3

NOTE: Other than 3,600 lb. (16 kN) gated hooks, large throat opening snap hooks should not be connected to standard size D-

rings or similar objects which will result in a load on the gate if the hook or D-ring twists or rotates. Large throat snap hooks are

designed for use on xed structural elements such as rebar or cross members that are not shaped in a way that can capture the

gate of the hook.

3. RESTRICTIONS REGARDING MAKING CONNECTIONS:

ŸUse connectors conforming to ANSI Z351.12.2009 to make connections.

ŸDo not make connections where the hook locking mechanism can come into contact with a structural member or other

equipment and potentially release the hook.

ŸDo not connect a snap hook into a loop or thimble of a wire rope or attach in any way to a slack wire rope.

ŸThe snap hook must be free to align with the applied load as intended (regardless of the size or shape of the mating connector)

ŸA carabiner may be used to connect to a single or pair of soft loops on a body support such as a body belt or full body harness,

provided the carabiner can fully close and lock. This type of connection is not allowed for snap hooks.

ŸA carabiner may be connected to a loop or ring connector that is already occupied by an automatic closing connector.

4. CONNECTING SUB-SYSTEMS: Personal fall arrest

systems used with this equipment must meet applicable

state, OSHA and ANSI requirements. A full body harness

must be worn when this equipment is used as a component

of a personal fall arrest system. As required by OSHA, the

personal fall arrest system must be capable of arresting the

user's fall with a maximum arresting force of 1,800 lbs. (8

kN), and limit the free fall to 6 ft. (1.8 m) or less. If the

maximum free fall distance must be exceeded, the employer

must document, based on test data, that the maximum

arresting force will not be exceeded, and the personal fall

arrest system will function properly. Free fall greater than 6

ft. (1.8 m), and up to a maximum of 12 ft. (3.7 m) is

possible, Safe Keeper recommends using a personal fall arrest

system incorporating a Safe Keeper Energy Absorbing Lanyard. Safe Keeper has performed testing using the Safe Keeper Energy

Absorbing Lanyard in free falls up to 12ft. (3.7 m) to ensure the maximum arresting force does not exceed 1,800 lbs. (8.0 kN),

and the system functions properly.

ŸRescue Plan: Rescue operation must be performed by the trained and competent personal. The rescue operation must be

performed under the supervision of the rescue expert team or personal. It is advised that while working on site work in pairs.

Before going for the work the user must have the rescue plan according to the work.

Ÿ If Equipment Is Subjected To A Fall: Remove the equipment from service immediately if it has been subjected to the

forces of a fall arrest. Contact your distributor or Safe Keeper about policies regarding replacement of Safe Keeper

components involved in a fall.

5. SPECIFIC INSTRUCTIONS: Safe Keeper Anchors are designed to provide complete attachment system to user in the event of a fall.

These attachment systems must be connected to the proper body support and connecting facility. These Anchors are meant to hold

the victim of fall till the rescue operation is performed, so this is important that the whole system must have the all the essential

components before going for the use. The whole fall arrest system must be used by the trained/competent person. It is advisable to

make a checklist of the essential components according to one's use before going for work.

C.

B.

A.

F.

E.

D.

G.

