SKC Split 2 User manual

www.skcltd.com

Operating Instructions

Split 2 Real Time Dust Monitor

This manual covers the following model:

770-300A

Page 2 770-300M Issue E www.skcltd.com

Purchase Details and Service History

Thank you for choosing an SKC product. Your purchase is covered by our warranty, details of

which can be found inside the rear cover of this manual.

Product Model Number Product Serial Number Date of Purchase

770-300A

SKC recommends a minimum service interval of one year for this product. The first service

is due one year from the date of purchase, and then at yearly intervals on this date. However,

it is the responsibility of the user to perform a risk assessment to determine the necessary

frequency of servicing that is required.

Service Date Service Date Service Date

159

2 6 10

3 7 11

4 8 12

Please note that SKC Ltd are the only authorised service centre in the UK, guaranteeing you

access to the full range of genuine SKC replacement parts. For all other areas a full list of

SKC approved distributors and service centres can be found at www.skcltd.com

SKC UK service centre -

Tel: +44 (0)1258 480188 Fax: +44 (0)1258 480184 Email: info@skcltd.com

www.skcltd.com 770-300M Issue E Page 1

Contents

Specifications ........................................................................................................................................ 2

1) Specifications ............................................................................................................................ 2

2) Kit Contents............................................................................................................................... 2

3) Features .................................................................................................................................... 3

General Information .............................................................................................................................. 4

1) Care of the Split2 Monitor......................................................................................................... 4

2) Sampling Methods .................................................................................................................... 4

3) The WEEE Directive................................................................................................................... 4

4) The Batteries Directive ............................................................................................................. 4

Split2 Monitor Diagram ......................................................................................................................... 5

Sensor Head Exploded Diagram............................................................................................................ 6

Getting Started....................................................................................................................................... 7

1) Charging the Battery Pack........................................................................................................ 7

2) The On/Off Push Button ............................................................................................................ 7

3) The Keypad................................................................................................................................ 7

4) Standby Mode............................................................................................................................ 8

5) Navigating the Menu Options.................................................................................................... 8

Initial Setup of the Split2 Monitor........................................................................................................ 10

1) Setting the Time and Date ...................................................................................................... 10

2) Clearing the Data Logging Memory........................................................................................ 11

Passive or Active Sampling.................................................................................................................. 13

1) Passive Sampling.................................................................................................................... 13

2) Active Sampling....................................................................................................................... 13

Setup of the Split2 Monitor for Sampling............................................................................................ 15

1) Set the Flow Rate When Performing Active (Pumped) Sampling .......................................... 15

2) Check the Battery Status ........................................................................................................ 16

3) Set the Particle Size................................................................................................................ 16

4) Set the Sample Rate ............................................................................................................... 17

5) Set the Alarm Concentration Level......................................................................................... 18

6) Perform an Auto-Zero............................................................................................................. 19

Sampling with the Split2 Monitor........................................................................................................ 20

1) Mounting the Split2 Monitor on the Worker ........................................................................... 20

2) Initiate Sampling..................................................................................................................... 20

3) Low Battery Function .............................................................................................................. 21

4) Finish Sampling ...................................................................................................................... 22

Reviewing the Sample Data................................................................................................................. 23

Setting a Custom Scale Factor ............................................................................................................ 25

Downloading the Sample Data to a PC................................................................................................ 27

Maintenance of the Split2 Monitor ...................................................................................................... 28

1) Checking the Calibration Span ............................................................................................... 28

2) Care of the Battery Pack......................................................................................................... 29

3) Cleaning the Sensor Optics..................................................................................................... 30

Split2 Monitor Replacement Parts and Accessories........................................................................... 32

1) Replacement Parts ................................................................................................................. 32

2) Accessories ............................................................................................................................. 32

Warranty Information .......................................................................................................................... 33

Page 2 770-300M Issue E www.skcltd.com

Specifications

1) Specifications

• Calibration: NIOSH method 0600 using ISO 12103-1 A2 Fine Test Dust

• Accuracy: ±10%

• Precision: 0.02 mg/m³

• Sensing range: 0.01 to 200 mg/m³

• Particle size ranges:

0.1 to 10 µm Respirable

0.1 to 50 µm Thoracic*

0.1 to 100 µm Inhalable

• Recording time: 1 second, 1 minute and 10 minute averages

• Memory: 21,500 data points

• Locations: 999 storage locations

• Data display: 20 character, 4 line backlit LCD

• Output: RS-232

• Operating temperature: 0°C to +50°C

• Humidity range: 95% non-condensing

• Casing IP rating: IP20 (Finger proof - Split 2 is not designated as waterproof)

• Battery: 7.2V 1.15Ah NiMH rechargeable battery

• Run time: 8 hours minimum (with fully charged battery)

