Simpro Microstacker User manual

User Manual // Simpro Microstacker

Original Instructions // English // v2.0 // August 2022

USER MANUAL

Copyright © 2022 Simpro Handling Equipment Ltd.

No part of this document may be reproduced or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the written

permission of Simpro Handling Equipment Ltd.

For the purposes of standards compliance and international conformity, this document uses

Système International (SI) units. These may be converted to Imperial units as follows:

1 kilogram (kg) = 2.2 pounds (lb)

1 metre (m) = 1000 millimetres (mm) = 39.37 inches (in) = 3.28 feet (ft) = 1.09 yards (yd)

The following stylistic conventions are used throughout this document:

Point of interest

Safety hazard

§Internal cross-reference (hyperlink in PDF edition)

Simpro Partcode (hyperlink in PDF edition)

Errors in this document should be reported to info@simpro.world

User Manual // Simpro Microstacker

Original Instructions // English // v2.0 // August 2022 // Page 2

A

2339

1033

2581

461

1521

878

MS1400 Default Layout

Con tents

1. Product Overview........................................................................................................ 5

1.1 Key features........................................................................................................................... 5

1.2 Construction .......................................................................................................................... 5

1.3 Mechanism ............................................................................................................................ 5

1.4 Safe Working Load................................................................................................................6

1.5 Duty cycle.............................................................................................................................. 6

1.6 Service life.............................................................................................................................. 6

1.7 Noise emissions ...................................................................................................................... 6

1.8 Environmental restrictions .................................................................................................... 7

1.9 Ingress protection ................................................................................................................. 7

1.10 Notes ...................................................................................................................................... 7

2. Operating Instructions ................................................................................................. 9

2.1 Identification of controls ...................................................................................................... 9

2.1.1 EMERGENCY STOP........................................................................................................................... 9

2.1.2 KEY SWITCH ...................................................................................................................................... 9

2.1.3 BATTERY INDICATOR and HOUR METER (if fitted).......................................................................... 9

2.1.4 RAISE/LOWER rocker switches...................................................................................................... 10

2.1.5 BATTERY SAVER button.................................................................................................................. 10

2.1.6 SAFETY SOUNDER button .............................................................................................................. 10

2.1.7 PARK BRAKE ................................................................................................................................... 10

2.2 Basic operation ................................................................................................................... 11

2.2.1 Turning on the power.................................................................................................................... 11

2.2.2 Moving and steering..................................................................................................................... 11

2.2.3 Lifting and moving bins ................................................................................................................ 11

2.3 Safety Norms........................................................................................................................ 13

3. Handling, Transport & Storage.................................................................................. 15

3.1 Assembly .............................................................................................................................. 15

3.2 Moving ................................................................................................................................. 15

3.3 Lifting .................................................................................................................................... 15

3.4 Transportation......................................................................................................................15

3.5 Storage................................................................................................................................. 16

4. Care and Maintenance............................................................................................ 17

4.1 Quick Troubleshooting Guide............................................................................................ 17

4.2 Cleaning .............................................................................................................................. 17

User Manual // Simpro Microstacker

Original Instructions // English // v2.0 // August 2022 // Page 4

4.3 Carriage jams......................................................................................................................18

4.3.1 Bin carriage jams while raising..................................................................................................... 18

4.3.2 Carriage jams while lowering ...................................................................................................... 18

4.4 Electrical System ................................................................................................................. 19

4.4.1 AGM battery.................................................................................................................................. 19

4.4.2 LFP battery ..................................................................................................................................... 20

4.4.3 Emergency Stop............................................................................................................................ 21

4.4.4 Circuit breaker............................................................................................................................... 21

4.5 Hydraulic System ................................................................................................................. 22

4.5.1 Powerpack .................................................................................................................................... 22

4.5.2 Control valves................................................................................................................................ 22

4.5.3 Lift Ram .......................................................................................................................................... 22

4.5.4 Open Ram ..................................................................................................................................... 22

4.5.5 Hydraulic fluid................................................................................................................................ 22

4.5.6 Maintenance................................................................................................................................. 23

4.6 Preventative Maintenance Inspections ........................................................................... 23

4.6.1 Pre-inspection checklist................................................................................................................ 23

4.6.2 Monthly inspection........................................................................................................................ 23

4.6.3 Annual inspection ......................................................................................................................... 25

