SKC chek-mate 375 series User manual

skcinc.com Form 39013 Rev 210827 Page 1

chek-mate Flowmeter

Cat. No. 375 Series

Operating Instructions

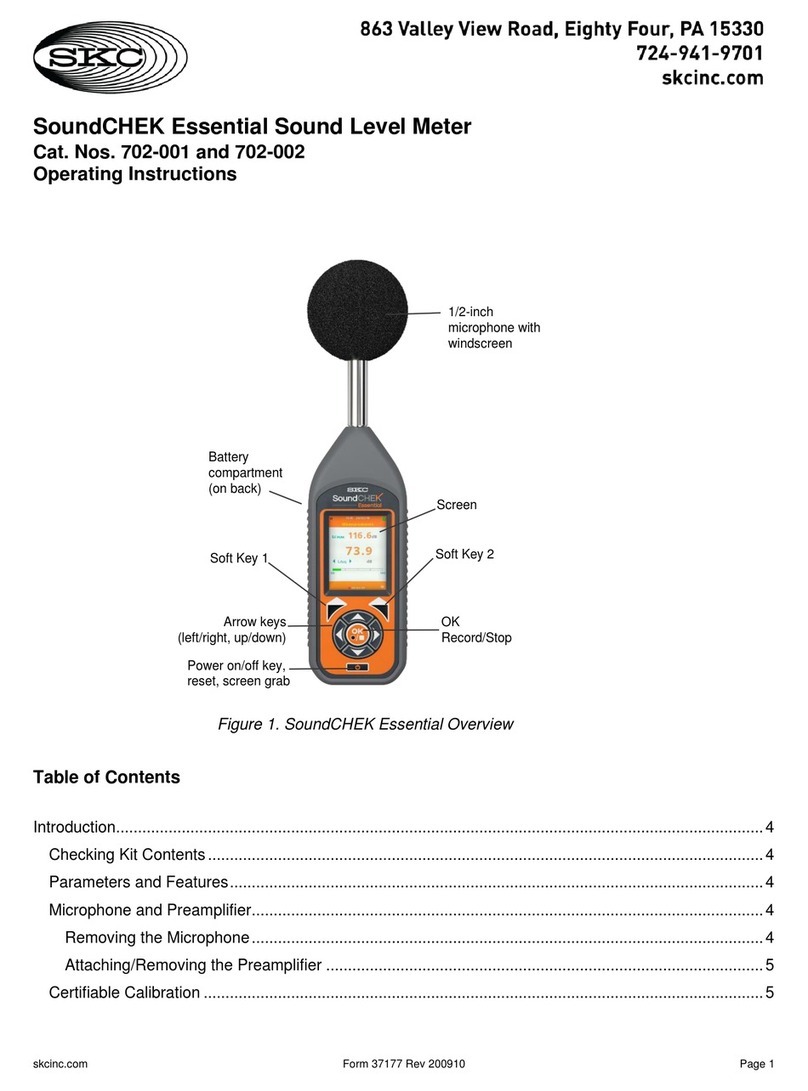

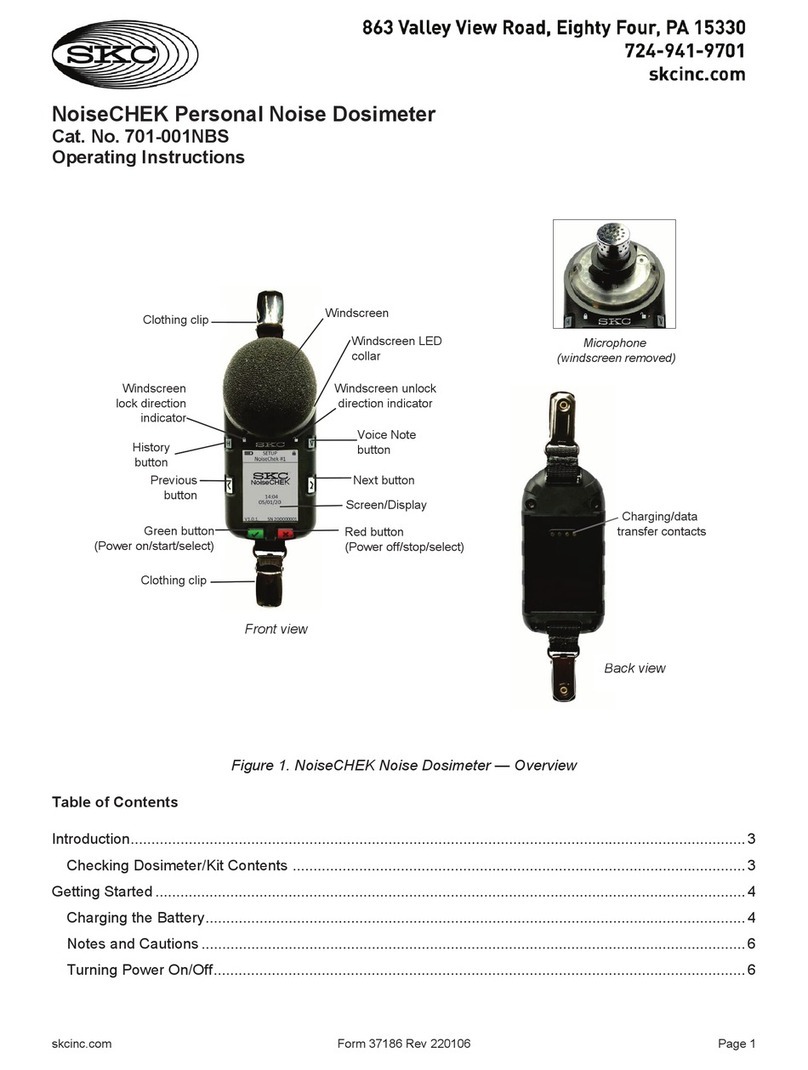

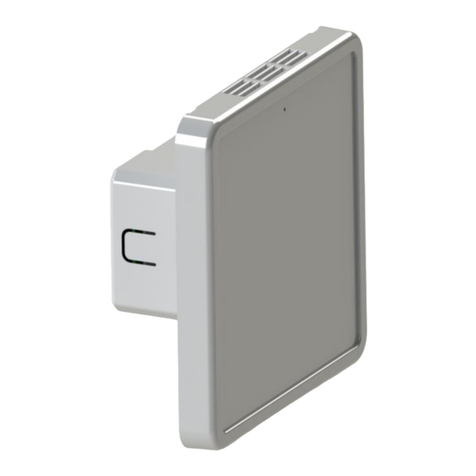

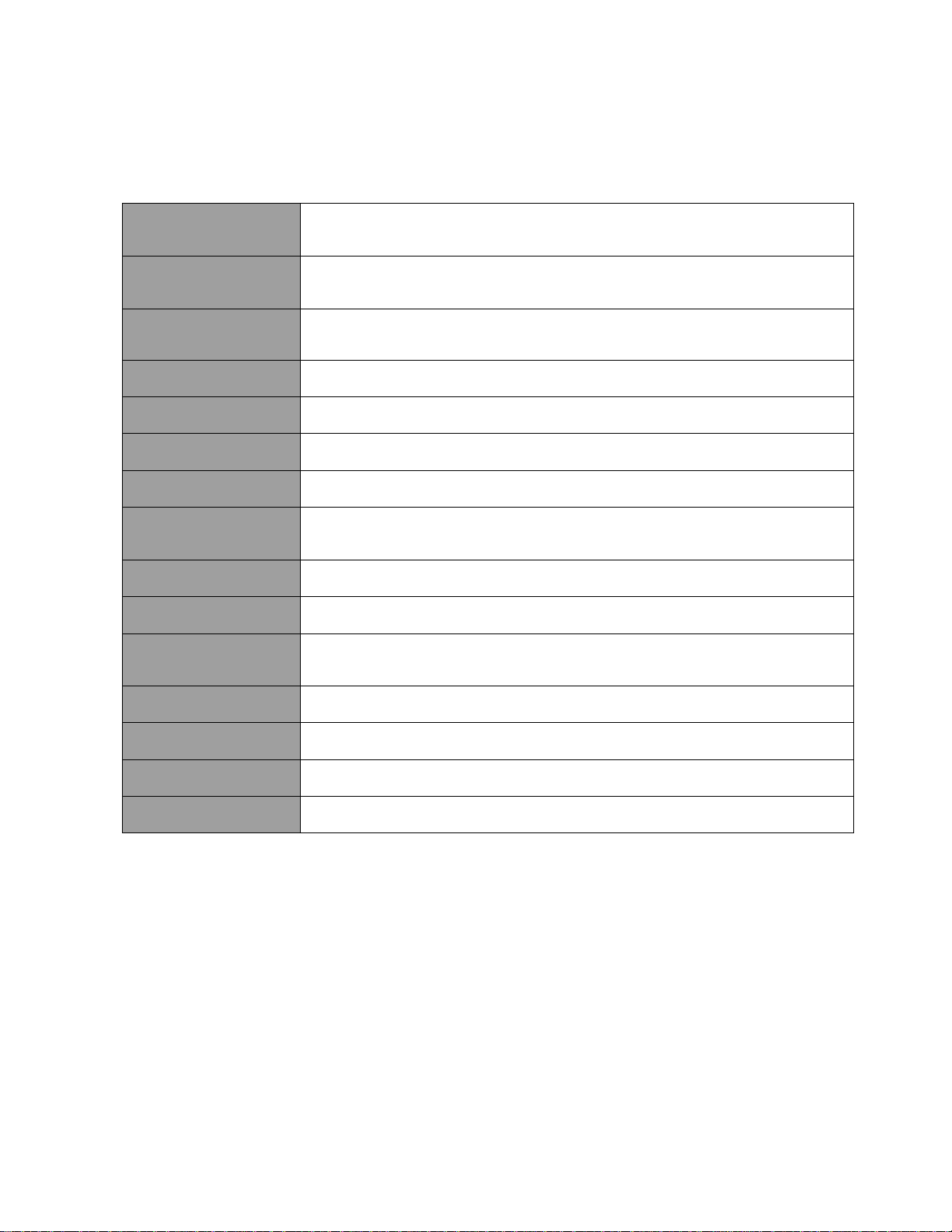

Figure 1. chek-mate Flowmeter Overview

INTRODUCTION

Description

The chek-mate® Flowmeter (Figure 1) is designed specifically for use with air sample pumps and is

available in three models as described below:

•High Flow chek-mate Flowmeter with CalChek Cat. Nos. 375-50300N, 375-50300, and

375-50300S –Flow measurement range of 5 to 30 L/min and CalChek capability. Volumetric

