The information contained in this document is subject to change without notice.

Repair Parts and Maintenance Guide

12

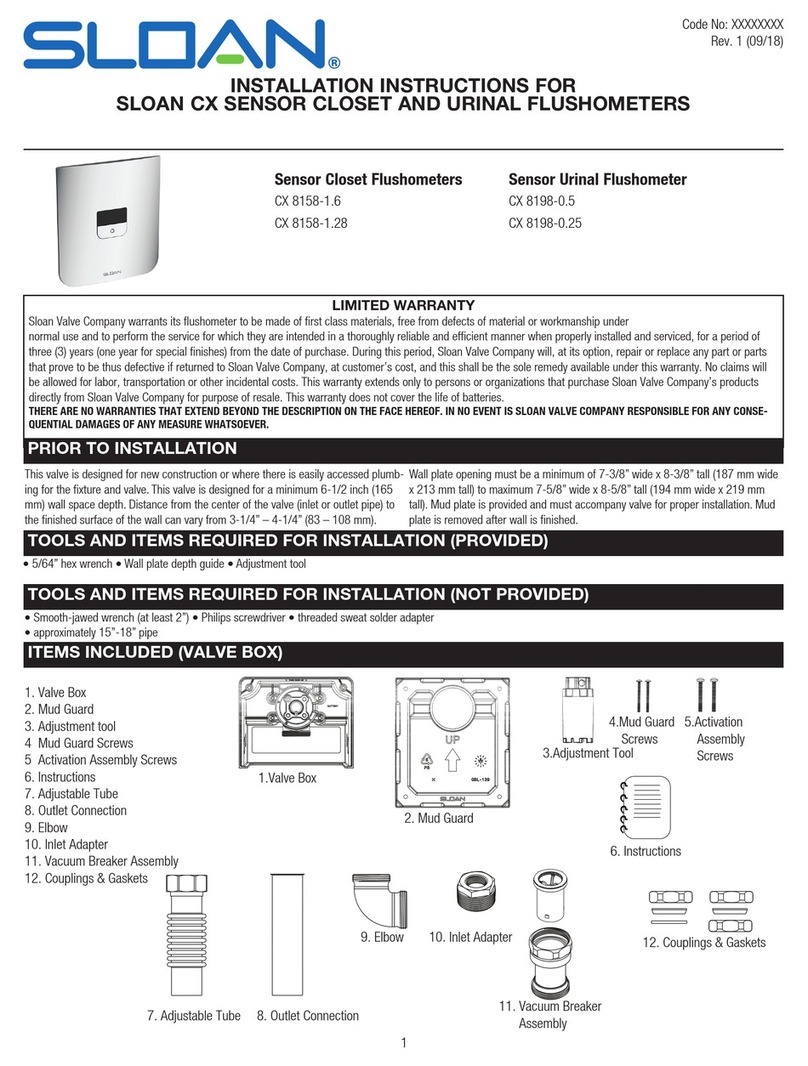

Manual Flushometers

Royal®Flushometer

ROYAL®PERFORMANCE KIT

Relief Refill Flow

Code No. Part No. Description Valve†Head* Ring

3301070 A-1101-A Low Consumption Water Closets-1.6 gpf (6.0 Lpf)** Green Gray Smooth

3301071 A-1102-A Water Saver Water Closets-3.5 gpf (13.2 Lpf)** White Gray Smooth

3301072 A-1103-A 9 Liter European Water Closets-2.4 gpf (9.0 Lpf) Blue Gray Smooth

3301073 A-1106-A Wash Down Urinals-0.5 gpf (1.9 Lpf) Green Black Smooth

3301074 A-1107-A Low Consumption Urinals-1.0 gpf (3.8 Lpf)** Green Black Slotted

3301075 A-1108-A Water Saver Urinals-1.5 gpf (5.7 Lpf)** Black Black Smooth

*Closet rell heads (gray) have larger slots than urinal rell heads (black).

*Contact factory for optional tune-up kits.

