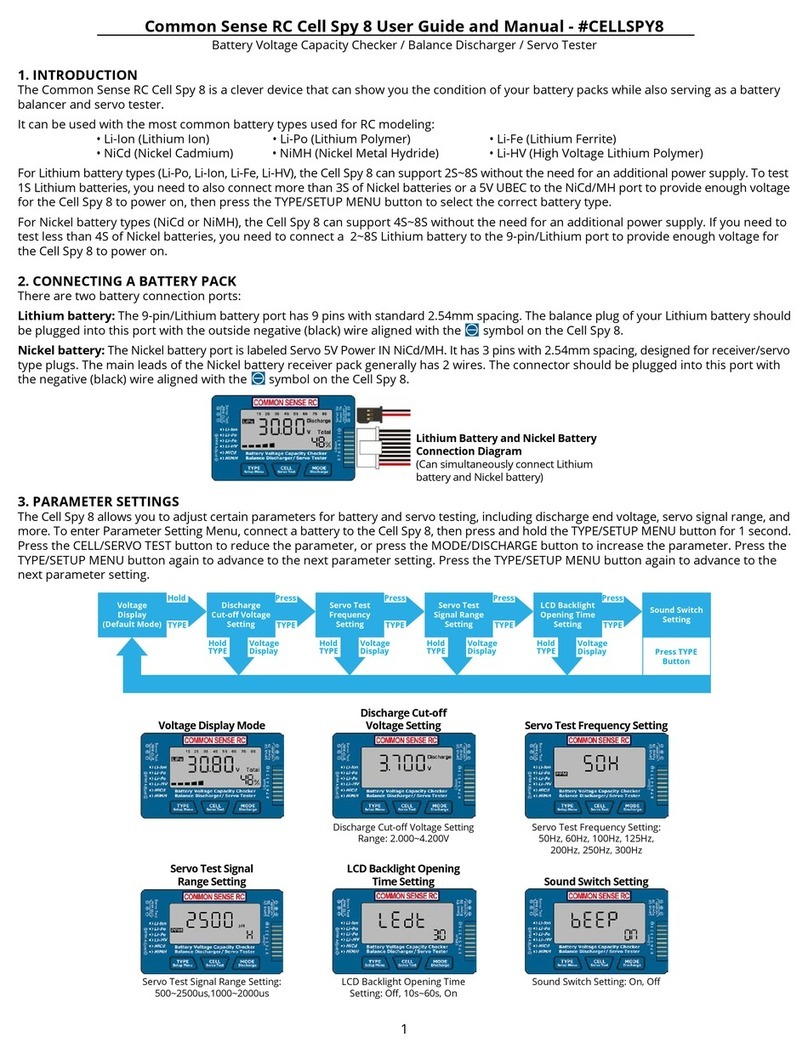

Sloan CX 8154-1.6 User manual

INSTALLATION INSTRUCTIONS FOR

SLOAN CX SENSOR CLOSET AND URINAL FLUSHOMETERS

Code No: 0816858

Rev. 3 (07/20)

LIMITED WARRANTY

Sloan Valve Company warrants its ushometer to be made of rst class materials, free from defects of material or workmanship under

normal use and to perform the service for which they are intended in a thoroughly reliable and efcient manner when properly installed and serviced, for a period of

three (3) years (one year for special nishes) from the date of purchase. During this period, Sloan Valve Company will, at its option, repair or replace any part or parts

that prove to be thus defective if returned to Sloan Valve Company, at customer’s cost, and this shall be the sole remedy available under this warranty. No claims will

be allowed for labor, transportation or other incidental costs. This warranty extends only to persons or organizations that purchase Sloan Valve Company’s products

directly from Sloan Valve Company for purpose of resale. This warranty does not cover the life of batteries.

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. IN NO EVENT IS SLOAN VALVE COMPANY RESPONSIBLE FOR ANY CONSE-

QUENTIAL DAMAGES OF ANY MEASURE WHATSOEVER.

