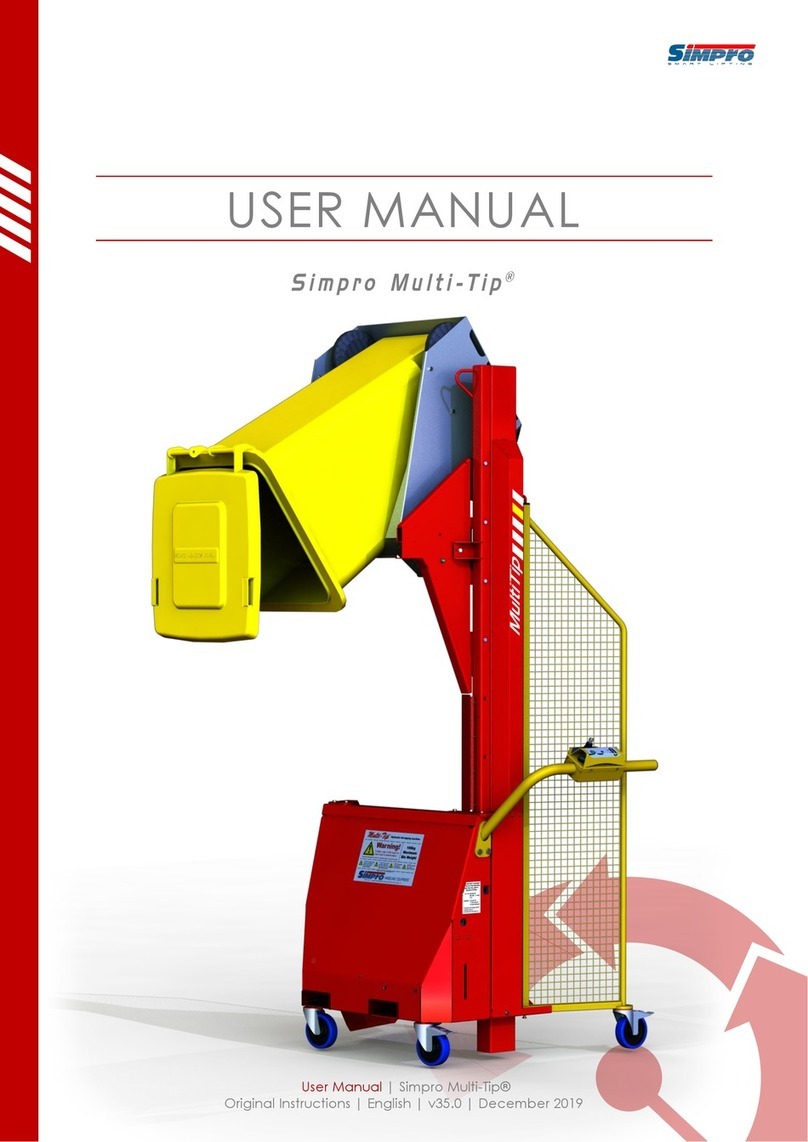

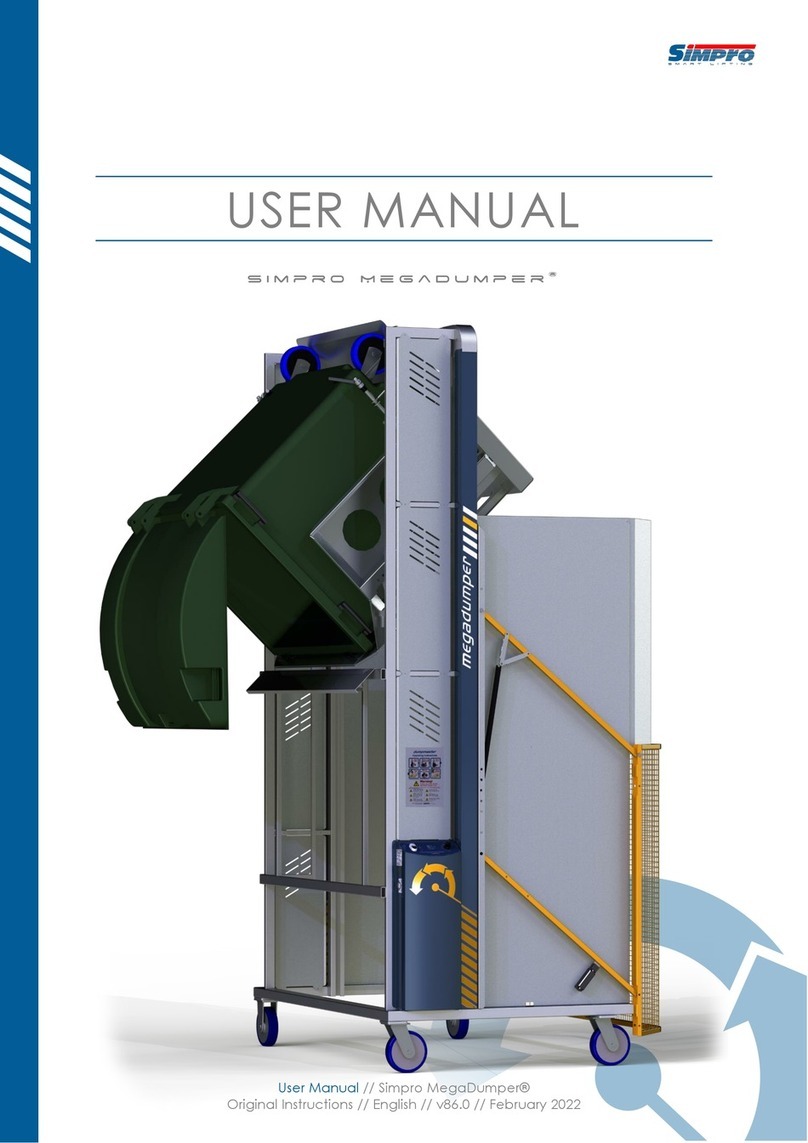

Simpro MegaDumper User manual

Hazard and Risk Assessment Guide

for MegaDumper bin-tipping machines

1

© Copyright 2013 Simpro Handling Equipment Ltd

This document is intended to assist potential customers to determine the level of guarding

required in order to meet their obligations under Workplace Health & Safety regulations.

Note that this does not remove the customer’s obligation to conduct his own Risk Assessment

and put procedures in place to eliminate, isolate, or minimize any residual risks.

Sometimes an assessment may show that a Cat3 level is recommended, but the cost is

prohibitive. In this case, the customer must ensure adequate procedures are put in place to

ensure the safety of all operators and other persons in the vicinity of the machine.

Operator safety for MegaDumper bin-tipping machines is one of the key design elements, and as a

consequence they are inherently very safe machines, by design. However, as with all powered mechanical

and hydraulic equipment, some hazards and risks cannot be entirely eliminated.

To ensure the Risk Assessment is absolutely comprehensive, Simpro ignores the standard guarding during

the initial assessment. Almost all common hazards are eliminated by the standard guarding; however, it is

necessary to demonstrate this. Potential hazards that have been identified include:

I. Jamming or amputation of fingers or limbs in moving parts

II. Crushing if the cradle was to come down or fall on a person

III. Operator or others being hit by falling or flying debris

IV. Crushing if the machine falls over

V. Electrocution or electric shock

With reference to the Assessment table and Legend below:

All hazards above are classified as ‘Serious’ (S2)

The Frequency classification may be either F1 or F2, depending on the specific application. As the

cycle time is very short (typically under 15 seconds) up to 5 cycles per hour could be classified as F1.

All hazards are avoidable and can be classified as P1.