DIAPHRAGM ONLY KIT

Relief Refill Flow

Code No. Part No. Description Valve†Head* Ring

3301502 A-1041-A Low Consumption Water Closets-1.6 gpf (6.0 Lpf)** Green Gray Smooth

3301501 A-1038-A Water Saver Water Closets-3.5 gpf (13.2 Lpf)** White Gray Smooth

3301505 A-1044-A 9 Liter European Water Closets-2.4 gpf (9.0 Lpf) Blue Gray Smooth

3301504 A-1043-A Wash Down Urinals-0.5 gpf (1.9 Lpf) Green Black Smooth

3301503 A-1042-A Low Consumption Urinals-1.0 gpf (3.8 Lpf)** Green Black Slotted

3301500 A-1037-A Water Saver Urinals-1.5 gpf (5.7 Lpf)** Black Black Smooth

3301506 A-1045-A High-Efciency Water Closets-1.28 gpf (4.8 Lpf) Blue Gray Smooth

3301142 A-1047-A High-Efciency Urinals-0.25 gpf (1.0 Lpf) with White Inserts White HEU Black Smooth

3301143 A-1050-A High-Efciency Urinals-0.125 gpf (0.5 Lpf) with White Inserts Blue HEU Black Smooth

3301594 A-1075-A-BX High-Efciency Water Closets-1.28 gpf (4.8 Lpf) RW Blue Black Smooth

3301592 A-1073-A-BX High-Efciency Urinals-0.5 gpf (1.9 Lpf) RW Green Black Smooth + Slotted

3301591 A-1077-A-BX High-Efciency Urinals-0.25 gpf (1.0 Lpf) RW White HEU Black Smooth

3301590 A-1070-A-BX High-Efciency Urinals-0.125 gpf (0.5 Lpf) RW Blue HEU Black Smooth

† Consult factory for availability of replacement plastic relief valves (green, black, blue, and white) and brass relief valves.

NOTE: For older water closets that require 4.5 gpf (17.0 Lpf), choose kits A-1102-A or A-1038-A, but remove the ow ring before use. For blowout-style urinals that require 3.5 gpf (13.2 Lpf),

choose kits A-1102-A or A-1038-A. For service sinks that require 6.5 gpf (24.6 Lpf), order A-36-A diaphragm repair kit (not shown Sloan Code No. 3301036) and remove the ow ring before

use. Regulations for low consumption xtures prohibit the use of higher ush volumes.

*Closet rell heads (gray) have larger slots than urinal rell Heads (black).

** Water Saver (3.5 gpf closet and 1.5 gpf urinal) and Low Consumption (1.6 gpf closet and 1.0 gpf urinal) xtures must use matching gpf (Lpf) diaphragm kits; using a smaller gpf (Lpf) kit in

xtures not intended for less volume will result in inadequate dilution in urinals and improper evacuation in closets.

RW for use with Reclaimed Water Flushometers.

*Contact factory for optional tune-up kits.