accuracy is 1% of reading for 5 to 30 L/min. The CalChek serial interface enables direct

communication with CalChek-ready pumps in the chek-mate flow range for single-point (single)

and multiple-point (full) automatic flow calibration.

•Medium Flow chek-mate Flowmeter with CalChek Cat. Nos. 375-0550N, 375-0550, and

375-0550S –Flow measurement range of 0.5 to 5 L/min and CalChek capability. Volumetric

accuracy is 1% of reading for 0.75 to 5 L/min and 2.5% of reading for 0.5 to 0.75 L/min. The

CalChek serial interface enables direct communication with CalChek-ready pumps in the chek-

mate flow range for single-point (single) and multiple-point (full) automatic flow calibration.

Back view

Battery compartment

cover

Battery

Front view

LCD screen

Outlet

Low battery

indicator

Inlet

On/off button

CalChek interface socket

(high flow and medium flow

models only)

skcinc.com Form 39013 Rev 210827 Page 2

•Low Flow chek-mate Flowmeter Cat. Nos. 375-00205N, 375-00205, and 375-00205S –Flow

measurement range of 20 to 500 ml/min. Volumetric accuracy is 1% of reading for 50 to

500 ml/min and 2.5% of reading for 20 to 50 ml/min.

Checking Flowmeter/Kit Contents

Use the table below to verify that you received all items associated with the Cat. No. ordered. If you are

missing items, contact SKC at 800-725-8472 (U.S. only) or 724-941-9701.

If You Ordered Cat.

No.