• Size: 180 x 80 x 45 mm (protruding sockets and belt clip excluded from measurements)

• Weight: 780 g

• Flow rate: 2 l/min using external pump (not included)

2) Kit Contents

• Carry Case

• Split2 monitor in carry pouch with detachable shoulder strap

• Sensor head assembly with spiral cable and locking plug

• Sensor mounting bracket with spring clip

• Battery charger complete with interchangeable plugs for UK / EU / US / AUS mains outlets

• Calibration span accessory

• Zeroing accessory

• I.O.M. cassette clip

• RS232 9-pin serial cable (female to male)

• Factory calibration certificate

• CD containing instruction manual and DustComm Pro software

www.skcltd.com 770-300M Issue E Page 3

Specifications

3) Features

Real-Time

Display

• Particulate exposure levels.

• TWA, STEL, Minimum and Maximum levels.

• Inhalable particulate mass in active mode with I.O.M. inlet fitted to

sensor head.

• Thoracic* particulate mass in active mode with I.O.M. inlet and

(optional) Thoracic size selective inlet.

• Respirable particulate mass in passive mode and in active mode

with I.O.M. inlet and size selective foam plug fitted to sensor head.

• Stored data by location code.

Functional

Features

• Calibration to NIOSH methods for lung damaging particles.

• In-line concurrent filter samples for gravimetric analysis (when

used in active mode with a suitable air sample pump).

• High sensitivity of 0.01 to 200 mg/m³.

• Passive and Active operating modes. Active mode requires an

optional air sampling pump set to 2 l/min flow rate.

• Belt clip on monitor or removable shoulder strap on carry pouch for

mounting on worker and lapel clip on sensor head for attachment

within the worker’s breathing zone for personal sampling.

• Simple cleaning of sensor hardware.

Operational

Features

• On screen programming of sampling and data storage parameters.

• Real-time clock.

• User selectable audible alarm.

• In-field zero and span check of instrument calibration.

Data

Management

Choice of 1 second, 1 minute, or 10 minute averaging / storage intervals.

Up to 21 weeks of sample/record time.

Memory storage of up to 21,500 data points that can be distributed into

a maximum of 999 location files.

DustComm Pro software supplied with RS-232 cable for downloading

data to a PC. Note that some PC’s may require a USB to RS-232 adapter

(not SKC supply) to enable this feature.

Data translation to ASCII text files, importable into Microsoft Excel and

other spreadsheet applications.

* Note that Thoracic particulate measurement is outside the scope of this instruction manual.

Page 4 770-300M Issue E www.skcltd.com

General Information

1) Care of the Split2 Monitor

• Always use the correct SKC battery pack and battery charger designated for the Split2

monitor.

• Ensure that the battery pack is fully charged before use. Refer also to Care of the Battery

Pack on page 29.

• It is recommended to switch the Split2 monitor off via the push button on/off switch prior

to charging. This will result in the shortest possible charging time.

• Internal surfaces of the sensor head are coated with a matt, light absorbing finish. Failure

to observe the correct cleaning method for the sensor head as detailed in Cleaning the

Optics on pages 30/31 will cause damage to the sensor head and will impact on the

accuracy of the Split2 monitor.

Warning - Failure to follow these guidelines will void the product warranty.

2) Sampling Methods

This instruction manual provides the necessary information to set up and operate the Split2

monitor. For more detailed information on air sampling terminology, theory and sampling

methods please refer to SKC’s Step-By-Step Guide to Air Sampling (Part No. 224-G1). To

obtain a free copy please contact SKC Ltd customer services on +44 (0) 1258 480188 or

download at www.skcltd.com.

3) The WEEE Directive

This product is marked with the crossed out wheelie bin symbol, which

identifies that it falls within the scope of the EU Directive 2002/96/EC on

waste electrical and electronic equipment (WEEE). At the end of it’s useful

life, this product must be disposed of in an environmentally sound way as

detailed in the Directive. Note that the battery pack must be separated from

the Split2 monitor and disposed of as detailed in the Batteries Directive (see

below). Please contact your local distributor or SKC Ltd for further details

on how to comply with the requirements of the WEEE Directive. SKC Ltd’s

producer registration number is WEE/KH0054TQ.

