simatherm IH 210 User manual

Other manuals for IH 210

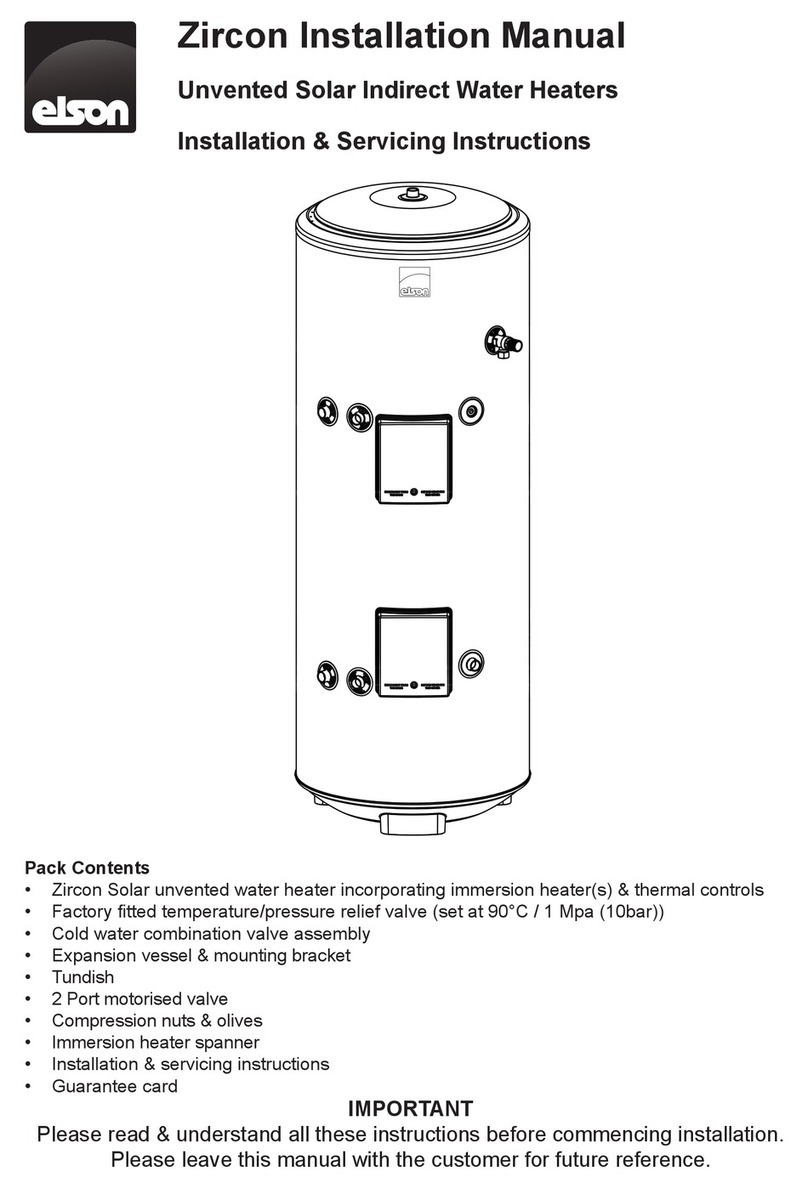

1

Table of contents

Other simatherm Heater manuals

simatherm

simatherm IH 045 User manual

simatherm

simatherm IH 240 User manual

simatherm

simatherm IH 240 User manual

simatherm

simatherm IH 210 User manual

simatherm

simatherm VOLCANO IH 025 User manual

simatherm

simatherm IH 070 User manual

simatherm

simatherm IH 045 User manual

simatherm

simatherm IH 070 User manual

Popular Heater manuals by other brands

Fostoria

Fostoria 222 Series manual

Argo

Argo MARGE operating instructions

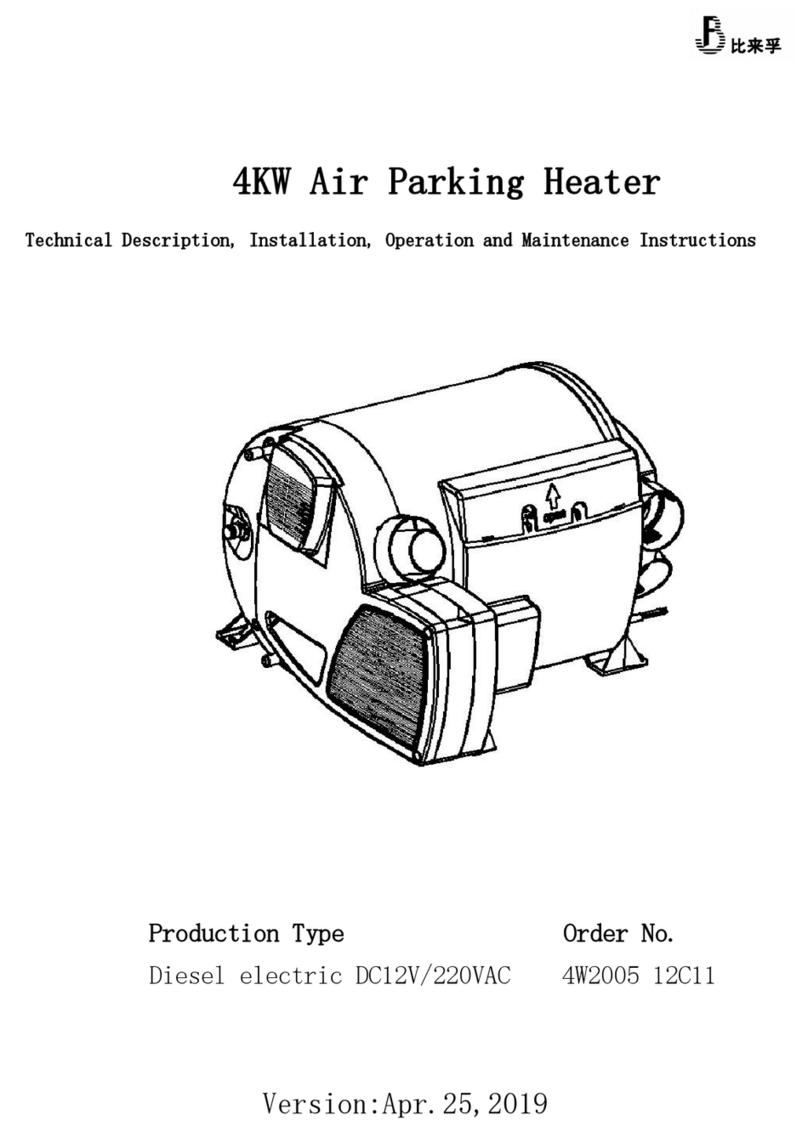

Belief

Belief 4W2005 12C11 Technical description, installation, operation and maintenance instructions

MICA

MICA HA6EM instruction manual

Sonnenkonig

Sonnenkonig OFR 5A MINI user manual

Elcalor

Elcalor SH 2020 Operation and installation

BASETech

BASETech 1527437 operating instructions

lifelong

lifelong Flash 1L quick start guide

Pinnacle Climate Technologies

Pinnacle Climate Technologies REMINGTON REM-16-TTC-B User's manual & operating instructions

HEATFun

HEATFun PRO LINE Installation and user instructions

HELLER

HELLER HWR2400 user manual

VOX electronics

VOX electronics PH-16 operating instructions