DA 17K Tunnel Inlet

1 Product description........................................................................................................................................4

2 Product survey ...............................................................................................................................................5

3 Mounting guide...............................................................................................................................................7

3.1 Recommended tools.................................................................................................................. 7

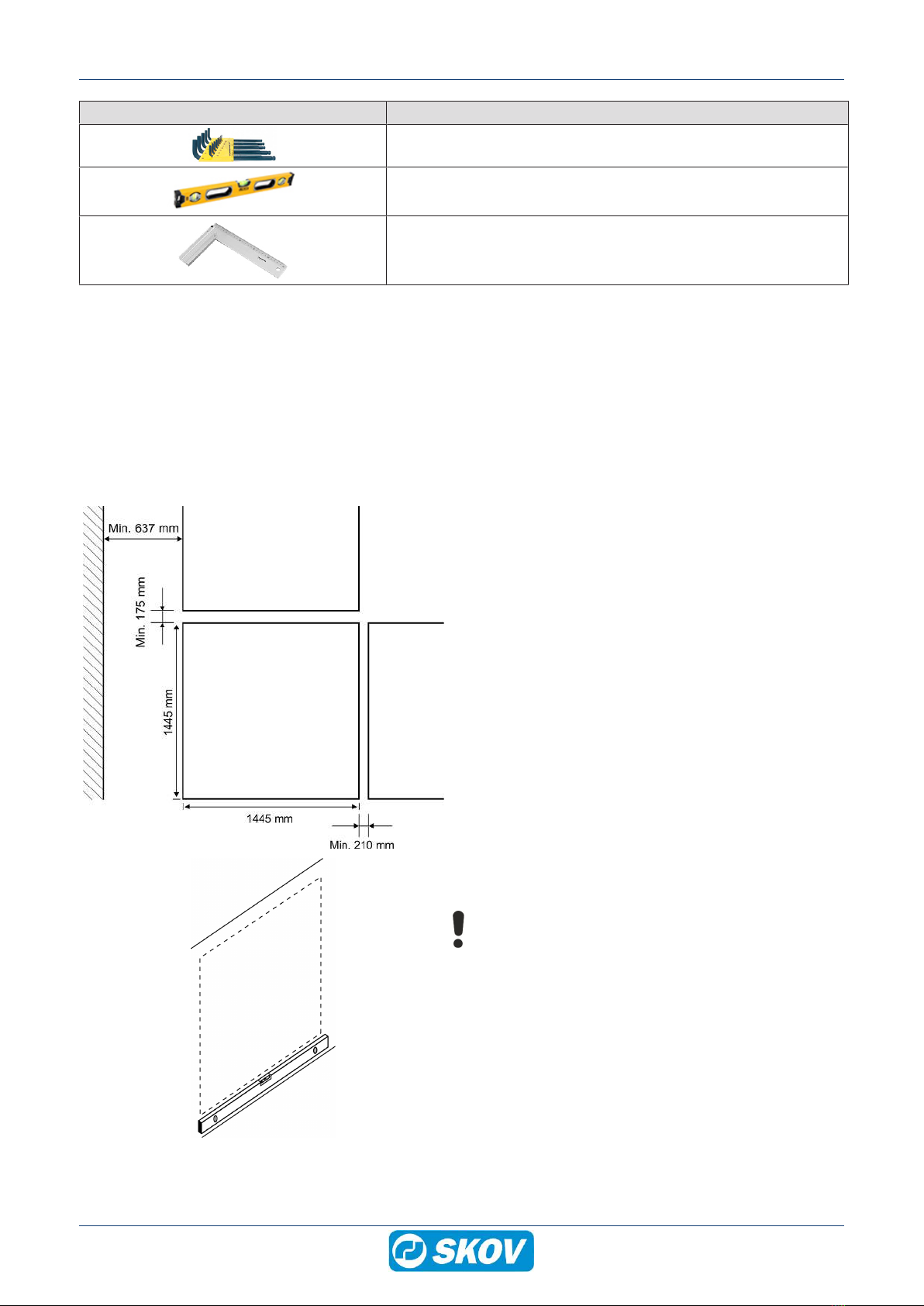

3.2 Wall inlet positioning................................................................................................................. 8

3.3 Mounting of tunnel inlet ............................................................................................................ 8

3.3.1 Preparing hole in wall................................................................................................................... 8

