Sit PROFLAME DFC Technical manual

9.957.061 00

PROFLAME DFC CONTROL BOARD

USE AND INSTALLATION INSTRUCTIONS

Read the instructions before use.

2

IMPORTANT

The Proflame DFC, is the flame ignition and control board, part of the Proflame System, which can

be made of these elements:

• Standalone Proflame system

o Proflame DFC: the flame ignition and control board

o Proflame DFC main wirings

o Proflame pilot assembly

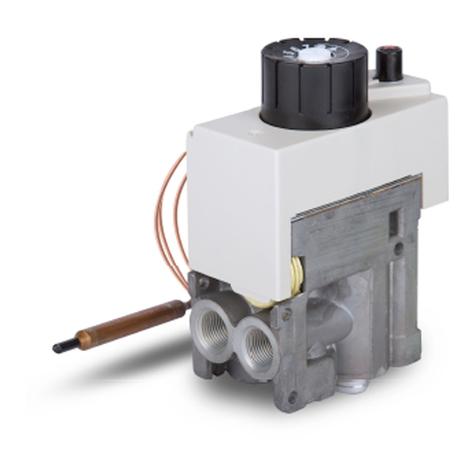

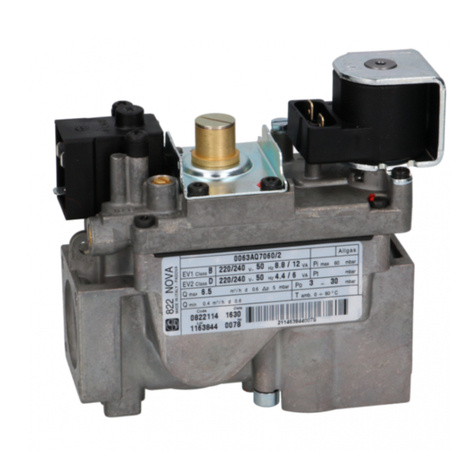

o Proflame 88# gas valve

o Proflame power supplies

• Remotely controlled Proflame system

o Proflame DFC: the flame ignition and control board

o Proflame DFC main wirings

o Proflame pilot assembly

o Proflame 88# gas valve

o Proflame GT*Transmitter

o Proflame GT*Receiver

o Proflame GT*main wirings

o Proflame GT Fan Control Module, or power supplies

o 540 split flow valve

in which the “#” character will be:

- “0” if a not modulating, or manual knob modulating valve is used,

- “5” if an electrical modulation valve is used,

- "6" if a manual knob modulating valve is used,

and the “*”string will be the composition of the following characters:

- “blank” if a not modulating, or manual knob modulating valve is used,

- “M” if an electrical modulation valve is used,

- “F” if the Fan Control Module peripheral is used, this will also supply power to the whole

system,

- “S” if the Split Flow Valve is used.

3

INTRODUCTION

The Proflame DFC (Digital Fireplace Control) board is a device that allows the automatic ignition

and pilot flame supervision, to command the functions of a hearth appliance.

It’s configured to control the ON/OFF main burner operation, giving the choice of both IPI

(intermittent pilot ignition), and CPI (continuous pilot ignition) modes.

The Proflame DFC board controls and connects directly to an automatic valve of the Proflame

880, and 885 families using low electric power.

The power supply could come from an AC/DC wall adapter, from a 4 AA battery pack, or from

both. This gives the capability to work both as a full battery, or a battery backup system.

If a remotely controlled Proflame system is used, no dedicated power to the DFC is needed, as

the supply comes through the wiring connections.

PROFLAME DFC BOARD GENERAL CONNECTIONS

See Fig. 1.

