237

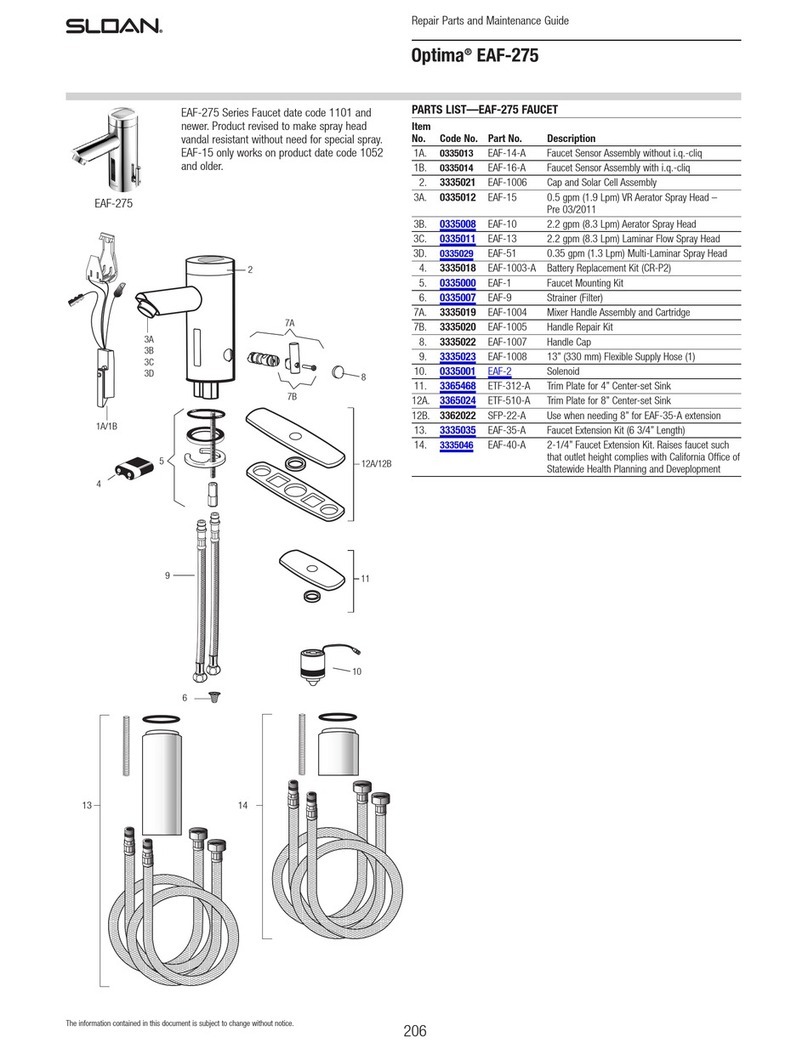

Repair Parts and Maintenance Guide

The information contained in this document is subject to change without notice.