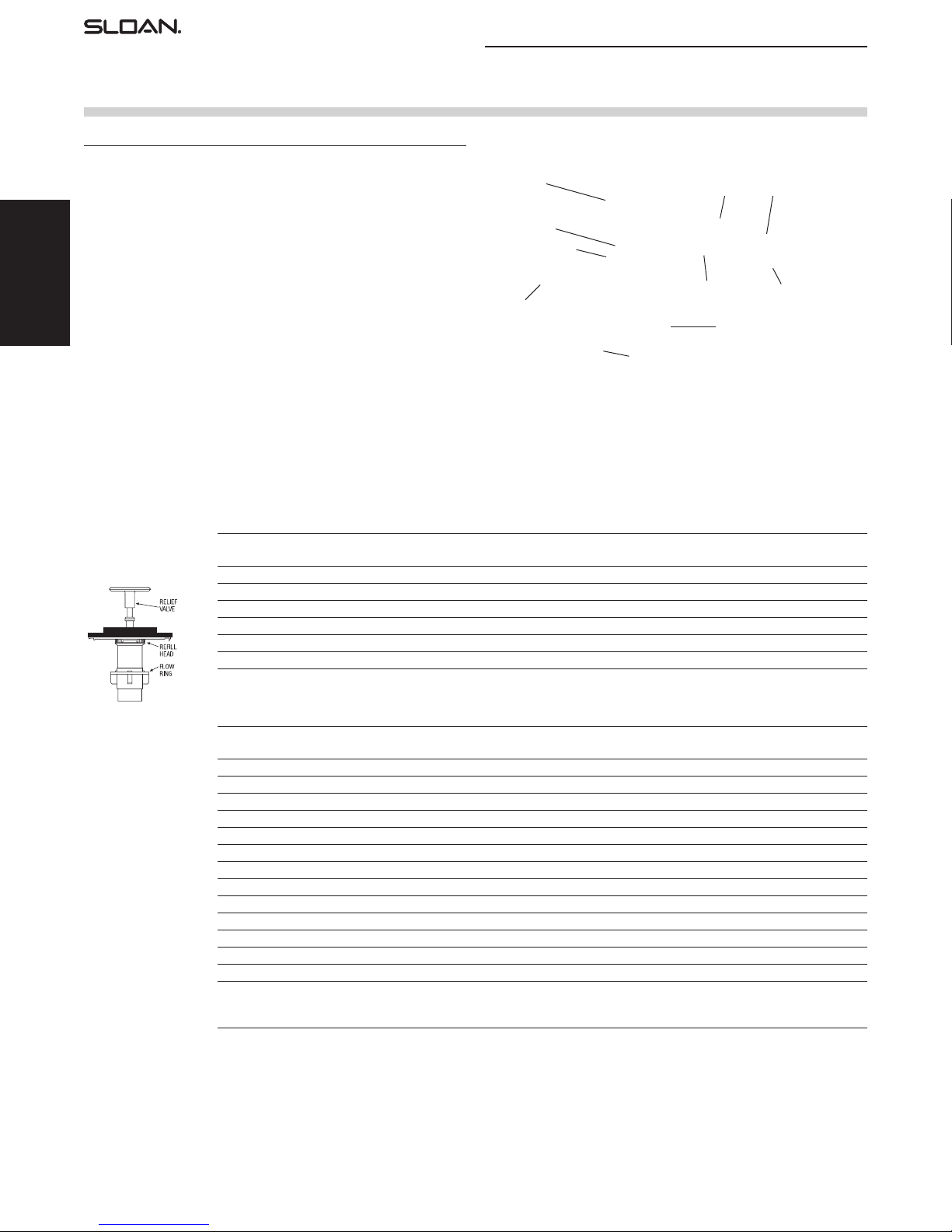

The colors of the relief valve and

the rell head plus the shape of

ow ring identify the ush volume

of a DUAL-FILTERED DIAPHRAGM

ASSEMBLY.

DUAL-FILTERED DIAPHRAGM ASSEMBLY

Available in diaphragm only and Royal®Performance™Kits.

Royal®Performance™Kit includes dual-ltered diaphragm assembly (item

3), handle repair kit with triple seal packing (item 8), high back pressure

vacuum breaker repair kit (item 11), and one tailpiece O-ring (item 15A).

DIAPHRAGM ONLY KIT contains “drop-in” dual-ltered diaphragm assembly

(item 3) ONLY.

The dual-ltered diaphragm can be used in Royal,

®Regal,

®and similar

diaphragm-style valve bodies. For use in Sloan valve bodies with a bell-

shaped cover (manufactured before 1964), replace the bottom lter ring in

these kits with a blue A-108 lter ring (not shown Sloan Code No. 5301283).

NOTE: In January 1998, the Royal®diaphragm design was upgraded to a

preassembled unit with two (2) plastic ltering rings attached to the rubber diaphragm

(one on top and one on bottom). If the ushometer you are servicing has our older,

segmented diaphragm with brass by-pass hole, refer to our Regal section for

additional troubleshooting information.

