7

Advancements in endurance testing

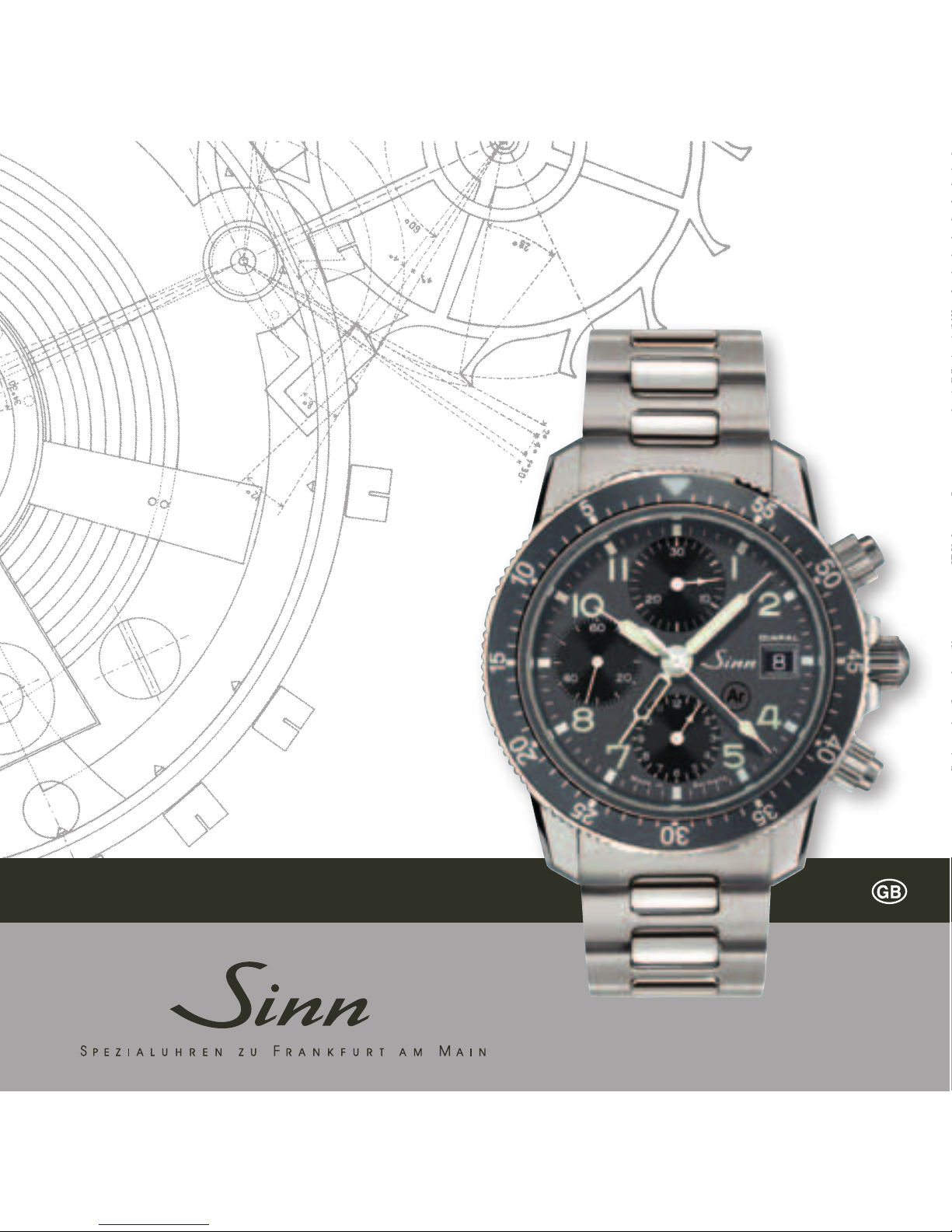

Take, for example, the absolutely condensation-

free, anti-reflective, german submarine steel diving

watch – made possible by HYDRO technology.

Other examples include a chronometer

chronograph fashioned from a 22-carat gold alloy

that is as hard as stainless steel and a chronometer

with a magnetic resistance 20 times the standard.

There are also watches with a clockwork

mechanism optimally protected from aging by an

inert gas and integrated dehumidifying capsule.

