Sloan ESD-400 User manual

Other Sloan Plumbing Product manuals

Sloan

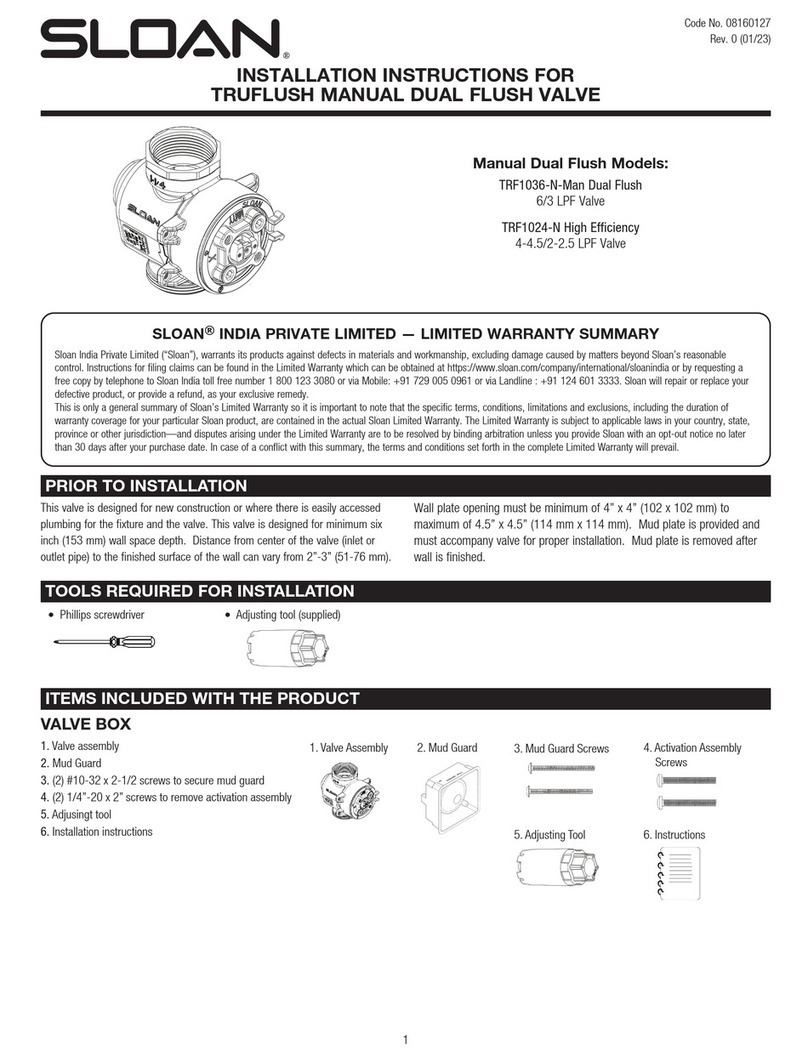

Sloan TRUFLUSH TRF1036-N User manual

Sloan

Sloan BASYS EFX-8 Use and care manual

Sloan

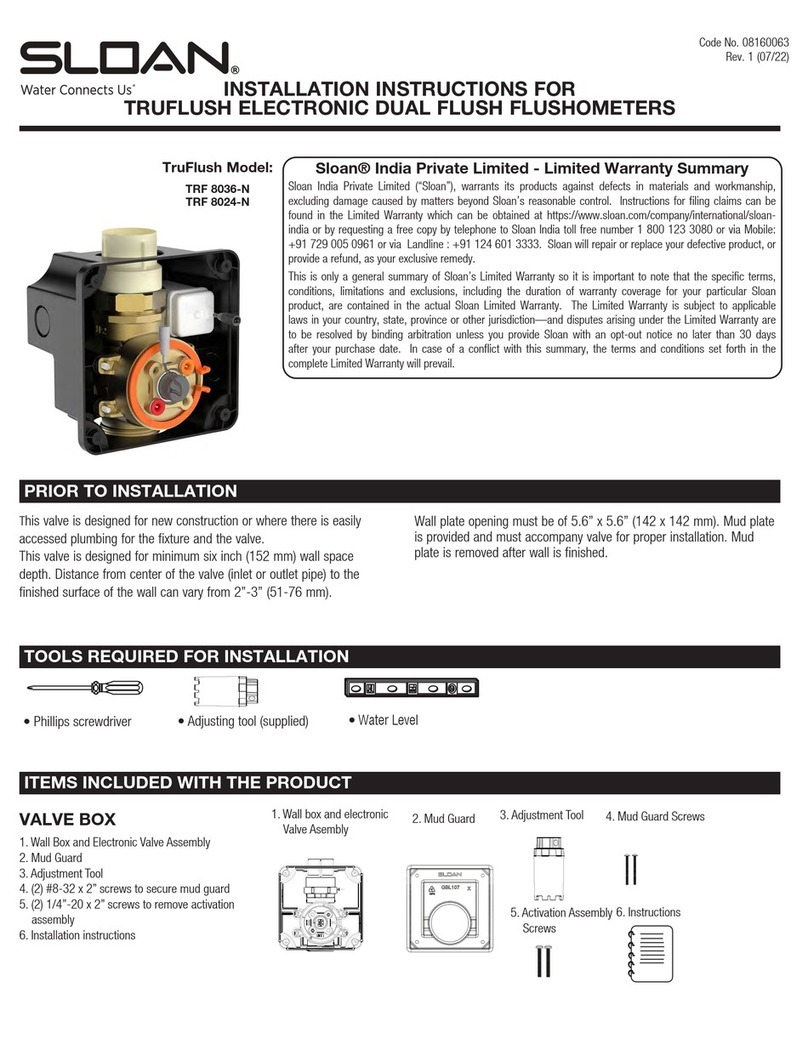