Your Package Should Contain

375-50300N

Flowmeter, 5 to 30 L/min, with 9-volt alkaline battery and NIST standard

traceable calibration certificate

375-50300

Flowmeter, 5 to 30 L/min, with 9-volt alkaline battery and UK standard traceable

calibration certificate

375-50300S

Flowmeter, 5 to 30 L/min, with 9-volt alkaline battery and ISO standard

traceable calibration certificate

375-0550N

Flowmeter, 0.50 to 5 L/min, with 9-volt alkaline battery and NIST standard

traceable calibration certificate

375-0550

Flowmeter, 0.50 to 5 L/min, with 9-volt alkaline battery and UK standard

traceable calibration certificate

375-0550S

Flowmeter, 0.50 to 5 L/min, with 9-volt alkaline battery and ISO standard

traceable calibration certificate

375-00205N

Flowmeter, 20 to 500 ml/min, with 9-volt alkaline battery and NIST standard

traceable calibration certificate

375-00205

Flowmeter, 20 to 500 ml/min, with 9-volt alkaline battery and UK standard

traceable calibration certificate

375-00205S

Flowmeter, 20 to 500 ml/min, with 9-volt alkaline battery and ISO standard

traceable calibration certificate

375-50300-KN

High Flow chek-mate Kit, 5 to 30 L/min, includes flowmeter, 9-volt alkaline

battery, NIST standard traceable calibration certificate, and Pulsation

Dampener Cat. No. 375-150

375-50300-KNS

High Flow chek-mate Kit, 5 to 30 L/min, includes flowmeter, 9-volt alkaline

battery, ISO standard traceable calibration certificate, and Pulsation Dampener

Cat. No. 375-150

375-0550-KN

Medium Flow chek-mate Kit, 0.50 to 5 L/min,includes flowmeter,

9-volt alkaline battery, NIST standard traceable calibration certificate, and

Pulsation Dampener Cat. No. 375-100

375-0550-KNS

Medium Flow chek-mate Kit, 0.50 to 5 L/min,includes flowmeter,

9-volt alkaline battery, ISO standard traceable calibration certificate, and

Pulsation Dampener Cat. No. 375-100

Required Equipment

✓¼-inch ID tubing for low and medium flow chek-mates

✓3/8-inch ID tubing for high flow chek-mate

skcinc.com Form 39013 Rev 210827 Page 3

GETTING STARTED

Notes and Cautions

•Allow chek-mate to equilibrate for at least 10 minutes after moving it from one temperature

extreme to another beforeuse.

•The chek-mate case is rated IP40, not as waterproof or splashproof; do not use it where

water can enter thecase.

•Ensure that fluids do not enter either the inlet or outlet.

•Protect the chek-mate from direct exposure to sunlight to prevent it from heating thecase.

•Avoid extended use of the chek-mate in areas with high levels of airborne particulates. If this

cannot be avoided, use an external inlet filter with high collection efficiency (i.e., one that

collects the majority of all dust particles) and low back pressure. SKC does not supplythis.

•Use only the specified disposable or rechargeable battery types.

•Ensure that discharged batteries are not left in the battery compartment for long periods to

prevent damage caused by electrolyte leakage.

•There are no user-serviceable parts in the chek-mate flowmeter. Opening the chek-mate

case will void the product warranty and could affect the instrument calibration. An anti-tamper

warning label is fitted to the case to indicate that the case has beenopened.

•Failure to follow these guidelines will void the warranty.

Turn On/Off

Allow the chek-mate to equilibrate for at least 10 minutes in the location where it

will be used to ensure that it has stabilized to ambient temperature.

To turn the chek-mate on or off, press the on/off button on the front. See Figure 1.

Read Battery Status on LCD

When the battery voltage drops below 8 volts as it nears the end of its life, “LOW BATTERY”will be

displayed in the upper left corner of the LCD (Figure 1). Replace the battery. See Maintenance.

When the battery voltage drops below 7 volts, the “LOW BATTERY”message displayed on

the LCD will flash on and off and the chek-mate will turn off automatically. If the chek-mate

is turned on again with the battery still in this condition, the LCD will display "bAtt LO”10

times and then turn off automatically.

skcinc.com Form 39013 Rev 210827 Page 4

OPERATION

Set/Calibrate Flow Rate

•Allow the chek-mate to equilibrate for at least 10 minutes after moving it from one temperature

extreme toanother.

•Protect the chek-mate from direct exposure to sunlight to prevent it from heating thecase.

•Ensure that fluids do not enter either the inlet or outlet.

•Avoid extended use of the chek-mate in areas with high levels of airborne particulates. See Notes

andCautions.

•chek-mate does not zero the flow reading at startup, so you can turn it on with the sample train

already connected and airflow passing through the flowmeter without affecting the accuracy of the

flow reading.

•To achieve the highest possible accuracy when calibrating pumps with flow rate ≥ 5 L/min,

Pulsation Dampener Cat. No. 375-150 is always required in line between the flowmeter outlet and

the calibration train inlet.

1. Turn on the flowmeter. The LCD screen will cycle through startup messages, “On” followed by the

upper limit of the flowmeter range (“30 L” for high flow model, “5.0 L” for medium flow model,

or “0.5 L” for low flow model) and will then indicate the current flow rate or “ ” if there is no

airflow or the flow rate isbelow the minimum display value. Note: Minimum display value

depends on the atmospheric conditions, but at 68 F (20 C) and 1 atm (1013.25 mbar), values are

5 ml/min for low flow model, 0.3 L/min for medium flow model, and 3 L/min for high flow

model. Minimum display values will behigher when the flowmeter is used at higher altitudes and

temperatures.

