Simpson Minilab PVF-C User manual

Table of contents

Other Simpson Measuring Instrument manuals

Simpson

Simpson 260-6XLM User manual

Simpson

Simpson 880 WATTMETER User manual

Simpson

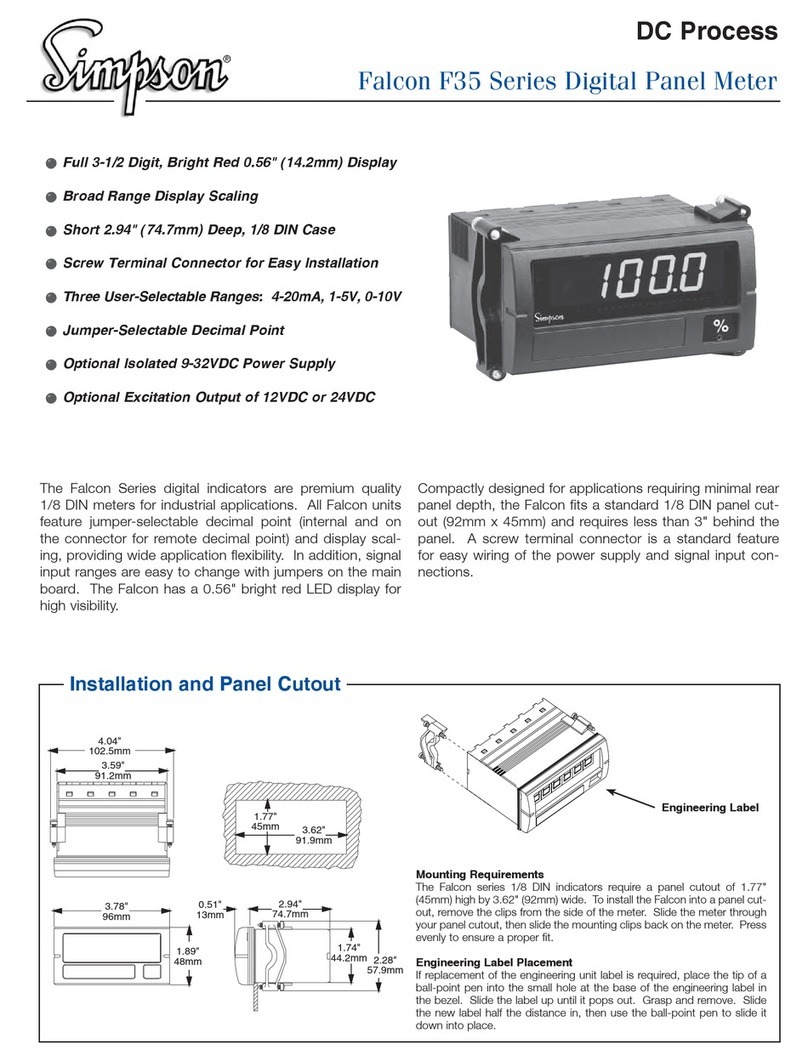

Simpson Falcon F35 Series User manual

Simpson

Simpson 444 User manual

Simpson

Simpson 884-2 User manual

Simpson

Simpson 228 User manual

Simpson

Simpson S664 User manual

Simpson

Simpson 260-8XPI User manual

Simpson

Simpson 215 User manual

Simpson

Simpson 260 series 5M User manual

Simpson

Simpson TS-113 User manual

Simpson

Simpson 260-8P User manual

Simpson

Simpson 2865 User manual

Simpson

Simpson 390-2 User manual

Simpson

Simpson 897 User manual

Simpson

Simpson 897 User manual

Simpson

Simpson 260-8XI User manual

Simpson

Simpson 886-2 User manual

Simpson

Simpson Falcon F45 Series User manual

Simpson

Simpson M245 Series User manual

Popular Measuring Instrument manuals by other brands

Fluke

Fluke i3000s Flex Series instruction sheet

Xylem

Xylem SENSUS PolluTherm Integrator Installation and operation instructions

NOYAFA

NOYAFA NF-801B instruction manual

Advanced Instruments

Advanced Instruments OsmoTECH PRO Installation & Training Guide

Brooks Instrument

Brooks Instrument 1250 Series Installation and operation manual

BIO RAD

BIO RAD SmartSpec 3000 instruction manual