FLAME

SENSOR

ROD

DIAGNOSTIC

/BUZZER

SPARK ROD

PILOT GROUND

+

+

-

-7VDC STABILIZED

SUPPLY

4 X 1.5 BATTERY

SET

MAIN ON / OFF

IPI / CPI MODE

VALVE BODY GROUND

EV2

EV1

Fig. 1

CN4

CN3 CN2 CN1

CN0

CHASSIS

9 8 7 6 5 4 3 2 1

1

2

3

4

4

DFC control board

Supply voltage DC IN: 7Vdc - 200mA max (Class 2 power supply)

BB IN: 6Vdc - 200mA max (four 1.5V size AA batteries)

Ambient temperature ratings -18 .. +80 °C (0 .. +176 °F)

Spark voltage >15kV

Spark energy >0,7mJ

Spark frequency 1Hz

Tested gas types the system has been tested for NG, and LPG gas

types/mixtures

Pilot ignition source Intermittent/Continuous

Please refer both to the Gas Valve, and to the Pilot Assembly User and Installation manuals for:

- the recommended gas input for the pilot burner;

- the electrical specifications;

- the operating temperatures and the components that have to be directly exposed to flame.

TECHNICAL DATA

GENERAL CONNECTION & SET-UP GUIDE FOR PROFLAME DFC BOARD

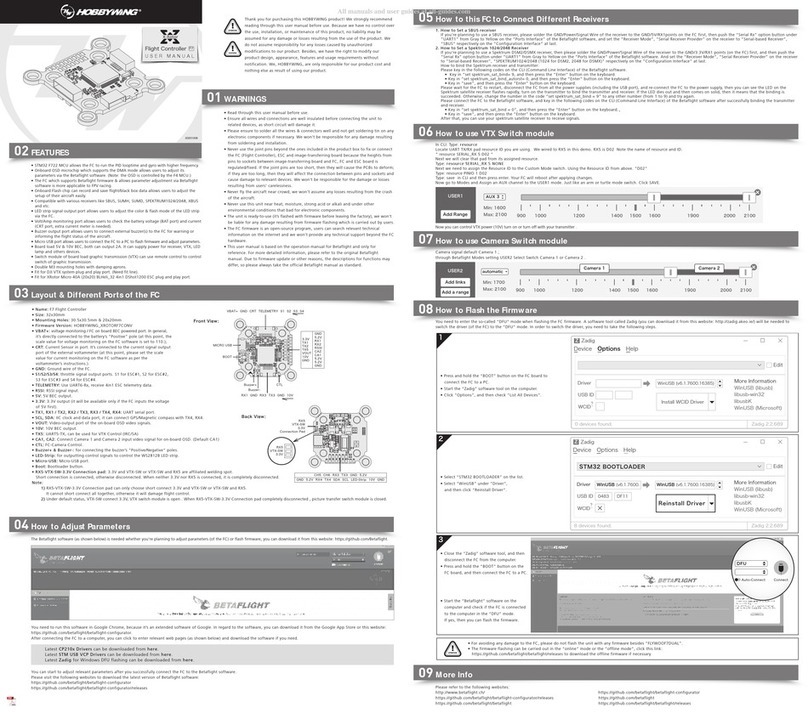

General Connection & Set-Up Guide for Proflame DFC board:

1. The DFC board should be placed in a low temperature area of the appliance.

2. Connect the pilot and control valve as indicated in fig. 2. (Stand Alone System, No Remote)

3. Connect the pilot, control valve and remote system as indicated in fig. 3. (DFC with Remote

System & Wall AC Adaptor)

4. Connect the pilot, control valve and remote system as indicated in fig. 4. (DFC with Remote

System & Fan Control Module Power)

5

FUNCTIONS

Preliminary check of a Standalone Proflame system

Before applying any power supply to the DFC board please verify that the electrical connections are

in accordance to Fig. 2

Initializing the System for the first time

Set the main burner flame ON/OFF command to its OFF position.

If installed, set the pilot flame mode selector to its IPI position.

If provided, install the 4 AA batteries into the battery holder, and respect the polarity indicated on the

battery holder silkscreen. Connect the battery holder to the DFC’s main wiring harness.

Connect the AC/DC wall adapter to the DFC’s DC-jack connector on the main wiring harness, and

plug it into the wall mains supply.