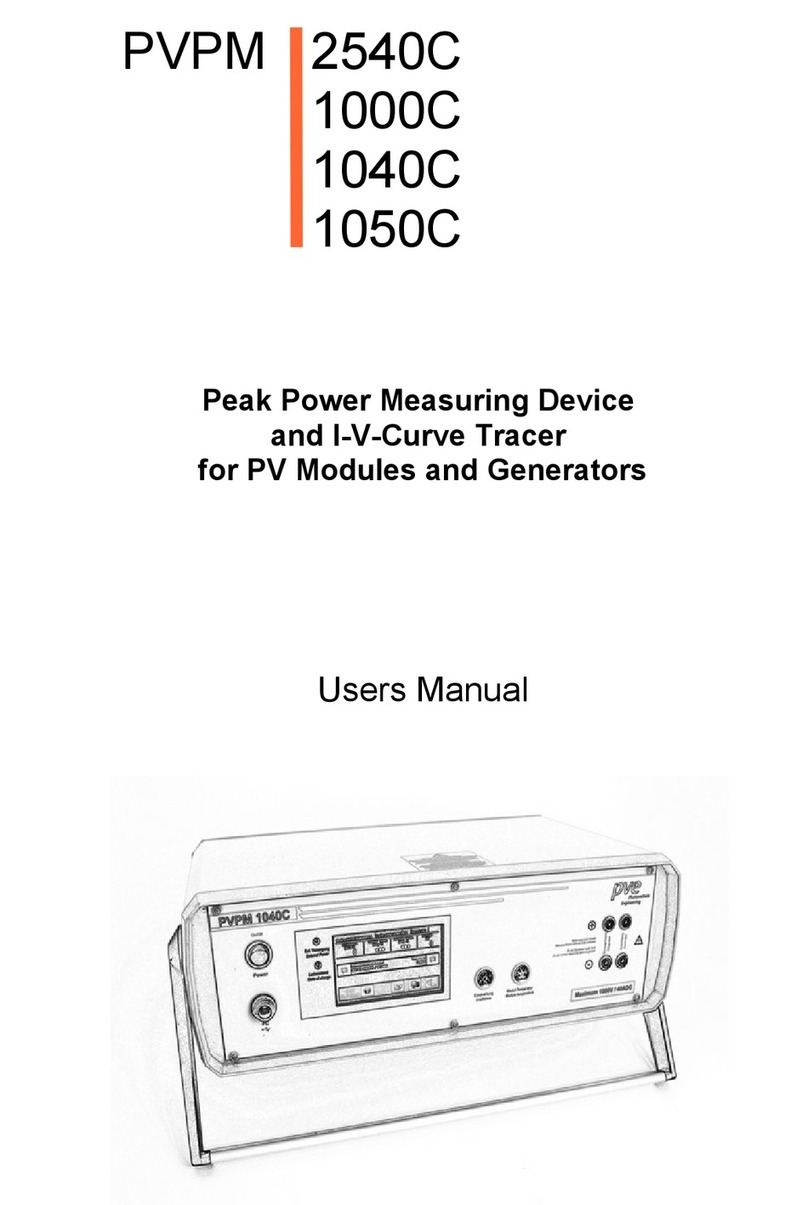

2. Prepare the calibration train. Connect the flowmeter outlet to the calibration train inlet (Figures 2

and 3):

a. For medium flow and low flow models, use flexible 1/4-inch ID tubing, and if required

by the sampler, a calibration adapter. See Figure 2.

