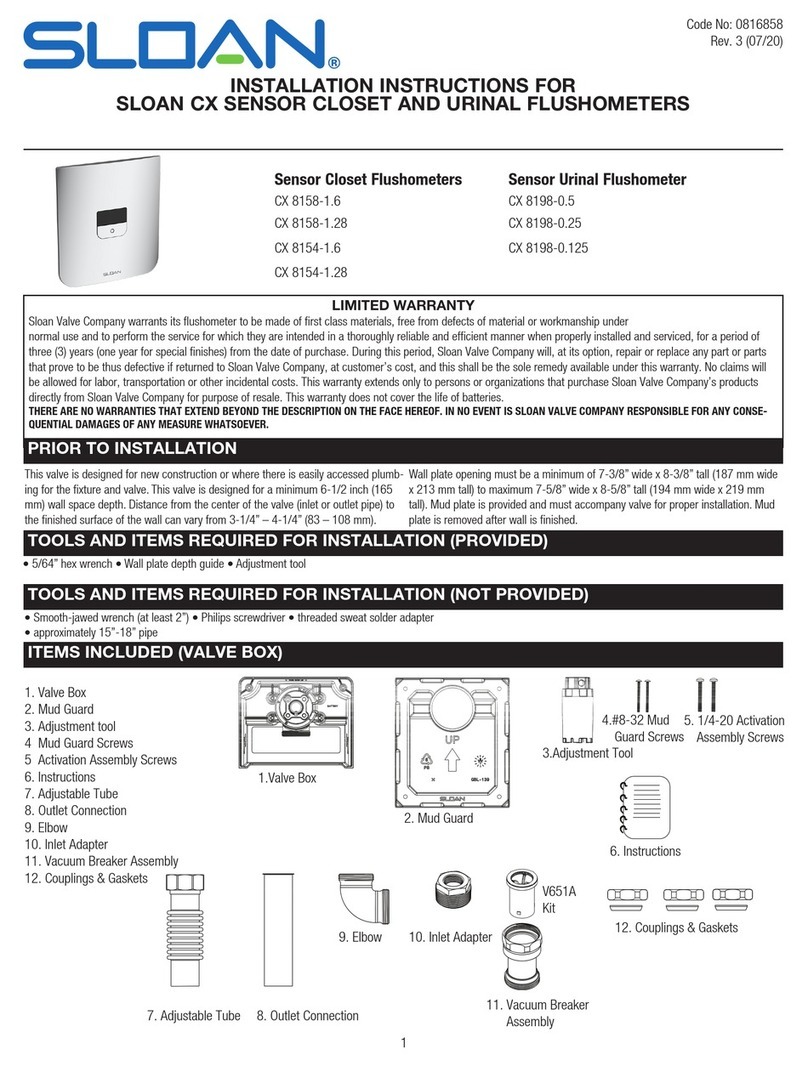

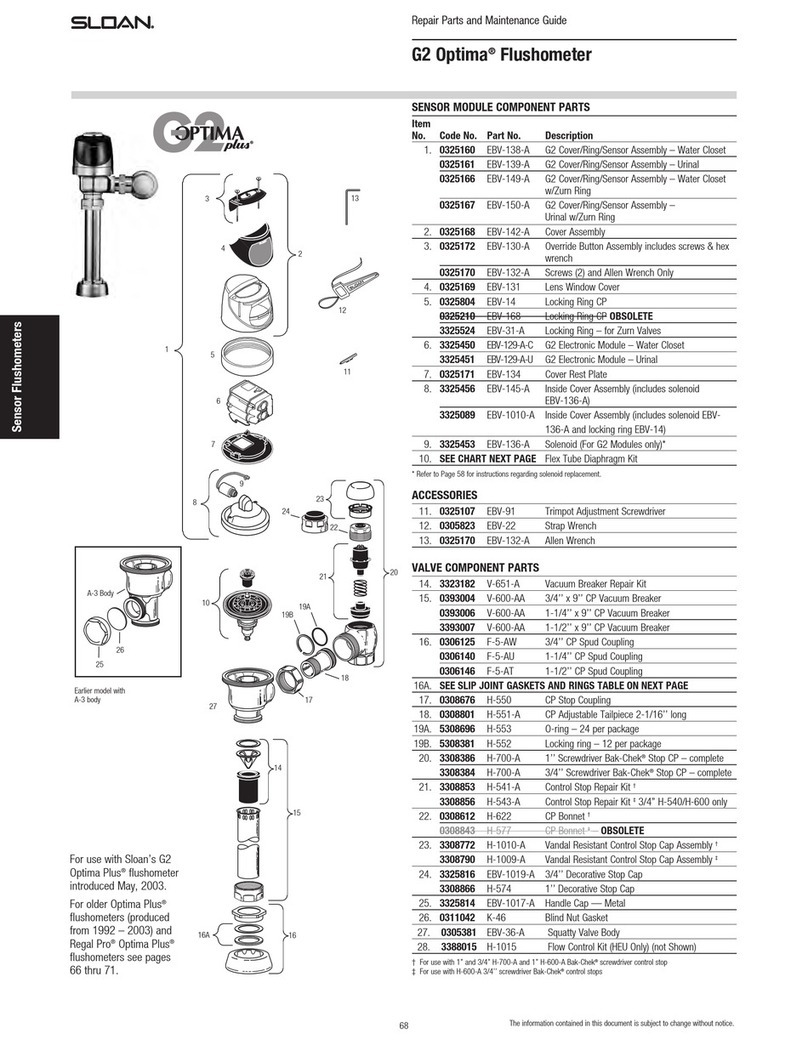

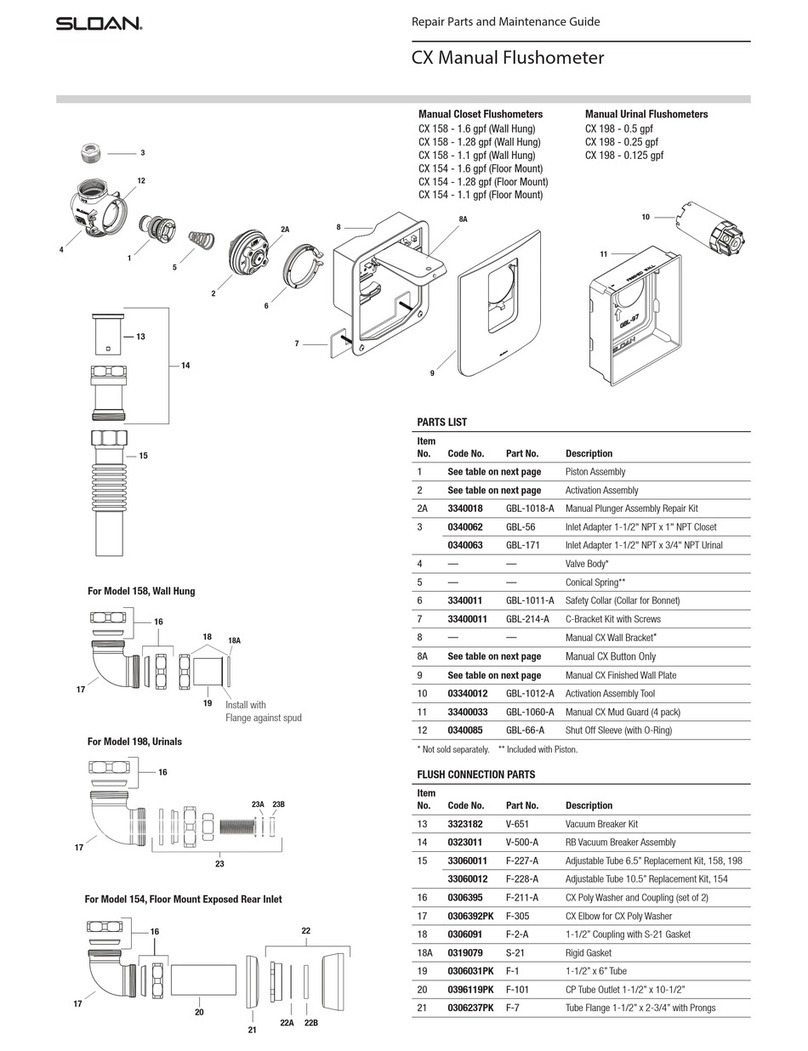

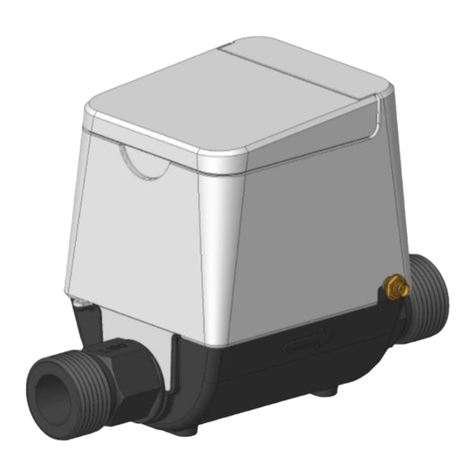

CX Manual Flushometers

TROUBLESHOOTING GUIDE

Item No. Part No. Description

1See Table Piston Assembly

2See Table Activation Assembly

Code No. Description Plug Color*

3340048 1.6 gpf/6.0 Lpf closet activation assembly Green

3340049 1.28 gpf/4.8 Lpf closet activation assembly Purple

3340051 0.5 gpf/1.9 Lpf urinal activation assembly Red

3340052 0.25 gpf/1.0 Lpf urinal activation assembly Burgundy

ACTIVATION ASSEMBLY SELECTION GUIDE

* Colors may differ. Consult factory to conrm you have the correct piston assembly.

Item Code No. Description

1 0323182 V-651 Vacuum Breaker

2 0323279 Short Vacuum Breaker Tube

3 0306394 Adjustable Tube

4 0306395 Poly Washer Coupling (set of two)

5 0306392PK Elbow

6 3306002 1-1/2" Coupling with S-21 Gasket

7 0306031PO 1 1/2" (38 mm) Flanged outlet tube RB, 6"