4) The Batteries Directive

The NiMH battery pack supplied with this instrument and any spare battery packs purchased

for it, fall within the scope of the EU Directive 2006/66/EC on batteries and accumulators and

waste batteries and accumulators. At the end of the battery pack’s life it must be disposed

of in an environmentally sound way as detailed in the Directive. Please contact your local

distributor or SKC Ltd for further details on how to comply with the requirements of the

Batteries Directive. SKC Ltd’s batteries producer registration number is BPRN00454.

www.skcltd.com 770-300M Issue E Page 5

Split2 Monitor Diagram

Split2 Monitor

RS-232 Data Port

Sensor Head

Socket

On/Off

Switch

Charging

Socket

Keypad

LCD Screen

Sensor Head Plug

Sensor Head

Sensor Bracket

Spring Clip

Page 6 770-300M Issue E www.skcltd.com

Sensor Head Exploded Diagram

IOM dust cap

IOM front plate

IOM inlet

Rubber seal

Sensor head body

Sensor head bracket

O rings Filter*

IOM cassette grid IOM body

O ring

Tube end cap

IOM cassette inlet

*For gravimetric analysis

www.skcltd.com 770-300M Issue E Page 7

Getting Started

1) Charging the Battery Pack

Prior to first use the battery pack should be fully charged, ideally overnight. Note that a new

battery pack may require 2 - 3 charge / discharge cycles to achieve full capacity.

The Split2 monitor must only be charged using the correct SKC charger (Part No. 770-320).

The charger is supplied with mains input plugs suitable for use in the UK, Europe, USA and

Australia / New Zealand. Select the correct mains input plug and fit it to the charger.

Plug the charger output jack plug into the matching charging socket on the side of the Split2

monitor. Plug the charger into the electrical mains supply and switch on the power.

When fully charged disconnect the charger plug from the Split2 monitor.

2) The On/Off Push Button

Power can be supplied to the Split2 either from its internal battery or from a mains power

source by leaving the charger connected.

Press the on/off push button switch on the side of the Split2 monitor to turn it on. The LCD

screen will operate showing the welcome screen.

Press the on/off push button switch on the side of the Split2 monitor to turn it off.

3) The Keypad

Down Key

Enter Key

Up Key

On/Standby Key

Keypad Operation

Use the On/Standby key to switch the Split2 monitor to standby and to

wake the monitor from standby.

Page 8 770-300M Issue E www.skcltd.com

Getting Started

Keypad Operation

The enter key activates the selected option on the LCD screen.

The up key scrolls the selection arrow upwards through a menu list on

the LCD screen or increases the selected setting value.

The down key scrolls the selection arrow downwards through a menu

list on the LCD screen or decreases the selected setting value.

4) Standby Mode

To place the Split2 monitor in standby mode press the I/O button. To wake the monitor from

standby mode press the I/O button again.

If the Split2 monitor will not wake from standby check that it is on by pressing the on/off push

button on the side of the monitor. If the monitor will still not wake from standby mode charge

it fully.

When first switched on, the Split2 unit monitor will

display the welcome screen as shown. Split 2

Real - Time

Dust Monitor

SKC Ltd V3.2 2/03

To clear the welcome screen and display the main

menu screen press the enter key. Run

Review Data

Special Functions

Auto-Zero

5) Navigating the Menu Options

Press the up and down keys to highlight the required

menu option, indicated by the selection arrow on the

screen.

Run

Review Data

Special Functions

Auto-Zero

Press the enter key to select the required menu option

and the new screen will be displayed. System Options

Date/Time

Set Alarm

Cancel

www.skcltd.com 770-300M Issue E Page 9

Getting Started

Press the enter key to select the required menu option

and the new screen will be displayed. System Options

Date/Time

Set Alarm

Cancel

In some screens, such as the Set Date/Time screen,

use the up and down keys to adjust the underlined

value.

Time: ▵ : :

Date: - -

Day:

Press the enter key to enter the selected value and

adjust the next digit of the setting. Time: 1▴: :

Date: - -

Day:

Page 10 770-300M Issue E www.skcltd.com

Initial Setup of the Split2 Monitor

Attach the sensor head plug to the socket on the side

of the Split2 monitor. Switch on the Split2 monitor

using the push button on/off switch on the side. The

LCD screen will show the welcome screen and a beep

will sound.

It is recommended to allow at least 10 minutes for the

electronics to stabilise to ensure a stable base line

reading.

Split 2

Real - Time

Dust Monitor

SKC Ltd V3.2 2/03

After stabilisation, to clear the welcome screen and

display the main menu screen press the enter key. Run

Review Data

Special Functions

Auto-Zero

1) Setting the Time and Date

On the main menu screen press the up and down keys

to highlight the Special Functions menu item, indicated

by the selection arrow on the screen.

Run

Review Data

Special Functions

Auto-Zero

Press the enter key to select the menu item and the

Special Functions menu screen will be displayed. System Options

Date/Time

Set Alarm

Cancel

Press the up and down keys to highlight the Date/Time

menu item on the Special Functions menu screen. System Options

Date/Time

Set Alarm

Cancel

Press the enter key to select the menu item and the

Date/Time menu screen will be displayed. View Date/Time

Set Date/Time

Cancel

Press the up and down keys to highlight the Set Date/

Time menu item on the Date/Time menu screen. View Date/Time

Set Date/Time

Cancel

Press the enter key to select the menu option and

the Set Date/Time menu screen will be displayed.