Sloan TRF 8036-N User manual

Sloan

Sloan Royal 310 User manual

Sloan

Sloan SF Series User manual

Sloan

Sloan 115 ES-S Service manual

Sloan

Sloan OPTIMA plus ERF-885 User manual

Sloan

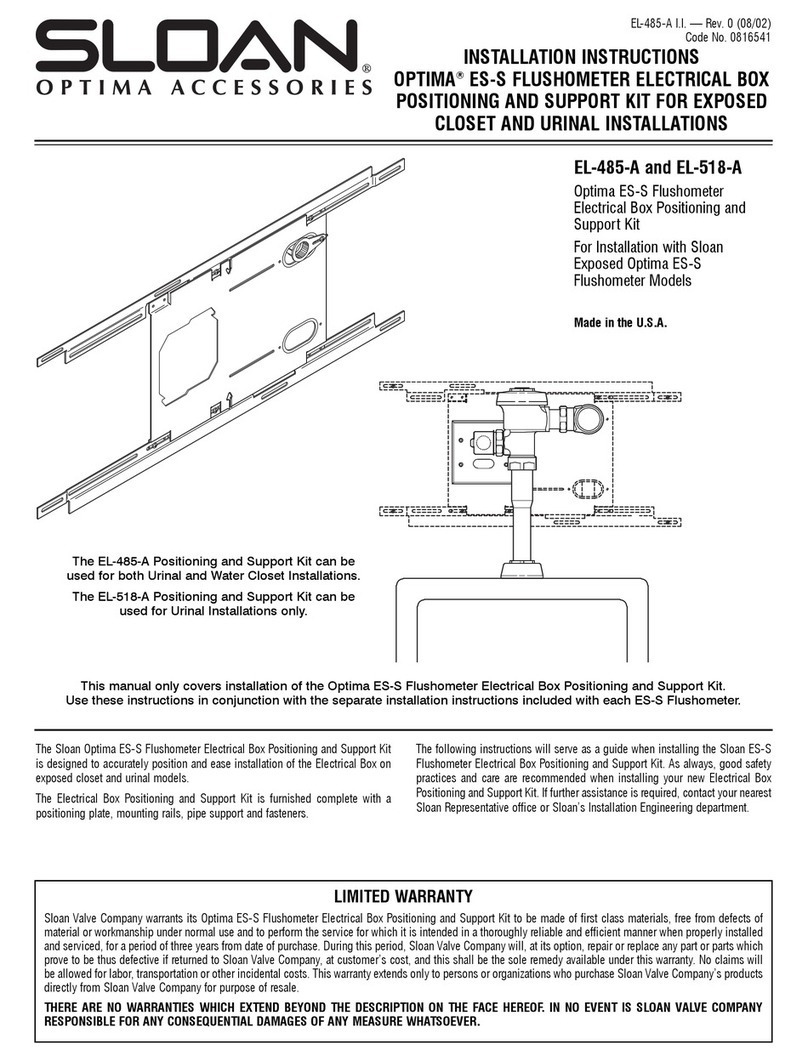

Sloan EL-485-A User manual

Sloan

Sloan EAF-700 Manual

Sloan

Sloan Solis EAF-275 Series User manual

Sloan

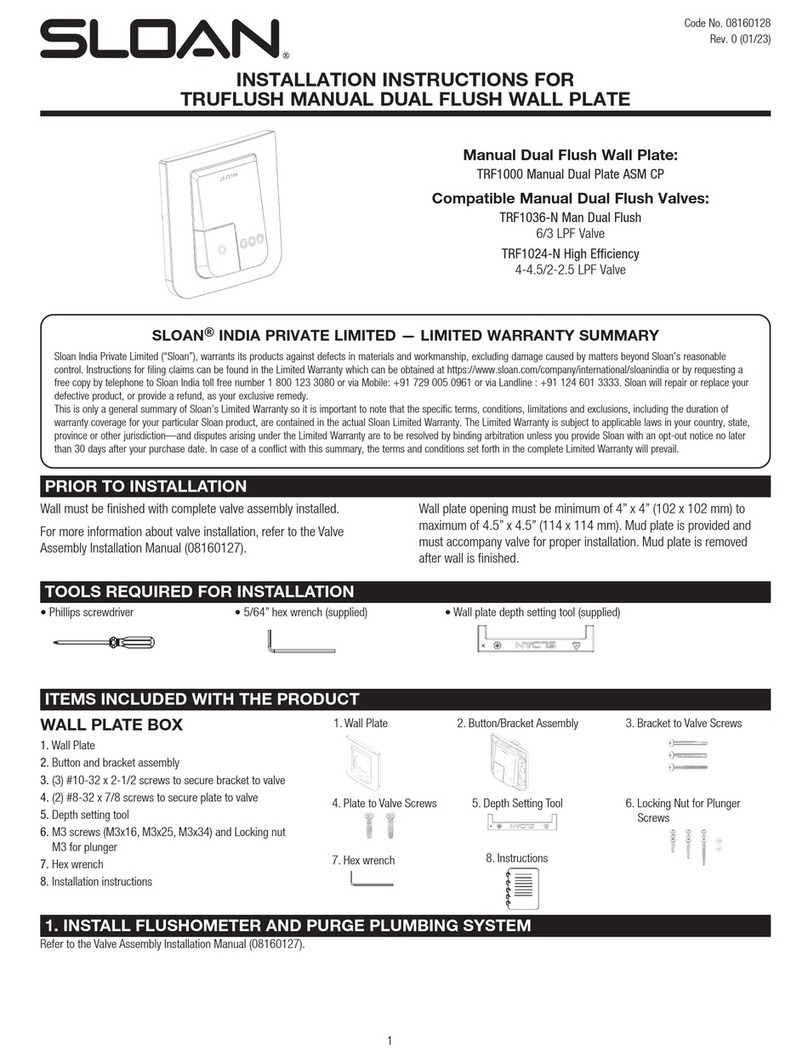

Sloan TRUFLUSH TRF1000 User manual

Sloan