5. Spare Parts.................................................................................................................. 27

6. Safety Assessment...................................................................................................... 29

6.1 Safety features .................................................................................................................... 29

6.2 Reasonably foreseeable misuse ....................................................................................... 29

6.3 ISO12100 Hazard and Risk Assessment Guide ................................................................. 29

6.3.1 ISO 12100:2010 risk assessment model ........................................................................................ 30

6.3.2 Identified Hazards ......................................................................................................................... 31

6.3.3 Residual Hazards ........................................................................................................................... 34

7. Warranty ..................................................................................................................... 35

8. Notes........................................................................................................................... 37

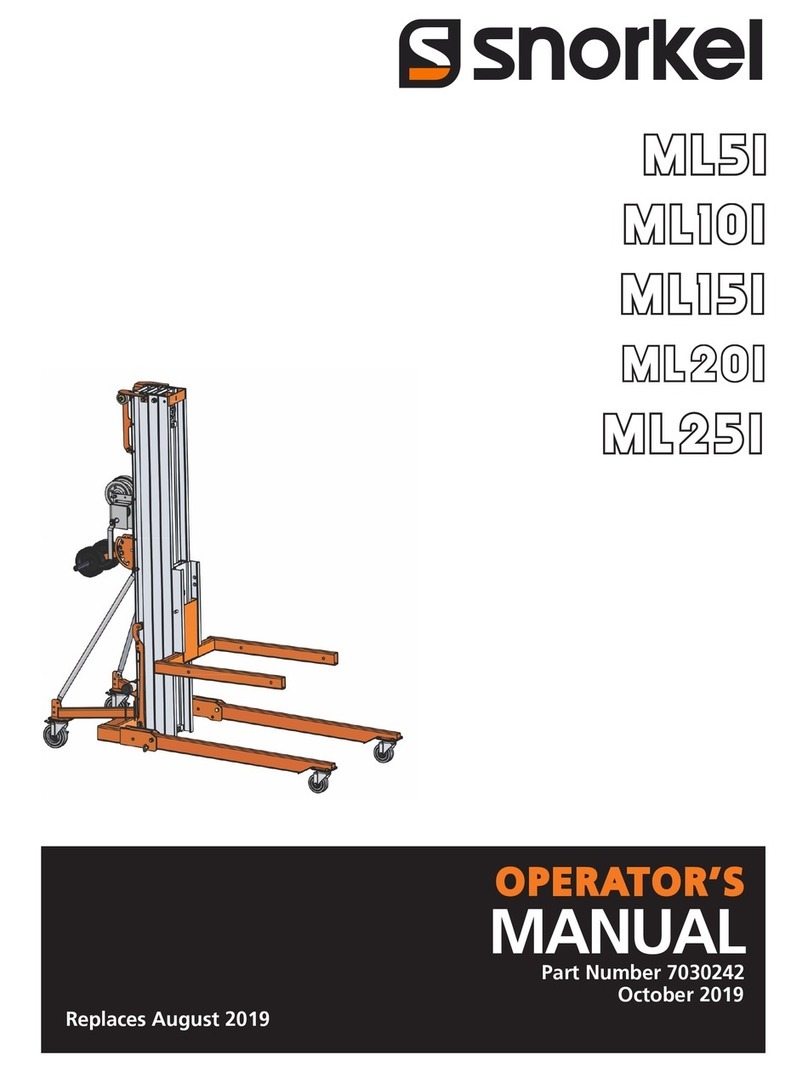

1. Product Overview

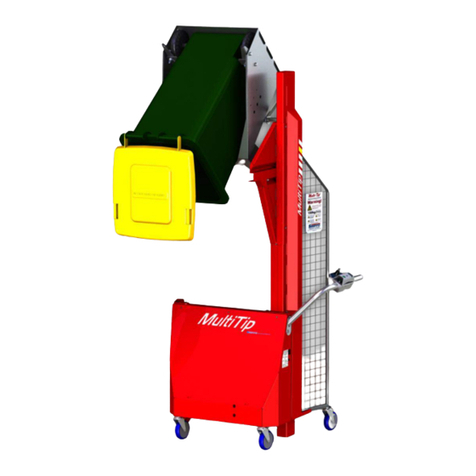

Congratulations on your purchase of a Simpro Microstacker

electro-hydraulic pedestrian bin stacker.