On this screen each digit of the time and date is set

individually. The current digit to be set is highlighted

by an underline cursor.

Time: ▴ : :

Date: - -

Day:

www.skcltd.com 770-300M Issue E Page 11

Initial Setup of the Split2 Monitor

Use the up and down keys to adjust the underlined

value. Time: ▵ : :

Date: - -

Day:

Press the enter key to enter the selected value and the

next digit is highlighted by the underlined cursor. Time: 1▴: :

Date: - -

Day:

Enter the hours, minutes and seconds of the time in 24

hour clock format. Time: 15:36:00

Date: ▴ - -

Day:

Enter the date in dd-MMM-yy format and the day of the

week. Time: 15:36:00

Date: 12-JUL-12

Day: THUR

On pressing the enter key after setting the day of the

week a confirmation screen is displayed. Set Date/Time

Cancel

Select the Set Date/Time menu item and press the

enter key to save the date and time just entered, or

select the Cancel menu item to retain the existing time

and date. The main menu screen is then displayed.

Run

Review Data

Special Functions

Auto-Zero

2) Clearing the Data Logging Memory

The memory of the Split2 monitor can be cleared at any time. Note that this operation will

clear all data points in all locations from the memory.

On the main menu screen use the up and down keys to

highlight the Special Functions menu item and press

enter to show the new screen.

System Options

Date/Time

Set Alarm

Cancel

On the System Options menu screen press enter to

select the System Options menu item and show the

new screen.

Extended Options

Sample Rate

Erase Memory

Cancel

Page 12 770-300M Issue E www.skcltd.com

Initial Setup of the Split2 Monitor

On the System Options menu screen use the up and

down keys to highlight the Erase Memory menu item

and press enter to show the new screen.

No

Yes

Erase Memory?

DATA WILL BE LOST

Select the Yes option and press enter to erase the

memory, or select the No option to retain the existing

logged data in memory. The Special Functions menu

screen is then displayed.

System Options

Date/Time

Set Alarm

Cancel

www.skcltd.com 770-300M Issue E Page 13

Passive or Active Sampling

The Split2 monitor can be used in two operating modes, Passive or Active (with optional air

sample pump). The choice of which operating mode to use will depend on the dust fraction

of interest - Respirable or Inhalable fractions, and whether a filter sample is required for

subsequent gravimetric and/or chemical analysis.

A different configuration of the Split2 monitor sensor head is requried for the various options

as detailed below.

1) Passive Sampling

In Passive mode the sensor head is configured as shown below, with only the IOM front plate

fitted to the front of the sensor head and the sensor head mounted onto the bracket in the

orientation shown below. Secure the sensor head to the bracket with the two thumb screws

supplied.

In Passive mode the Split2 monitor is calibrated to respond to the respirable fraction only

and cannot be used to measure the inhalable fraction. Also, it is not possible to take a filter

sample for subsequent analysis in this operating mode.

2) Active (Pumped) Sampling

In Active mode the sensor head is configured as shown below and with the sensor head

mounted onto the bracket in the orientation shown. Refer also to the exploded diagram of

the sensor head on page 6 for component identification and assembly positions. Secure the

sensor head to the bracket with the two thumb screws supplied.

Page 14 770-300M Issue E www.skcltd.com

Passive or Active Sampling

Connect the outlet hosetail of the IOM sampler body at the rear of the sensor head to the inlet

hosetail of the air sample pump using a suitable length of 1/4” bore flexible tubing (such as

Tygon tubing). The tubing can be passed through the coiled sensor cable which will help prevent

snagging of the tubing on the worker’s clothing.