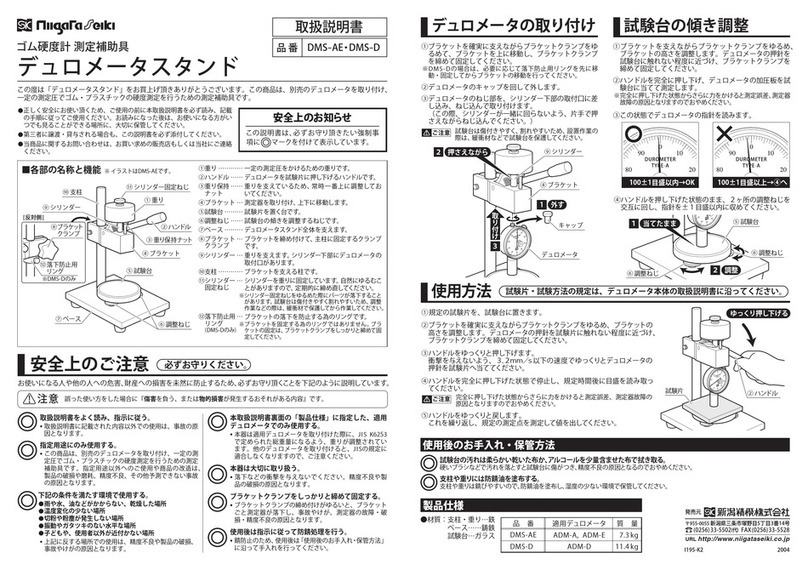

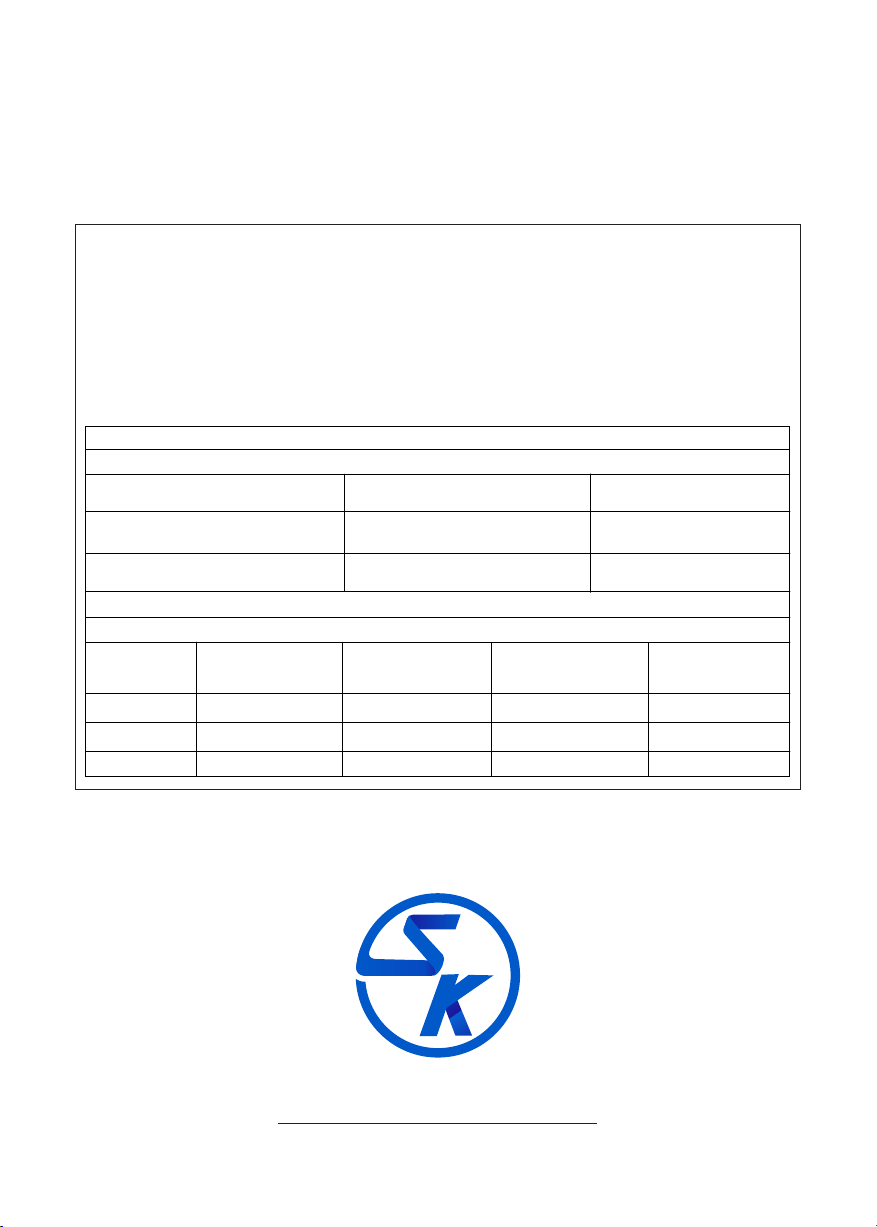

Fig. 3 - Inappropriate Connections

H.

If the connecting element to which a snap hook (shown) or

carabiner attached is undersized or irregular in shape, a

situation could occur where the connecting element applies

a force to the gate of the snap hook or carabiner. This force

may cause the gate (of either a self-locking or a non-

locking snap hook) to open, allowing the snap hook or

carabiner to disengage from the connecting point.

Small ring or other non-compatibly shaped element

1. Force is applied

to the snap hook.

2. The gate presses against

the connecting Ring.

3. The gate opens allowing

the snap hook to slip off.

Fig. 2 - Unintentional Disengagement (roll-out)