Sloan Optima EBF-750 Use and care manual

Sloan

Sloan CX Series User manual

Sloan

Sloan ECOS HET 8100 Series User manual

Sloan

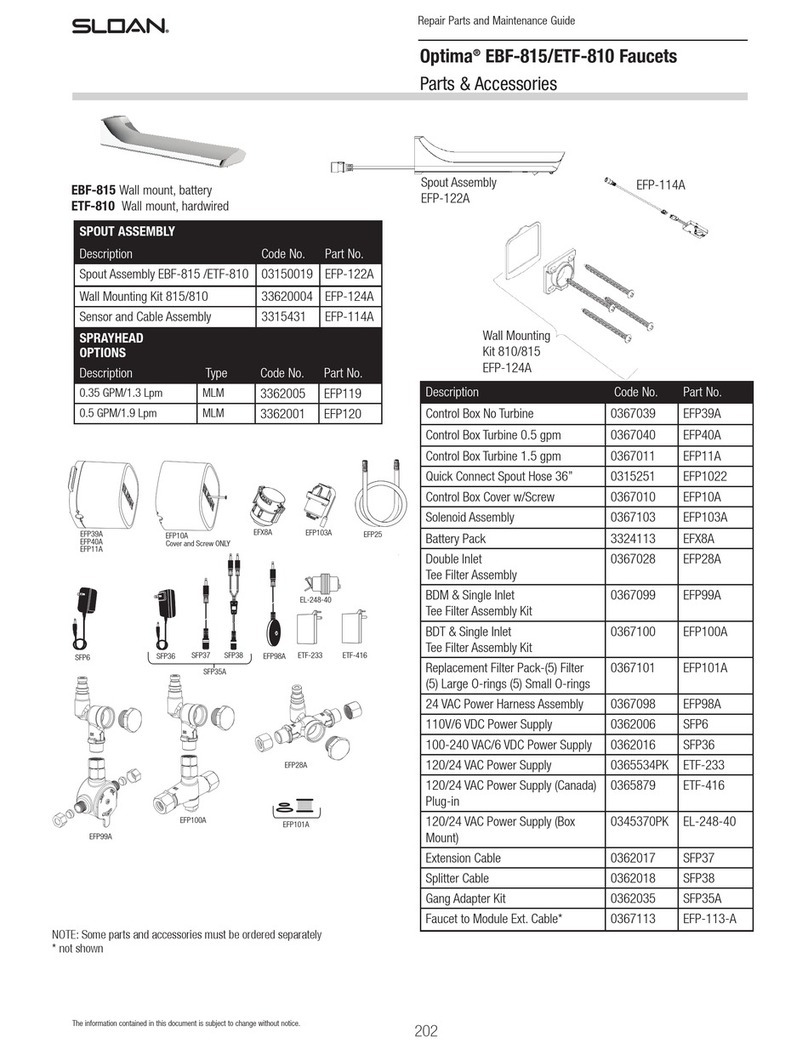

Sloan Optima ETF-810 Use and care manual

Sloan