Orange Green

Red

Black

880/886 Proflame

Battery

Holder

Chassis

connection

120 Vac INPUT

7 Vdc STABILIZED

SUPPLY OUTPUT

ON / OFF CPI / IPI MODE

ON/OFF IPI/CPI

BATTERY

DC SUPPLY

VALVE

GROUND

DFC

Fig. 2: electrical connections of standalone Proflame system

6

PRELIMINARY CHECK OF A REMOTELY COMMANDED SYSTEM

Before applying any power supply to the system, check that the electrical connections are

according:

• to Fig. 3 for Proflame system with the electrical modulation, and/or the fan control module,

and/or the split flow valve

• to Fig. 4 for Proflame system with the electrical modulation, and/or the AC/DC power

supply, and/or the split flow valve

REMOTE

REMOTE

120V OUT

Receiver 14

Pin Connector

Split Flow

Pilot

Pink

Blue

CPI / IPI MODE

MOTOR

IPI/CPI

RECEIVER

FCM-COM

SPLIT FLOW

ON / OFF

TH

TPTH

DC SUPPLY

DC SUPPLY

GROUND

Orange Green

Chassis

connection

885 PROFLAME

Fig. 3

Fig. 4

REMOTE

REMOTE

Receiver 14

Pin Connector

Split Flow

Pilot

Pink

Blue

CPI / IPI MODE

120 Vac INPUT

7 Vdc STABILIZED

SUPPLY OUTPUT

MOTOR

IPI/CPI

RECEIVER

DC SUPPLY

SPLIT FLOW

ON / OFF

TH

TPTH

DFC SUPPLY

DC SUPPLY

GROUND

885 PROFLAME

Orange Green

Chassis

connection

Remote control

Remote control

7

INITIALIZING THE SYSTEM FOR THE FIRST TIME

Place the 3 position slider switch in the “OFF” position as indicated in Fig. 5.

Install the 4 AA batteries into the receiver battery bay. Note the polarity of the batteries and insert

them into the battery bay as indicated on the Battery cover (+/-).

Using the end of a paper clip, or other similar object, press the button through the hole marked

“PRG” on the Receiver front cover Fig. 5. The Receiver will “beep” three (3) times to indicate that it is

ready to synchronize with a Transmitter. Install the 3 AAA type batteries in the Transmitter battery bay,

located on the base of the Transmitter. With the batteries already installed in the Transmitter, push the

ON button. The Receiver will “beep” four times to indicate the Transmitter’s command is accepted,

and the Receiver is now set to the particular code of that Transmitter.

Push the OFF button on the Transmitter. The Receiver will “beep” two (2) times to indicate the

Transmitter’s command is again accepted.

Place the 3 position slider switch on the Receiver at the “Remote” position as indicated in Fig. 5.

If installed, turn ON the fan control module, switching it to the ON (I) position.

The system is now initialized.

LOW BATTERY POWER DETECTION

Since the batteries that are mounted in the remote receiver also supply the DFC ignition board, the

endurance of the system batteries depend on various factors:

- the battery pack function, full battery operation, or battery backup operation,

- the chemistry type (normal, alkaline), and the quality of the batteries,

- the number of ignitions of the appliance,

- the number of changes to the room thermostat set point.

- the temperatures at which the batteries are exposed,

- the supervised pilot flame quality,

- etc.

When the Receiver batteries are low, no “beep” will be emitted from the Receiver when it receives an

ON/OFF command from the Transmitter. This is an alert for a low battery condition for the Receiver.

PRG Key

3 Position Slider

14 PIN terminal

Fig. 5

8

When the batteries are replaced the “beep” will be emitted from the Receiver when the ON/OFF key

is pressed (see Initialization of The System).

- in IPI (intermittent pilot ignition) mode the board upon receiving a main burner

command operation, will start its functional cycle from a completely shut OFF flame

state, by initially igniting the pilot flame, and keeping it under supervision before and

during the main burner operation;

- in CPI (continuous pilot ignition) mode, the board will start by initially igniting the pilot

flame, and keeping it permanently under supervision, then the board will be able to

rapidly serve a main burner command operation.