With 150kg capacity and 1400mm lift height, Microstacker

features interchangeable lifting arms to suit a range of

common industrial bins and containers –allowing them

to be lifted, stored, stacked, transported, and loaded

onto trucks –quickly and safely.

Microstacker has a tiny footprint and is easy to manoeuvre,

but is also very rugged and built to withstand years of rough handling. Like

all Simpro products, it requires little maintenance and is exceptionally reliable.

1.1 Key features

Key features of the Microstacker include:

1. A very compact footprint, allowing bins to be placed close

together.

2. A lightweight design which is easy to move and steer, with

a 3-point ‘stability triangle’.

3. A standard weight capacity of 150kg

4. A reliable, low-maintenance design.

5. A frame and lifting carriage manufactured

from either powder-coated mild steel or SAE304

stainless-steel.

6. IP54 ingress protection, suitable for outdoors use.

7. A modular lifting carriage which can be exchanged or modified to suit a wide range

of bins and containers.

1.2 Construction

The Microstacker consists of a steel or stainless-steel frame with a central mast and two

stabilizing legs; a lifting carriage with various lifting attachments; a hydraulic ram, a 12VDC or

24VDC GEL or Lithium-ion battery, a hydraulic powerpack with an electric motor, pump and

reservoir, a manual tiller with operating switches; electronic control circuits; two large steered

wheels and two roller wheels.

1.3 Mechanism

When both RAISE buttons are pressed, an electrically-operated pump forces hydraulic fluid

into the ram, causing it to extend. This movement is transmitted through a chain to the lifting

carriage, which travels vertically in the mast.

User Manual // Simpro Microstacker

Original Instructions // English // v2.0 // August 2022 // Page 6

When both LOWER buttons are pressed, a valve is opened which allows the hydraulic fluid to

flow out of the ram back into the reservoir, causing the lifting carriage to descend. This

action is not directly powered; the carriage is lowered by gravity alone.

1.4 Safe Working Load

The rated Safe Working Load of the Microstacker is 150 kilograms (330lb).

Never attempt to lift more than the factory-designated Safe Lifting Capacity of the

machine.

1.5 Duty cycle

The figures given below are estimates only.

Power Supply

Duty Cycle

No. of bins equivalent

(average ~75kg each)

Units

12V/20Ah GEL battery

3,000kg to 1.0m

40 bins

Per charge

24V/20Ah GEL battery*

6,000kg to 1.0m

80 bins

Per charge

24V/20Ah LFP battery

6,000kg to 1.0m

80 bins

Per charge

*2x 12V/20Ah batteries in series; default from 2022

Powerpack specifications can usually be found on the machine’s rating plate.

1.6 Service life

The nominal service life of the Microstacker is as follows:

Average Gross Load

Nominal Service Life

< 50kg

200,000 lift/lower cycles

50kg –100kg

150,000 lift/lower cycles

100kg –150kg

100,000 lift/lower cycles

1.7 Noise emissions

The noise emissions of the Microstacker do not typically exceed ~60 dB(A) at the operator’s

ear.

Hearing protection is not required, but is recommended if operating the machine for

extended periods.

ISO standards for machinery safety specify that noise emissions are to be measured in A-

weighted decibels (dB(A)), a unit of volume which is adjusted to reflect the sensitivity of

human hearing. The measurements are taken at a point 1.6 metres above the ground at

the operator’s working position.

1.8 Environmental restrictions

The Microstacker may be used indoors or outdoors. However, the following restrictions apply:

1. Minimum floor area 2 square metres, with a clear passage to exits;

2. Height above sea level not more than 1000m;

3. Ambient temperature not higher than +40℃and not lower than -10℃;

4. At ambient temperatures above 35℃, the relative humidity should not exceed 50%; at

lower temperatures, higher relative humidity is permitted;

Never operate the Microstacker in highly explosive, corrosive, acidic or alkaline

environments.

1.9 Ingress protection

Item

IP Rating

Push buttons, switches and lamps

IP66

Clamp-arms interlock

IP66

Coded magnetic switch

IP66

Motor

IP54 (additional protection provided by covers)

Overall

IP54 (optionally upgraded to IP66 or IP69K)

1.10 Notes

1. This User Manual describes approved procedures for the operation, maintenance,

and routine inspection of the Microstacker pedestrian bin stacker.