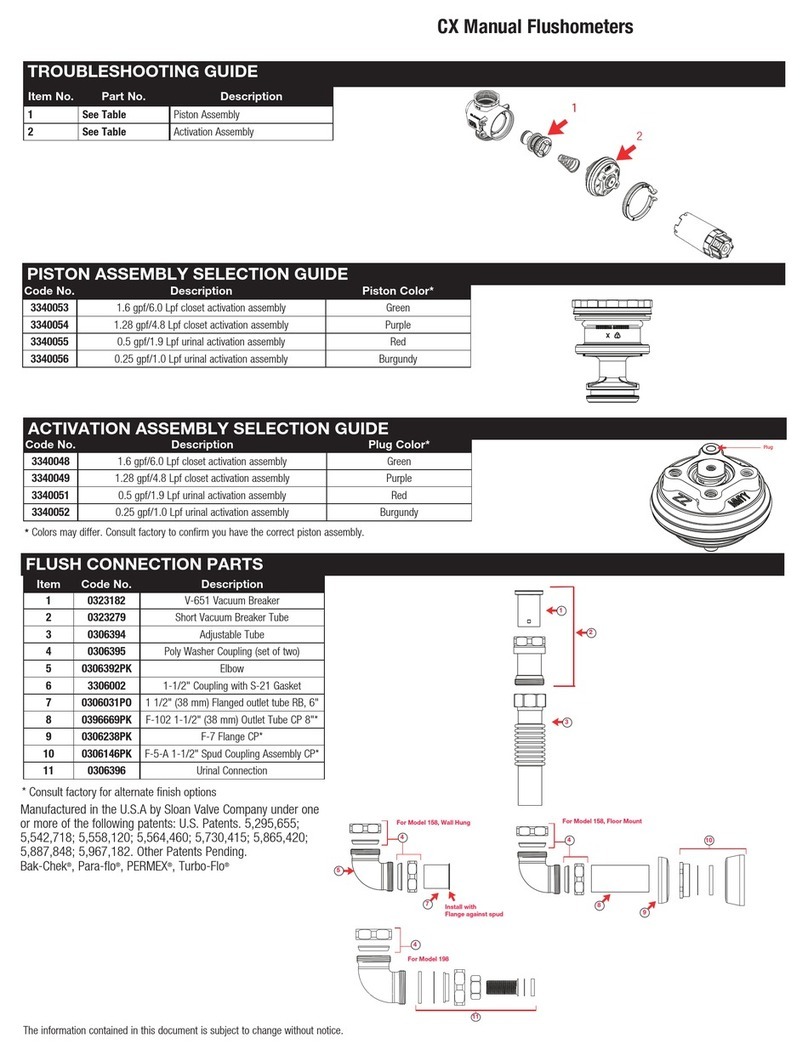

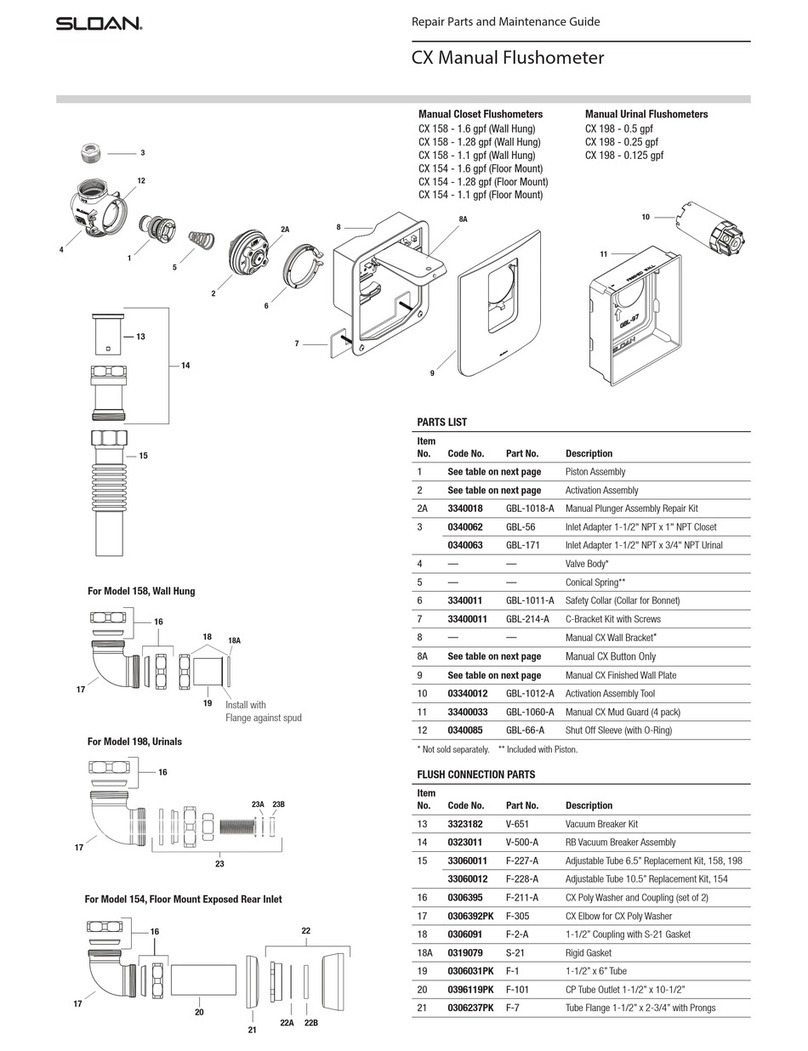

COVER

BODY

HANDLE COUPLING

HANDLE ASSEMBLY

FLUSH CONNECTION

(VACUUM BREAKER)

SPUD COUPLING

STOP

COUPLING

CONTROL

STOP

SUPPLY

FLANGE

TAILPIECE

OUTLET COUPLING

SPUD FLANGE

The information contained in this document is subject to change without notice.

Royal®

Flushometer

Repair Parts and Maintenance Guide

13

Manual Flushometers

ATTENTION INSTALLERS: With the exception of the control stop inlet,

DO NOT USE pipe sealant or plumbing grease on any valve component or

coupling! To protect the chrome or special nish of Sloan ushometers,

DO NOT USE toothed tools to install or service these valves. Use our

A-50 Super-Wrench or other smooth-jawed wrench to secure couplings.

