4 User Manual

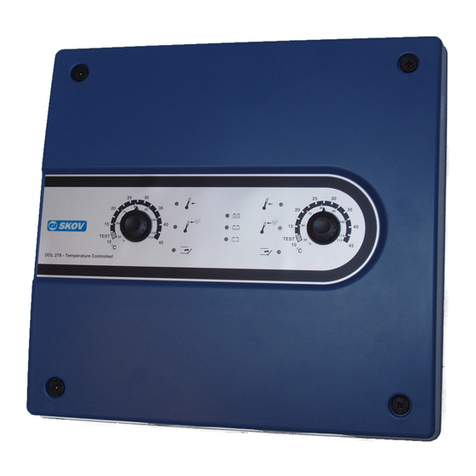

DOL 535 • DOL 539 Breeder

PRODUCT DESCRIPTION...........................................................................................6

GUIDELINES ................................................................................................................7

USER’S GUIDE ............................................................................................................8

1Operation.............................................................................................................. 8

1.1 Front view ......................................................................................................................8

1.1.1 Set-up of front view .................................................................................................................................9

1.2 Main menus .................................................................................................................10

1.3 Changing the settings ......................................................................................................10

1.4 Alarm log .....................................................................................................................10

1.5 Selection of language .................................................................................................11

1.5.1 Password...............................................................................................................................................11

MAIN MENUS.............................................................................................................13

2Production........................................................................................................13

2.1 Production Menus.............................................................................................................15

2.2 Animals.......................................................................................................................16

2.2.1 Add/remove animals..............................................................................................................................17

2.3 Bird Weigher................................................................................................................19

2.3.1 Correction Factor...................................................................................................................................20

2.3.2 Period without Weighing........................................................................................................................21

2.4 Filling (destination feeding)........................................................................................22

2.4.1 Filling program.......................................................................................................................................24

2.4.2 Manual filling .........................................................................................................................................25

2.4.3 Manual restart of filling after alarm from external input.........................................................................25

2.4.4 Manual restart of filling after filling alarm...............................................................................................25

2.4.5 Adjust the feed amount in destinations .................................................................................................25

2.4.6 Feed type selection ...............................................................................................................................26

2.5 Feed Control...............................................................................................................27

2.5.1 Feed Programs......................................................................................................................................29

2.5.2 Destination Feeding ..............................................................................................................................30

2.5.3 Pan Feeding..........................................................................................................................................31

2.5.4 Chain Feeding.......................................................................................................................................34

2.5.5 Feed Mixture (Drum Weigher and DOL 9940)......................................................................................36

2.5.6 Feed supplement...................................................................................................................................36

2.6 Feed Consumption.....................................................................................................37

2.6.1 Manual Distribution of Feed before Batch Start (Breeder)....................................................................37

2.7 Week Program............................................................................................................38

2.8 Water...........................................................................................................................38

2.8.1 Water Control ........................................................................................................................................39