Sloan FLUSHMATE III 503 Series Application guide

Sloan

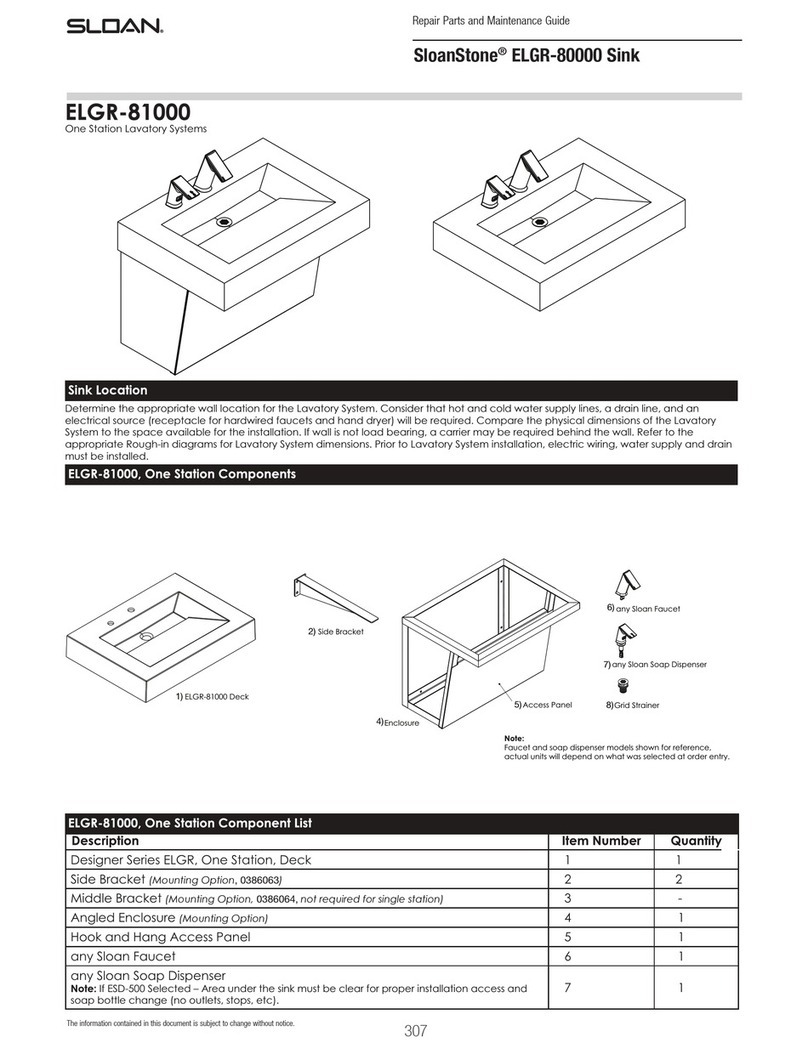

Sloan ELGR-81000 Use and care manual

Sloan

Sloan BASYS Operating manual

Sloan

Sloan ESD601A User manual

Sloan

Sloan TRF 156-1.1 User manual