1

Sensor Closet Flushometers

CX 8158-1.6

CX 8158-1.28

CX 8154-1.6

CX 8154-1.28

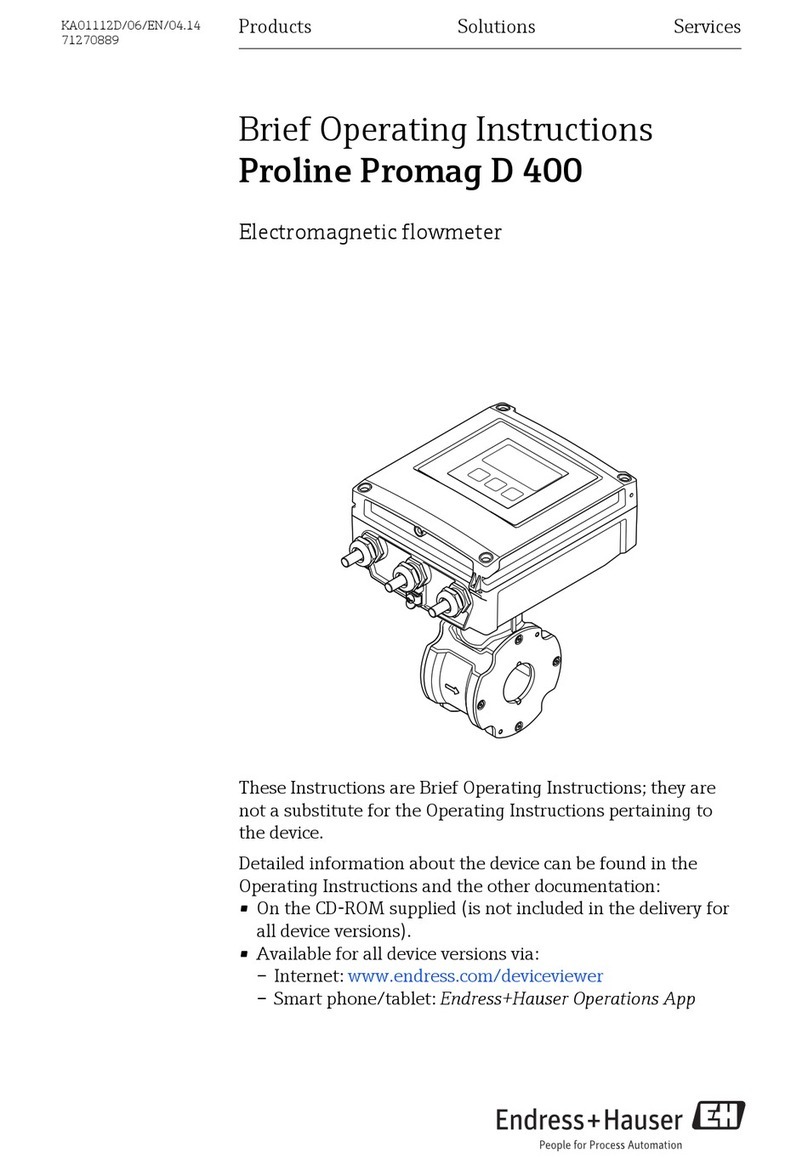

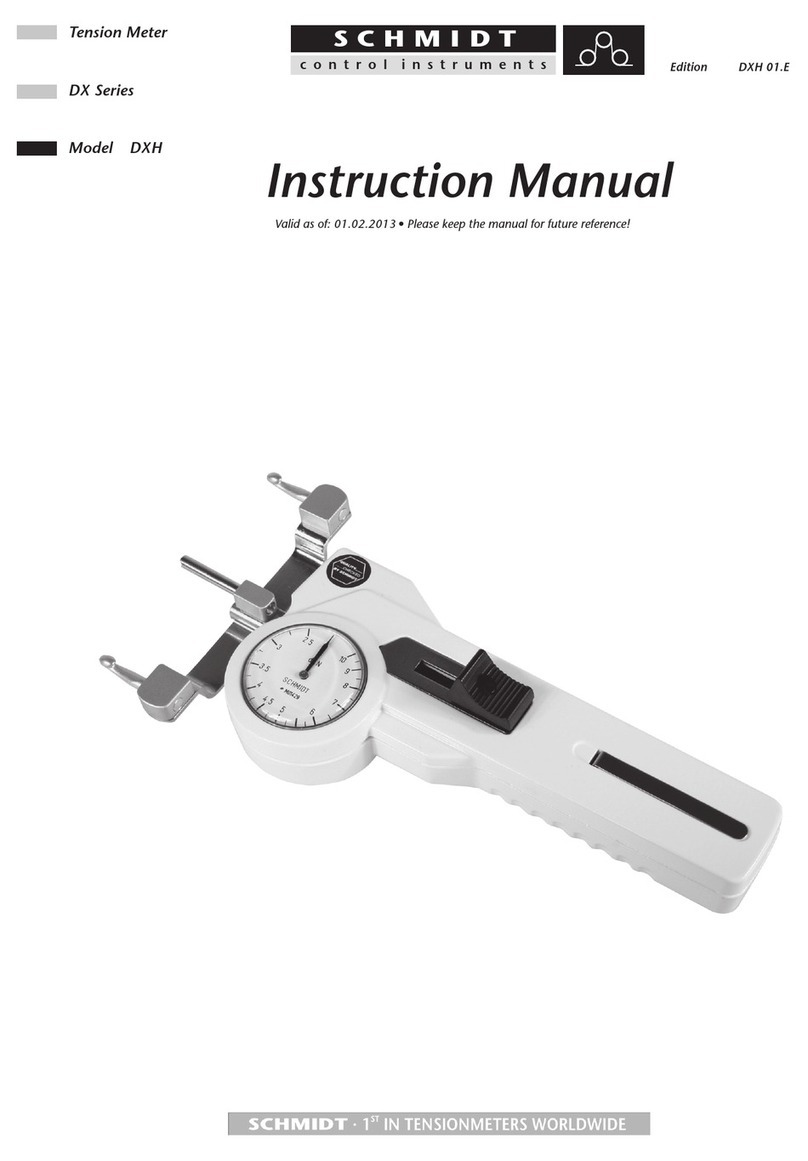

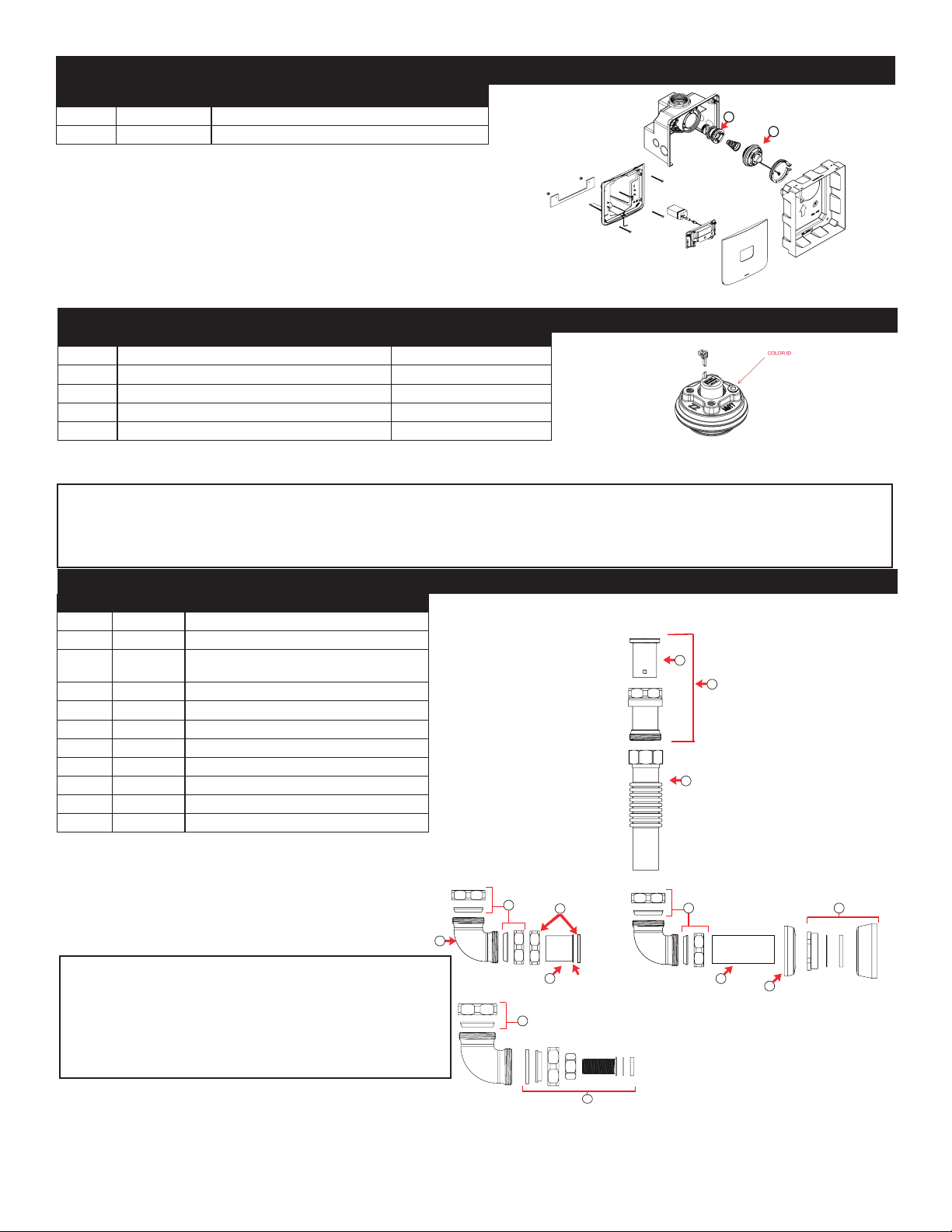

ITEMS INCLUDED (VALVE BOX)

1. Valve Box

2. Mud Guard

3. Adjustment tool

4 Mud Guard Screws

5 Activation Assembly Screws

6. Instructions

7. Adjustable Tube

8. Outlet Connection

9. Elbow

10. Inlet Adapter

11. Vacuum Breaker Assembly

12. Couplings & Gaskets

PRIOR TO INSTALLATION

Sensor Urinal Flushometer

CX 8198-0.5

CX 8198-0.25

CX 8198-0.125

This valve is designed for new construction or where there is easily accessed plumb-

ing for the xture and valve. This valve is designed for a minimum 6-1/2 inch (165

mm) wall space depth. Distance from the center of the valve (inlet or outlet pipe) to

the nished surface of the wall can vary from 3-1/4” – 4-1/4” (83 – 108 mm).

Wall plate opening must be a minimum of 7-3/8” wide x 8-3/8” tall (187 mm wide

x 213 mm tall) to maximum 7-5/8” wide x 8-5/8” tall (194 mm wide x 219 mm

tall). Mud plate is provided and must accompany valve for proper installation. Mud

plate is removed after wall is nished.

TOOLS AND ITEMS REQUIRED FOR INSTALLATION (PROVIDED)

• 5/64” hex wrench • Wall plate depth guide • Adjustment tool

TOOLS AND ITEMS REQUIRED FOR INSTALLATION (NOT PROVIDED)

• Smooth-jawed wrench (at least 2”) • Philips screwdriver • threaded sweat solder adapter

• approximately 15”-18” pipe

1.Valve Box

3.Adjustment Tool

4.#8-32 Mud

Guard Screws

5. 1/4-20 Activation

Assembly Screws

6. Instructions

7. Adjustable Tube 8. Outlet Connection

9. Elbow 10. Inlet Adapter

11. Vacuum Breaker

Assembly

2. Mud Guard

12. Couplings & Gaskets

V651A

Kit

2

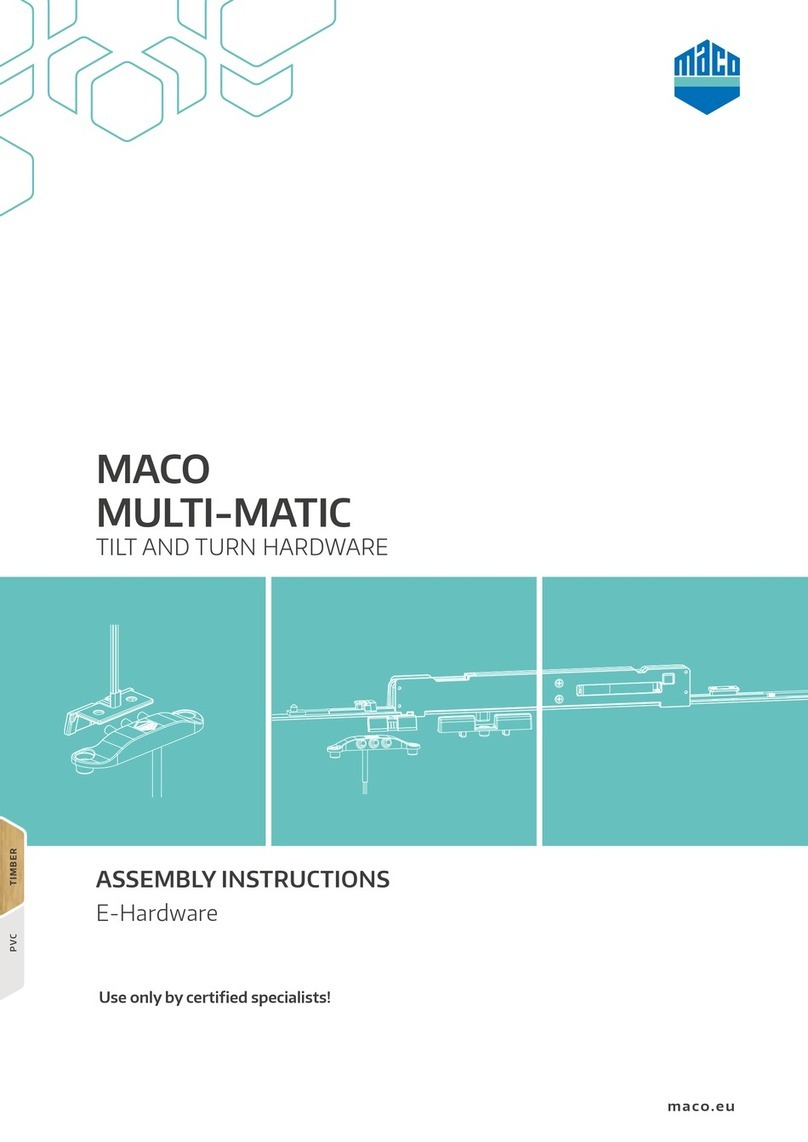

ITEMS INCLUDED (WALL PLATE BOX)

IMPORTANT:

• INSTALL ALL PLUMBING IN ACCORDANCE WITH APPLICABLE CODES AND REGULATIONS.

• WATER SUPPLY LINES MUST BE SIZED TO PROVIDE AN ADEQUATE VOLUME OF WATER FOR EACH FIXTURE.

• FLUSH ALL WATER LINES PRIOR TO MAKING CONNECTIONS.

Sloan’s ushometers are designed to operate with 20 to 80 psi (138 to 552 kPa) of water pressure. THE MINIMUM PRESSURE REQUIRED

TO THE VALVE IS DETERMINED BY THE TYPE OF FIXTURE SELECTED.

Consult xture manufacturer for minimum pressure requirements. Most high efciency water closets require a minimum owing pressure of 25 psi

(172 kPa). Many building codes and the ASME A112.19.2 xture standard list maximum static water pressure as 80 PSI (552 kPa).

MODEL 8158

CLOSET

WALL HUNG

REAR INLET

ROUGH-IN CLOSETS

1½” (38 mm)

1½” min. ADA

(38 mm)

33”

(836 mm)

top of plate

1½” (38 mm)

ADA 36” MAX.

(914 mm)

7-1/2” (191 mm)

NO

TE: If fixture inlet i

s

b

e

l

ow r

i

m

l

eve

l,

consu

l

t

fl

oo

r m

ou

nt r

ea

r inl

e

t

rou

g

h-in dimensions.

V

alve

C

L to

f

ixture inlet

:

12

¼”

- 12

½

”

(

311 mm-318 mm

)

11“-11

¼

” (279-286 mm)

I

nlet

p

i

p

e CL to fin. wall

3

¼” - 4

¼

”

(83 mm - 108 mm)

Rear o

f

valve to

f

in. wall

5

¼

”

- 6

¼

”

(

134 mm - 160 mm

)

Fixture inlet to wall opening:

n

let

t

5

¾” -

6

”

6

mm - 152 mm

)

(

14

6

4

½

“-

-

4

”

(114-121 mm)

¾”

Valve CL to fixture inlet:

L

to

f

1

2

¼”

-

1

1

2

½

”

(

311 mm - 318 mm

)

11

“

-

1

1

1

(

279-286 mm

)

¼

”

2

”

(

51 mm

)

open

i

n

g

i

n wa

ll

1. Wall Bracket

2. Wall Plate

3. Sensor Assembly

4 C-Bracket

5 Battery Pack

6. Batteries

7. Screws

8. Allen Key

9. Lock Nuts

10. Instructions

1. Wall Bracket 2. Wall Plate

4.C-Bracket3. Sensor Assembly

5. Battery Pack

7. #8-32 Screws

6. Batteries

8. Allen Key

9. Lock Nuts

10. Instructions

Roughin for Sloan CX is determined relative to the spud connection for the xture being used.

SIDE VIEW FRONT VIEW

ACCURACY IS IMPORTANT FOR

WALL OPENING DIMENSIONS.

VALVE MUST BE CENTERED

HORIZONATLLY IN OPENING

WITHIN 1/8". FOR ASSITANCE,

PLEASE CONSULT ROUGH-IN

TEMPLATE.

!!! IMPORTANT !!!