2. This manual is written in English, and is to be considered the ‘Original Instructions’ for

the purposes of EU Machinery Directive 2006/42/EC.

3. Operator(s) must read and understand this manual before using the machine.

4. If the machine is to be leased, sold or otherwise transferred, then this manual shall

accompany the machine.

5. This is a generic manual. Simpro reserves the right to change the design of our

products at any time without notification. In cases where the manual does not

correspond with the actual product, use the manual as a reference guide only, and

contact your authorized Simpro agent for assistance if required.

6. Contact your authorized Simpro agent if you encounter any problems or faults with

the machine.

7. Errors in this manual should be reported by email to in[email protected].

User Manual // Simpro Microstacker

Original Instructions // English // v2.0 // August 2022 // Page 8

2.Operat ing Instruction s

Follow the instructions in this section to operate the Microstacker. Used correctly, the

Microstacker can bring great improvements to workplace safety and efficiency.

The Microstacker must be operated in strict accordance with the Safety Norms in §2.3.

Before the Microstacker is used for the first time, a site-specific Hazard and Risk

Assessment should be completed as per §6.3.

Never attempt to operate the Microstacker if it is damaged or malfunctioning.

2.1 Identification of controls

2.1.1 EMERGENCY STOP

Press this button DOWN to instantly cut all power to the machine. Pull UP to reset.

The Emergency Stop also functions as a heavy-duty battery isolator switch.

2.1.2 KEY SWITCH

Turn the key CLOCKWISE to turn on the power. Once turned on, the key cannot be removed.

If the machine does not power on, check that the Emergency Stop is pulled UP.

2.1.3 BATTERY INDICATOR and HOUR METER (if fitted)

Some Microstacker models are fitted with a digital battery indicator and hour-meter. The

level of charge in the battery is shown by a sequence of LED lamps. When the battery

indicator shows one or two bars of charge, the machine should not be used, and should be

placed on charge immediately as per §4.4.1.2 (AGM battery) or §4.4.2.2 (LFP battery).

The hour-meter shows the accumulated run time of the machine.

User Manual // Simpro Microstacker

Original Instructions // English // v2.0 // August 2022 // Page 10

2.1.4 RAISE/LOWER rocker switches

Press the UPPER part of both switches (U1+U2) to raise the bin carriage.

Press the LOWER part of both switches (D1+D2) to lower the bin carriage.

The carriage will stop moving when either toggle switch is released, or when it reaches the

maximum travel extent.

When the arms reach the top of the mast, the lift ram comes up against a stopper. If the

RAISE switches are hold on after the maximum height is released, the motor will continue

to run, and hydraulic fluid will bypass through a pressure-relief valve. Although this causes

no harm in normal operation, extended operation of the motor when the arms are not

moving causes the hydraulic fluid to heat up and may eventually result in damage. The

RAISE switches should not be held on longer than necessary.

The pressure-relief valve limits the maximum weight that the machine can lift. If an

attempt is made to lift more than the factory-set maximum (normally 150kg) the motor

will run but the arms will not lift. If this occurs, DO NOT keep trying to lift the bin. Remove

some material from the bin and try again.

A flow-control valve is fitted to govern the lowering speed, which can be adjusted by a

qualified technician.

2.1.5 BATTERY SAVER button

Where fitted, this button lights up to indicate that the Microstacker is powered on and ready

to use. If the machine is left idle for several minutes, the power will be cut out automatically

to maximise battery life. Pressing the button will re-awaken the machine.

2.1.6 SAFETY SOUNDER button

Press this button to sound an electronic warning tone.

The horn should be regularly used when the Microstacker is moving through busy

warehouses and dispatch zones, or when approaching corners.

2.1.7 PARK BRAKE

Lift the pedal with your foot to apply the park brake, and press down on the pedal to release

the park brake. Both rear wheels are locked when it is applied.

The park brake is not a service brake; it should not be used to slow the machine while

moving down a ramp, or to bring the machine to a stop.

2.2 Basic operation

This section provides an overview of basic operation of the Microstacker.

The Microstacker does not require a license to operate. However, before using the

machine in a production context, operators should be given the opportunity to familiarise

themselves with its use in a safe, supervised and low-pressure environment.

