SKC chek-mate User manual

www.skcltd.com

chek-mate Air Flowmeter

Operating Instructions

This manual covers the following models:

375-00205 / 375-0550

Page 2 007-03-004 Issue D www.skcltd.com

Purchase Details and Service Record

Thank you for choosing an SKC product. Your purchase is covered by our warranty, details of which can

be found inside the rear cover of this manual.

Product Model Number Product Serial Number Date of Purchase

SKC recommends a minimum service interval of one year for this product. The first service is due one

year from the date of purchase, and then at yearly intervals on this date. However, it is the responsibility

of the user to perform a risk assessment to determine the necessary frequency of servicing that is

required.

Service Date Service Date Service Date

159

2 6 10

3 7 11

4 8 12

Please note that SKC Ltd is the only authorised service centre in the UK, guaranteeing you access

to the full range of genuine SKC replacement parts. For all other areas a full list of SKC-approved

distributors and service centres can be found at www.skcltd.com

www.skcltd.com 007-03-004 Issue D Page 1

Contents

Specifications................................................................................................................2

Introduction to the chek-mate Flowmeter........................................................................4

General Information .......................................................................................................6

Diagram of the chek-mate Flowmeter .............................................................................8

Using the chek-mate Flowmeter ...................................................................................10

Battery Care................................................................................................................14

Calibration of the chek-mate Flowmeter........................................................................16

Notes..........................................................................................................................18

Warranty .....................................................................................................................20

Page 2 007-03-004 Issue D www.skcltd.com

Specifications

Parameter Model 375-00205 Model 375-0550

Airflow range 20 ml/min to 500 ml/min 0.5 litre/min to 5.0 litre/min

Airflow display resolution < 100 ml/min : 0.01 ml/min

>= 100 ml/min : 0.1 ml/min 0.001 litre/min

Airflow accuracy

20 to 50 ml/min : ±2.5% of

reading

50 to 500 ml/min : ±1% of

reading

0.5 to 0.75 litre/min : ±2.5% of

reading

0.75 to 5.0 litre/min : ±1% of

reading

Weight 232 g (8.2 oz) 236 g (8.3 oz)

Operating temperature range 0 °C to 40 °C (32 °F to 104 °F)

Operating atmospheric

pressure range 700 mbar to 1090 mbar (20.7 inHg to 32.2 inHg)

Operating altitude Sea level to approximately 3050 m (10000 ft) above sea level

Enclosure IP rating IP40

Battery 9V alkaline disposable PP3 / 6LR61 / 1604A or equivalent, or

8.4V NiMH rechargeable PP3 / 6HR61 / 8.4H5 or equivalent

Automatic power off timer 15 minutes

www.skcltd.com 007-03-004 Issue D Page 3

Specifications

83.5mm ( 3.3”) 33.5mm ( 1.3”)

178.5mm ( 7.1”)

Note:

SKC Ltd reserves the right to make changes to the specification and design of this product at any time

without prior notice to the end user.

The chek-mate flowmeter is manufactured by SKC Ltd under a sole license from Graham Blatchford.

Page 4 007-03-004 Issue D www.skcltd.com

Introduction to the chek-mate Flowmeter

The chek-mate flowmeter is designed specifically for use in the occupational health and

safety industry for the purpose of calibrating the air flow rate into air sample trains. Its flow

range makes it suitable for use across a broad range of air sampling methods and with a

broad range of air samplers, sample media and air sample pumps.

Operating Principle

The chek-mate is an orifice type flowmeter. Its reading is determined by measuring the

pressure drop across the orifice caused by the flow of air through the orifice, using a

differential pressure sensor. This type of flowmeter gives a mass flow reading meaning

that the pressure drop across the orifice will be constant for a given mass flow of gas

independent of the density of the gas.

The chek-mate also incorporates an ambient temperature sensor and an atmospheric

pressure sensor and uses the readings of these sensors to correct the mass flow reading

generated by measuring the pressure drop across the orifice to the current ambient

temperature and atmospheric pressure. This correction provides an indicated flow reading

that is equivalent to a volumetric flow reading when the inlet of the flowmeter is open to

atmosphere.