THIS PRODUCT CONTAINS

MECHANICAL COMPONENTS

THAT ARE SUBJECT TO

NORMAL WEAR. THESE

COMPONENTS SHOULD BE

CHECKED ON A REGULAR

BASIS AND REPLACED AS

NEEDED TO MAINTAIN THE

VALVE’S PERFORMANCE.

!!! IMPORTANT !!!

Valve CL to fixture inlet:

L

to

f

12

¼” -

12

½

”

½

(311 mm - 318 mm)

m

- 3

5

¾

” -

6

”

(146 mm-152 mm)

2

m

m

I

nlet

p

i

p

e

C

L to

f

in. wall

3

¼

” - 4

¼

”

(83 mm - 108 mm)

R

ea

r

of

v

a

lv

e

t

o

f

in. w

a

ll

5

¼

”

- 6

¼

”

(

134 mm - 160 mm

)

V

alve CL to fixture inlet

:

12 ¼

”

- 12 ½

”

(311 mm - 318 mm)

2

”

(

51 mm

)

Openin

g

in wall

3

ROUGH-IN CLOSETS

1½” (38 mm)

36

”

MAX

(

914 mm

)

FIN

.

FL

OO

R

A

DA

G

RAB BAR

1½” (38 mm)

A

DA

G

RAB BAR

FIN

.

WALL

7 ½”

(191 mm)

8 ½”

(216 mm)

6 ½”

(165 mm)

Inlet

p

i

p

e

C

L to

f

in. wall

3

¼

” -

4

¼”

(

83 mm - 108 mm

)

R

ea

r

of

v

a

lv

e

t

o

f

in. w

a

ll

5

¼

” -

6

¼

”

(

134 mm - 160 mm

)

NO

TE: I

f

f

ixture inlet i

s

a

bove rim level

,

consult

wa

ll

h

ung rear

i

n

l

et

rough-in dimensions

V

alve

C

L to

f

ixture inlet

:

15

”

-

1

5 ¼” (381 mm-387 mm)

14

¾

“

-1

5

”

(375-381 mm)

Fixture inlet to wall opening:

n

n

let t

o

8

½

”

-

8

¾

¾

¾

” 16 mm -222 mm

)

(

2

8

¼

“-8

8

8

½

(

210-216 mm

)

”

Valve CL to fixture inlet:

L

to fi

1

5

”

- 1

5

¼

¼

” 81 mm - 387 mm)

(

3

14

¾

“

“

-15 (375-381 mm)”

2

”

(

51 mm

)

open

i

n

g

i

n wa

ll

1

½

½

n

.” mi

n

(38 mm)

3

8 mm

)

33

”

MAX

(

836 mm

)

top o

f

plate

MODEL 8198

URINAL

REAR INLET

SIDE VIEW

SIDE VIEW FRONT VIEW

FRONT VIEW

MODEL 8154

CLOSET

FLOOR MOUNT

REAR INLET

Roughin for Sloan CX is determined relative to the spud connection for the xture being used.

THIS PRODUCT CONTAINS

MECHANICAL COMPONENTS THAT

ARE SUBJECT TO NORMAL WEAR.

THESE COMPONENTS SHOULD

BE CHECKED ON A REGULAR

BASIS AND REPLACED AS NEEDED

TO MAINTAIN THE VALVE’S

PERFORMANCE.

!!! IMPORTANT !!!

ROUGH-IN URINALS

ACCURACY IS IMPORTANT FOR

WALL OPENING DIMENSIONS.

VALVE MUST BE CENTERED

HORIZONATLLY IN OPENING

WITHIN 1/8". FOR ASSITANCE,

PLEASE CONSULT ROUGH-IN

TEMPLATE.

!!! IMPORTANT !!!

ACCURACY IS IMPORTANT FOR

WALL OPENING DIMENSIONS.

VALVE MUST BE CENTERED

HORIZONATLLY IN OPENING

WITHIN 1/8". FOR ASSITANCE,

PLEASE CONSULT ROUGH-IN

TEMPLATE.

!!! IMPORTANT !!!

4

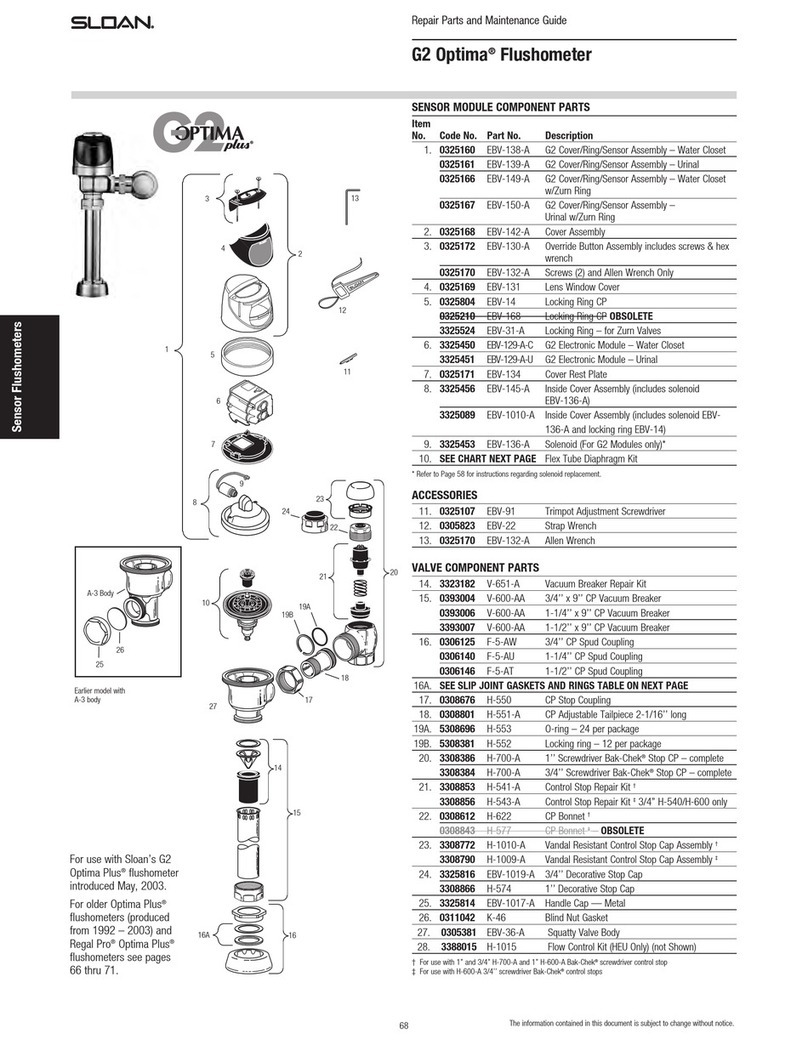

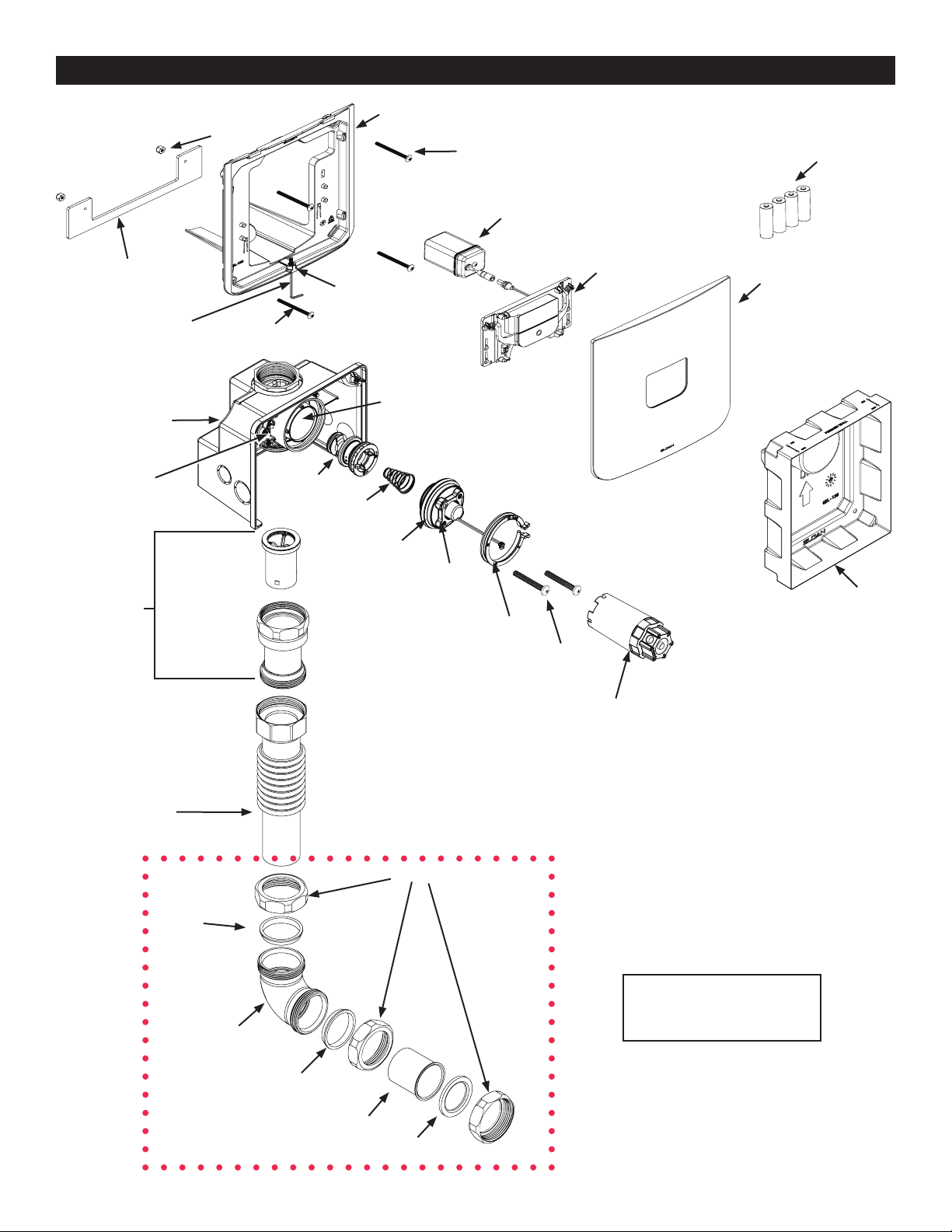

PARTS OVERVIEW

Piston Assembly

Conical

Spring

Activation Assembly

Collar

Activation Assembly

Removal Screws

Adjustment Tool

Flush Volume

Color I.D. Plug

Battery Pack

Mud Guard

Metal C- Bracket

Wall Bracket

F-1 Outlet Connection

S-21 Gasket

Poly Washer

F-305 Elbow

Poly

Washer

F-2 Coupling

Adjustable Tube

V-500A RB

Vacuum Breaker

Assembly

V-651-A

Vacuum Breaker

Kit

Valve Body

Wall Box

Shut-off Sleeve

Lock Nuts (2)

Two (2) Screws Wall Bracket

to Wall Box

Sensor Assembly Wall Plate

Four (4) AA

Batteries

Two (2) Screws Wall Bracket

to Metal C-Bracket

Anti-Vandal Screw

Hex Wrench

NOTE: wall hung closet shown.

