5

SAFETY INSTRUCTIONS….cont

supply.

KEEP WORK AREA CLEAN AND WELL LIT: Cluttered work areas and dark areas invite ac-

cidents. Floors must not be slippery due to oil, water or sawdust etc.

HAVE YOUR BANDSAW REPAIRED BY A QUALIFIED PERSON: The bandsaw is in accord-

ance with the relevant safety requirements. Repairs should only be carried out by

qualified persons using original spare parts, otherwise this may result in considerable

danger to the user and void the warranty.

DANGER! Check that the bandsaw is in sound condition and good working order be-

fore each use; Take immediate action to repair or replace faulty / damaged parts.

WARNING! Only operate on a level and stable surface.

WARNING! RISK OF ELECTRIC SHOCK. Do not expose the bandsaw to water spray, rain,

dripping water or moisture of any kind.

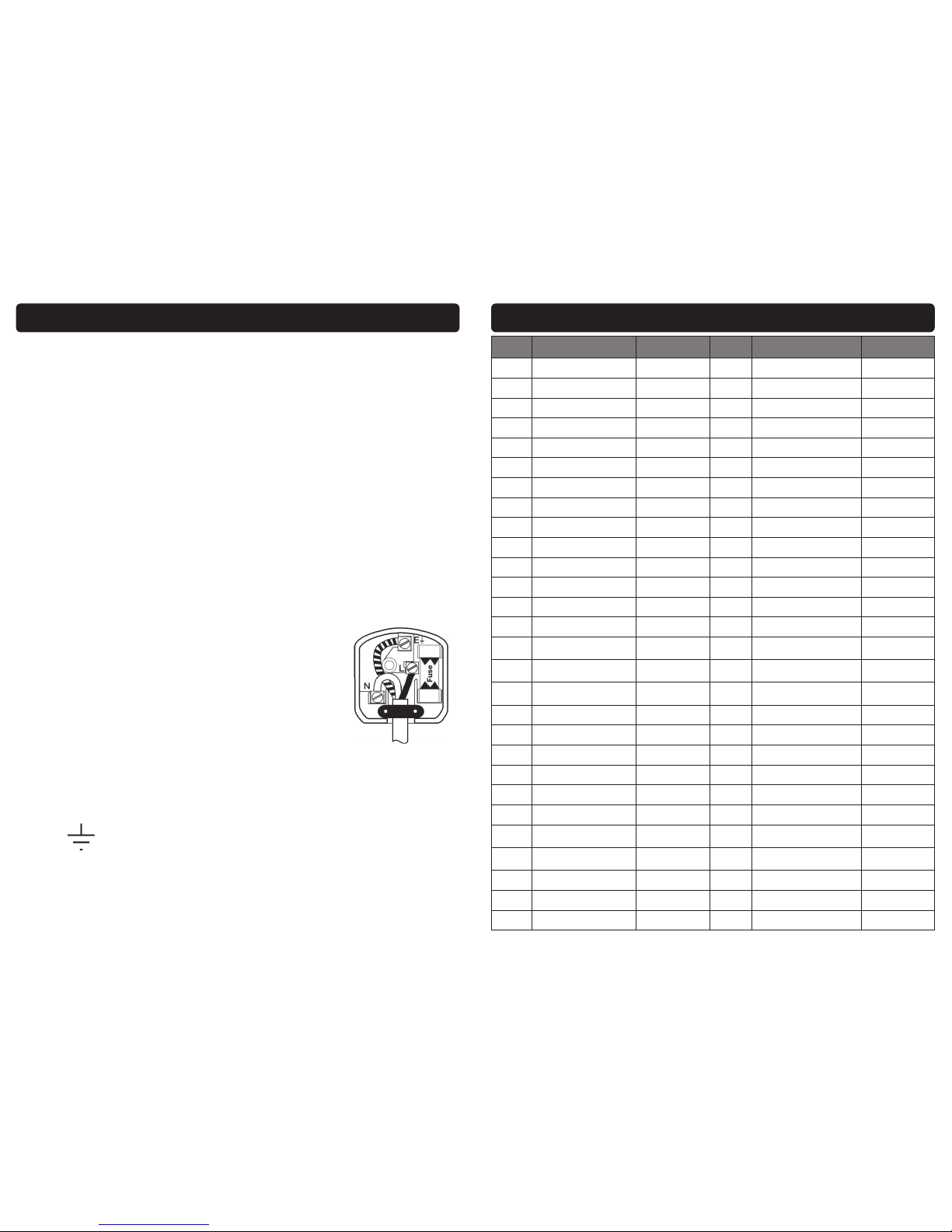

PROTECT YOURSELF FROM ELECTRIC SHOCK: When working with power tools, avoid

contact with any earthed items (e.g. pipes, radiators, hobs and refrigerators, etc.). It is

advisable wherever possible to use an RCD (residual current device) at the supply

socket.

DO NOT ABUSE THE MAINS LEAD: Never pull the mains lead to remove the plug from

the mains socket, or to move the bandsaw from place to place. Keep the mains lead

away from heat, oil and sharp edges. If the mains lead is damaged, it must be re-

placed by the manufacturer or its service agent or a similarly qualified person in order

to avoid unwanted hazards.

ALWAYS check that the belt guard and blade guards are in place, adjusted correctly,

undamaged and firmly attached.

NEVER STAND ON THE BANDSAW: The bandsaw is not designed for this purpose.

DO NOT dismantle, tamper with or modify the bandsaw, as this may be dangerous

and will invalidate the warranty.

SECURE THE WORK-PIECE: Use the vice to hold the work-piece; this frees up both hands

to operate the saw.

REMOVE ADJUSTING KEYS AND WRENCHES: Form a habit of checking to see that keys

and adjusting tools are removed from the bandsaw before every use.

If a problem with the bandsaw is experienced or suspected stop using the bandsaw

immediately and contact your distributor for repair.

Regularly inspect the bandsaw, ensuring that it is in good working order and condi-

tion.

Always ensure that the work area is clean, tidy and free from unrelated materials.

Operate away from flammable objects, materials & surfaces.

Use in a location where accidental contact (particularly by children) is unlikely.

Ensure on/off switches are switched to off position (0) before connecting the mains

lead to the power supply.

Keep the work area clean and clear of possible tripping hazards.

Keep children and unauthorised persons away from the bandsaw, as it has a sharp

blade!

Disconnect from the mains before moving or attempting any cleaning or mainte-