CalChek Pump Calibration

The 375-0550 chek-mate model incorporates a CalChek serial interface which enables it to

communicate directly with SKC AirChek 2000, AirChek 3000 and AirChek Touch pumps, in

www.skcltd.com 007-03-004 Issue D Page 5

Introduction to the chek-mate Flowmeter

order to perform automatic flow calibration of these pumps.

The chek-mate is connected to the pump using a CalChek communication cable (P/N 375-

200) which plugs into a socket on the right hand side of the chek-mate, and to the serial

interface port on the pump.

The chek-mate automatically outputs its flow rate reading via the CalChek serial interface at

3.5 second intervals when airflow through the chek-mate is present.

Refer also to the specific pump user manual for detailed instructions on performing CalChek

calibration.

Page 6 007-03-004 Issue D www.skcltd.com

General Information

1) Care of the chek-mate Flowmeter

• Use only the specified disposable or rechargeable battery types.

• Ensure that discharged batteries are not left in the battery compartment for long periods

to prevent damage caused by electrolyte leakage.

• Avoid extended use of the flowmeter in areas with high levels of airborne particulates.

An external inlet filter (not SKC supply) can be used with the chek-mate flowmeter if

this cannot be avoided. Any filter used should have high collection efficiency (collect the

majority of all dust particles) and low back pressure.

• Ensure that fluids do not enter the flowmeter inlet or outlet ports.

• If the flowmeter has been stored in a cold location and is immediately taken to a hot,

humid location, do not use the flowmeter until it has stabilised to the higher ambient

temperature to prevent condensation forming inside the flowmeter.

• The flow meter case is IP40 rated: it is not rated as waterproof or splashproof and,

therefore, must not be used where it is possible for water to enter the casing.

• There are no user serviceable parts within chek-mate flowmeter. Opening of the chek-

mate case will void the product warranty and could affect the instrument calibration. An

anti-tamper warning label is fitted to the case which will identify that the case has opened.

Warning - Failure to follow these guidelines will void the product warranty.

www.skcltd.com 007-03-004 Issue D Page 7

General Information

2) The WEEE Directive

This product is marked with the crossed out wheelie bin symbol, which identifies that it falls

within the scope of the European Directive 2002/96/EC on waste electrical and electronic

equipment (WEEE). At the end of it’s useful life, this product must be disposed of in an

environmentally sound way as detailed in the Directive. Note that the battery must be

separated from the product and disposed of as detailed in the Batteries Directive (see

below). Please contact your local distributor or SKC Ltd for further details on how to comply

with the requirements of the WEEE Directive. SKC Ltd’s producer registration number is

WEE/KH0054TQ.

3) The Batteries Directive

The alkaline disposable battery supplied with this flowmeter and any spare

batteries purchased for it, fall within the scope of the European Directive

2006/66/EC on batteries and accumulators and waste batteries and

accumulators. At the end of the battery’s life it must be disposed of in an

environmentally sound way as detailed in the Directive. Please contact

your local distributor or SKC Ltd for further details on how to comply with

the requirements of the Batteries Directive. SKC Ltd’s batteries producer

registration number is BPRN00454.