Consult page 7 for other

configurations.

5

INSTALL OPTIONAL SWEAT SOLDER ADAPTER (ONLY IF YOUR SUPPLY PIPE DOES

NOT HAVE A MALE THREAD)

BRemove mud plate from valve and save for later use-DO NOT

DISCARD

CInsert sweat adapter into 1 1/2” to 1” threaded adapter (provided).

DConnect 1 1/2” to 1 “ adapter into top of ushometer (“IN”), Tighten

ttings securely into valve body with a xed jaw wrench.

NOTE: DO NOT EXERT FORCE ON WALL BOX TO TIGHTEN

FLUSHOMETER. USED FIXED JAW WRENCH TO HOLD THE

VALVE.

For hardwire

use only:

remove wall

box knock/

cap closest

to the conduit

connection.

FUsing a sweat union (not supplied), connect valve assembly to water

supply pipe.

Water Supply

Sweat Union

(not supplied) Sweat Connections

E

15”-18”

C

D

THREADED

SWEAT ADAPTER

PIPE

AOn a 15”-18” length of pipe (not provided), slide threaded sweat

adapter (not provided) onto water supply pipe until end of pipe rests

against shoulder of adapter. Sweat solder the adapter to pipe

(1" copper x 1" NPT tting).

NOTE: PROPERLY BRACE SUPPLY PIPE AFTER

SWEATING CONNECTIONS TO PREVENT VALVE

MOVEMENT DURING INSTALLATION AND USE

SLOAN RECOMMENDS BRACING VALVE WITHIN 6"

OF INLET CONNECTION.

6

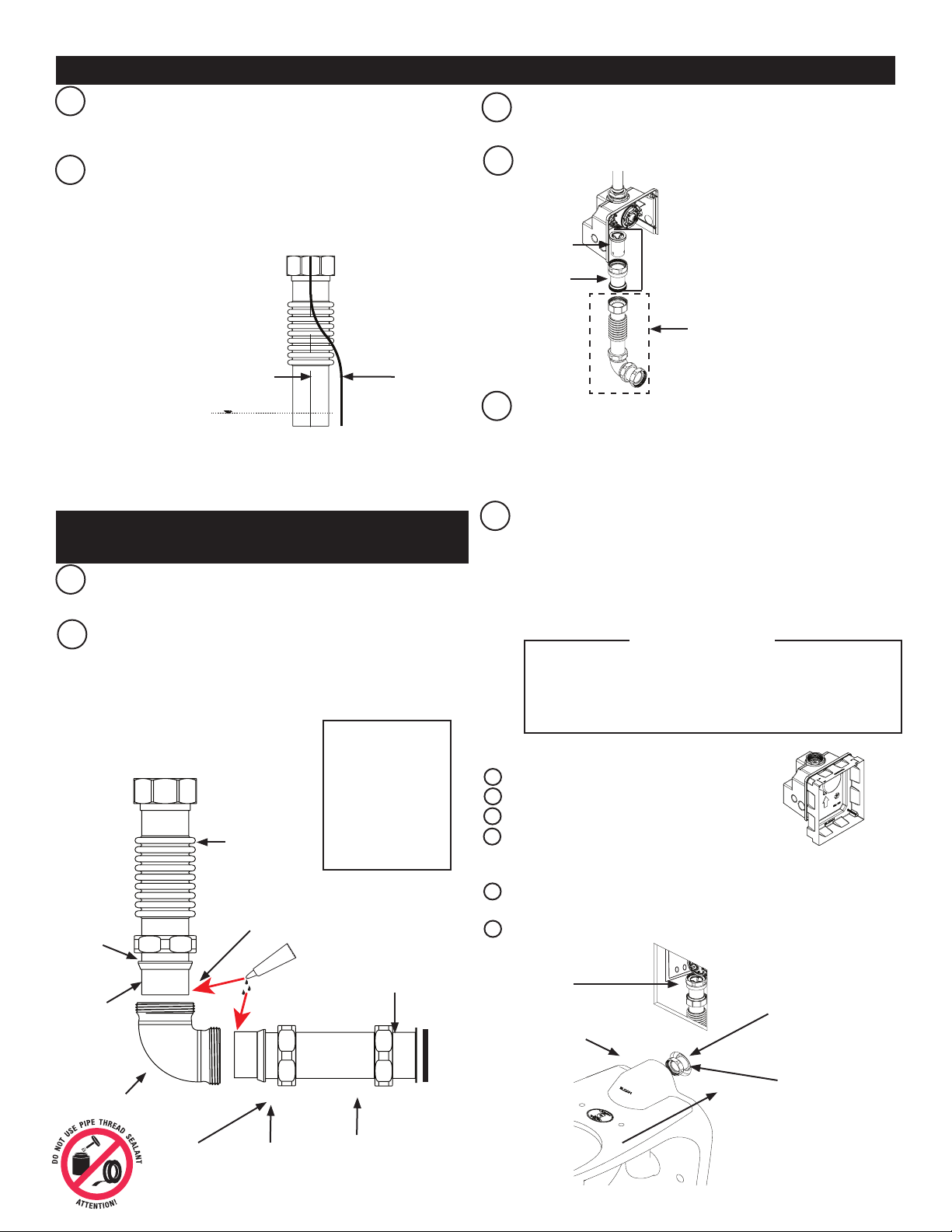

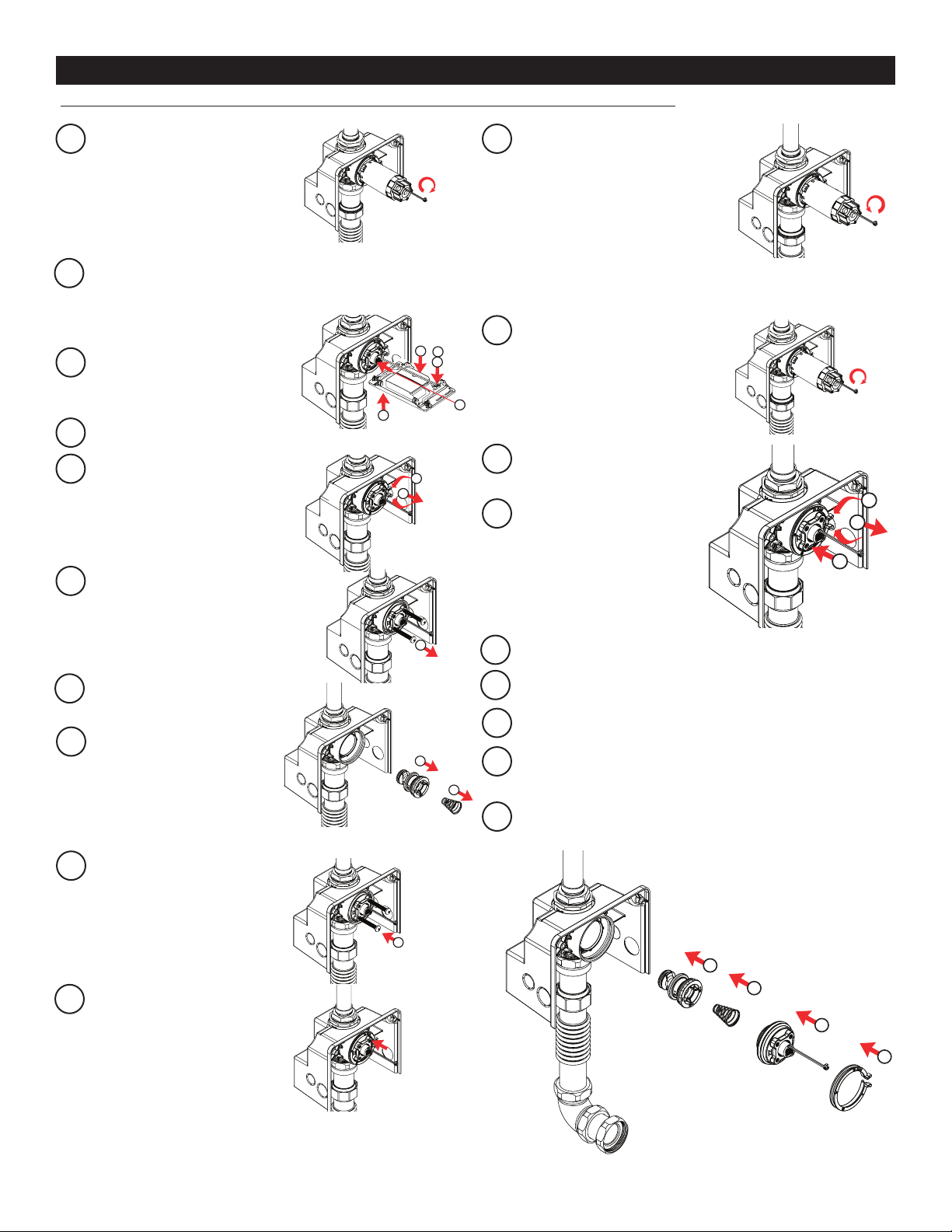

CONFIGURE VACUUM BREAKER AND FLUSH CONNECTION AND CONNECT TO VALVE

AIf needed, trim bottom of adjustable tube using grinding style cut-off

tool

• NOTE: would only be needed for certain ADA

water closet installations.

• Consult rough-in guide (page 2-3)

As needed based on rough-in, pre-bend the adjustable tube to

account for side-to-side misalignment of water supply pipe relative

to xture spud.

B

C

D

Cut F-1 ush connection to length as needed for particular rough-in.

• Consult rough-in

Connect F-1 ush connection and adjustable tube to the elbow

using coupling and poly washer. Apply Loctite to tube ends,

insert tube ends into elbow, and tighten coupling securely (Do not

apply Loctite to coupling threads.

A

Cut as needed

B

Adjustable

Tube

Coupling

nut

Poly washer

Elbow

Taper towards

elbow

Poly washer

Taper towards

elbow F-1 Flush Connection

Coupling nut

EInsert V-651A vacuum breaker kit into vacuum breaker casing.

Attach to valve hand tight.

Attach ush connection to vacuum breaker.

F

GFor hardwire use only: insert conduit and tightly secure it to the wall

box. Run transformer wires through the conduit to the wall box.

NOTE: TRANSFORMER NOT PROVIDED. IT IS VERY

IMPORTANT THAT THE OUTPUT VOLTAGE OF THE

TRANSFORMER BE 6VAC FOR THE UNIT TO FUNCTION

PROPERLY. SLOAN EL-386 OR EL-451 IS RECOMMENDED.