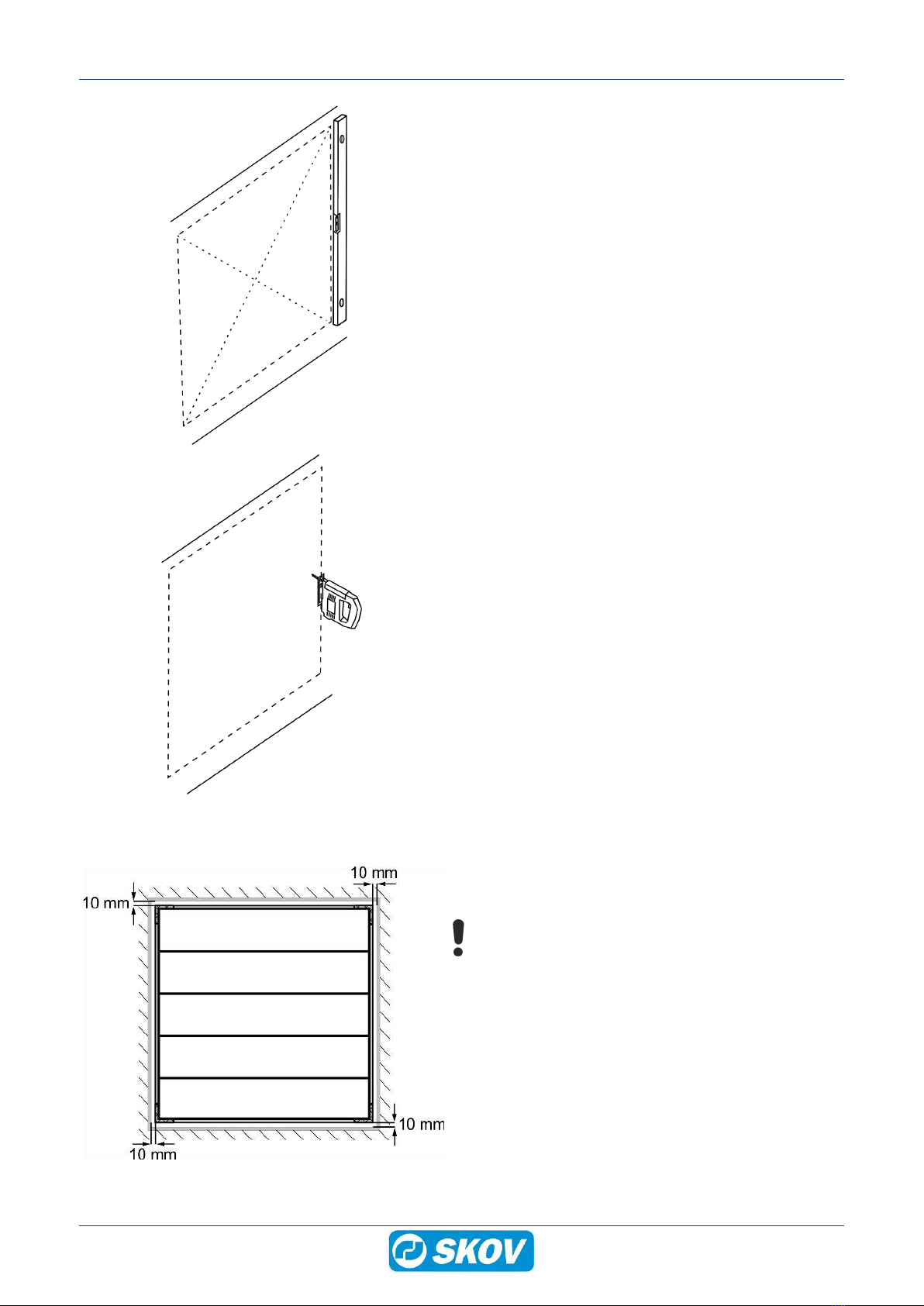

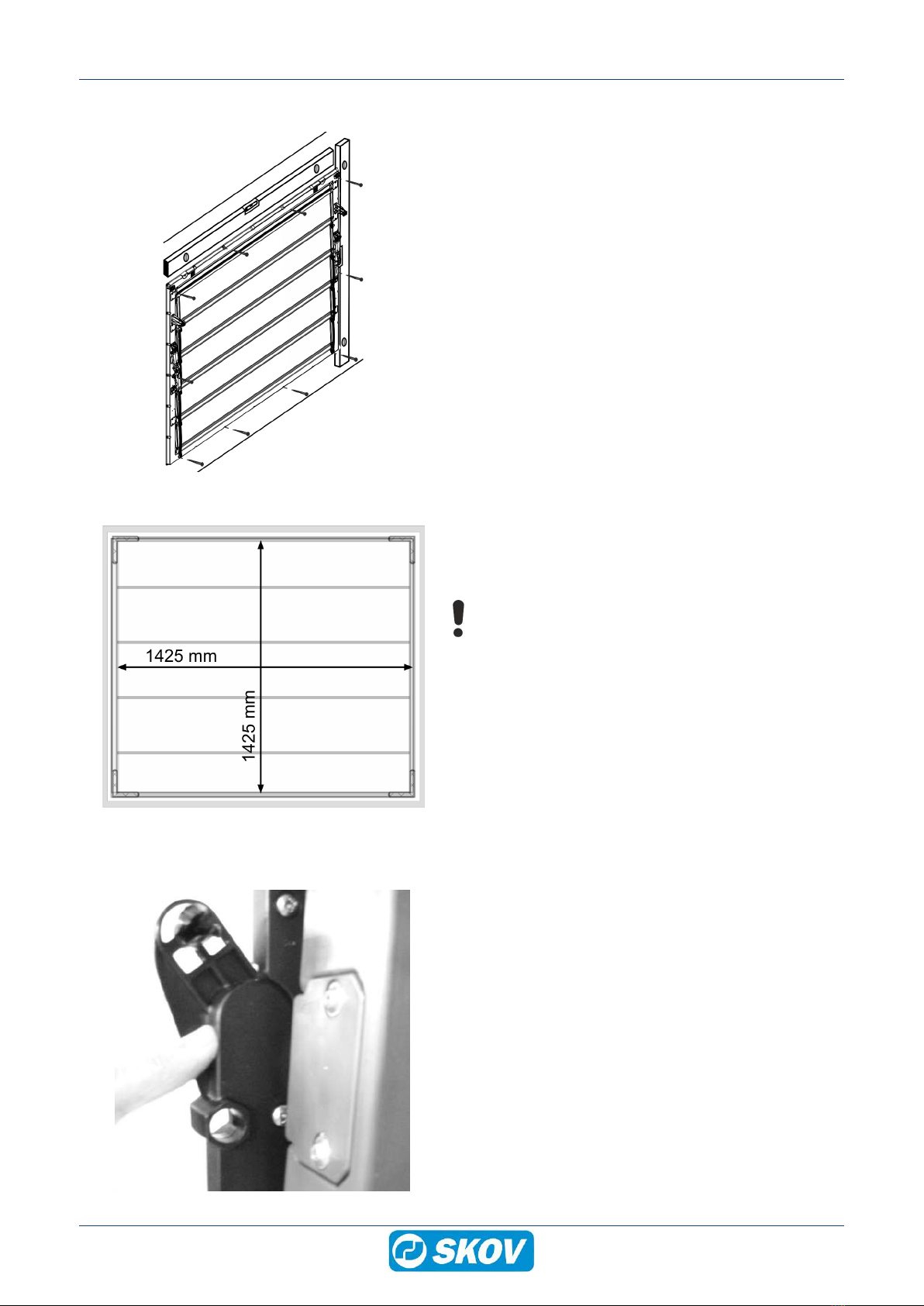

3.3.2 Mounting in wall ........................................................................................................................... 9

3.3.3 Check the tightness ................................................................................................................... 10

3.3.4 Foaming ..................................................................................................................................... 13

3.3.5 Jointing....................................................................................................................................... 13

3.4 Mounting of tunnel inlet parts ................................................................................................14

3.4.1 Wheel set ................................................................................................................................... 15

3.4.2 Brackets for single pull............................................................................................................... 15

3.4.3 Brackets for pull rod ................................................................................................................... 16

3.4.4 Pull rod....................................................................................................................................... 16

3.4.5 Pulley on pull rod ....................................................................................................................... 17

3.4.6 Coil spring .................................................................................................................................. 17

3.4.7 String.......................................................................................................................................... 18

3.5 Mounting of bird net ................................................................................................................ 19

3.6 Mounting examples ................................................................................................................. 20

4 Maintenance..................................................................................................................................................21

4.1 Recycling/Disposal .................................................................................................................. 21

5 Technical Data ..............................................................................................................................................22

5.1 Dimension drawing for tunnel inlet........................................................................................ 23

Mounting Guide