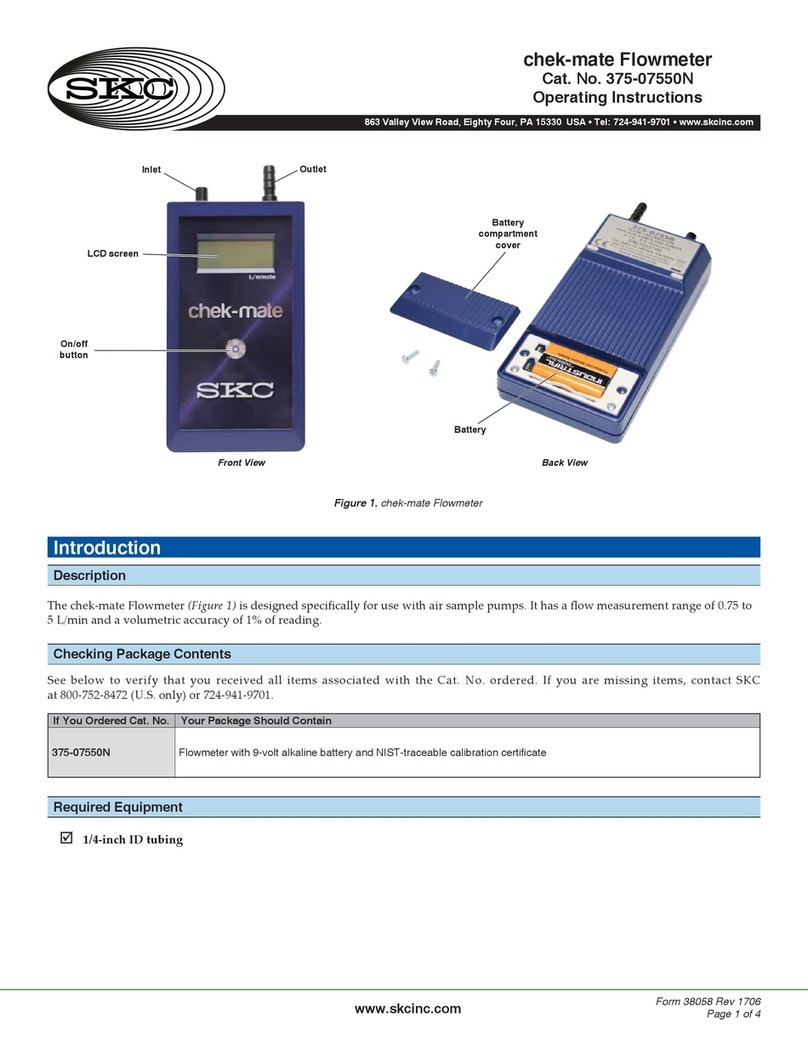

The pump flow rate must be adjusted to 2 l/min using a suitable air flow calibrator such as the

SKC chek-mate and a calibration adapter for the IOM sampler (SKC part number 391-01).

In Active mode with a size selective foam plug fitted to the IOM inlet at the front of the sensor head

the Split2 monitor will respond to the respirable fraction. Without a size selective foam fitted to

the IOM inlet the Split2 monitor will respond to the inhalable fraction.

If a filter sample is to be taken for subsequent gravimetric and/or chemical analysis, place a 25mm

diameter filter into the supplied IOM cassette (part of the sensor head assembly). Pre-weigh the

filter and cassette and then fit it into the IOM body at the rear of the sensor head. Ensure that all

of the sealing O rings are in place (refer to Sensor Head Exploded Diagram on page 6). The sensor

head must be removed from the bracket to enable this.

www.skcltd.com 770-300M Issue E Page 15

Setup of the Split2 Monitor for Sampling

Set up the sensor head assembly as detailed on pages 13 & 14 dependent on whether Passive or

Active (Pumped) sampling is to be performed and which particle size is to be sampled.

Ensure that the correct time and date have been set as detailed in on page 10.

Ensure that the Split2 monitor and sensor head assembly are allowed sufficient time to stabilise

to the ambient temperature of the sampling location. A minimum of 20 minutes is recommended

to achieve this.

Then perform the following steps:

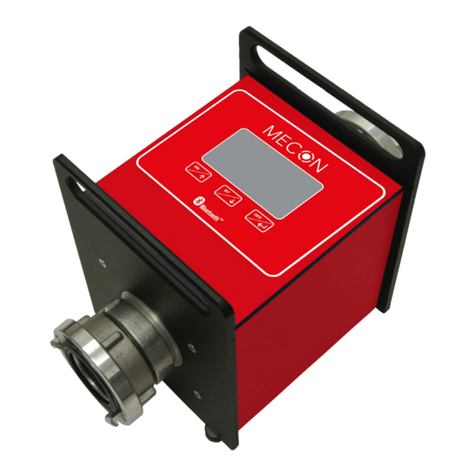

1) Set the Flow Rate When Performing Active (Pumped) Sampling

The Split2 monitor does not need to be switched on when setting the flow rate.

The required flow rate is 2 l/min.

The required equipment is a flow meter with traceable calibration such as the SKC chek-mate,

a calibration adapter for the IOM sampler (SKC part number 391-01) and a length of 1/4” bore

flexible tubing.

Connect the outlet hosetail of the flow meter to the hosetail on the calibration adapter with the

length of flexible tubing.

Switch on the air sample pump and allow to run for at least 5 minutes to stabilise before proceeding.

Press the foam pad of the calibration adapter firmly against the IOM front plate on the sensor head

assembly. Maintain the pressure to keep the calibration adapter in place and ensure a consistent

seal throughout the calibration process.

Observe the reading of the flow meter and adjust the pump flow rate as detailed in the pump

instruction manual until the required flow rate of 2 l/min is achieved. Switch off the air sample

pump.