STANDARD IDENTIFICATION: ANS Z21.20, Automatic Ignition Systems.

WARNING

Fire Hazard. Can cause severe injury or death.

The Remote Receiver causes ignition of the appliance. The appliance can turn on suddenly.

Keep away from the appliance burner when operating the remote system or activating manual

bypass of the remote system.

WARNING

All the parts of the system are not intended to operate in presence of water dripping, spraying,

rain, etc. that could generate also by condensation or ice that melts, etc.. Otherwise means

shall be provided to protect all the components.

WARNING

Battery operated device.

Read the battery instructions before installing them into the system. Do not expose any battery,

or its holder, or a device in which batteries are installed, to a working temperature greater than

54°C / 129°F. Avoid battery overheating even if the working temperature of the device to which

the batteries are connected is reported to be greater than 54°C / 129°F. In case of overheating

the batteries will degrade their stored charge capacity, or leak corrosive liquids, or in bad

cases, develop hydrogen gas and explode.

CAUTION:

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper

and dangerous operation.

Ensure that high voltage carrying wires (i.e. the spark igniter wire) are laid down far away (i.e.

farther than 2,5cm – 1inch) from the electronic controlled devices.

CAUTION

Property Damage Hazard.

Excessive heat can cause property damage.

The appliance can stay lit for many hours.

Turn off the appliance if it is not going to be attended for any length of time.

Always place the Transmitter where children can not reach it.

The board reset from a volatile lock-out can be accomplished by the switching

action of a thermostat or a similar device on the command input.

9

APPENDIX

1. Command definitions

Pilot IPI / CPI switch Main Turn ON switch,

or state of the remote

control contact

Command reference

name

Commanded Fireplace

State

Opened, IPI Opened, remote

switch set OFF

Turn-OFF Flames OFF

Opened, IPI Closed, remote switch

set ON

Turn-ON Pilot + Main burner

flames ON

Closed, CPI Opened, remote

switch set OFF

Pilot-ON Pilot flame ON

Closed, CPI Closed, remote switch

set ON

Turn-ON Pilot + Main burner

flames ON

2. DFC board operation

2.1 IPI operation mode

The IPI operation mode means Intermittent Pilot Ignition. In this mode the CPI/IPI switch

must be left opened.

In this mode the board can be commanded to follow the ignition sequences for both the

Pilot, and the Main Burner Flame as follows:

- assume to start from a completely shut OFF fireplace, with IPI Mode initially set,

- a Turn-ON command will initiate, and bring to completion the Pilot Flame ignition

sequence, then the Main Burner Flame ignition sequence is automatically commanded

after the Pilot Flame is detected steadily established,

- a Turn-OFF command will determine the gas valve shutdown so both the Pilot

Flame, and the Main Flame will extinguish.

2.2 CPI operation mode

The CPI operation mode means Continuous Pilot Ignition. In this mode the CPI/IPI switch

must be left closed.

In this mode the board immediately completes the ignition sequence for the Pilot Flame,

and then remains with the Pilot Flame ON, waiting for a command to ignite the Main Burner

Flame as follows:

- assume to start from a completely shut OFF fireplace, with CPI Mode initially set,

- the Pilot Flame ignition sequence is initiated, and brought to completion, the Pilot

ON state is maintained,

- a Turn-ON command will initiate the Main Burner Flame ignition sequence,

- a Pilot-ON command will shut down the Main Burner portion of the gas valve so

the Main Flame will extinguish, leaving a permanent Pilot ON flame.

A Turn-OFF command is only possible by setting the IPI/CPI switch back to IPI position.

2.3 Details about the ignition sequences for the Pilot Flame

For the DFC board the Pilot flame is the supervised safety flame: it is used as the ignition

flame source for the more powerful Main Burner Flame.