Becoming a skilled Microstacker operator requires time and practice. Although the

machine may feel clumsy at first, with frequent use it will soon become intuitive.

2.2.1 Turning on the power

1. Insert the KEY into the KEYSWITCH and turn it clockwise to power up the machine.

a. The EMERGENCY STOP button may also need to be pulled out. This large red

button instantly cuts power to all of the machine’s systems, and also functions

as a battery isolator switch.

2. If a BATTERY INDICATOR is fitted, it will now light up so you can check the level of

charge.

a. If the indicator shows only one or two bars, the Microstacker should not be

used right now and should be plugged in overnight to recharge the battery.

b. If the indicator shows two or more bars, the Microstacker is good to go.

2.2.2 Moving and steering

1. Release the park-brake by pressing it down with your foot.

2. Take hold of the tiller with both hands. By pressing forward on the tiller and turning it,

you will find the machine moves and turns easily.

When operating the stacker around other people, you can make them aware of the

machine by pressing the SAFETY SOUNDER button to emit an electronic warning tone.

2.2.3 Lifting and moving bins

1. Press both LOWER buttons to lower the carriage until it reached ground level.

2. Move the stacker towards a bin. The bin should be approached squarely from either

the front or the rear, so that the lifting carriage correctly engages with it.

Bins that are not properly engaged with the lifting carriage may fall out at any time.

3. Press both RAISE buttons until the bin is lifted a short distance off the ground, then

press forward on the tiller to start transporting the bin.

4. Once the destination (such as racking) is reached, press both RAISE buttons until the

bin is lifted to the appropriate height, then slowly move the stacker forward until the

bin is above the desired position.

If the racking has wheel chocks to prevent bins from moving, ensure that the bin’s wheels

are correctly aligned with the chocks before lowering it.

5. Press both LOWER buttons until the bin has been deposited, and the lifting arms have

disengaged. The Microstacker can now be withdrawn.

User Manual // Simpro Microstacker

Original Instructions // English // v2.0 // August 2022 // Page 12

2.3 Safety Norms

The following safety norms must be observed for the safe use of a Microstacker.

Only trained and authorised personnel may use the

machine.

Operators must read and obey all instructions and

warning signs on the machine and elsewhere.

Never transport bins while lifted more than 500mm

from the ground

Never operate the machine on soft, uneven or

sloping ground.

Never operate the machine near the edge of an

elevated platform or dock with no fall protection.

Never operate machine with covers or guarding

panels removed.

Never attempt to lift bins for which the machine was

not specifically designed.

Ensure persons other than the operator are at least 2

metres clear while operating the machine.

Always keep feet and hands well clear of the lifting

carriage and bins while operating.

Do not place feet or foreign objects underneath the

lifting carriage while it is raised.

Do not lift over-filled or overflowing bins.

User Manual // Simpro Microstacker

Original Instructions // English // v2.0 // August 2022 // Page 14

Before connecting the machine to a power

supply to charge the battery, ensure the voltage

and frequency correspond with that listed on the

rating plate.

Do not attempt to charge the machine if the

power cable or insulation is damaged.

Do not connect to a damp power socket.

Ensure the power socket is fitted with a residual

current device.

Ensure there is complete continuity between the

machine and an effective earthing system which

complies with local and national regulations. The

manufacturer cannot be held liable for the

consequences of an inadequate earthing system.

3.H an dl in g, Tr an sp ort & S t or ag e

3.1 Assembly

The Microstacker is usually delivered fully assembled.

3.2 Moving

When the machine is standing upright it may be easily moved on its wheels, using the

steering tiller. To ensure stability, the lifting carriage should be positioned just off the ground

when moving the machine.

Extra care should be taken when moving the machine on sloping ground.

3.3 Lifting

If the machine needs to be lifted for any reason, carry out the following procedure:

1. Confirm the weight of the machine on the rating plate and check that the lifting

equipment that is to be used has sufficient capacity.

2. Affix a lifting sling or chain around the top frame cross-member (or to the lifting lugs if

provided).

3. Use one person to operate the lifting equipment, and at least one other person to

watch for obstructions and hold the machine steady if required.

4. Lift, move and lower the machine into place, ensuring it always remains upright.

The Microstacker weighs between 150kg and 200kg. Always verify the weight of the

machine on the rating plate, and check the lifting equipment that is to be used has

sufficient capacity.