If performing a concurrent filter sample for gravimetric analysis note the flow rate reading for

use in calculating the dust concentration. The filter in place during calibration should be replaced

after the calibration with a clean filter and the filter and IOM cassette pre-weighed.

Page 16 770-300M Issue E www.skcltd.com

Setup of the Split2 Monitor for Sampling

2) Check the Battery Status

Always ensure that the battery is fully charged before commencing sampling. The Split2

battery pack has a nominal voltage of 7.2V. A fully charged battery pack will have a voltage of

8.0V or higher. If the battery voltage is below 7.4V it is recommended to recharge the battery

before commencing sampling. Check the battery status as follows:

On the main menu screen press the up and down keys

to highlight the Special Functions menu item, and

press enter to show the new screen.

Run

Review Data

Special Functions

Auto-Zero

On the Special Functions menu screen press enter to

select the System Options menu item and show the

new screen.

System Options

Date/Time

Set Alarm

Cancel

On the System Options menu screen press enter to

select the Extended Options menu item and show the

new screen.

Extended Options

Sample Rate

Erase Memory

Cancel

On the Extended Options menu screen press the up and

down keys to highlight the Battery Status menu item

and press enter to select and show the new screen.

Size Select

Battery Status

Cancel

The Battery Status screen displays the current battery

voltage. Press enter to return to the main menu screen. Battery Level

Status: 8.05 Volts

3) Set the Particle Size

To set the particle size, on the main menu screen

press the up and down keys to highlight the Special

Functions menu item and press enter to show the new

screen.

Run

Review Data

Special Functions

Auto-Zero

On the Special Functions menu screen use the up and

down keys to highlight the System Options menu item

and press enter to show the new screen.

System Options

Date/Time

Set Alarm

Cancel

www.skcltd.com 770-300M Issue E Page 17

Setup of the Split2 Monitor for Sampling

On the System Options menu screen press enter to

select the Extended Options menu item and show the

new screen.

Extended Options

Sample Rate

Erase Memory

Cancel

On the Extended Options menu screen press enter to

select the Size Select menu item and show the new

screen.

Size Select

Battery Status

Cancel

On the Size Select menu screen press enter to select

the Select menu item and show the new screen. Select

Apply Scale

Restore Defaults

Cancel

On the Select screen press the up and down keys to

highlight the required particle size and press enter to

select it and return to the main menu screen.

Respirable

Thoracic

Inhalable

4) Set the Sample Rate

To set the sample rate, on the main menu screen

press the up and down keys to highlight the Special

Functions menu item and press enter to show the new

screen.

Run

Review Data

Special Functions

Auto-Zero

On the Special Functions menu screen use the up and

down keys to highlight the System Options menu item

and press enter to show the new screen.

System Options

Date/Time

Set Alarm

Cancel

Press the up and down keys to highlight the Sample

Rate menu item and press enter to show the new

screen.

Extended Options

Sample Rate

Erase Memory

Cancel

On the Sample Rate screen use the up and down keys

to highlight the required sample rate. The options

state the sample interval time and also the maximum

sample duration for each option. Press enter to save

the setting and return to the main menu screen.

1 Sec (6hrs)

10 Sec (60hrs)

1 Min (15Days)

30 Min (15Mos)

Page 18 770-300M Issue E www.skcltd.com

5) Set the Alarm Concentration Level

An audible alarm can be set to alert the worker that the dust concentration level is approaching

a threshold limit. As a starting point it is recommended to set the alarm concentration level to

80% of the WEL (Worker Exposure Limit) for the particulate type being sampled.

To set the alarm concentration level, on the main

menu screen press the up and down keys to highlight

the Special Functions menu item and press enter to

show the new screen.

Run

Review Data

Special Functions

Auto-Zero

On the Special Options menu screen press the up and

down keys to highlight the Set Alarm menu item. System Options

Date/Time

Set Alarm

Cancel

Press the enter key to select the menu option and the

Set Alarm screen will be displayed. SET ALARM

Conc: ▴00.00 mg/m

Use the up and down keys to adjust the value of the

digit highlighted by the underlined cursor. SET ALARM

Conc: ▵00.00 mg/m

Press the enter key to enter the selected digit value

and the next digit is highlighted by the underlined

cursor. Use the up, down and enter keys to enter the

required alarm concentration.

SET ALARM

Conc: 120.0▴ mg/m

On pressing the enter key after adjusting the value of

the last digit of the alarm concentration the setting is

saved and the main menu screen is displayed.

Run

Review Data

Special Functions

Auto-Zero

6) Perform an Auto-Zero

The auto-zero function sets the measurement baseline of the Split2 monitor to zero mg/m³

and should be performed prior to beginning a new set of measurements. The battery should

be fully charged and the unit switched on for at least 10 minutes prior to performing the auto-

zero.