LEGEND

S

SEVERITY OF INJURY

Selection of categories B, 1 to 4

S1=

Slight

= Preferred categories for reference

points

= Possible categories which may

require additional measures

= Measures which can be over-

dimensioned for the relevant risk

S2=

Serious (normally irreversible) injury, including death

F

FREQUENCY AND/OR DURATION OF EXPOSURE TO THE

HAZARD

F1=

Seldom to quite often, and/or short exposure time

F2=

Frequent to continuous and/or long exposure time

P

POSSIBILITY OF AVOIDING THE HAZARD

P1=

Possible under specific conditions

P2=

Nearly impossible

It follows then that

MegaDumpers tipping less than 5

bins per hour could be rated as

Cat1 or Cat2, and those tipping

more than 5 bins per hour could be

rated as Cat3.

This is offered as a general guide

only. Some companies have a

policy that all new equipment be

monitored to Cat3 or higher.

2

© Copyright 2013 Simpro Handling Equipment Ltd

In order to minimize the risk of harm to operators and other persons in the

vicinity, MegaDumpers may incorporate various safety features as described below.

Items I to III above:

MegaDumpers are fully guarded on both sides to at least 2.2m, and on the ‘front’up to the

‘tipping height’.

A swing-up door is provided, which is fitted with a solenoid-operated lock, of ‘power-to-

open’type, and is only unlocked when the cradle is on the ground.

Further options:

The electrical system may be monitored to a Category 3 or 4 safety level, and/or to

Performance Level ‘d’or ‘e’.

1 or more proximity switches may be fitted so the machine cannot operate unless it is in

position against the skip.

A ‘hood’may be provided on the tipping opening, to prevent access to moving parts

through the front of the machine.

An Operator Guard may be provided, which screens the operator from the hopper or skip,

and makes it impossible for the operator to reach into the tipping opening while pressing

the Raise or Lower buttons.

The machine may be guarded to within 20mm of the floor on all sides, including around

the castors and under the door, if required.

An additional button may be fitted, requiring both hands to operate the machine.

Item IV above:

MegaDumpers are very stable due to the fact that the centre of gravity always remains

well within the footprint of the machine throughout the tipping cycle.

Option:

Hooks may be fitted to hold the MegaDumper securely to the skip or hopper.

Item V above (Customer’s responsibility):

The power supply to all mobile equipment should always be fitted with an RCD.

Power leads should be checked frequently to ensure they are in good condition. If any part

of the lead is damaged, the entire lead should be replaced immediately.

3

© Copyright 2013 Simpro Handling Equipment Ltd

A comprehensive list of specific potential faults and circumstances that could contribute

to or result in a ‘harm event’ is given below, along with relevant Control methods.

Control methods shown in green apply if the machine is monitored to a Cat3 safety level.

General:

Risk Event: Use by unauthorized or untrained personnel.

Control Method: Only allow trained and authorized operators to use the machine.

Operators must read, understand, and obey the instructions provided with the machine.

Mechanical:

Risk Event: The operator could get a part of his body entangled in, crushed or cut by the

moving cradle.

Control Method: This hazard is isolated by the guarding.

The door lock prevents persons from entering the area underneath the cradle while the cradle

is moving or in a raised position.

Risk Event: One of the lifting chains could break.

Control Method: This hazard is isolated by the guarding.

The door lock prevents persons from entering the area underneath the cradle while the cradle

is moving or in a raised position.

Risk Event: A bin could fall out of the cradle when inverted.

Control Method: The cradle is designed to hold the bin securely as soon as it is raised above ground level.

Risk Event: The machine could tip over when the bin is raised.

Control Method: The MegaDumper should only be used on flat, level ground.

If ‘Skip hooks’ are provided these should be engaged in the skip at all times.

If a ‘Skip or hopper’ proximity sensor is fitted the machine cannot be used unless it is in

position.

Hydraulic:

Risk Event: The steel tubing could burst or leak, allowing the cradle to come down.

Control Method: This hazard is isolated by the guarding.

The door lock prevents persons from entering the area underneath the cradle while the cradle

is moving or in a raised position.

Risk Event: The lifting ram could develop a leak, allowing the cradle to come down.

Control Method: This hazard is isolated by the guarding.

The door lock prevents persons from entering the area underneath the cradle while the cradle

is moving or in a raised position.

Risk Event: The check valve could fail.