Page 8 007-03-004 Issue D www.skcltd.com

2 1 5 4

367

8

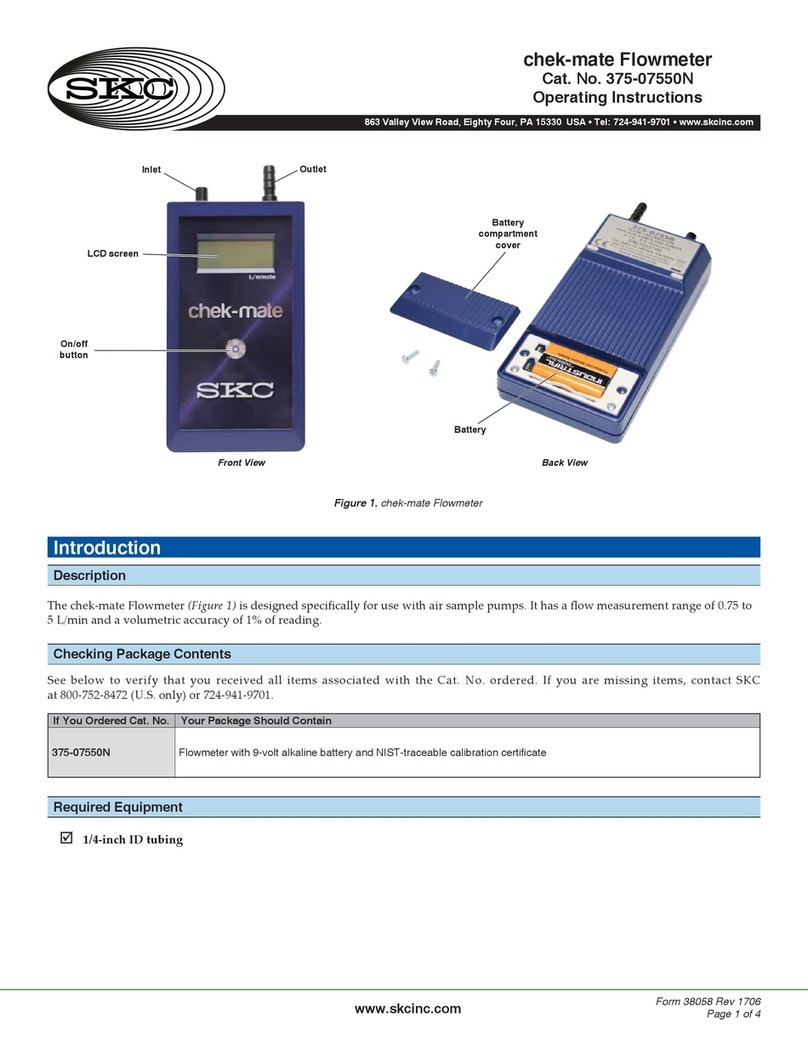

Diagram of the chek-mate Flowmeter

www.skcltd.com 007-03-004 Issue D Page 9

Key to Flowmeter Diagram

1. LCD screen

2. Low battery indicator

3. On/Off button

4. Inlet port

5. Outlet port

6. Battery compartment cover

7. Battery

8. CalChek interface socket (375-0550 model only)

Page 10 007-03-004 Issue D www.skcltd.com

1) Setting an Air Sample Train Flow Rate

a. Ensure that the chek-mate flowmeter has been in the location where it is to be used for

enough time for its temperature to stabilise to the ambient temperature. A minimum of

10 minutes is recommended. Shield the flowmeter from exposure to direct sunlight to

prevent heating of the case by the sunlight.

b. Switch on the flowmeter by pressing the on/off button on the front. The LCD screen will

cycle through the startup messages ‘On’ followed by the flow meter range (‘0.5 L’ for the

375-00205 model and ‘5.0 L’ for the 375-0550 model), and will then indicate the current

flow rate or ‘- - - -’ if there is no airflow or the flow rate is below the minimum display

value. The minimum display value is dependent on the atmospheric conditions, but at

20 °C and 1013.25 mbar (1atm) the values are 5 ml/min for the 375-00205 model and

0.3 litre/min for the 375-0550 model. The minimum display value will be higher when the

chek-mate is used at higher altitudes and temperatures.

Note: The chek-mate flowmeter does not perform a zero of the flow reading at startup

therefore it is also possible to switch on the flowmeter with the air sample train already

connected and airflow passing through the flowmeter without affecting the accuracy of

the flow reading.

c. Connect the flowmeter outlet hosetail to the inlet of the air sample train using a length

of flexible tubing (1/4” or 6.5mm bore tubing is recommended) and calibration adapter

if required.

Using the chek-mate Flowmeter

www.skcltd.com 007-03-004 Issue D Page 11

Using the chek-mate Flowmeter

d. Start the air sample pump and observe the reading of the flowmeter until it achieves

a steady value. The reading may fluctuate by a small amount either side of the steady

value (up to ±0.5 ml/min on the 375-00205 model and ± 0.005 litre/min on the 375-0550

model).

If the flow is fluctuating there are two suggested options to determine the average flow

value -

• Observe the highest and lowest readings and calculate the average of these two

readings, or

• Note 10 chek-mate readings and calculate the average of the 10 readings.

Note: It is recommended to allow the pump to run for a minimum of 5 minutes to

stabilise before adjusting the flow rate.

e. Adjust the air sample pump to give the desired sample airflow rate.

f. Disconnect the tubing from the flowmeter outlet hosetail taking care to pull the tubing

in line with the axis of the hosetail and not to twist the tubing. Switch off the flowmeter

using the on/off button.