Never stand or reach underneath the machine while it is being lifted.

3.4 Transportation

Carry out the following procedure to prepare the machine for transport:

1. Apply the brake and press the Emergency Stop.

2. Use appropriate lifting equipment to place the machine onto a wooden pallet, and

securely strap it into place. If necessary, the Microstacker can be laid over onto its left

or right side before being strapped down.

To prevent oil leaks and damage to the frame, do not lie the machine onto its front or

back for transport.

3. Load the pallet onto the truck or trailer.

4. Tie the pallet and machine into position using only marked tie-down points and strops

rated to at least 1000kg. Ensure it is fastened against lateral forces from any direction.

User Manual // Simpro Microstacker

Original Instructions // English // v2.0 // August 2022 // Page 16

3.5 Storage

If the Microstacker is not to be used for a period of two months or more, it should be stored in

a clean, dry place with good ventilation, at temperatures not below 0℃. Before placing the

machine into storage, carry out the following procedures:

1. Clean the machine thoroughly.

2. Carry out several full lifting cycles, then lower the carriage to the ground.

3. Apply a thin layer of silicone lubricant to exposed surfaces of moving parts.

4. Charge the battery and apply a suitable contact oil to the electrical contacts.

5. Depress the Emergency Stop.

6. Remove the key and store in a safe location.

4. Care and Maintenance

The Microstacker is designed to give many years of service with minimal maintenance. In the

event a fault or malfunction does occur, refer to the Quick Trouble Shooting Guide in §4.1

before contacting your agent for support.

Contact your agent if repair or service work is required.

Repair and service work must be carried out by qualified personnel.

Replacement parts must be supplied by Simpro or an authorized Simpro agent, and must

be of the same design and specification as the original parts.

4.1 Quick Troubleshooting Guide

Refer to the Quick Troubleshooting Guide below before contacting your agent for service.

Problem

Possible Causes

Remedy

Reference

The machine

will not lift

bins, and the

motor does

not run

Flat Battery

Recharge the battery.

§4.4.1.2

§4.4.2.2

Tripped master

circuit breaker

The master circuit-breaker may be tripped if

the machine is operated with a flat battery,

or a short-circuit occurs. It is designed

automatically reset after a short delay.

§4.4.4

Tripped battery

circuit breaker

PRO machines are supplied with an EL20_C

Lithium-ion battery pack, which has an

integrated circuit breaker. Press the

BATTERY SAVER button to reset this breaker.

§4.4.2

Faulty raise/lower

buttons or wiring

Check and rectify.

Faulty raise relay

The relay contactor should click when the

‘up’ button is pressed – if not, contact your

agent.

The machine

will not lift

bins,

although the

motor runs

Bin too heavy

Manually remove material from the bin to

reduce the weight. The Microstacker is

designed to lift 150kg max.

§1.4

§4.3.1.1

Pressure-relief

valve set too low

Contact your agent for instructions on how

to adjust the pressure-relief valve.

§4.5.2.2

Carriage will

not come

down from

the fully

raised

position

Carriage sticking

in masts

Spray lubricant inside of masts.

Lubricate the roller arms at top of carriage.

§4.3.2

Lift ram jamming

Contact your agent for support.

§4.3.2

Faulty switch,

wiring, or lowering

valve

The lowering valve should click when the

button is pressed –if not, check the switch,

wiring and electro-magnetic coil.

§4.3.2

4.2 Cleaning

The machine can be washed down using water and a mild cleaning agent. Avoid directing

high-pressure water jets at the controls or powerpack enclosure.

For IP ratings of the machine and various subcomponents see §1.9.

User Manual // Simpro Microstacker

Original Instructions // English // v2.0 // August 2022 // Page 18

4.3 Carriage jams

Occasionally the bin carriage may become jammed at some point. This is normally a minor

issue which can be easily rectified.

The bin carriage is not powered down –it is lowered by gravity alone.

See §4.5 for details and schematics of the hydraulic system.

4.3.1 Bin carriage jams while raising

If the carriage jams while raising the cause may be either an overweight bin, or a

mechanical fault, such as a bent mast or misaligned sliding block.

4.3.1.1 Overweight bin

1. Lower the bin carriage to ground level.

2. Remove some material from the bin, then try again.

If the pressure-relief valve is adjusted incorrectly, the Microstacker might stall even when

lifting bins that are within the machine’s Safe Working Load (150kg) – see §4.5.2.2.

