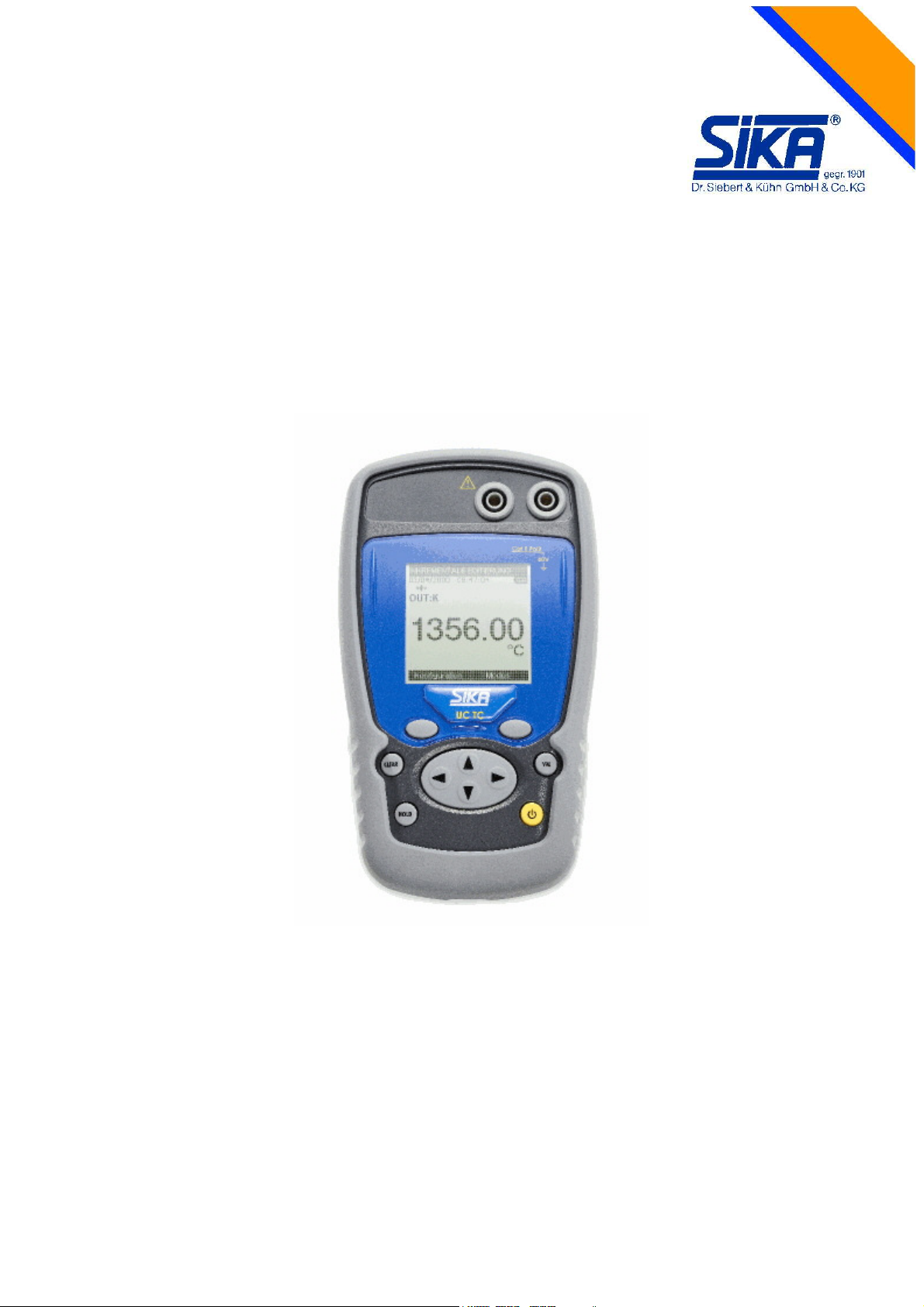

SIKA, Dr. Siebert & Kühn GmbH & Co. KG, Struthweg 7- , 34260 Kaufungen, Germany 4/40

Tel: +4

-5605-803-0, Fax: +4

-5605-803-54, email:

[email protected], web: www.SIKA.net

Contents

A.

General .......................................................................................................................................................5

A.1

Introduction .................................................................................................................................................5

A.2

Parts ...........................................................................................................................................................5

A.3

Safety .........................................................................................................................................................5

A.3.1

Compliance with safety standards...........................................................................................................5

A.3.2

Environmental conditions.......................................................................................................................6

A.3.3

Worn devices .......................................................................................................................................6

A.3.4

Device destruction procedure .................................................................................................................6

A.3.5

Instructions .........................................................................................................................................6

A.3.6

Making measurements ..........................................................................................................................7

A.3.7

Defects and abnormal stresses ...............................................................................................................7

A.3.8

Definitions ...........................................................................................................................................7

A.4

Maintenance.................................................................................................................................................8

B.

Using the instrument.....................................................................................................................................

B.1

Power-up .....................................................................................................................................................