2) Automatic Power Off Timer

The chek-mate flowmeter will remain on indefinitely provided that an airflow rate above the

minimum display value is indicated. With an airflow rate lower than the minimum display

Page 12 007-03-004 Issue D www.skcltd.com

Using the chek-mate Flowmeter

value or no airflow (‘- - - -’ indicated on the screen) the flowmeter will automatically switch

off after 15 minutes to preserve battery power.

3) CalChek Flow Calibration

a. To perform automatic flow calibration of SKC AirChek 2000, AirChek 3000 and AirChek

Touch pumps using the 375-0550 chek-mate, the optional CalChek communication

cable (P/N 375-200) is required. Plug one end of the cable into the socket on the right

hand side of the chek-mate flowmeter and the other end of the cable into the serial

interface socket on the pump (the socket is mounted on the charging cradle for the

AirChek Touch pump and the pump must be fitted to the charging cradle to perform

CalChek calibration).

b. When performing a single point CalChek calibration of a complete sample train connect

the outlet port of the chek-mate to the inlet of the sample train (using a calibration

adapter if required).

c. A full CalChek calibration, which automatically calibrates the pump across its entire

operating range, is performed with no sample train connected between the chek-mate

and the pump. A pulsation dampener (P/N 375-100) is therefore required to be connected

in place of the sample train between the chek-mate outlet port and the pump inlet port.

d. The CalChek function is initiated on the pump. Refer to the specific pump users manual

for detailed instructions on this. When airflow through the chek-mate is detected the

www.skcltd.com 007-03-004 Issue D Page 13

Using the chek-mate Flowmeter

chek-mate automatically outputs its flow readings via the CalChek interface at 3.5

second intervals.

e. The pump will automatically read in the chek-mate flow readings as required to complete

the CalChek process, and completion of the process will be indicated on the pump

display.

Page 14 007-03-004 Issue D www.skcltd.com

Battery Care

• SKC recommends the use of quality alkaline primary (disposable) batteries to ensure

long battery life and prevent damage due to leaking battery electrolyte. A quality primary

battery such as the Duracell Industrial model supplied with the flowmeter should provide

as much as 30 hours of operation.

• When the battery voltage drops below 8V as it nears the end of its life, the flowmeter

LCD indicates ‘LOW BATTERY’. It is recommended to replace the battery at this point

to ensure uninterrupted use of the flowmeter. When the battery voltage drops further

to below 7V the LCD ‘LOW BATTERY’ indication will flash on/off and the flowmeter will

automatically switch off. If the flowmeter is switched on again with the battery in this

condition, the LCD will indicate ‘bAtt’ ‘LO’ ten times and then automatically switch off.

• To replace the battery, unfasten the two captive screws securing the battery compartment

cover using a Pozi-drive size 1 screwdriver and remove the battery compartment cover.

Lift the old battery straight up out of the battery compartment. Fit the replacement

battery ensuring the correct orientation of the terminals as detailed on the label at the

bottom of the battery compartment. Fit the battery compartment cover and secure with

the two captive screws taking care not to overtighten the screws.

• The SKC replacement primary (disposable) battery part number is P37500.

• NiMH secondary (rechargeable) batteries may also be used (not available from SKC), but

it must be ensured that the battery used is an 8.4V nominal type, and not a 7.2V nominal

type which are also manufactured.

www.skcltd.com 007-03-004 Issue D Page 15

Battery Care

• The European Batteries Directive and equivalent legislation in other countries requires

that all batteries are disposed of correctly at the end of their working life. This means that

they must be collected and treated separately from other waste.

• It is recommended to remove the battery from the battery compartment if the flowmeter

is not to be used for an extended period of time. Deep discharge of alkaline batteries

can result in the eventual leakage of battery electrolyte even from quality batteries and

can cause corrosion of the battery compartment terminals and potentially the flowmeter

printed circuit board.

Page 16 007-03-004 Issue D www.skcltd.com

Calibration Interval

SKC recommend a minimum calibration interval of one year for this product. However, it is

the responsibility of the user to determine the most suitable interval in order to meet their

quality assurance system requirements. Consideration should also be given to the frequency

of use and operating environment when determining the calibration interval.

