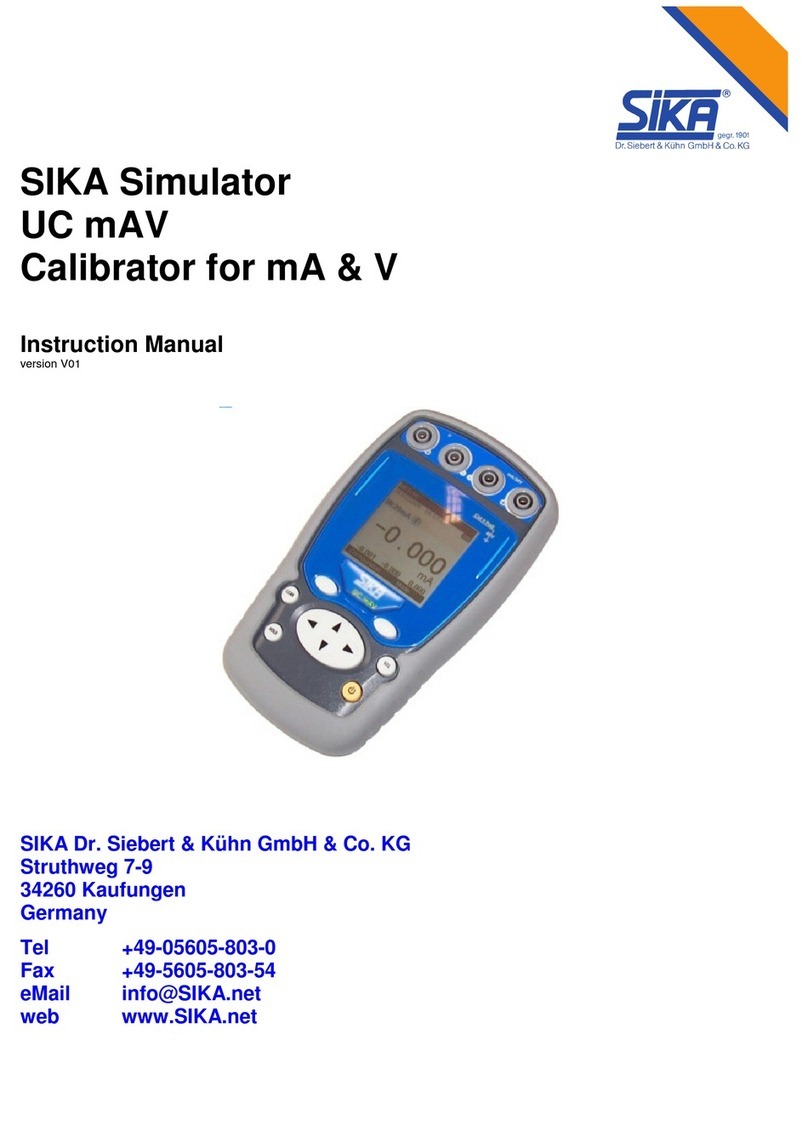

1Device description .........................................................................................................5

1.1 Delivery, unpacking and accessories .........................................................................6

1.2 Intended use................................................................................................................7

1.3 Warranty......................................................................................................................7

1.4 Exclusion of liability ....................................................................................................8

2Safety Instructions ........................................................................................................8

2.1 Safety instructions for the application of calibration liquids ...................................10

3Construction and function...........................................................................................11

3.1 Construction..............................................................................................................11

3.2 Functions...................................................................................................................12

3.3 Data interface (S versions)........................................................................................12

4Commissioning and operation ....................................................................................14

4.1 Operating conditions .................................................................................................14

4.2 Electrical connection ................................................................................................15

4.3 Preparation of the calibrator ....................................................................................16

4.3.1 Dry block calibrator ..............................................................................................17

4.3.2 Calibrator for infrared thermometer ...................................................................18

4.3.3 Calibrator for surface temperature sensors .......................................................19

4.3.4 Micro bath calibrator ............................................................................................20

4.4 Switching on, cool down and switching off ...............................................................24

4.5 Operating modes.......................................................................................................25

5Operation .....................................................................................................................26

5.1 Control elements of the controller (controller type K32SK) ....................................26

5.2 Calibration (calibration mode) ..................................................................................27

5.2.1 Display of reference and set temperature ...........................................................27

5.2.2 Display of temperature control ............................................................................27

5.2.3 Display of fan/ cooling control..............................................................................28

5.2.4 Display of heating / cooling capacity and operating duration..............................28

5.2.5 ConF menu............................................................................................................28

5.3 Set a temporary set temperature (set point mode)..................................................29

5.4 Main menu.................................................................................................................30

5.4.1 Automatic control .................................................................................................32

5.4.2 Manual control......................................................................................................33

5.4.3 Set point memory (S version) ...............................................................................34

5.4.4 Gradient control / temperature profile (S version) ..............................................35