Finish wall. Use supplied mud guard to protect valve during nishing

process.

• Use two (2) mounting screws, if needed, to hold mud

guard to wall box

• Use the marks on mud guard to make sure nished wall

is between 3 ¼” and 4 ¼” from the center line of the pipe.

Vacuum Breaker

V651A Kit

Vacuum Breaker

casing

Flush Connection

Loosen vacuum breaker to valve.

Partially mount xture onto carrier bolts.

Pull ush connection forward through wall.

Make spud connection wrench tight.

• NOTE: Space permitting or chase present, spud

connection can be made behind wall.

Push xture back to wall. Tighten carrier bolts and complete

xture installation.

Re-connect vacuum breaker to valve.

I

J

K

L

M

N

I, N

J

M

L

K

FOR WALL HUNG REAR SPUD FIXTURES

(WATER CLOSETS)

H

NOTE:

Do not trim tube before pre-bending

V500A RB

Loctite must cure

for 24 hours before

turning on water

otherwise the

Loctite will wash

out and joint will

leak

Wall plate opening must be a minimum 7-3/8” wide x

8-3/8” tall (187 mm wide x 213 mm tall) to maximum

7-5/8” wide x 8-5/8” tall (194 mm wide x 219 mm tall)

Valve must be centered within opening.

!!! IMPORTANT !!!

Loosen vacuum breaker to valve.

Mount xture

Pull ush connection forward through wall.

Pre-install escutcheon and ttings in the following order:

1. Wall trim plate

2. Coupling

3. Friction ring

4. Gasket

5. Escucheon

Connect coupling (2) to spud, wrench tight.

Slide wall trim plate against wall.

Re-connect vacuum breaker to valve.

H

5 4 32 1

7

FOR REAR SPUD URINALS

F, L

F

G

H

I

J

K

L

FOR FLOOR MOUNT REAR SPUD FIXTURES (WATER CLOSET)

Adjustable Tube

Coupling

nut

Poly washer

Elbow

Taper towards

elbow

Coupling nut

A

B

Cut F-1 ush connection to length as needed for particular rough-in.

• Consult rough-in

Connect F-1 ush connection and adjustable tube to the elbow

using coupling and poly washer. Apply Loctite to tube ends,

insert tube ends into elbow, and tighten coupling securely (Do not

apply Loctite to coupling threads).

F-1 Flush Connection

Poly Washer

CInsert V-651 vacuum breaker kit into vacuum breaker casing.

Attach to valve hand tight.

Attach ush connection to vacuum breaker.

D

EFor hardwire use only: insert conduit and tightly secure it to the wall

box. Run transformer wires through the conduit to the wall box.

NOTE: TRANSFORMER NOT PROVIDED. IT IS VERY

IMPORTANT THAT THE OUTPUT VOLTAGE OF THE

TRANSFORMER BE 6VAC FOR THE UNIT TO FUNCTION

PROPERLY. SLOAN EL-386 OR EL-451 IS RECOMMENDED.

Finish wall. Use supplied mud guard to protect valve during nishing

process.

• Use two (2) mounting screws, if needed, to hold mud

guard to wall box

• Use the marks on mud guard to make sure nished wall

is between 3 ¼” and 4 ¼” from the center line of the pipe.

Vacuum Breaker

V-651-A Kit

Vacuum Breaker

casing

Flush Connection

Wall

opening

If needed, trim urinal ush tube.

Slide 3/4" coupling over urinal ush tube.

If cutting tube, thread adapter rst, then cut. After

cut, remove adapter to help chase/clean threads.

Thread F-28 brass ange onto urinal ush tube.

Amount of thread engagement will depend on rough-in.

Use provided Loctite to secure and seal F28 ange.

Apply Loctite to tube threads (completely around tube)

where ange will sit on tube. Then thread ange into Loctite.

Ensure Loctite is visible on both sides of ange. Allow time

for Loctite to "set", approx. 30 minutes.Slide F2 coupling over

urinal connection tube, and then install urinal connection tube

to urinal spud and tighten spud coupling.

Secure urinal ush tube to elbow using

1-1/2” gasket.

B

C

B

C

B

C

Adjustable

Tube

Taper toward

elbow

Coupling nut

Coupling

nut

Poly

washer

Elbow

G. Finish wall. Use supplied mud guard to protect valve during nish-

ing process.

• Use two (2) mounting screws, if needed, to hold mud gaurd to

wall box.

• Use the marks on mud guard to make sure finished wall is

between 3 1/4" and 4 1/4" from the center line of the pipe.

Hang urinal on mounting bracket.

Loosen vacuum breaker to valve.

Make spud connection behind the wall.

Re-connect vacuum breaker to valve.

I, K

J

Loctite must cure for

24 hours before turning

on water; otherwise the

Loctite will wash out

and joint will leak.

V500A RB

Loctite must cure

for 24 hours before

turning on water

otherwise the

Loctite will wash

out and joint will

leak

F28 Flange

Loctite must cure

for 24 hours before

turning on water

otherwise the

Loctite will wash

out and joint will

leak

A

B

C

F

D

G

H

I

J

K

Wall plate opening must be a

minimum 7-3/8” wide x 8-3/8”

tall (187 mm wide x 213 mm

tall) to maximum 7-5/8” wide

x 8-5/8” tall (194 mm wide x

219 mm tall). Valve must be

centered horizontally within

opening.

!!! IMPORTANT !!!

Wall plate opening must be a minimum 7-3/8” wide x

8-3/8” tall (187 mm wide x 213 mm tall) to maximum

7-5/8” wide x 8-5/8” tall (194 mm wide x 219 mm tall).

Valve must be centered horizontally within opening.

!!! IMPORTANT !!!

Once lines are ushed clear, turn

activation assembly clockwise to

shut off water.

8

FLUSHING WATER LINES

Note: Valve is shipped with flow adjustment turned off. Requires sensor assembly.

AEnsure water is shut off:

use adjustment tool to turn

activation assembly fully

clockwise.Make sure solenoid

wire passes through center of

adjustment to avoid damage to

the cable.

BVerify valve is not pressurized

i. connect solenoid to sensor assembly.

ii. Connect battery pack.

iii. Press override button to

relieve pressure.

Disconnect Solenoid from Sensor

assembly. Pull on end connector

to prevent damage to wires.

Press in activation assembly.

ESqueeze tabs on Collar and pull

out.

FAttached provided 1/4-20 screws

to activation assembly. Pull to

remove assembly

R

Remove conical spring. Do not

discard!

Remove piston assembly by

pulling straight out. If unable to

grip piston, remove screw from

activation assembly and insert

into center hole of piston.

J

Reinstall activation assembly

and press until fully seated.

Remove screws.

CLOSE

G

H

G1

OPEN CLOSE

G

Reinstall Collar. Collar will

spin freely in valve body when

properly installed.

H

Using adjustment tool, turn activation

assembly counter clockwise to open

ow of water through the valve.

Push in activation assembly.

Squeeze tabs on Collar and pull

out.

I

K

M

L

Reinstall piston. Insert smaller sized end rst until fully seated.

Reinstall conical spring, small end rst, into piston.

Reinstall activation assembly and press until fully seated.

Reinstall orange collar securely. Collar will spin freely in valve body

when properly installed.

Adjust ow rate of valve as described in Section ADJUSTING FLOW

N

S

O

P

Q

CLOSE

E1

E2

B1

C

B3

D

B2

D

C

D

CLOSE

E1

E2

B1

C

B3

D

B2

D

CLOSE

E1

E2

B1

C

B3

D

B2

D

G

H

G1

OPEN CLOSE

G

H

G1

OPEN CLOSE

N2

N1

M

M

Q

R

O

P

N2

N1

M

M

Q

R

O

P

CLOSE

OPEN

9

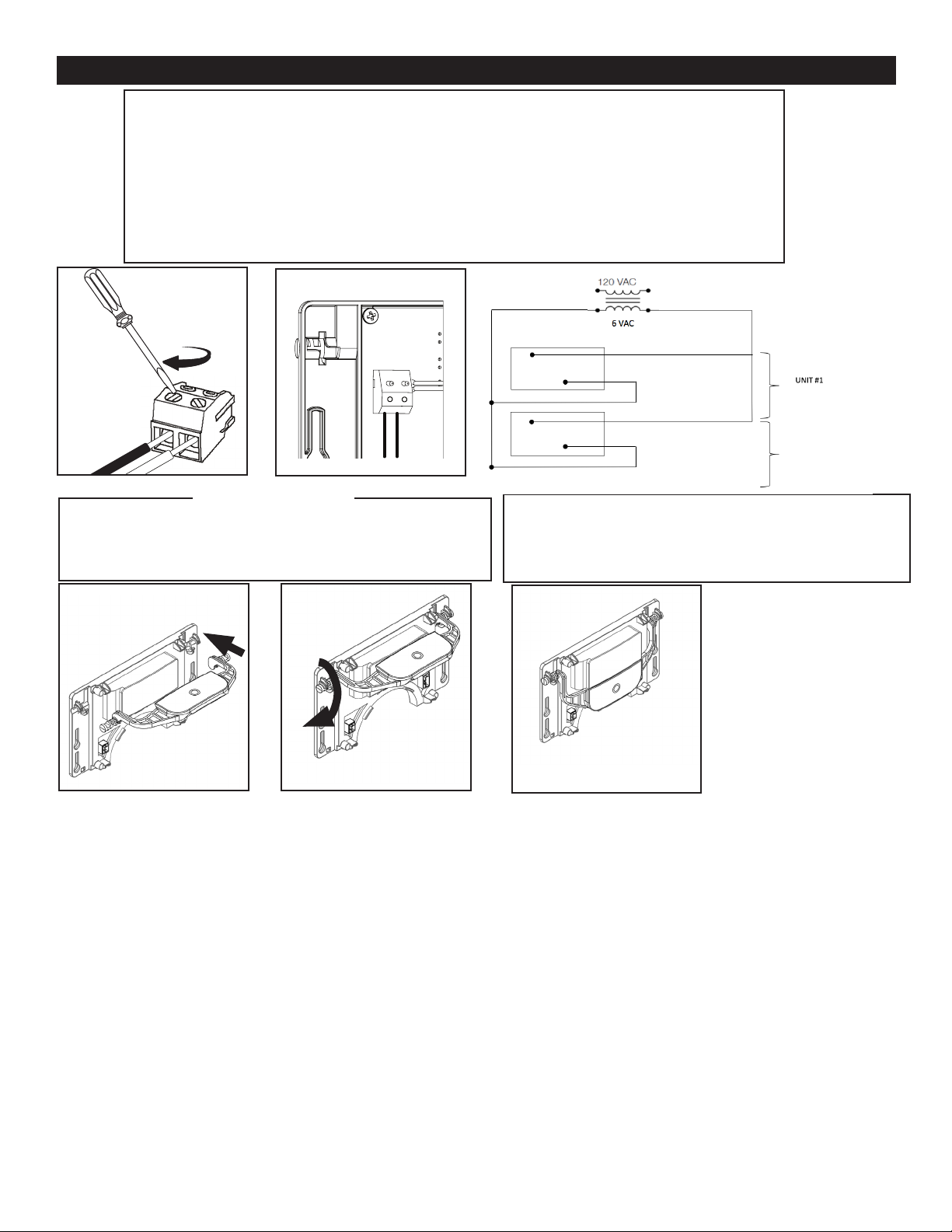

INSTALL WALL PLATE ASSEMBLY

For Hardwire connection use.

i. Using a wire stripper strip the two wire transformer connection from the conduit.

ii. Insert the wire to the Blue Terminal Block provided with the Sensor Assembly

iii. Tighten the terminal block screws using a athead screwdriver 0.118” (3 mm) or smaller.

iv. Connect the Blue terminal block to the two pins in the back of the Sensor Assembly.