The list would not be complete without mentioning

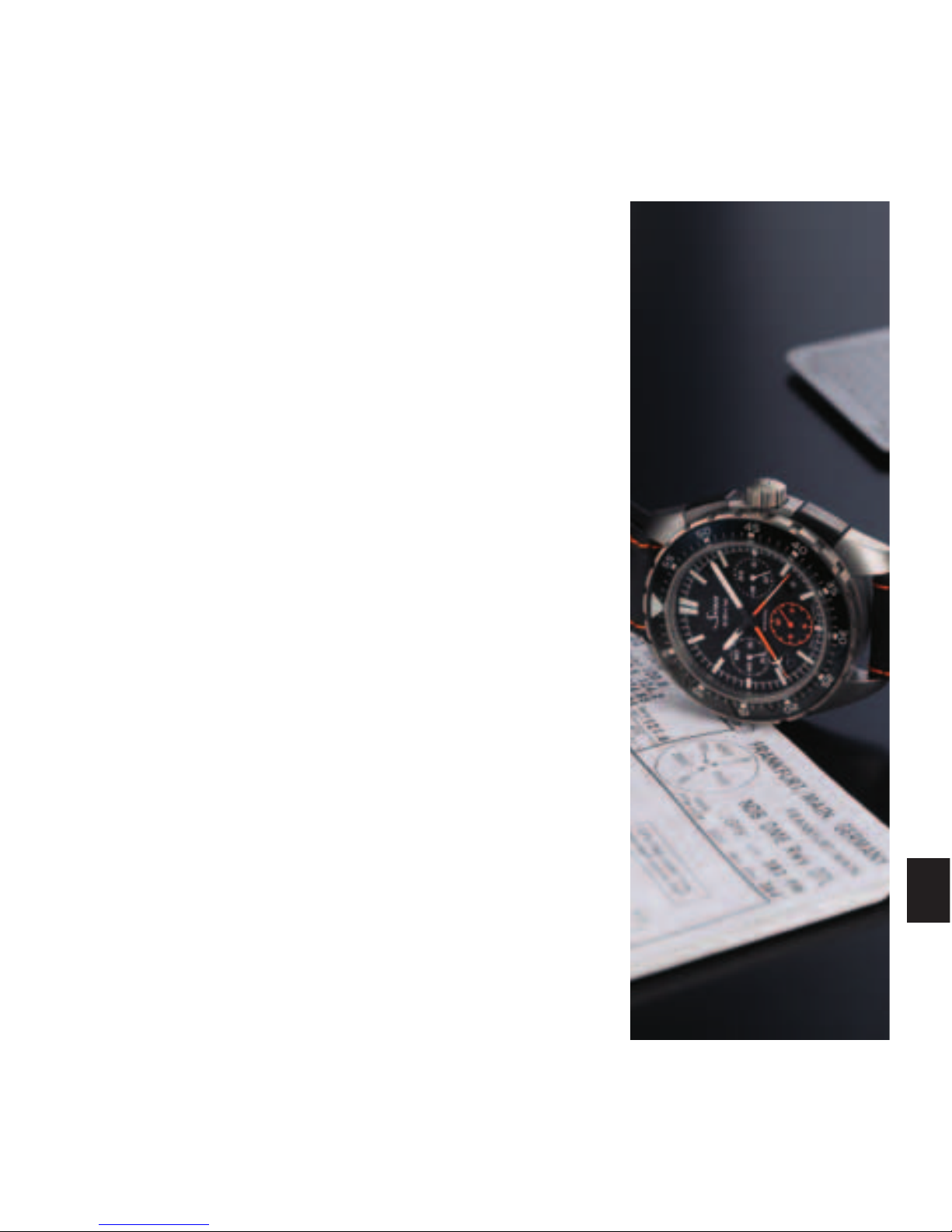

the development of mission timers

(Einsatzzeitmesser or EZM in German) for special

police units and border patrol guards as well as

temperature resistance technology to keep

mechanical watches performing at temperatures

ranging from –45°C to + 80°C. This technology has

proven its worth in the EZM 10 TESTAF model, for

example, used as part of the official approvals

procedure for Eurocopter's EC 145 T2 high-

performance helicopter. Hot and cold climate tests

and high-altitude experiments were carried out in

the deserts of the USA, the Rocky Mountains and

the frozen wastes of Canada. The watch was worn

unprotected, outside the pilot's overall, during cold

climate tests at temperatures reaching –45°C.