Calibration Method

The chek-mate is primarily designed to perform flow calibration of air sample trains which

incorporate an air sample pump to provide the airflow, therefore the airflow is pulled through

the chek-mate by the vacuum generated by the air sample pump.

To ensure that the SKC factory flow calibration is representative of how the chek-mate

is actually used the flow calibration is performed under vacuum. Factory calibrations are

performed by applying the airflow alternately to the chek-mate and reference flowmeters.

SKC recommend that subsequent flow calibrations of the chek-mate flowmeter are also

performed under vacuum and applying the airflow alternately to the chek-mate and reference

flowmeters. However, positive pressure flow calibration using compressed laboratory air or

nitrogen gas is also acceptable, and series connection of the chek-mate and reference

flowmeters under either vacuum or positive pressure are also acceptable.

Calibration of the chek-mate Flowmeter

www.skcltd.com 007-03-004 Issue D Page 17

Calibration of the chek-mate Flowmeter

Important notes for third party flow calibrations:

1. It is strongly recommended to send a copy of this instruction manual with the chek-mate

unit when sending to a third party calibration laboratory.

2. It is recommended to fit a new battery prior to sending the chek-mate for third party

calibration.

3. The chek-mate indicates air flow in ml/min on model 375-00205 and litre/min on model

375-0550, at the current ambient temperature and atmospheric pressure, therefore the

reference flow measurement must be corrected to these conditions for comparison with

the chek-mate indicated flow reading.

4. The factory flow calibration is performed under vacuum therefore the calibration gas

used is ambient air with relative humidity of 50% ±20% RH. When performing positive

pressure flow calibrations using compressed dry laboratory air or nitrogen gas, the

difference in gas density must be corrected for.

5. When performing flow calibration under vacuum with the chek-mate connected in series

with the reference flow meter the chek-mate should be connected with its inlet port open

to atmosphere.

6. When performing flow calibration under positive pressure with the chek-mate connected

in series with the reference flow meter the chek-mate should be connected with its outlet

port open to atmosphere.