Figure 2. Medium Flow Calibration Train

Representative

sample medium

Pump inlet

Flowmeter

outlet

skcinc.com Form 39013 Rev 210827 Page 5

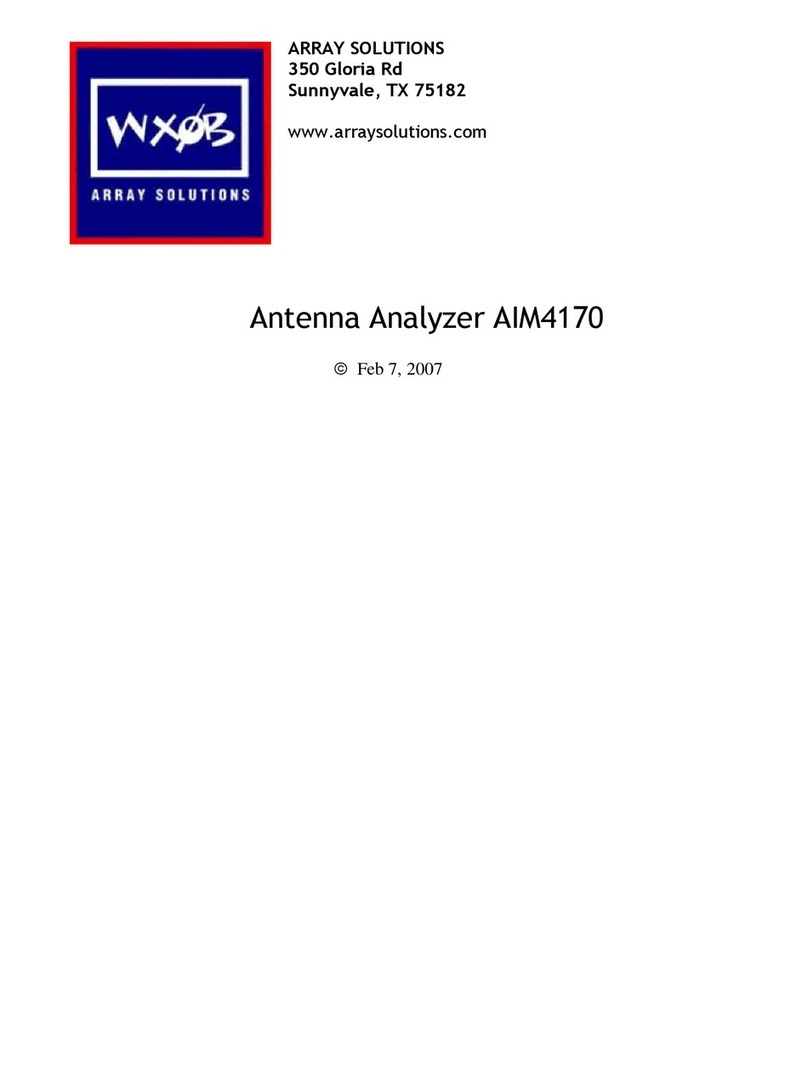

b. For high flow model, use flexible 3/8-inch ID tubing and place Pulsation Dampener Cat.

No. 375-150 in line between the flowmeter outlet and representative sample medium

inlet. If required by the sampler, use a calibration adapter. See Figure 3.

Note: If a cyclone or similar size-selective sampler does not have a calibration adapter, see

optional Jarless Calibration Method.

3. Start the sample pump and observe the flowmeter LCD until it shows a steady value. The reading

may vary around the steady value by up to ±0.05 L/min on the high flow model,

± 0.005 L/min on the medium flow model, and ± 0.5 ml/min on the low flow model. If the flow is

fluctuating, calculate and display the average flow value by activating the Average Display

function*:

a. Press and hold the on/off button for several seconds. “AVE” and then “On” will be

displayed on the LCD screen. The current flow rate will be recorded every 3.5 seconds

for 10 readings. “AVE” will appear briefly on the LCD screen followed by the average flow

value of those 10 readings. The average will be displayed for 7.5 seconds and then a

new cycle of readings will begin. This sequence takes approximately 45 seconds.

b. Reset the average reading at any time during a cycle, press and hold the on/off button for

several seconds. The next 10 readings will be used to calculate the average flow.

c. To cancel the Average Display function, turn off the flowmeter by briefly pressing the

on/off button and then turn it on again.

Run the pump for a minimum of 5 minutes to stabilize before adjusting the flowrate.

4. Adjust the sample pump to reach the desired sample flow rate.

5. Disconnect the tubing from the flowmeter outlet, taking care not to twist the tubing.

6. Turn off the flowmeter.

* For older models without Average Display function, determine the average flow value in one of two

ways: observe the highest and lowest readings and calculate the average of these two readings OR

record ten flowmeter readings and calculate the average of thereadings.

Figure 3. High Flow Calibration Train

Pulsation

dampener

Pump inlet

Flowmeter

outlet

Representative

sample medium

skcinc.com Form 39013 Rev 210827 Page 6

Jarless Calibration Method (Optional)

If a cyclone or similar size-selective sampler does not have a calibration adapter, attach the sample pump

to the chek-mate outlet (suction port) with Pulsation Dampener Cat. No. 375-100 for medium flow

chek-mate or Cat. No. 375-150 for high flow chek-mate in line between the pump and flowmeter.

Attach the sampler/media to the chek-mate inlet using the shortest length of tubing possible. Proceed with

calibration per the instructions above and pump operatinginstructions.

Perform CalChek Calibration (Medium Flow and High Flow chek-mate Models Only)

•CalChek Communication Cable Cat. No. 375-200 is required for automatic flow calibration of

AirChek TOUCHand Leland Legacypumps.

•CalChek Single-point (Single) Calibration requires sampling media in line. High Flow chek-mate

Flowmeter Cat. Nos. 50300N, 50300S, and 375-50300 also require Pulsation Dampener Cat. No.

375-150 in line between the flowmeter outlet and calibration train inlet.

•CalChek Multiple-point (Full) Calibration automatically calibrates the pump across its entire

operating range and so is performed without sampling media in line; instead, install Pulsation

Dampener Cat. No. 375-100 for medium flow chek-mate or Cat. No. 375-150 for high flow chek-

mate between the flowmeter andpump.

1. Preparethe pump perpump operatinginstructions.Note: For AirChek TOUCH pump, ensure that

the appropriatepower supply isinstalled on the pump charging cradle and the pump is seated

correctly in the cradle.

2. Turn on the flowmeter.

3. Connect the CalChek Communication Cable to the flowmeter and the pump.

a. Install one connector end of cable into CalChek interface socket on flowmeter.