Popular Plumbing Product manuals by other brands

HORNE

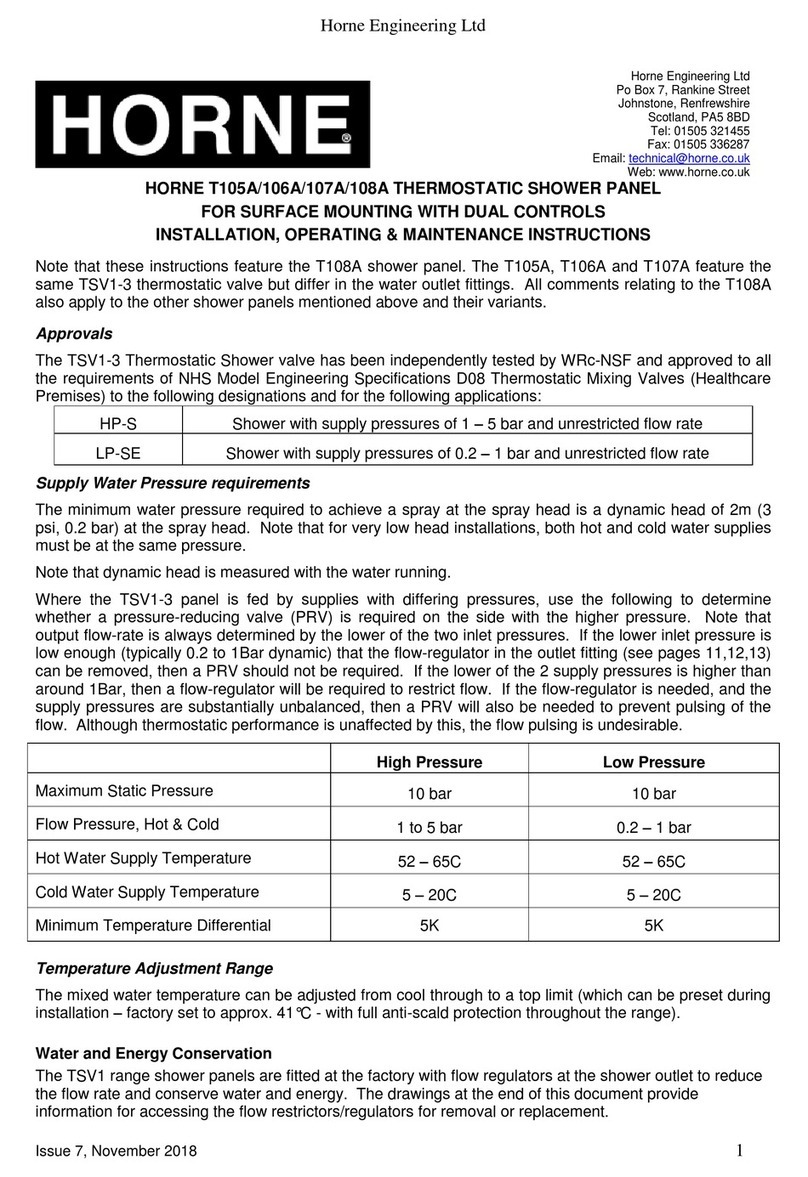

HORNE T105A Installation, operating and maintenance instructions

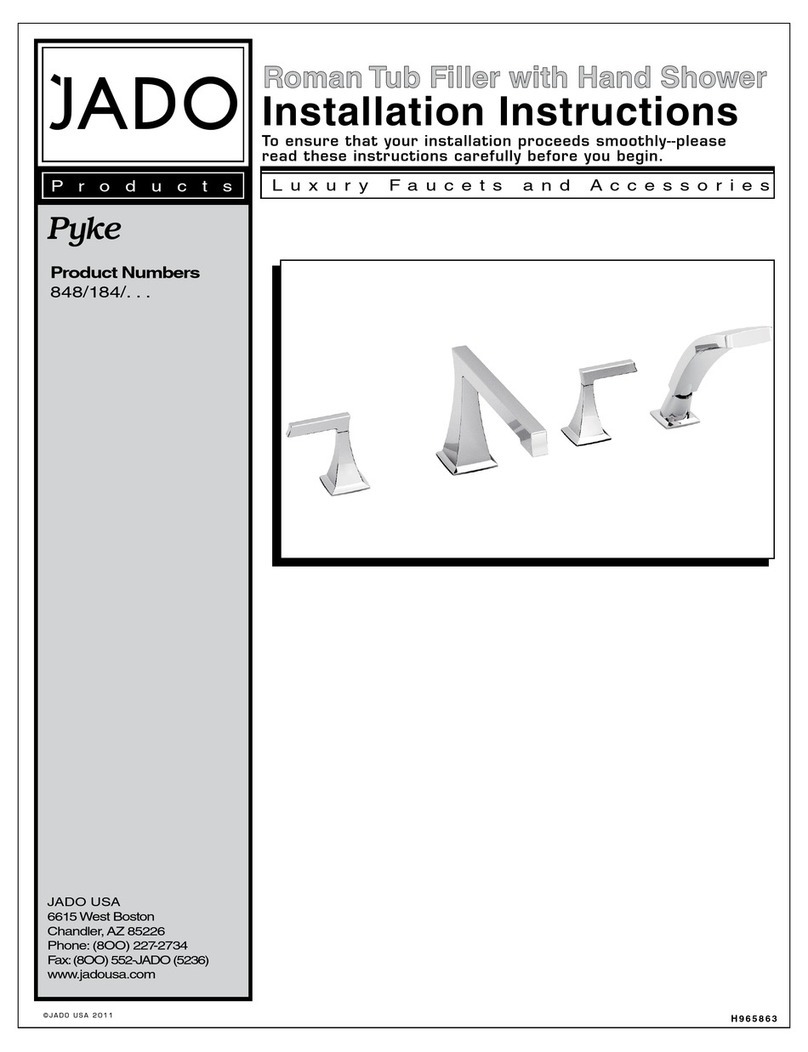

JADO