B.1.1

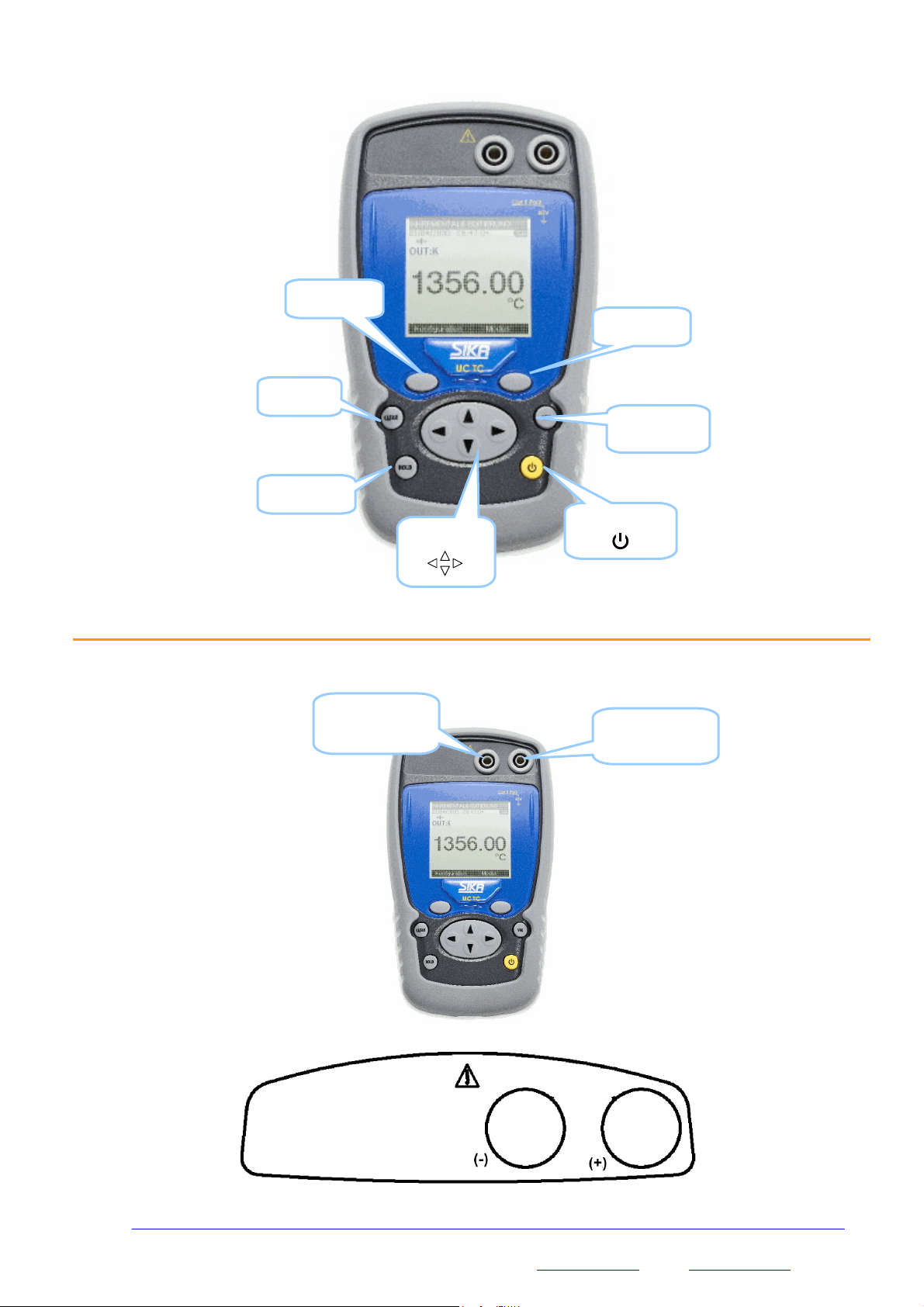

The keyboard.......................................................................................................................................

B.1.2

The measuring and simulation terminals................................................................................................ 10

B.1.3

The USB connector ............................................................................................................................. 11

B.1.4

The screen......................................................................................................................................... 11

B.1.5

Getting started (after power-up) .......................................................................................................... 12

B.1.6

Operating modes ................................................................................................................................ 13

C.

Mode Programming ..................................................................................................................................... 14

C.1.1

Voltage or temperature measurement by thermocouple........................................................................... 14

C.1.2

Voltage or temperature emission by thermocouple.................................................................................. 15

D.

Related Functions ....................................................................................................................................... 20

D.1

Scaling ...................................................................................................................................................... 20

D.2

Nulling....................................................................................................................................................... 21

D.3

Calibrated sensors ...................................................................................................................................... 22

D.4

Configuration of predefined set points ........................................................................................................... 24

D.5

Storage of acquisitions in progress................................................................................................................ 25

D.5.1

Synthesiser configuration .................................................................................................................... 2

D.5.2

Configuration of the ramp generation.................................................................................................... 31

E.

Parameter settings...................................................................................................................................... 34

E.1

Contrast adjustment.................................................................................................................................... 34

E.2

Date and time setting.................................................................................................................................. 34

E.3

“Preferences” setting. .................................................................................................................................. 35

E.3.1

Filtering setting. ................................................................................................................................. 35

E.3.2

Display resolution setting. ................................................................................................................... 35

E.3.3

Lighting duration setting...................................................................................................................... 35

E.3.4

“Key beeping” setting.......................................................................................................................... 35

E.3.5

Language setting ................................................................................................................................ 36

E.3.6

Temperature unit setting ..................................................................................................................... 36

E.4

“Maintenance” menu ................................................................................................................................... 36

E.5

“About the instrument” menu ....................................................................................................................... 36

F.

Technical specifications................................................................................................................................ 37

F.1

Measurement Function................................................................................................................................. 37

F.1.1

Constant voltage (measurement) ......................................................................................................... 37

F.1.2

Temperature per thermocouple (measurement)...................................................................................... 38

F.2

Emission function........................................................................................................................................ 3

F.2.1

Constant voltage simulating................................................................................................................. 3

F.2.2

Temperature per thermocouple (simulating) .......................................................................................... 3

F.3

Power supply - Autonomy................................................................................................................................. 40