2.3.1 Turn-OFF

In this state, the gas to the appliance is cut-off by the gas valve.

In this state the DFC board will wait for a command.

10

2.3.2 Pilot-ON

In this state the Pilot Flame sequence is executed, and it will lead the system to a

continuous Pilot flame condition through these steps:

- if the previous state was Turn-OFF,

the Pilot Flame detection is turned ON,

a Pilot Flame check sequence is completed to avoid parasitic flame detection,

the spark generator is activated,

the Pilot gas valve solenoid is set to open the gas flow to the pilot hood,

in the mean time the Main Burner gas valve solenoid is set to close the gas flow;

- if the previous state was Turn-ON,

the Pilot Flame detection is maintained ON,

the Pilot gas valve solenoid is set to keep opened the gas flow to the pilot hood,

in the mean time the Main Burner gas valve solenoid is set to close the gas flow.

2.3.3 Turn-ON

In this state both the Pilot, and the Main Burner Flames sequences are executed, and it

will lead the system to a fireplace completely lit:

- if the previous state was Turn-OFF,

the Pilot Flame detection is turned ON,

a Pilot Flame check sequence is completed to avoid parasitic flame detection,

the spark generator is activated,

the Pilot gas valve solenoid is set to open the gas flow to the pilot hood,

in the mean time the Main Burner gas valve solenoid is set to close the gas flow,

the Pilot Flame is let to stabilize,

the Main Burner gas valve solenoid is set to open the gas flow;

- if the previous state was Pilot-ON,

the Pilot Flame detection is maintained ON,

the Pilot gas valve solenoid is set to keep opened the gas flow to the pilot hood,

in the mean time the Main Burner gas valve solenoid is set to open the gas flow.

2.3.4 Lockout state definition

A lockout state is reached when an ignition error occurs, in any case the lockout on this

board is volatile, this means that the lockout state will remain set in memory as long as the

power supplies are applied.

This could mean both an anomalous flame detection, and/or too many unsuccessful

ignition tries.

This state is a safe condition for the appliance, and is entered automatically by the DFC

board.

When the DFC gets into lockout state:

1. both the Pilot, and the Main Burner solenoids in the gas valve are de-energized;

2. a diagnostic code is sent through the diagnostic port: if a signalling device is

applied to the port the signal could be heard or seen by the user and recognized

through a numeric code.

Having no diagnostic mean, the symptom of a lockout could be verified on a not

responding board by trying to set the Pilot-ON command in CPI mode, because

the board will not ignite the pilot flame;

3. the DFC board will ignore any command setting, and remain into Turn-OFF state,

unless the unlock command sequence is met.

The causes of lockout must be investigated under safe conditions by the user and / or the

service personnel.

The return of the system to the normal operation can be done releasing the DFC board

from lockout in one of the following ways:

11

- turning all the system power supplies OFF for a defined number of seconds, and

then restoring a power supply back ON,

- a complete manual reset sequence: since the command reset sequence can be

commanded through a remote receiver the lockout can be defined as Soft Lockout.

The return of the system to normal operation must be checked under safe conditions by

the user and / or service personnel.

2.3.4.1 Lockout reset sequence

The command sequence to unlock the DFC board from the lockout state is the same

whatever the command source is installed on the Main Turn ON command input.

Standalone system, Fig. 2:

- act on the Main Turn ON switch to put it into OFF position for at least 2s,

then put it into ON position for at least 2s,

then the DFC board will execute the internal tests and begin the ignition sequences.

Remotely commanded system, Fig. 3, Fig. 4:

- act on the Proflame GT* receiver slide switch:

set it to OFF position for at least 2s,

then set it to ON position for at least 2s,

then the DFC board will execute the internal tests and begin the ignition sequences,

or:

- act on the Proflame GT* transmitter once the GT* receiver slide switch is set to

REMOTE position:

turn OFF the flame request by the transmitter and wait in OFF state for at least 2s,

then turn ON the flame request for at least 2s,

then the DFC board will execute the internal tests and begin the ignition sequences:

the proper acknowledgement of the transmitted OFF/ON commands should be

heard through the GT* receiver beeps.