If performing respirable sampling in Passive mode ensure that the auto-zero is performed in

a clean, dust free environment as in this mode the auto-zero is performed without using the

zeroing accessory.

If performing sampling in Active mode insert the zeroing accessory supplied with the Split2

monitor into the IOM inlet on the sensor head and ensure the air sample pump is running.

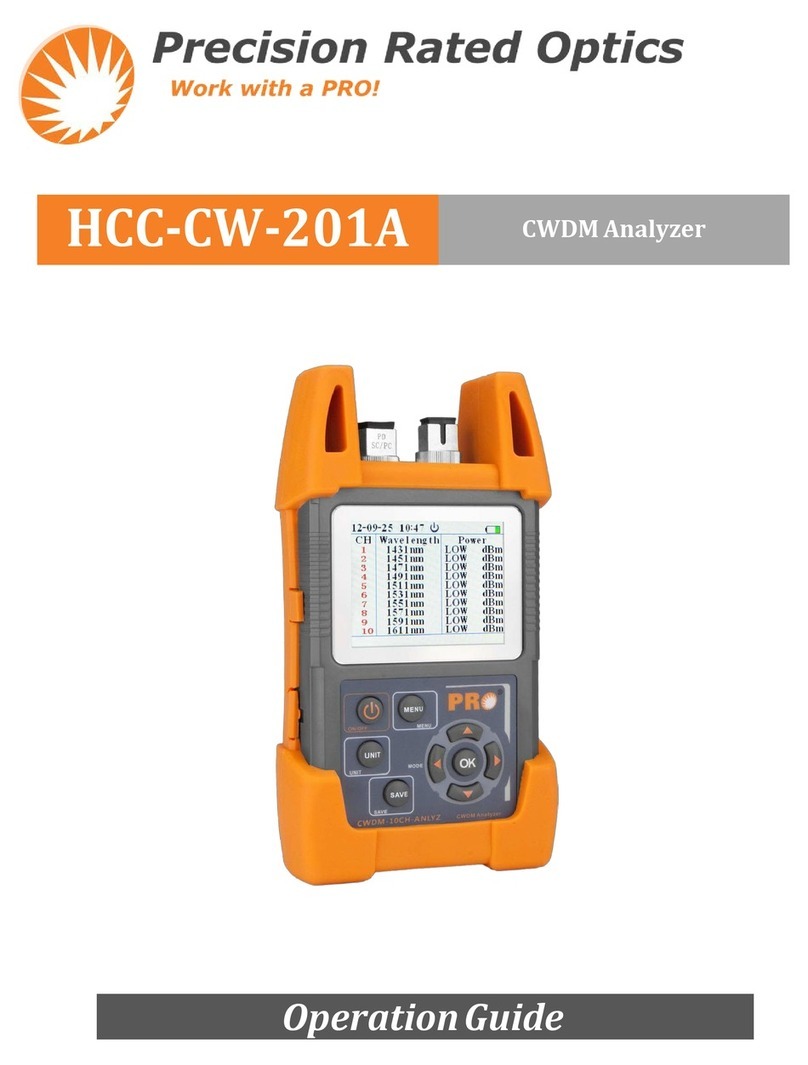

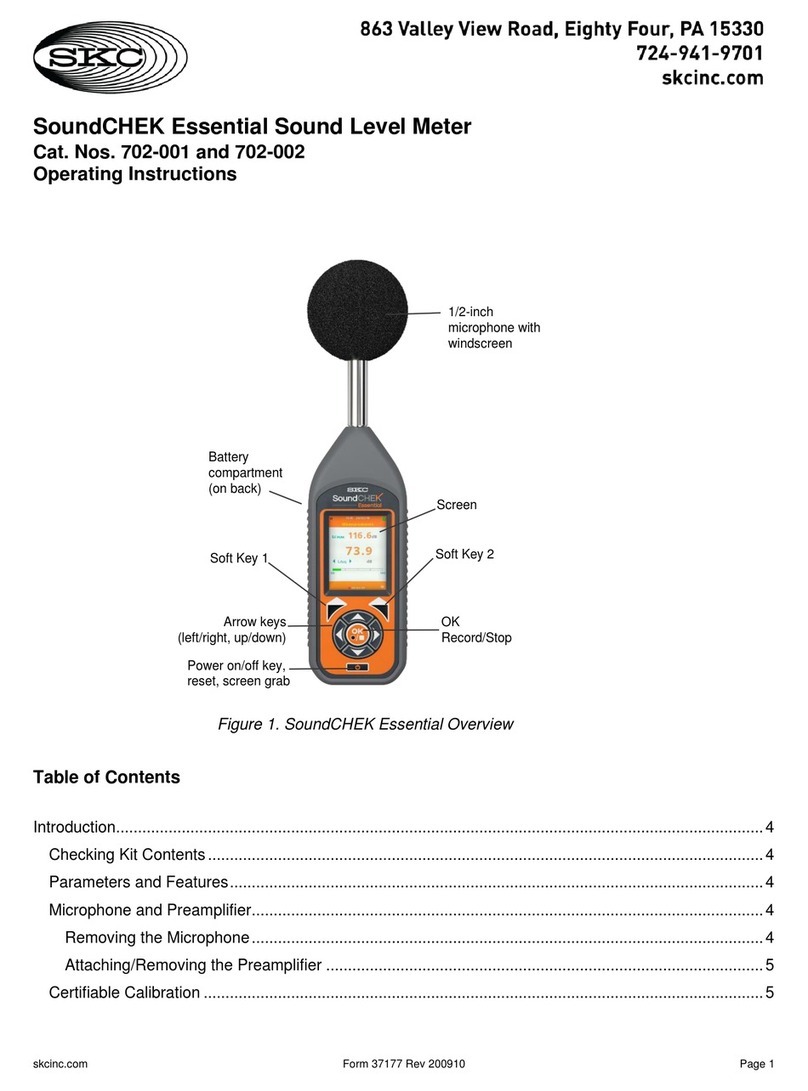

Setup of the Split2 Monitor for Sampling

