Form 39013 Rev 1905

Page 5 of 6

www.skcinc.com

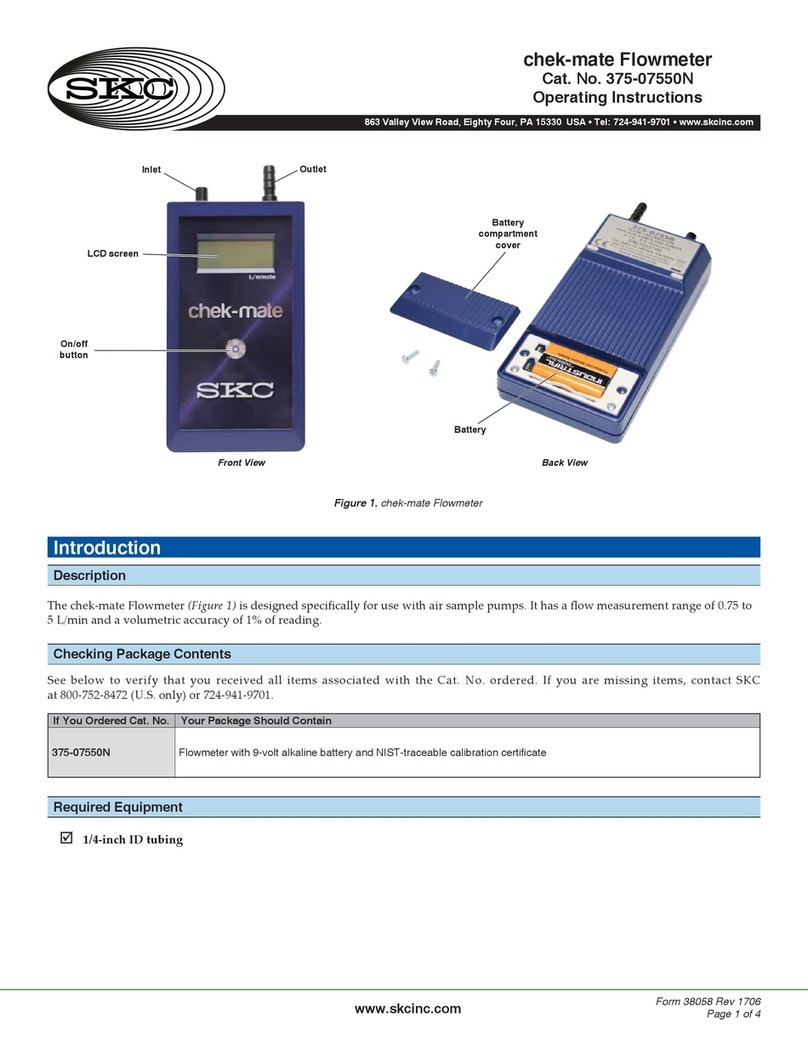

Calibrate the chek-mate Flowmeter

SKC recommends a minimum calibration interval of one year, however, users are responsible for determining the most suitable interval

to meet their quality assurance system requirements; they should also consider the frequency of use and operating environment.

Calibration Method

The chek-mate is designed primarily to perform flow calibration of air sample trains that incorporate an air sample pump to

provide the airflow, which is pulled through the chek-mate by the vacuum generated by the air sample pump. To ensure that

the SKC factory flow calibration is representative of how the chek-mate is actually used, the flow calibration is performed under

vacuum. Factory calibrations are performed by applying the airflow alternately to the chek-mate and reference flowmeters.

SKC recommends that subsequent flow calibrations of the chek-mate flowmeter are also performed under vacuum and by

applying the airflow alternately to the chek-mate and reference flowmeters. However, positive pressure flow calibration using

compressed laboratory air or nitrogen gas is also acceptable, and series connection of the chek-mate and reference flowmeters

under either vacuum or positive pressure is also acceptable.

SKC CAL Service offers calibration and documentation for the chek-mate and other flowmeters. The SKC Calibration Laboratory

will calibrate the chek-mate at predefined flow rates. NIST-traceable and ISO/IEC 17025:2005 services are available. Order

SKC CAL Service at www.skcinc.com.

Important notes/recommendations for third-party flow calibrations:

• Before sending the chek-mate for third-party calibration, install a new battery in it.

• Enclose a copy of these instructions with the chek-mate when sending it to a third-party calibration laboratory.

• Airflow is indicated in ml/min on Cat. Nos. 375-00205N and 375-00205 and in L/min on Cat. Nos. 375-0550N and 375-0550 at

the current ambient temperature and atmospheric pressure; therefore, the reference flow measurement must be corrected to

these conditions for comparison with the chek-mate indicated flow reading.

• Factory flow calibration is performed under vacuum, therefore, the calibration gas used is ambient air with relative

humidity of 50 ± 20%. When performing positive pressure flow calibrations using compressed dry laboratory air or nitrogen

gas, correct for the difference in gas density.

• When performing flow calibration under vacuum with the chek-mate connected in series with the reference flowmeter,

connect the chek-mate with its inlet open to atmosphere.

• When performing flow calibration under positive pressure with the chek-mate connected in series with the reference

flowmeter, connect the chek-mate with its outlet open to atmosphere.

Accessories/Replacement Parts

CalChek Communication Cable, for use with Cat. Nos. 375-0550N and 375-0550, required for automatic flow

calibration of AirChek TOUCH Sample Pump

375-200

Pulsation Dampener, for use with Cat. Nos. 375-0550N and 375-0550, required for CalChek Full Calibration of

AirChek TOUCH Sample Pump

375-100

Battery, 9-volt alkaline P37500

SKC Limited Warranty and Return Policy

SKC products are subject to the SKC Limited Warranty and Return Policy, which provides SKC’s sole liability and the buyer’s exclusive

remedy. To view the complete SKC Limited Warranty and Return Policy, go to hp://www.skcinc.com/warranty.