The IPI/CPI switch will not operate to unlock the board: it could be used anyway to test if

a properly supplied DFC board is in lockout because setting the switch to CPI position,

the DFC will not initiate the Pilot Flame ignition.

2.4 Diagnostics

The diagnostic signalling could be provided through these diagnostic means installed on

the board:

1. visually, through a LED annunciator, or

2. acoustically, through a piezoelectric buzzer, or

3. through a dedicated high speed diagnostic port.

2.4.1 Real-time diagnostic messages – LED/buzzer indications

If the optional signalling device is connected to DFC board on CN0, the following

diagnostic/alert signals could be interpreted in case of a system anomaly: obviously any

indication is provided until a reliable level of power supply gets to the DFC board.

The following codes appear in the reported order of priority:

12

2.5 Special sequences: automatic safety restart

Whatever the DFC board state is in, it will execute automatically a Turn OFF command

within 24 hours of continued pilot flame ignition.

This command sequence will led the system to OFF state to verify the correct functioning

of safety means.

After the turn OFF sequence is completed, the FBC board will re-execute the latest

command.

3. DFC board behaviours under abnormal, or particular conditions

3.1 A Pilot Flame is revealed before the Pilot Flame ignition sequence

The system will not proceed to the gas ignition until a pilot flame is detected lit

upon the start-up for the Pilot Flame ignition sequence.

3.2 No pilot flame is established during the pilot ignition sequence

If no pilot flame is sensed during the pilot flame ignition sequence, the system will

retry for a predefined number of times.

A waiting period is introduced between retries to purge the unburned gas from the

appliance combustion chamber.

After the last try with no successful ignition, the system will shut down the gas, and

enter a VOLATILE LOCKOUT.

3.3 Pilot loss of flame in Pilot-ON, or in Turn-ON states

If a loss of the pilot flame signal is sensed during a state in which the pilot flame

should remain lit, the system will proceed to restore the pilot flame ignition, and will

close the main burner gas valve, and will start a timer to count the time from the

flame failure.

If too many repeated pilot flame signal losses are detected within the timer

expiration, the system will shut down the gas, and enter a VOLATILE LOCKOUT.

If the pilot flame robustness timer elapses with the number of pilot flame losses

within the predefined limit, the ignition sequence will continue normally.

Diagnostic signals

Code Lockout

state

Parasitic

pilot

flame

detected

at startup

DFC power supply

Number

of

LED

Flashes

or Buzzes

Pause

time

between

signals

C3 Yes Doesn’t

care Enough power supply to signal 3

Some

seconds

C2 No Yes Enough power supply to signal 2

C1 No No

Enough power supply to signal,

and the battery level is between

the predefined minimum power

supply range for the battery

1

C0 No No

Enough power supply for

operation, battery voltage at

reliable level or absent

none

13

3.4 Behaviour of the DFC board in relation to the power supplies

3.4.1 Operation on dropout DC supply condition: the battery backup

The battery supply is provided to connect to the system upon a permanent, or

momentary AC line voltage loss that will make the DC input power supply to drop.

The DFC will continue operation in backup, so without apparent interruption, if

the batteries are installed in the system, and if the battery charge level is into the

specified range.

If also the battery voltage drops too much, the pilot flame start-up could become

impossible and the system will proceed to shutdown.

If a low battery level is detected connected to the DFC board, it will signal this

anomaly through the diagnostic BUS signalling device.

3.4.2 Operation upon the restoration of the DC supply conditions, or replacement of the

batteries

If the AC line voltage comes back again, or the batteries are replaced in the

system with new ones, the system will re-execute the command that was last set at

its command inputs.

This means that if a thermostatic, or a manual switch is in closed position on the

Turn-ON switch input, or the IPI/CPI switch is in CPI position, the DFC board will

initiate the selected flame ignitions.