4.3.1.2 Mechanical fault

1. If possible, lower the carriage to ground level and remove the bin.

2. Attempt to visually identify the cause of the jamming. The most likely causes are:

a. The mast may have been bent or damaged.

b. Lack of lubrication.

3. With the carriage lowered, rectify the problem by straightening and/or realigning the

mechanical components as required. If the mast is bent, you may need to contact

your agent for support.

4. Carry out several complete lifting cycles to ensure the problem is fully resolved.

4.3.2 Carriage jams while lowering

If the carriage jams on the way down, or has jammed on the way up but will not come

down, it may be due to a hydraulic, electrical, or mechanical fault.

4.3.2.1 Hydraulic or electrical fault

When the LOWER button is pressed, the lowering valve should emit a ‘click’ sound as it

opens. If it does not, the problem may be either a hydraulic or electrical fault.

1. If the lowering valve is receiving a signal but not opening, it may simply need to be

cleaned. This can be carried out by a technician with a knowledge of electro-

hydraulic systems:

a. Provide support for the bin carriage with a sling attached to a forklift or crane.

Never place any part of your body beneath the bin unless it is securely supported.

b. Isolate the battery by pressing the EMERGENCY STOP button, and remove the

covers from the powerpack enclosure.

c. Remove the lowering valve coil from the valve stem.

d. Unscrew the lowering valve cartridge.

e. Clean the cartridge with compressed air.

f. Replace the lowering valve by reversing the above procedure.

2. Release the bin carriage, power on the machine and carry out several lift/lower

cycles to ensure the problem has been properly resolved.

3. If the lowering valve still does not operate correctly even after being thoroughly

cleaned, it may need to be replaced –contact your Simpro agent.

4.3.2.2 Mechanical fault

If the lowering valve is operating correctly (emits a ‘click’ sound when the LOWER button is

pressed), the problem may be a mechanical fault.

1. Isolate the battery by pressing the EMERGENCY STOP button.

2. Provide support for the carriage and bin with a sling attached to a forklift or crane.

Never place any part of your body beneath the bin unless it is securely supported.

3. Attempt to visually identify the cause of the jamming. The most likely causes are:

a. The mast is bent or damaged.

b. Lack of lubrication.

4. Rectify the problem by straightening, realigning, and/or lubricating the components

as required. If the mast is bent, you may need to contact your agent for support.

5. Release the bin carriage, power on the machine and carry out several lift/lower

cycles to ensure the problem has been properly resolved.

6. If the bin carriage still does not lower, contact your Simpro agent for support.

4.4 Electrical System

The Microstacker operates on either 12VDC or 24VDC electric current provided by an

onboard battery. This current is used to power the control circuits, as well as the series-wound

0.8kW electric motor which drives the hydraulic pump.

The electric motor only runs when both RAISE buttons are pressed; the bin carriage is lowered

by gravity alone. As a rule, one full charge is sufficient to lift at least 40 bins, but this is

dependent on the lifting height and type of battery which is fitted.

4.4.1 AGM battery

The Microstacker SME 12V model is fitted with a single maintenance-free 12V/20Ah AGM

battery, while the PRO 24V model has two such batteries, connected in series to provide

24VDC output. Both models are fitted with an onboard 12V/24V smart charger.

4.4.1.1 AGM battery indicator and hour meter

Some Microstacker models are fitted with a combined battery indicator and hour meter,

mounted onto the body of the machine.

When the indicator is showing one or two bars of charge, the machine should not be

used, and should be recharged as soon as possible.

Attempting to operate the machine with flat battery may trip the master circuit breaker

(see §4.4.4) and can also damage the battery.

Table of contents

Other Simpro Lifting System manuals

Simpro

Simpro Multi-Tip 1600 User manual

Simpro

Simpro Dumpmaster User manual

Simpro

Simpro Multi-Tip User manual

Simpro

Simpro MegaDumper Series User manual

Simpro

Simpro Multi-Tip User manual

Simpro

Simpro MegaDumper User manual

Simpro

Simpro QUIKSTAK QS10MM User manual

Simpro

Simpro EUROVER User manual

Simpro

Simpro Multi-Tip MT1200 User manual