Control Method: This hazard is isolated by the guarding.

The door lock prevents persons from entering the area underneath the cradle while the cradle

is moving or in a raised position.

Risk Event: The lowering valve could jam open or shut.

Control Method: If the valve jammed open the cradle would not be able to lift off the ground and no hazard

would arise.

If the valve jammed shut the cradle would not be able to come down. This hazard is isolated by

the guarding. The door lock prevents persons from entering the area underneath the cradle

while the cradle is moving or in a raised position.

4

© Copyright 2013 Simpro Handling Equipment Ltd

Electrical:

Risk Event: The contacts on (one of) the motor contactor(s) could fuse or weld, so the

motor does not stop when the Raise button is released.

Control Method: Provision of an isolating switch either on the machine or nearby allows the power supply to be

turned off quickly, stopping the motor.

The system will go into Safe mode and cannot be reset until the fault has been remedied.

Pressing the E-Stop puts the machine into Safe mode and stops the motor running.

Risk Event: A wire could come off the coil of (one of) the motor contactor(s), or a

switching wire could come off, or a complete contact block could fall off the

‘Raise’ switch.

Control Method: In all these situations the contactor will not operate, and the cradle cannot be raised. The

machine cannot be used until the fault has been remedied.

Risk Event: A wire could come off (one of) the contactor auxiliary contact(s).

Control Method: The system cannot be reset and the machine cannot be used until the fault has been

remedied.

Risk Event: The contacts in the Raise switch could jam in the ‘On’ position

Control Method: Provision of an isolating switch either on the machine or nearby allows the power supply to be

turned off quickly, stopping the motor.

The machine cannot be used until the fault has been remedied.

Pressing the E-Stop isolates the signal to the contactor and stops the motor running.

Risk Event: The contacts in the Lower switch could weld together or jam in the ‘On’

position

Control Method: Provision of an isolating switch either on the machine or nearby allows the power supply to be

turned off quickly, which will close the lowering valve.

The fault must be remedied before the machine can be used again.

Pressing the E-Stop isolates power to the lowering solenoid.

Risk Event: A switching wire could come off, or a complete contact block could fall off a

‘Lower’ switch, or the plug could come off the solenoid, or the solenoid could

come off the valve.

Control Method: In all these situations the lowering valve will not operate, and the cradle cannot be lowered.

The machine cannot be used until the fault has been remedied.

Risk Event: Electrocution from the supply lead.

Control Method: The power supply lead should have an RCD fitted. Power leads should come down from above

where possible.

If not possible, leads should be as short as possible, and must be protected from damage by

vehicles, heavy and/or sharp objects falling on them, and persons tripping on them.

Leads should be regularly checked and tagged by a registered electrician, and replaced if there

are any signs of damage to the insulation.

Summary:

MegaDumpers are inherently very safe machines due to their design and method of operation.

Guarding prevents access to all moving parts during operation.

Safety devices may be monitored to Cat3 level or higher as required.

5

© Copyright 2013 Simpro Handling Equipment Ltd

Standard Operating Instructions

Read and understand the following instructions before attempting to use the machine.

Before use ensure that:

All covers and safety guards are in place.

The wheel brakes are applied (if fitted).

All personnel other than the operator are well clear of the machine.

To empty bins:

Open the door and wheel the bin onto the cradle, ensuring that it

is properly positioned. Close the door.

(Cat3/4 machines only) Press and hold the blue Reset button for

approx. 1 second then release. The machine is ready for use if the

light goes out. If the Reset light remains ‘On’ after holding down for

1 second, a fault may be indicated. The machine should be checked

by a qualified person.

Press the ‘RAISE’ (↑) button on the control panel, holding down

until the bin reaches the inverted position, then release.

When the contents of the bin have emptied, press the ‘LOWER’ (↓)

button, holding until the cradle rests on the ground.

Open the door and remove the bin.

The bin may be stopped at any point of the cycle, by simply

releasing the button.

Caution!

Keep feet and hands well clear of bin and cradle when operating.

Never operate with any covers or guards removed.