This is due to the fact that the DFC board assumes the command switches state

as an operational mode assertion principle, and is not able to distinguish a closed

contact as closed intentionally, or automatically.

14

This page is intentionally left blank

15

This page is intentionally left blank

Table of contents

Other Sit Controllers manuals

Popular Controllers manuals by other brands

digitalview

digitalview ALR-1920-SDI instructions

Sound Sation

Sound Sation Scenemaker 1216 Pro USB user manual

wattstopper

wattstopper LMRC-111 quick start guide

All LED

All LED DynColor DC300-RL-RGB-Rope user guide

Atronix

Atronix X45/10 Installation and operating instructions

AstroGadget

AstroGadget DobsonDream user guide

Hobby-Wing

Hobby-Wing 8A UBEC user manual

superbrightleds

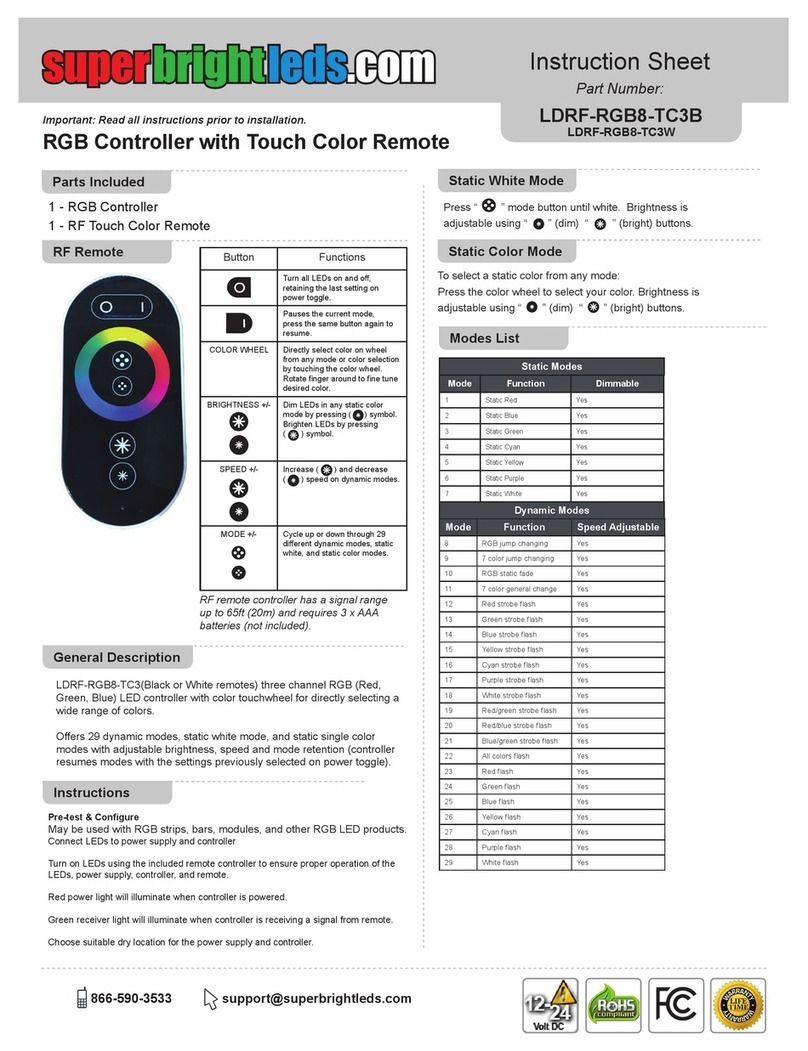

superbrightleds LDRF-RGB8-TC3B instruction sheet

BOSSCO

BOSSCO EA218 Series quick start guide

System air

System air TControl POD glass EC Installation and maintenance manual

InnoMedia

InnoMedia InnoMedia ESBC 9578-4B Quick install guide

Delta

Delta 29FWC-100E instruction manual