Automatic Power Off Timer —chek-mate will remain on indefinitely provided that

a flow rate higher than the minimum display value (see Step 1 above) is indicated.

With a flow rate lower than the minimum display value or noairflow (“ ” indicated

on the LCD), the flowmeter will automatically turn off after 15 minutes to preserve

battery power.

skcinc.com Form 39013 Rev 210827 Page 7

b. Install other connector end of cable into CalChek port on back of charging cradle

(or e-Cradle) for AirChek TOUCH pump or into data port on top of Leland Legacy pump.

4. Prepare appropriate CalChek single or full calibration train (see Figures 4 through 7). Note: Use

1/4-inch ID flexible tubing for AirChek TOUCH and 3/8-inch ID flexible tubing for Leland Legacy.

Use a calibration adapter if required.

CalChek Single Calibration Trains

AirChek TOUCH charging cradle CalChek port

Data port

Leland Legacy data port

Representative

sample medium

CalChek

cable

Flowmeter

outlet

Power

supply

Pump inlet

Figure 4. CalChek Single Calibration Train (AirChek TOUCH Pump)

Figure 5. CalChek Single Calibration Train (Leland Legacy Pump)

Representative

sample medium

Pulsation dampener

Flowmeter

outlet

Pump inlet

CalChek cable

skcinc.com Form 39013 Rev 210827 Page 8

CalChek Full Calibration Trains

5. Initiate CalChek function from the pump per pump operating instructions.

6. When airflow through the flowmeter is detected, it automatically produces its flow rate reading via

the CalChek serial interface at 3.5-second intervals. The pump will automatically read in the flow

readings as required to complete the CalChek process and will indicate completion on its screen

display.

Figure 6. CalChek Full Calibration Train (AirChek TOUCH Pump)

Flowmeter outlet

CalChek

cable

Power

supply

Pump inlet

Pulsation dampener

375-0550

FLOW CALI BRATOR

FOR AIR SA MPLING PUMP S

0.5 - 5.0 litre/min

S/No185 44134

CALIBRATE UNDER VACUUM

MANUFACTUREDBYSKC LIMITEDUNDER A

SOLELICENSE FROM GRAHAMBLATCHFORD

www.skcltd.com

Figure 7. CalChek Full Calibration Train (Leland Legacy Pump)

CalChek cable

Pulsation

dampener

Pump inlet

Flowmeter outlet

skcinc.com Form 39013 Rev 210827 Page 9

MAINTENANCE

If the chek-mate is not going to be used for an extended period, remove the battery from the

battery compartment. Deep discharge of alkaline batteries can result in the eventual

leakage of battery electrolyte even from quality batteries and can corrode the battery

compartment terminals and potentially the flowmeter printed circuit board.

Replace the Battery

•SKC recommends using quality alkaline batteries to ensure long battery life and prevent damage

due to leaking battery electrolyte. A quality battery such as the Duracell Industrial model supplied

with the chek-mate should provide as many as 30 hours ofoperation.

•If using a rechargeable battery, it must be 8.4-volt NiMH. See Performance Profile for

specifications.

•Failure to follow these guidelines will void the warranty.

When the battery voltage drops below 8 volts as it nears the end of its life, “LOW BATTERY”will be

displayed in the upper left corner of the LCD. Replace the battery as follows:

1. Unscrewthetwocaptivescrews securingthebatterycompartmentcover using asmallPhillipshead

screwdriverandremovethe cover.

2. Lift the old battery straight up and out of the battery compartment.

3. Insert the replacement battery into the compartment, ensuring that the terminals are oriented

correctly as shown on the label at the bottom of the compartment.

4. Insert the battery compartment cover and secure it with the two captive screws. Do not

overtighten the screws.

When the battery voltage drops below 7 volts, the “LOW BATTERY”message displayed on

the LCD will flash on and off and the chek-mate will switch off automatically. If the chek-

mate is turned on again with the battery still in this condition, the LCD will display “bAtt LO”

10 times and then turn off automatically.

Calibrate the Flowmeter

SKC recommends a minimum calibration interval of one year, however, users are responsible for

determining the most suitable interval to meet their quality assurance system requirements; they should

also consider the frequency of use and operating environment.

Calibration Method

The chek-mate is designed primarily to perform flow calibration of air sample trains that incorporate an air

sample pump to provide the airflow, therefore the airflow is pulled through the chek-mate by the vacuum

generated by the air sample pump. To ensure that the SKC factory flow calibration is representative of

how the chek-mate is actually used, the flow calibration is performed under vacuum. Factory calibrations

are performed with the chek-mate connected in series with the referenceflowmeter.