IMPORTANT: SURGE PROTECTOR BEFORE THE TRANSFORMER IS RECOMMENDED

iii. iv.

One EL-386 Transformer (sold separately) serves one (1) CX Closet/

Urinal ushometer.

One EL-451 Transformer (sold separately) serves up to (6)CX Closet/

Urinal ushometer with 20 gauge wire within 50 feet

UNIT #2 THRU #10

(IF EL-451 USED)

THE SENSOR ASSEMBLY COMES WITH THE BUTTON

ALREADY INSTALLED. IN CASE THE BUTTON HAS COME

OFF FROM THE SENSOR ASSEMBLY DURING SHIPMENT,

INSTALL IT FOLLOWING THE FIGURE BELOW.

!!! NOTE !!!

Sloan CX

Sloan CX

10

INSTALL WALL PLATE ASSEMBLY (CONT.)

A

B

B

C

D

Assemble C-Bracket to the wall bracket using two (2) 2” long

#8-32 screws.

Tighten two (2) locking nuts to the screws about ¼” away from tail

of the screws.

A

Rotate wall bracket slightly about vertical axis and slide C-Bracket

behind the nished wall while holding the top of the wall bracket.

Once C-bracket is behind the wall, align top two (2) holes on the

bracket to the wall box and secure in place using two (2) 2” long

#8-32 screws. Tighten the bottom two (2) screws on the bracket.

Make sure the wall bracket is positioned plumb and level before

tightening the screws completely.

The Sloan CX sensor assembly is designed to work with both

hardwire and battery as a back-up or only the battery power

connection

INSERT SOLENOID

CONNECTOR HERE

D

Connect Battery Box D-shape connector to Sensor assembly.

NOTE: RED LED WILL START BLINKING WHEN POWER IS

CONNECTED TO THE SENSOR ASSEMBLY.

Mount the Sensor Assembly to the wall bracket.

i. Aligned the four (4) slots on the sensor assembly with the

mounting pegs on the wall bracket.

ii. Slide the sensor Assembly all the way down.

G

Insert ushometer solenoid connector to the sensor assembly.

F

INSTALL BATTERY BOX AND SENSOR ASSEMBLY

NOTE: Solenoid can only be installed in one orientation

WATER DOES NOT HAVE TO BE TURNED OFF TO REPLACE

BATTERIES. USE ALKALINE BATTERIES FOR PROPER UNIT

OPERATION.

Remove battery cover by loosening screw using a

Phillips head screwdriver.

Install four (4) Alkaline AA-size batteries into the battery box in the

orientation noted on the inside the battery box.

NOTE

CReinstall the battery cover and, using a screwdriver, tighten the screw

until the battery cover is tightly secure.

Insert the Battery Box on the right side of the ushometer as shown.

E

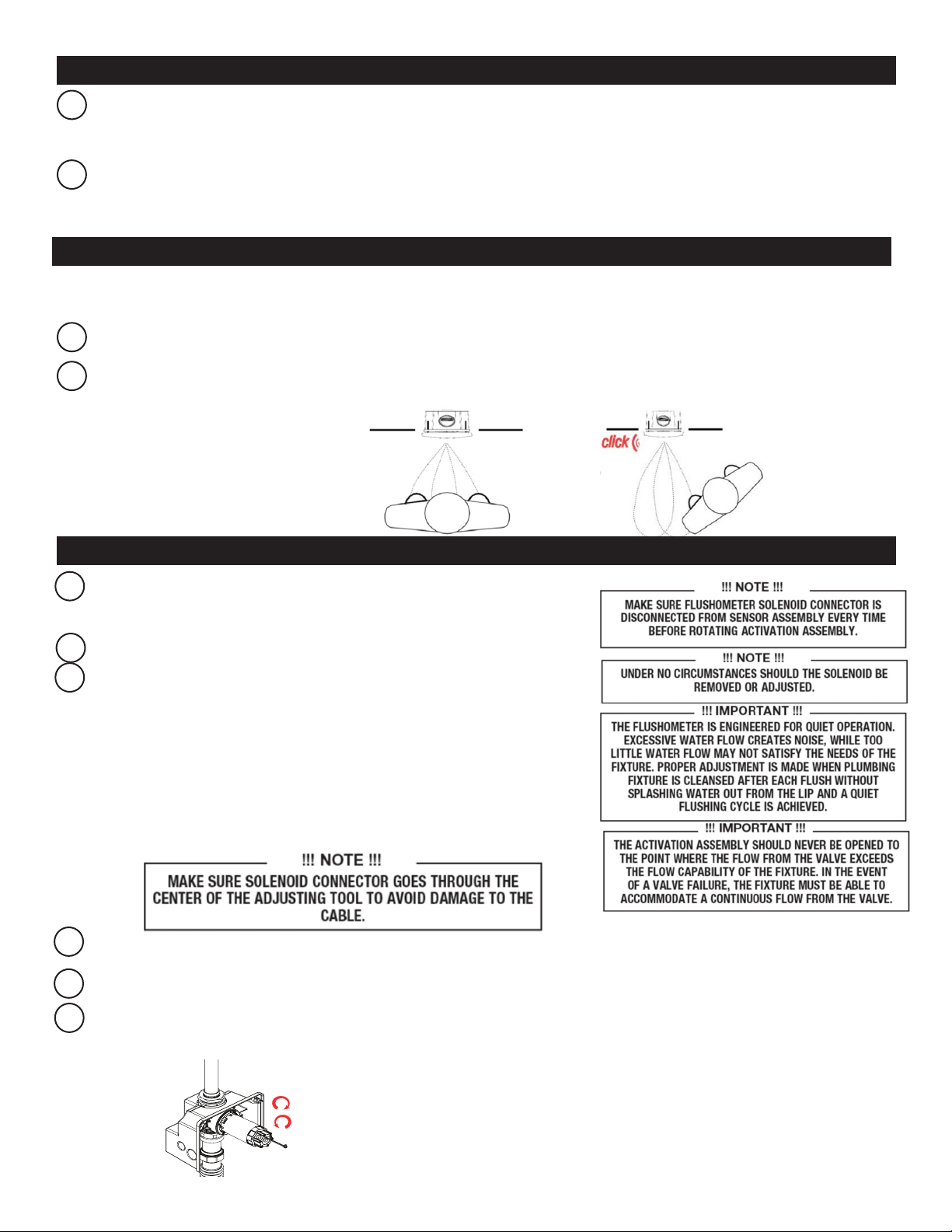

SENSOR OPERATION

After power is applied, the Sensor Module will perform its Start-up routine for approximately 3 minutes 30 seconds with LED blinking. Step

away from sensor during this

time. Sensor will calibrate without user in detection area to calibrate "non-use" enviroment.

NOTE: A one (1) second long Red LED, followed by one slow Red LED blinking in the Sensor Window indicates sensor is in the start-up mode.

There will be two (2) Red LED pulses (each two (1) second long) in the Sensor Window to indicate the start-up routine is complete.

After the start-up routine is complete, in the rst ten (10) minutes of operation, a visible Red LED ashes in the Sensor Window of the CX

Flushometer when a user is detected.

The CX Flushometer has a factory set sensing range:

i. Water Closet Models – 22” to 46” (559 mm to 1168 mm)

ii. Urinal Models – 15” to 34” 381 mm to 864 mm)

Test sensor by stepping in front of the sensor for 10 seconds.

After 10 seconds step away from the sensor and listen for a “CLICK”

The factory setting should be satisfactory for most installations. If a range adjustment is required, refer to the range adjustment instructions in this

installation guide (See page 13).

TEST SENSOR OPERATION

Flushometer is shipped with the ow control adjustment turned OFF.

Disconnect Flushometer Solenoid connector from the Sensor Assembly. Pull on end

connector to prevent damage to wires.

Lift the Sensor Assembly Override Button up to access the activation assembly.

Open water ow by turning activation assembly slowly COUNTERCLOCKWISE using

adjusting tool and a screwdriver or a wrench.

Connect Flushometer Solenoid connector to the Sensor Assembly.

Activate Flushometer by pressing the Override Button.

Adjust Activation Assembly after each ush until the ow rate

delivered properly cleanses the xture (turn CLOCKWISE to lessen

ow and COUNTERCLOCKWISE to increase ow).

A

B

A

B

C

A

B

D

E

F

CLOSE

OPEN

ADJUST WATER FLOW

11

i.There is approximately 1/8-turn (45°) of free spinning as the activation

assembly engages the shut-off sleeve between opening and closing

the valve.

ii. A 1-1/2" socket or wrench can be attached to the adjustment tool or

a screwdriver can be passed through the side side holes to provide

additional torque.