Page 18 007-03-004 Issue D www.skcltd.com

Notes

Other manuals for chek-mate

1

Table of contents

Other SKC Measuring Instrument manuals

SKC

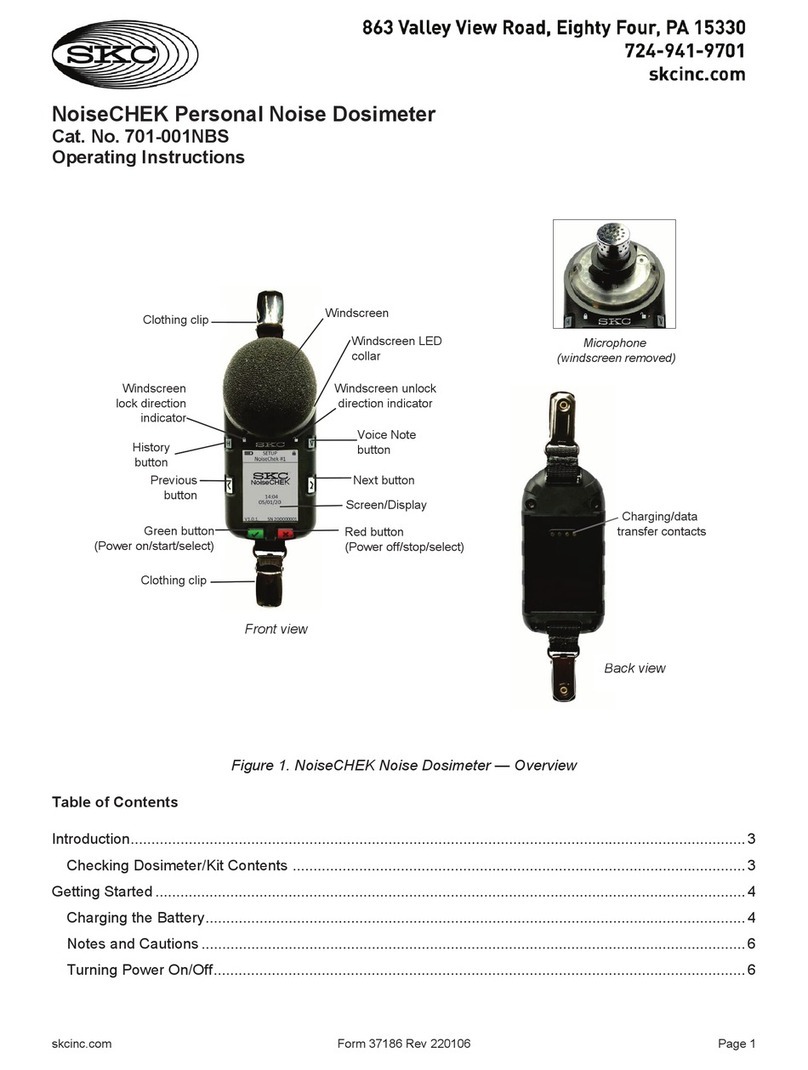

SKC NoiseCHEK User manual

SKC

SKC Leland Legacy User manual

SKC

SKC chek-mate 375 series User manual

SKC

SKC chek-mate 375 series User manual

SKC

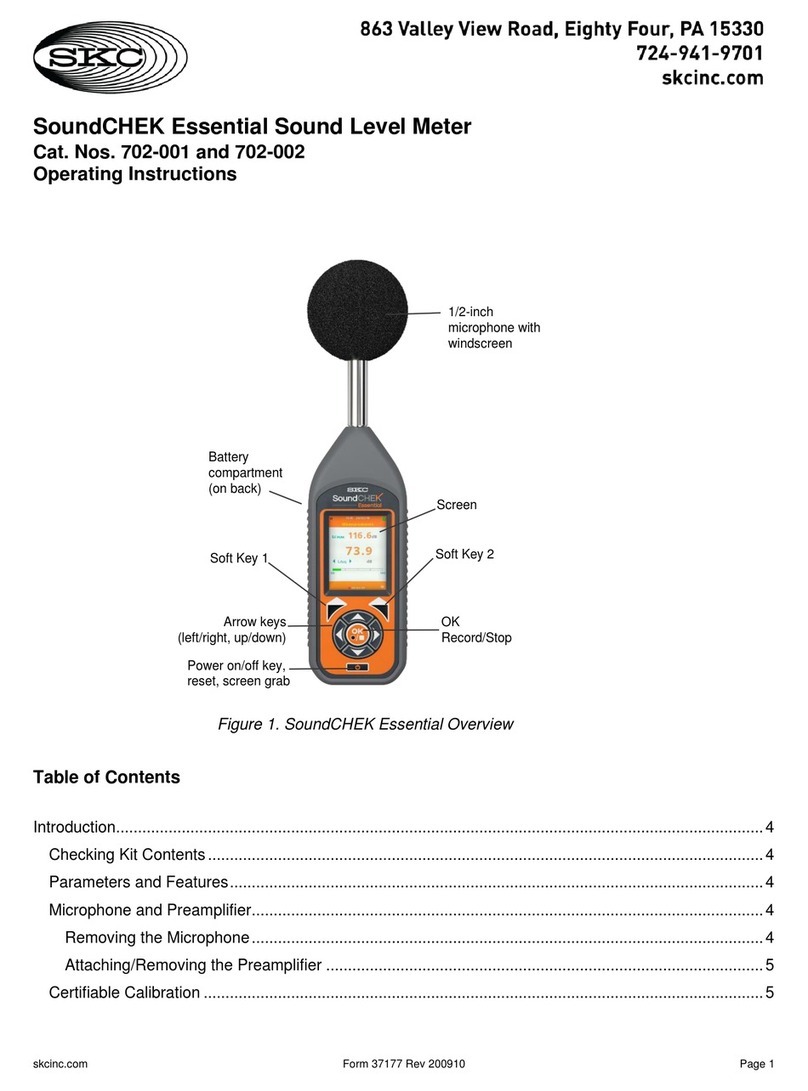

SKC SoundCHEK User manual

SKC

SKC 701-001NBS User manual

SKC

SKC chek-mate User manual

SKC

SKC NoiseCHEK User manual

SKC

SKC 224-6580 User manual

SKC

SKC SoundCHEK 702 Series User manual