SKC recommends that subsequent flow calibrations of the chek-mate flowmeter are also performed under

vacuum and with the chek-mate connected in series with the reference flowmeter. However, positive

pressure flow calibration using compressed laboratory air or nitrogen gas is also acceptable, with the

chek-mate connected in series with the reference flowmeter.

skcinc.com Form 39013 Rev 210827 Page 10

SKCCAL Serviceoffers calibration anddocumentationfor thechek-mateand otherflowmeters.The SKC

CalibrationLaboratory will calibrate the chek-mate at predefined flow rates. NIST-traceable and ISO/IEC

17025:2017 services are available. Order SKC CAL Service at www.skcinc.com/skccal.

Important notes/recommendations for third-party flow calibrations:

•Install a new battery in the chek-mate before sending it for third-party calibration.

•Enclose a copy of these instructions with the chek-mate when sending it to a third-party

calibration laboratory.

•Airflow is indicated in ml/min on Cat. Nos. 375-00205N, 375-00205S, and 375-00205 and in L/min

on Cat. Nos. 375-0550N, 375-0550, 375-0550S, 375-50300N, 375-50300, and 375-50300S at the

current ambient temperature and atmospheric pressure, therefore, the reference flow

measurement must be corrected to these conditions for comparison with the chek-mate indicated

flow reading.

•Factory flow calibration is performed under vacuum, therefore, the calibration gas used is ambient

air with relative humidity of 50 ± 20%. When performing positive pressure flow calibrations using

compressed dry laboratory air or nitrogen gas, correct for the difference in gas density.

•When performing flow calibration under vacuum with the chek-mate connected in series with the

referenceflowmeter, connect the chek-mate with its inlet open to atmosphere.

•When performing flow calibration under positive pressure with the chek-mate connected in series

with the reference flowmeter, connect the chek-mate with its outlet open to atmosphere.

skcinc.com Form 39013 Rev 210827 Page 11

ACCESSORIES/REPLACEMENT PARTS

CalChek Communication Cable, required for automatic

calibration of AirChek TOUCH and Leland Legacy Sample Pumps 375-200

Pulsation Dampener, required for use with Cat. Nos. 375-0550N,

375-0550, and 375-0550S for CalChek full calibration of AirChek TOUCH

Sample Pumps 375-100

Pulsation Dampener, required for use with Cat. Nos. 375-50300N,

375-50300, and 375-50300S for calibration of high flow pumps and

CalChek calibration of Leland Legacy Sample Pumps 375-150

Battery, 9-volt alkaline P37500

SKC Limited Warranty and Return Policy

SKC products are subject to the SKC Limited Warranty and Return Policy, which provides SKC’s sole liability and

the buyer’s exclusive remedy. To view the complete SKC Limited Warranty and Return Policy, go to

skcinc.com/warranty.

skcinc.com Form 39013 Rev 210827 Page 12

APPENDIX

Performance Profile

Flow Measurement

Range

High flow: 5 to 30 L/min

Medium flow: 0.5 to 5 L/min

Low flow: 20 to 500 ml/min

Airflow Display

Resolution

High flow: 0.01 L/min

Medium flow: 0.001 L/min

Low flow: 0.01 up to 100 ml/min and 0.1 above 100 ml/min

Airflow Accuracy

± 1% of reading for 5 to 30 L/min (high flow), 750 to 5000 ml/min (medium flow), and

50 to 500 ml/min (low flow)

2.5% outside of above ranges for medium flow and low flow models

Operating Temperature

Range

32 to 104 F (0 to 40 C)

Operating Atmospheric

Pressure Range

20.7 to 32.2 in Hg (700 to 1090 mbar)

Operating Altitude

Sea level to approximately 10,000 ft (3050 m) above sea level

Dimensions

7.1 x 3.3 x 1.3 in (18 x 8.3 x 3.3 cm)

Weight

High flow: 8.6 oz (244 gm)

Medium flow: 8.3 oz (236 gm)

Low flow: 8.2 oz (232 gm)

Tubing

Medium and low flow: Requires 1/4-in ID tubing

High flow: Requires 3/8-in ID tubing

Enclosure IP Rating

IP40

Power Supply

9-V alkaline (disposable) PP3/6LR61/1604A or equivalent - should provide

30 hrs of operation; or 8.4-V NiMH (rechargeable) PP3/6HR1/8.4H5 or

equivalent

Low Battery

When battery voltage drops below 8 V, LCD displays LOW BATTERY.

Low Battery Fault

When battery voltage drops below 7 V, flowmeter shuts down.

Automatic Power Off

Timer

15 min

Certifications

CE marked

Other manuals for chek-mate 375 series

1

This manual suits for next models

13

Table of contents

Other SKC Measuring Instrument manuals