JADO Pyke Roman 848 installation instructions

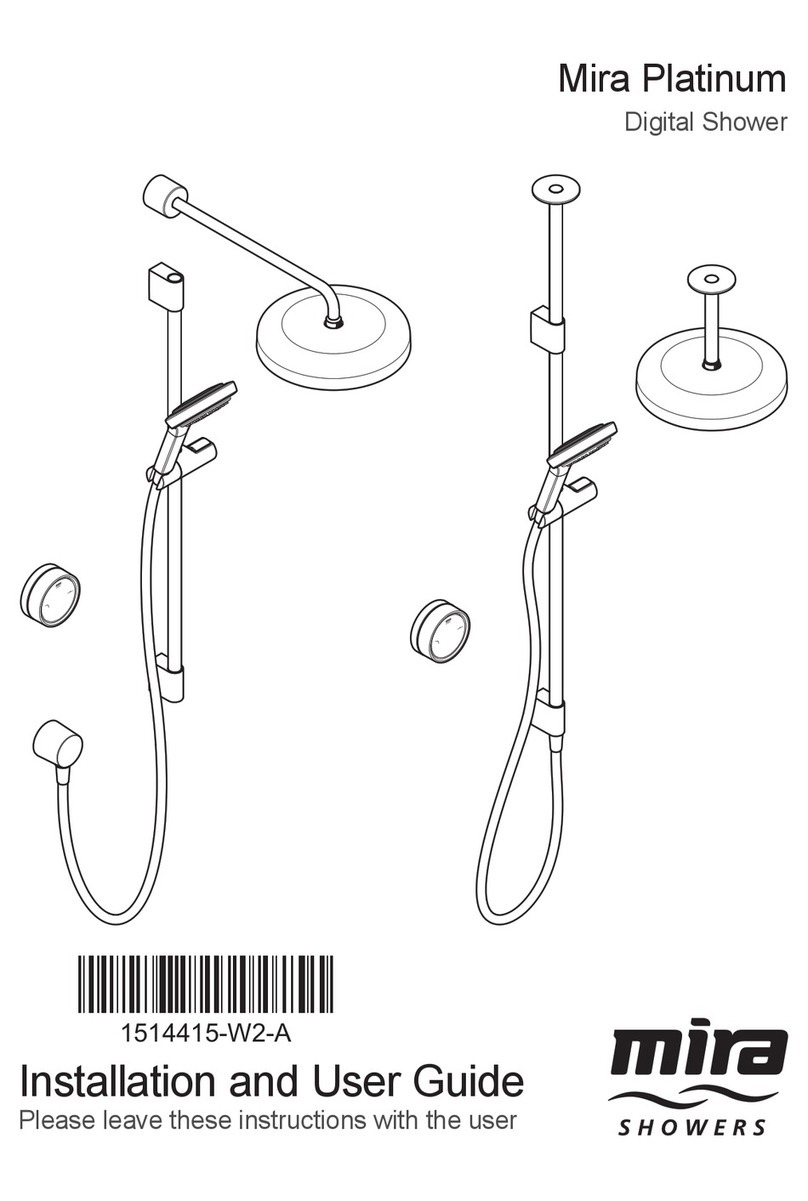

Mira

Mira Advance user guide

Symmons

Symmons Symmetrix S-23 Series Installation and service instructions

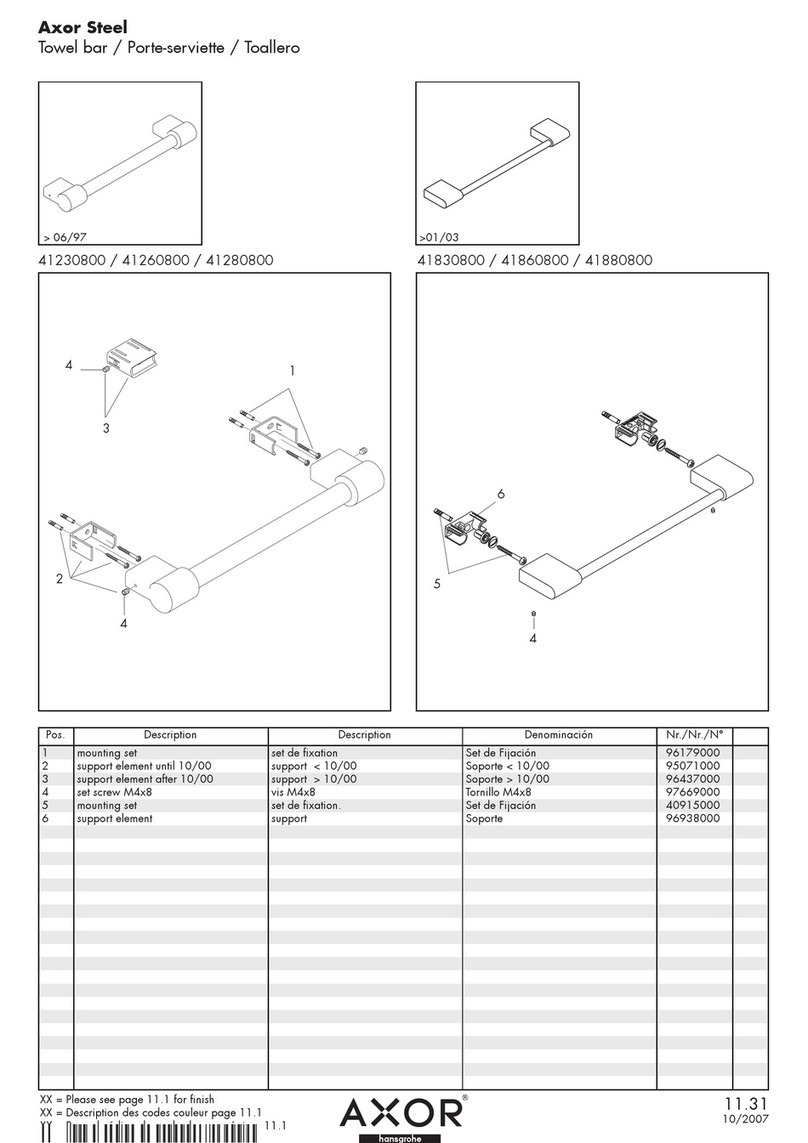