This manual suits for next models

1

Table of contents

Other SKC Measuring Instrument manuals

SKC

SKC chek-mate 375 series User manual

SKC

SKC chek-mate User manual

SKC

SKC SoundCHEK 702 Series User manual

SKC

SKC SoundCHEK User manual

SKC

SKC 224-6580 User manual

SKC

SKC chek-mate User manual

SKC

SKC chek-mate 375 series User manual

SKC

SKC AIRCHEK 2000 User manual

SKC

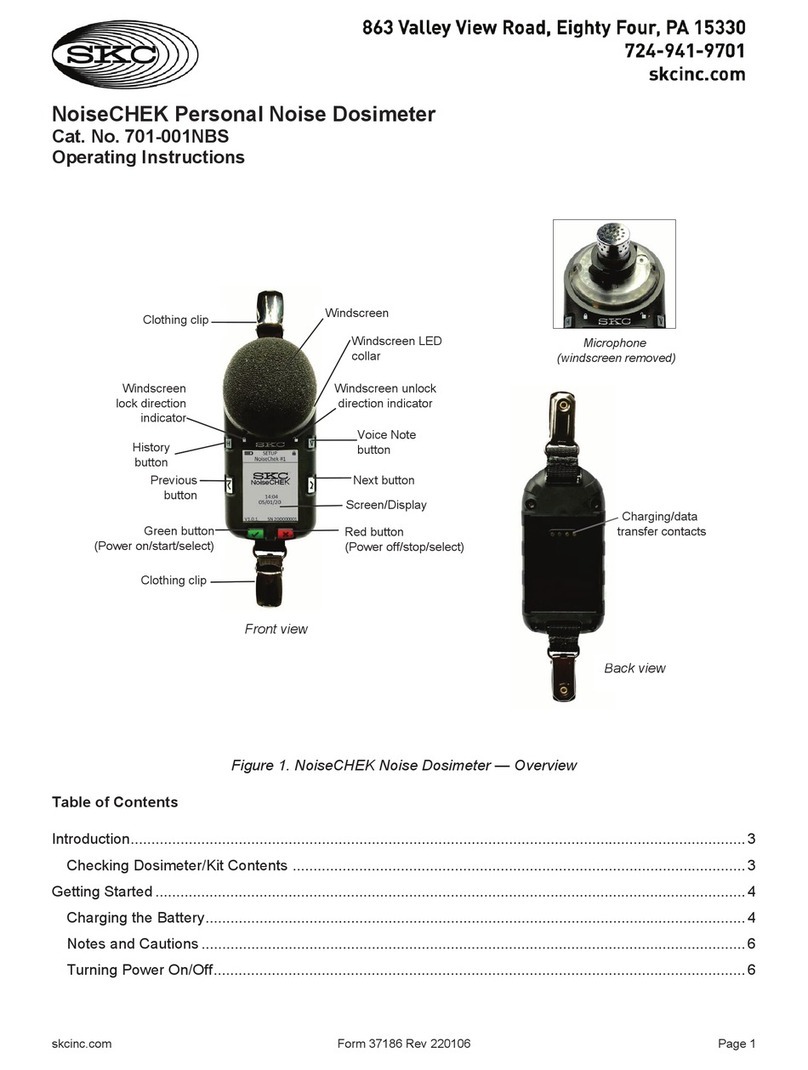

SKC 701-001NBS User manual

SKC

SKC NoiseCHEK User manual