Never operate with a broken or damaged electrical supply lead.

All persons other than the operator must stand clear of the machine

while in operation.

Other manuals for MegaDumper

2

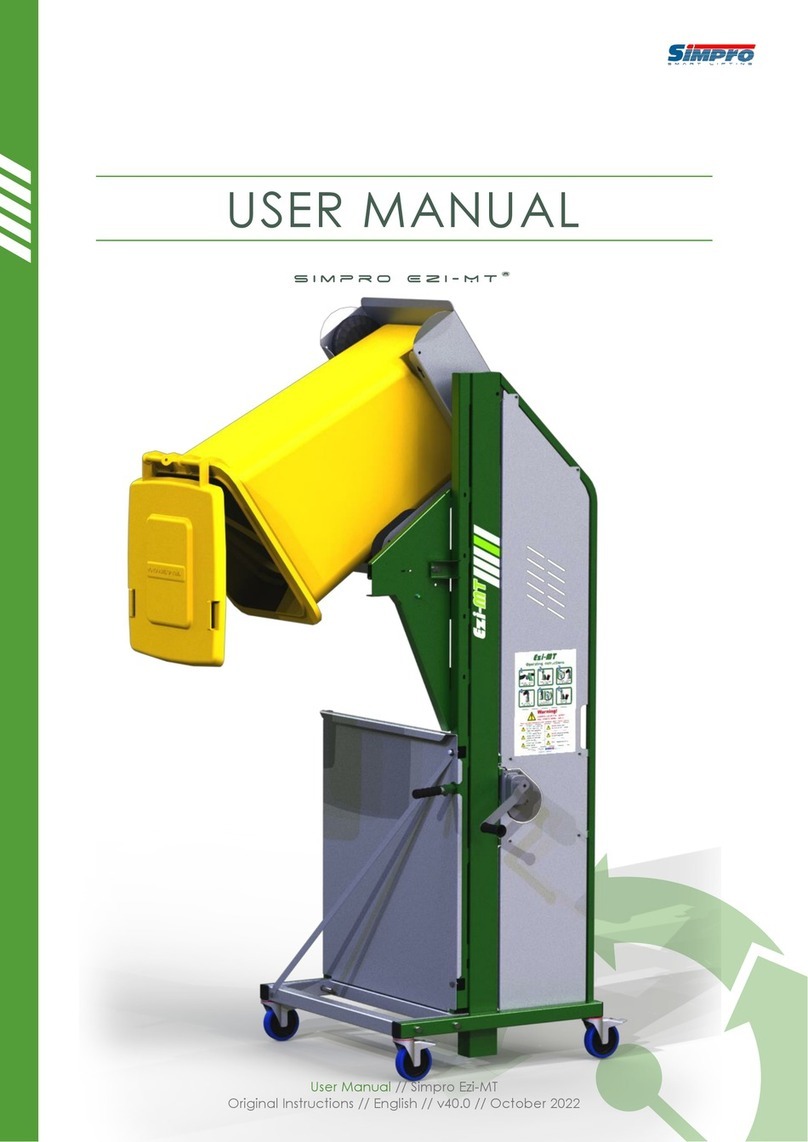

Other Simpro Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

SMC Networks

SMC Networks KFG2H-E Series Operation manual

AIRMATIC

AIRMATIC Syntron TAM Service instructions

SAMCHULLY

SAMCHULLY QJC instruction manual

ABB

ABB HT842160 Operation manual

Wilo

Wilo SiBoost Smart Series Installation and operation instructions

PennBarry

PennBarry Domex Operation & maintenance manual

Endura

Endura XL100 Installation operation & maintenance

Amtrol

Amtrol THERM-X-TROL ST-35LCL Installation & operation instructions

RADEMACHER

RADEMACHER RolloTron Comfort 1623 45 19 Translation of the Original Operating and Assembly Manual

Asco

Asco 450 Series quick start guide

Asyril

Asyril Asycube 240 Programming guide

D+H

D+H ZA 35-K-BSY+ Original instructions