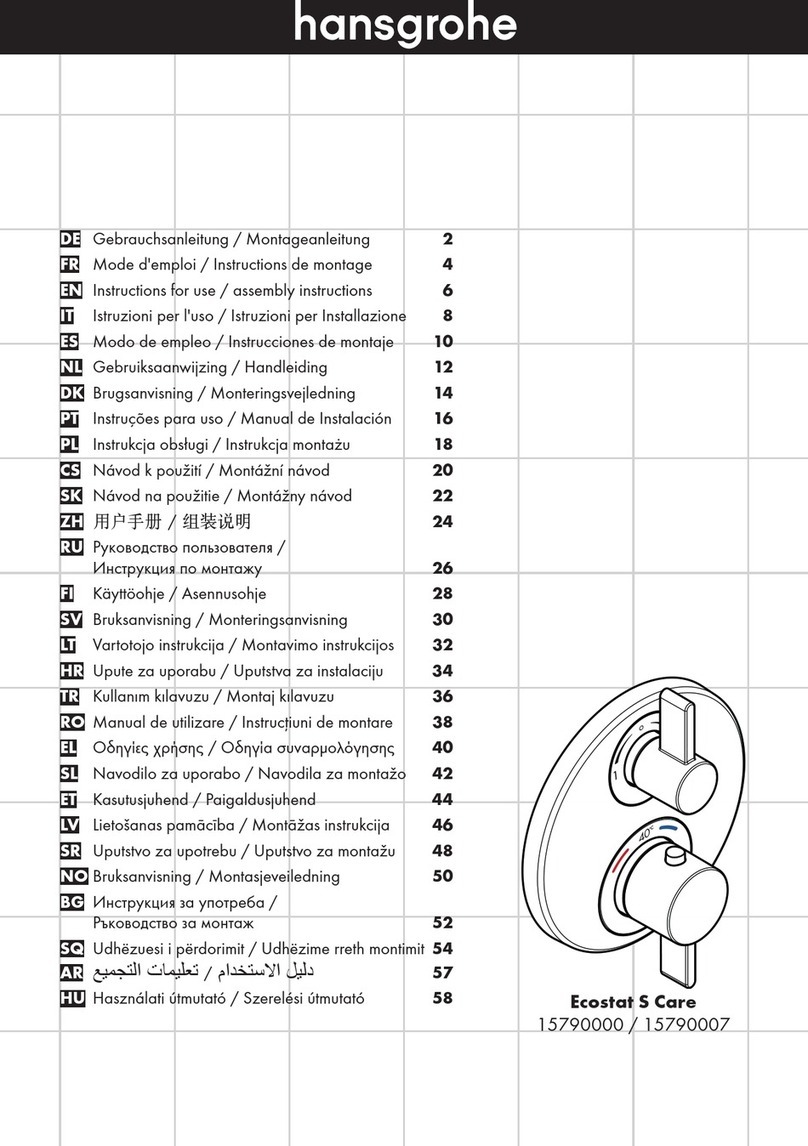

Hans Grohe

Hans Grohe Ecostat S Care 15790000 Instructions for use/assembly instructions

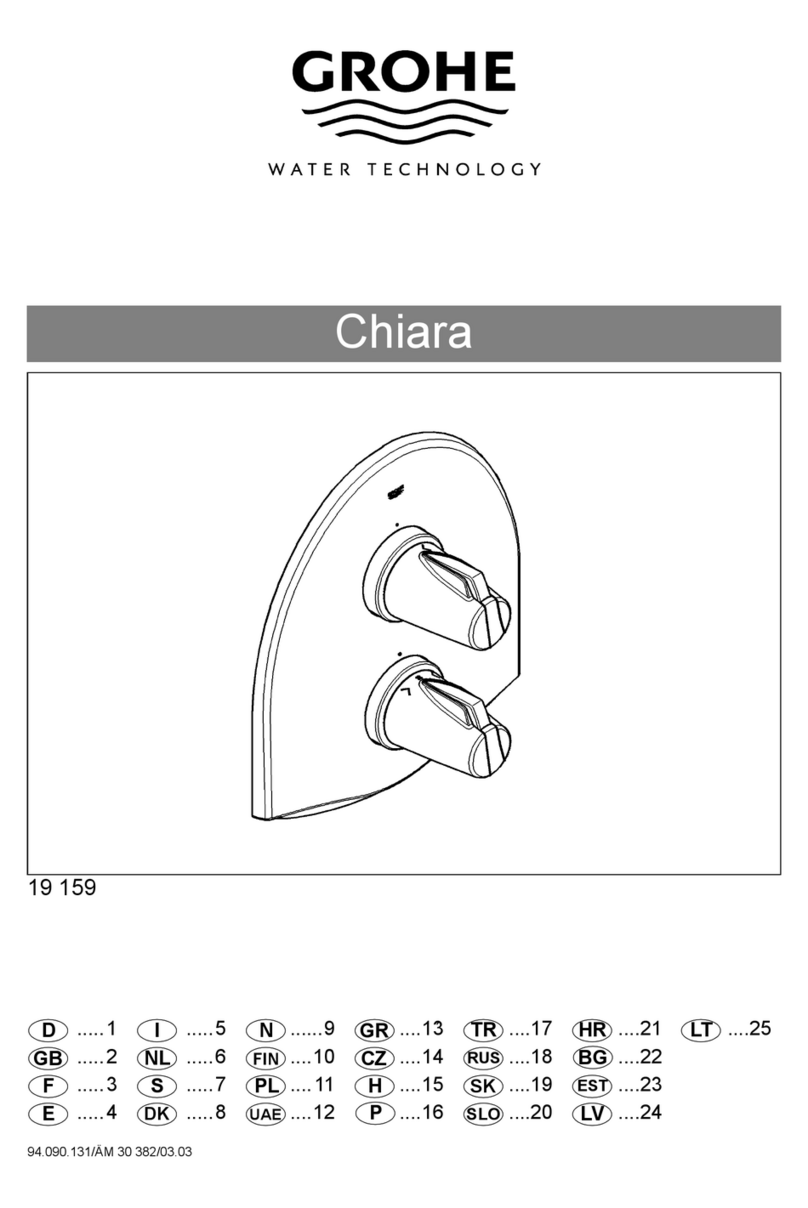

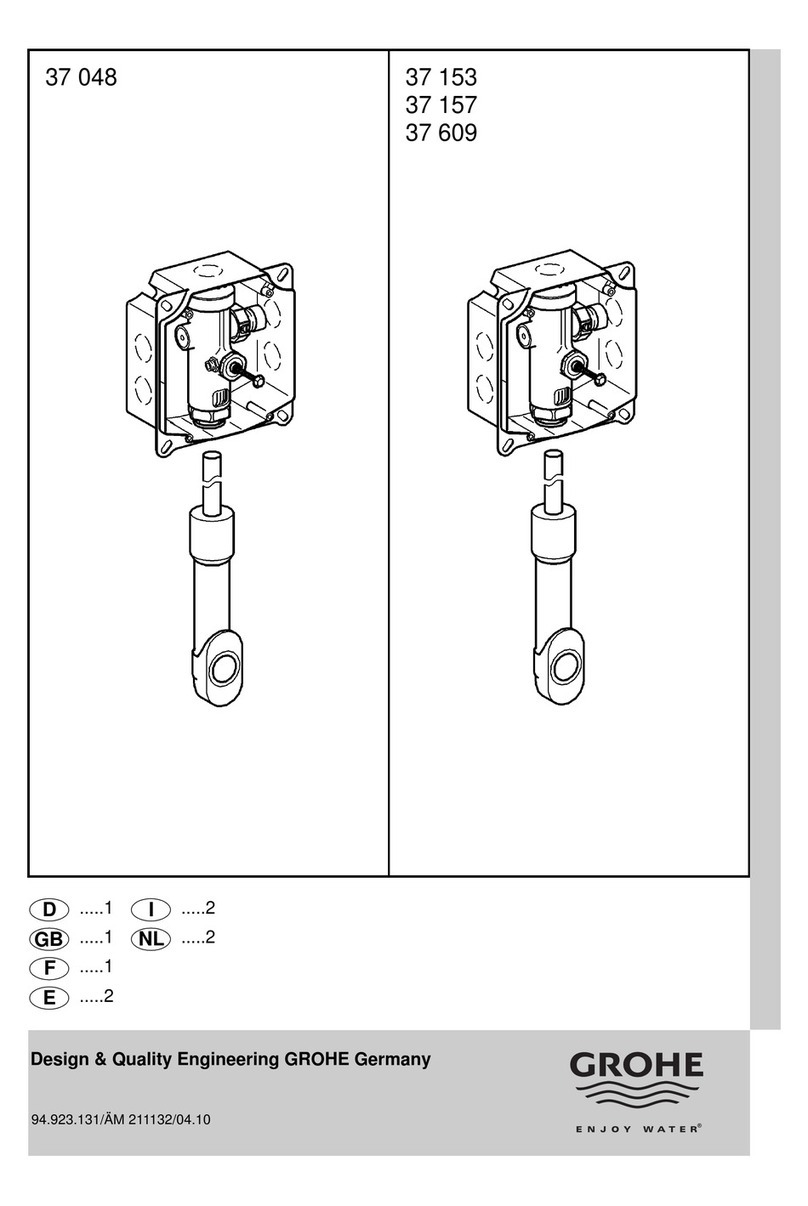

Grohe

Grohe 37 048 manual