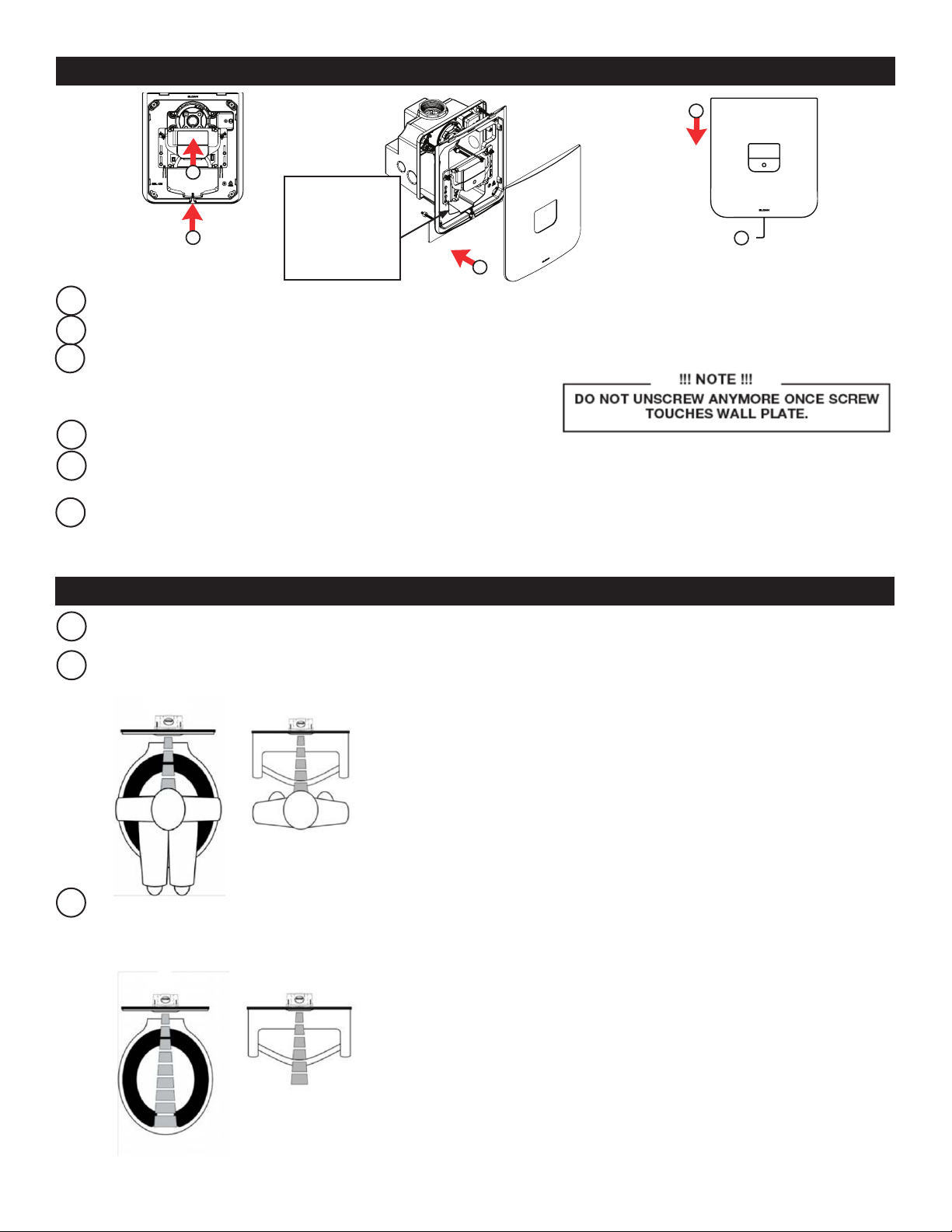

INSTALL WALL PLATE

Make sure retaining screw on bracket is fully tightened clockwise.

Slide Sensor Assembly all the way up.

Align Wall Plate cut out with the window and Override Button of Sensor Assembly and

push Wall Plate all the way in.

i.Make sure sensor window and button are sitting inside the wall plate cut out.

Slide Wall Plate all the way down.

Retaining screw is designed to rest inside the wall plate. Turning the retaining screw counter clockwise using supplied Allen key until it

touches wall plate will lock plate in place, preventing the plate from sliding upward and being removed.

Make sure Wall Plate doesn’t slide up.

A

B

C

OPERATION

A continuous, INVISIBLE light beam is emitted from the Sloan CX Sensor.

After the user enters the beam’s effective range, 22 to 46 inches (559 mm to 1168 mm) for closet installations and 15 to 34 inches (381 mm to

864 mm) for urinal installations for ten (10) seconds the ushometer is armed.

A

B

When the user steps away, the sensor initiates a “one-time” signal that activates the ushing cycle to ush the xture (1 second delay for urinal,

3 seconds delay for closet). The Circuit automatically resets and is ready for the next user.

C

A

B

D

E

C

A

B

D

E

C

A

B

D

E

C

D

E

F

12

NOTE: If desired,

orange flow

adjustment tool

can be stored

here.

RESTART SENSOR (ONLY IF NECESSARY)

The Sloan CX Flushometer has a factory set sensing range:

Water Closet Models - 22” to 46” (559 mm to 1168 mm)

Urinal Models - 15” to 34” (381 mm to 864 mm)

The Factory setting should be satisfactory for most installations. If the range is too short (i.e. not picking up users) or too long (i.e., picking up

opposite wall or stall door) the range can be adjusted.

NOTE: WATER DOES NOT HAVE TO BE TURNED OFF TO ADJUST RANGE.

Make sure to remove all the non-permanent targets in sensor view area.

Push Override button for 20-30 seconds.

The Red LED in the sensor window starts slow blinking.

Release the button during the LED blinking and step away.

The CX will enter into start-up mode.

The setting mode will run for one minute.

A

B

C

D

E

F

BASIC SERVICING

A. Remove wall plate.

Note: water can be shut-off without removing plastic mounting plate. Removal of plastic mounting plate provides more hand room for servicing valve

and accessing ush connection.

i. Turn the retaining screw at the bottom of wall plate using Allen Key clockwise

ii.Slide wall plate up, then pull out.

B. Disconnect ushometer solenoid connector from the sensor assembly. Pull on end connector to prevent damage to wires.

C. Shut off water: use adjustment tool to turn activation assembly fully clockwise. Pass solenoid wire through center of tool to avoid damage. Remove

tool when closed.

D. Reconnect the sensor assembly to the solenoid. Press override button to relieve pressure. Disconnect solenoid. Pull on end connector to prevent

damage to wires.

E. Push in activation assembly until fully seated.

F. Squeeze tabs on Collar and pull out.

G. Attach provided screws to activation assembly. Pull to remove assembly.

DO NOT TURN THE ASSEMBLY TO AVOID TURING WATER FLOW BACK ON. DO NOT REMOVE OR ADJUST THE

SOLENOID.

H. Remove conical spring. Do not discard!

I. Remove piston assembly by pulling straight out. If unable to grip piston, remove screw from activation assembly and insert

into center hole of piston.

J. Reinstall or replace piston. Insert smaller sized end rst until fully seated.

K. Reinstall or replace conical spring, small end rst, into piston.

L. Reinstall or replace activation assembly and press until fully seated.

M. Reinstall orange safety ring securely. Safety ring will spin freely in valve body when properly installed. NOTE: using screws attached to activation

assembly, pull activation assembly forward to ensure proper alignment.

N. Using adjustment tool, slowly turn the activation assembly counterclockwise to open ow.

O. Adjust ow as described on page 11.

P. Install wall plate as described on page 12.

13

TROUBLESHOOTING

CARE AND CLEANING

DO NOT use abrasive or chemical cleaners (including chlorine bleach)

to clean Flushometers that may dull the luster and attack the chrome or

special decorative nishes. Use ONLY mild soap and water, then wipe dry

with clean cloth or towel. While cleaning the bathroom tile, protect the

Flushometer from any splattering of cleaner. Acids and cleaning uids will

discolor or remove chrome plating.

A. Sensor Flashes Continuously Only When User Steps Within Range.

i. Unit in Start-Up mode; no problem. This feature is active for the rst ten (10) minutes of operation.

B. Valve Does Not Flush; Sensor Not Picking Up User.

i. Range too short; increase the range.

C. Valve Does Not Flush; Sensor Picking Up Opposite Wall or Surface, or Only Flushes When Someone Walks By.

Red Light Flashes Continuously for First 10 Minutes Even with No One in Front of the Sensor.

i. Range too long; shorten range.

D. Valve Does Not Flush Even After Adjustment.

i. Ensure water supply to valve is turned on.

ii. Activation Assembly sleeve is in closed position. Turn counterclockwise to open water ow. NOTE: there is approximately 1/8-turn (45°) of free

spinning as the activation assembly engages the shut-off sleeve between opening and closing the valve.

iii. Batteries completely used up; replace batteries.

iv. Problem with activation assembly; replace activation assembly.

v. Problem with Sensor Assembly; replace Sensor Assembly.

E. Red Light Blinks four (4) Times When User Steps Within Range (Battery Only).

i. Batteries low; replace batteries.

F. Red Light Blinks four (4) Times When User Steps Within Range (Hardwire and Battery).

i. Battery box not connected; connect battery box to sensor assembly.

ii. Batteries low; replace batteries.

G. Valve Does Not Shut off.

i. Metering bypass hole in piston is clogged. Remove the piston O-ring from groove and wash under clean running water.

Replace piston if cleaning does not correct the problem.

ii. Supply line water pressure has dropped and is not sufcient to close the valve. Close Activation Assembly until pressure is

restored. NOTE: under some conditions, opening the shut-off sleeve can correct the force imbalance and cause the valve close.

iii. Piston is damaged. Replace with new proper gpf/Lpf piston.

iv. Solenoid latched in open position during valve shipment. Connect sensor assembly and press override button. See "install battery box and sensor

assembly" section on page 10 for additional information.

H. Too much water to Fixture.

i. Activation Assembly not adjusted properly. Readjust Activation Assembly.

ii. Piston is damaged. Replace with new proper gpf/Lpf piston

iii. Wrong CX model installed; i.e.,1.6 gpf. model installed on 0.5 gpf/1.9 Lpf or 0.25 gpf/1.0 Lpf urinal xture. Replace

with proper CX model per guide.

I. Not enough water to Fixture.

i. Activation Assembly not adjusted properly. Readjust Activation Assembly by turning counterclockwise.

ii. Wrong CX model installed; i.e. 0.5 gpf. urinal installed on 1.6 gal. closet xture. Replace with proper CX model.

iii. Water supply pressure is inadequate (low). Increase the water supply pressure. Contact the xture manufacturer for

minimum water supply requirements of the xture.

J. Chattering noise is heard during flush.

i. Reduce ow pressure by turning Activation Assembly.

ii. Air trapped inside the valve and/or supply pipe. Air takes time - both count of ushes and actual duration-to be fully removed.