Regulations for low consumption xtures (1.6 gpf/6.0 Lpf closets and

1.0 gpf/3.8 Lpf urinals) prohibit use of higher ush volumes.

1. Flushometer does not function (no flush).

A. Control stop or main supply valve is closed. Open control stop or main

supply valve.

B. Handle assembly is damaged. Replace B-73-A handle or repair with

B-51-A handle repair kit.

C. Relief valve is damaged. Replace relief valve.

2. Handle leaks.

A. Handle seal or handle assembly is damaged. Replace B-73-A handle

or repair with B-51-A handle repair kit.

3. Water splashes from fixture.

A. Control stop is open wider than necessary. Adjust control stop for

desired delivery of water volume.

B. Water saver/conventional diaphragm assembly is installed on low

consumption xture or closet diaphragm assembly is installed on

urinal xture. Determine the required ush volume (see label on valve

or markings on xture). Replace diaphragm assembly or relief valve

for appropriate ush volume of xture.

4. Volume of water is insufficient to adequately siphon fixture.

A. Control stop is not open wide enough. Adjust control stop for desired

delivery of water volume.

B. Diaphragm assembly is damaged. Replace diaphragm assembly.

C. Low consumption diaphragm assembly is installed on water saver/

conventional xture or urinal diaphragm assembly is installed on

closet xture. Determine the required ush volume (see label on valve

or markings on xture). Replace diaphragm assembly or relief valve

for appropriate ush volume of xture.

D. Inadequate water volume or pressure is available from supply.

Increase ow rate or pressure to the valve. If gauges are not available

to measure supply pressure/volume, remove relief valve from

diaphragm assembly and open the control stop.

If the xture siphons: Additional water volume is required. Install

higher ushing volume relief valve or diaphragm assembly or cut

ow ring from guide. IMPORTANT: LAWS AND REGULATIONS

PROHIBIT THE USE OF HIGHER FLUSHING VOLUMES THAN

LISTED ON FIXTURE OR FLUSHOMETER.

If the xture DOES NOT siphon (or a low consumption ush is

required): Additional steps must be taken to increase the water

pressure and/or volume at the water supply. Contact xture

manufacturer for minimum supply requirements of xture.

5. Flushometer valve closes immediately (short flush).

A. Worn or damaged diaphragm assembly. Replace diaphragm

assembly.

B. Handle assembly is damaged. Replace B-73-A handle or repair with

B-51-A handle repair kit.

C. Low consumption diaphragm assembly is installed on water saver/

conventional xture or urinal diaphragm assembly is installed on

closet xture. Determine the required ush volume (see label on valve

or markings on xture). Replace relief valve or diaphragm assembly

for appropriate ush volume of xture.

6. Length of flush is too long (long flush) or fails to shut off.

A. Bypass hole (upper lter ring) of diaphragm assembly is dirty. Remove

the diaphragm assembly. Disassemble the lter rings from the

diaphragm, wash under running water, and reassemble. Replace as

necessary.

B. Relief valve or diaphragm assembly is damaged. Replace relief valve

or diaphragm assembly.

C. Water saver/conventional diaphragm assembly is installed on low

consumption xture or closet diaphragm assembly is installed on

urinal xture. Determine the required ush volume (see label on valve

or markings on xture). Replace diaphragm assembly or relief valve

for appropriate ush volume of xture.

D. Inside cover is damaged. Install new A-71 part.

E. Line water pressure dropped and is insufcient to close valve. Close

the control stop until pressure is restored.

F. Relief valve is not seated properly. Disassemble diaphragm

components (relief valve, lter rings, and diaphragm unit), wash under

running water, and reassemble. Replace as necessary.

7. Chattering noise is heard during flush.

A. Inside cover is damaged. Install new A-71 part.

B. Relief valve or diaphragm assembly is damaged. Replace relief valve

or diaphragm assembly.

CARE AND CLEANING INSTRUCTIONS

DO NOT USE abrasive or chemical cleaners to clean ushometers that may

dull the luster and attack the chrome or decorative nish. Use ONLY mild

soap and water, then wipe dry with a clean towel or cloth. When cleaning

the bathroom tile, protect the ushometer from any splattering of cleaner.

Acids and cleaning uids can discolor or remove chrome plating.

When assistance is required, please contact

Sloan Technical Support at: 1-888-SLOAN-14 (1-888-756-2614).

TROUBLESHOOTING GUIDE

372626_Master_Book_ccg.indd 10 9/18/17 7:52 AM