8 0396669PK F-102 1-1/2" (38 mm) Outlet Tube CP 8"*

9 0306238PK F-7 Flange CP*

10 0306146PK F-5-A 1-1/2" Spud Coupling Assembly CP*

11 0306396 Urinal Connection

FLUSH CONNECTION PARTS

Plug

The information contained in this document is subject to change without notice.

Manufactured in the U.S.A by Sloan Valve Company under one

or more of the following patents: U.S. Patents. 5,295,655;

5,542,718; 5,558,120; 5,564,460; 5,730,415; 5,865,420;

5,887,848; 5,967,182. Other Patents Pending.

Bak-Chek®, Para-flo®, PERMEX®, Turbo-Flo®

* Consult factory for alternate nish options

1

2

3

410

5

4

8

7Install with

Flange against spud

For Model 158, Wall Hung For Model 158, Floor Mount

9

4

For Model 198

11

Code No. Description Piston Color*

3340053 1.6 gpf/6.0 Lpf closet activation assembly Green

3340054 1.28 gpf/4.8 Lpf closet activation assembly Purple

3340055 0.5 gpf/1.9 Lpf urinal activation assembly Red

3340056 0.25 gpf/1.0 Lpf urinal activation assembly Burgundy

PISTON ASSEMBLY SELECTION GUIDE