14

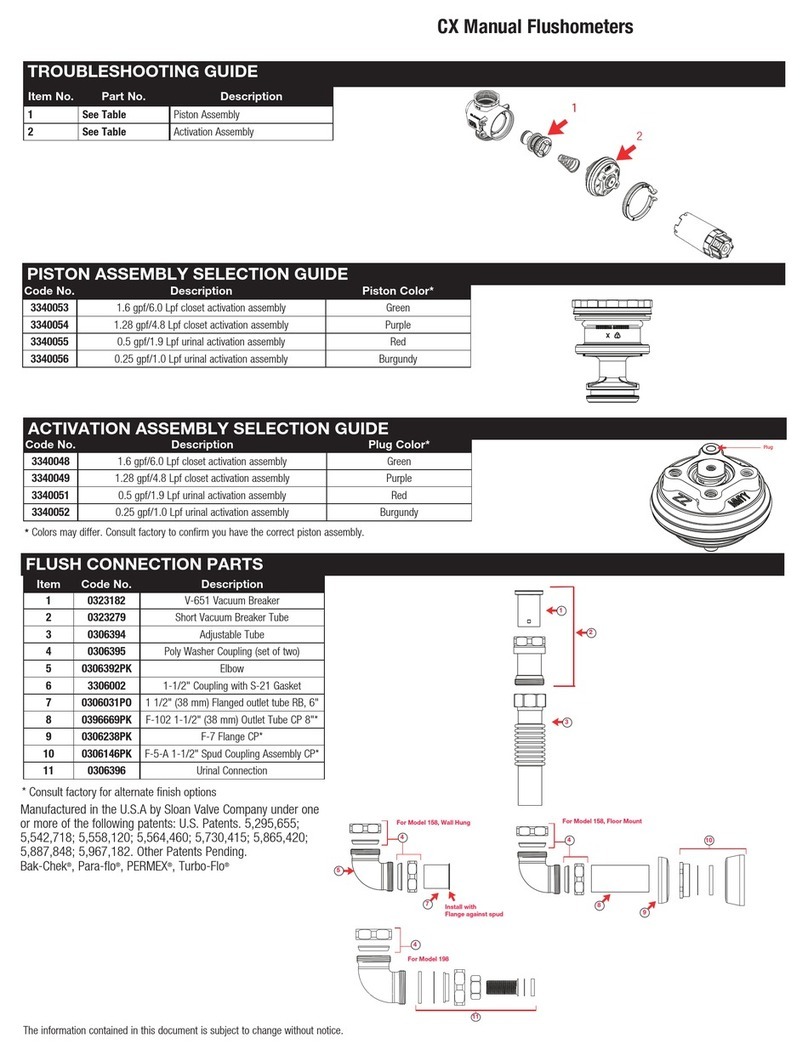

2

1

Item No. Part No. Description

1Consult Factory Piston Assembly

2See Table Activation Assembly

VALVE ASSEMBLY GUIDE

15

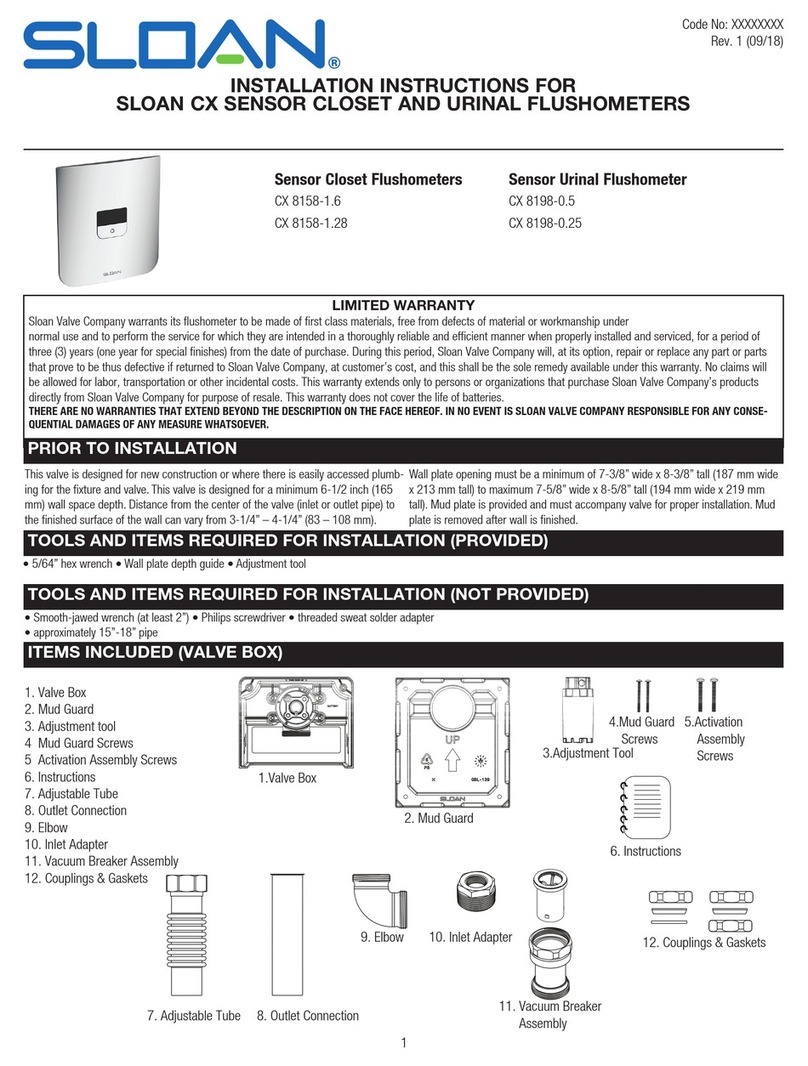

Code No. Description Plug Color*

3340057 1.6 gpf/6.0 Lpf closet activation assembly Green

3340058 1.28 gpf/4.8 Lpf closet activation assembly Purple

3340059 0.5 gpf/1.9 Lpf urinal activation assembly Red

3340060 0.25 gpf/1.0 Lpf urinal activation assembly Burgundy

33400006 0.125 gpf/0.5 Lpf urinal activation assembly Not Applicable

ACTIVATION ASSEMBLY SELECTION GUIDE

* Colors may differ. Consult factory to conrm you have the correct activation assembly.

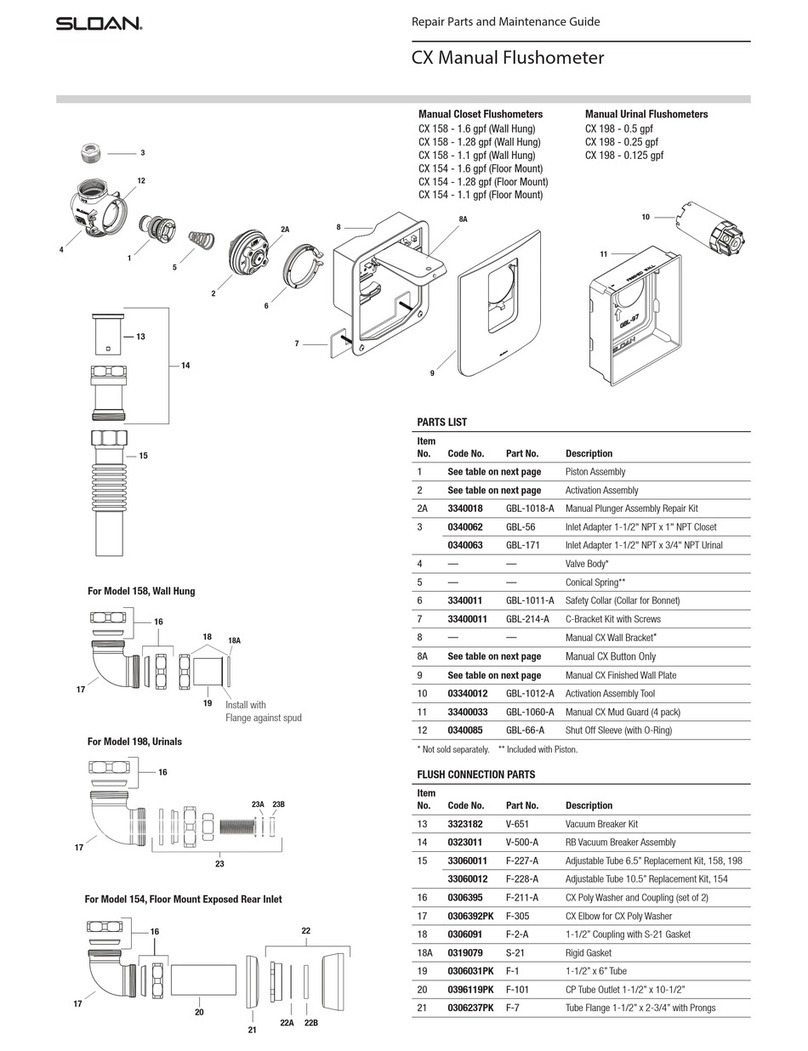

Item Code No. Description

13323182 V-651 Vacuum Breaker Repair Kit

2 0323279 V500A RB Short Vacuum Breaker Assembly

30306391

0306367

Adjustable Tube for Wall Hung Closets and Urinals

Adjustable Tube for Floor Mount Closets

4 0306395 CX Poly Washer Coupling (set of 2)

5 0306392PK F-305 CX Elbow For CX Poly Washer

6 0306091 F-2-A 1-1/2" Coupling with S-21 Gasket

7 0306031PO F-1 1 1/2" (38 mm) Flanged outlet tube RB, 6"

8 0396669PK F-102 1-1/2" (38 mm) Outlet Tube CP 8"*

9 0306237PK F-7 Flange 1 1/2" x 3" w/Prongs, CP*

10 0306146PK F-5-A 1-1/2" Spud Coupling Assembly CP*

11 0306396 CX Urinal Connection

FLUSH CONNECTION PARTS

The information contained in this document is subject to change without notice.

Manufactured in the U.S.A by Sloan Valve Company under one or

more of the following patents: U.S. Patents. 5,295,655; 5,542,718;

5,558,120; 5,564,460; 5,730,415; 5,865,420; 5,887,848;

5,967,182. Other Patents Pending.

Bak-Chek®, Para-flo®, PERMEX®, Turbo-Flo®

* Consult factory for alternate nish options

IN ORDER FOR THE WATER CLOSET AND THE URINAL TO PERFORM PROPERLY FOR ITS INTENDED USE, YOU MUST FOLLOW THESE INSTRUCTIONS:

A. IDENTIFY YOUR FLUSHOMETER MODEL NO.

B. CHECK FOR THE WATER CONSUMPTION LABEL ATTACHED TO THE FLUSHOMETER AND FIXTURE, ENSURING THEY MATCH

C. REFER TO SPECIFIC FLUSHOMETER SECTION IN GUIDE FOR APPROPRIATE REPLACEMENT PART NO.

SLOAN VALVE COMPANY • 10500 SEYMOUR AVENUE • FRANKLIN PARK, IL 60131

Phone: 1.800.982.5839 or 1.847.671.4300 • Fax: 1.800.447.8329 or 1.847.671.4380 • sloan.com

COPYRIGHT © 2020 SLOAN VALVE COMPANY Code No: 0816858 – Rev. 3 (07/20)

Tech Support: 1.888.756.2614 or 1.888.SLOAN14

1

2

3

410

5

4

8

7Install with

Flange against spud

For Model 8158, Wall Hung For Model 8154, Floor Mount

9

4

For Model 8198

11

6

For complete listing of items available for repair,

please consult Maintenance and Repair Guide.

Contact Technical Support for assistance.

1.888.756.2614 or 1.888.SLOAN14

This manual suits for next models

7

Table of contents

Other Sloan Measuring Instrument manuals

Sloan

Sloan CX Series User manual

Sloan

Sloan CX 158 Use and care manual

Sloan

Sloan CX Guide

Sloan

Sloan Royal Use and care manual

Sloan

Sloan TruFlush Use and care manual

Sloan

Sloan NAVAL Operating manual

Sloan

Sloan G2 Optima Plus Instruction sheet

Sloan

Sloan EBV-200-A SMOOTH User manual

Sloan

Sloan CX 8158 Use and care manual

Sloan

Sloan EL-750/Hardwired Use and care manual