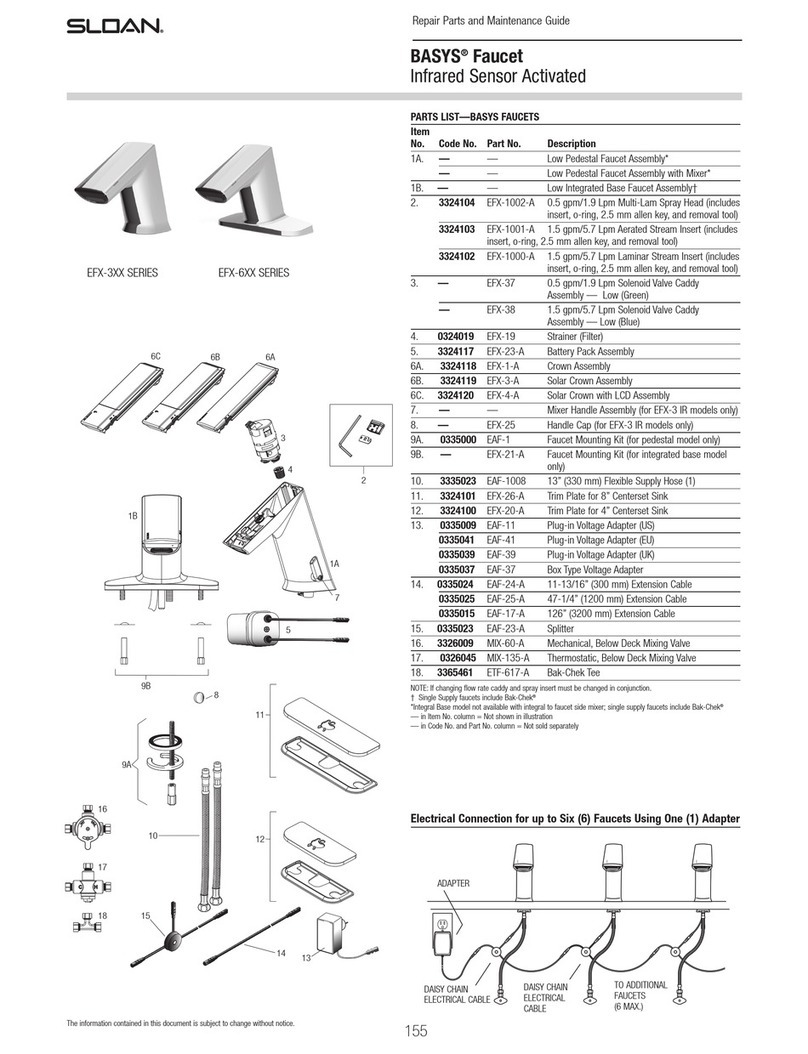

1. Problem: Faucet not activating after installation.

Cause: Not properly started up. See step 5

Solution: Remove adhesive label from sensor eye.

Solution: Press button on faucet throat one time.

2. Problem: Faucet delivers water in an uncontrolled manner.

Cause: Faucet is not working properly.

Solution: Contact the Sloan Valve Company Installation Engineering

Department (see below).

3. Problem: Faucet does not deliver any water when Sensor is

activated.

Indicator: Solenoid valve produces an audible “CLICK.”

Cause: Water supply stop(s) closed.

Solution: Open water supply stop(s).

Cause: Water supply stop strainer(s) clogged.

Solution: Clean water supply stop strainer(s).

Indicator: Solenoid valve DOES NOT produce an audible “CLICK.”

Cause: Battery low (EAF-150 Models).

Solution: Replace battery (refer to Battery Replacement on Previous page).

Cause: Power failure (EAF-100 Models).

Solution: Check power supply.

4. Problem: Faucet delivers only a slow flow or dribble when

Sensor is activated.

Cause: Water supply stop(s) are partially closed.

Solution: Completely open water supply stop(s).

Cause: Water supply stop strainer(s) clogged.

Solution: Remove, clean, and reinstall water supply stop strainer(s).

Replace strainer(s) if required.

Cause: Aerator is clogged.

Solution: Remove, clean, and reinstall Aerator. Replace Aerator if required.

Cause: Faucet is not working properly.

Solution: Contact the Sloan Valve Company Installation Engineering

Department (see below).

5. Problem: Faucet drips between uses or runs on. Solenoid is

heard activating

Cause: Debris caught in solenoid

Solution: Clean Solenoid Valve - Turn off water, remove and unplug

sensor/throat plate assembly with 2.5-mm hex wrench, remove solenoid

using 6-mm hex wrench, clean solenoid diaphragmof plumbing debris,

clean solenoid base in faucet with a dry towel, install solenoid (do not

over-tighten), connect sensor/throat plate and install, dry fire solenoid

(listen for clicking), then turn on water and test faucet. Also flush lines

at stops as well to remove any plumbing debris in the line, check supply

hose filters at that time as well.

6. Problem: LED indicator blinks when Faucet is in use.

Cause: Battery low (EAF-150 Models).

Solution: Replace battery (refer to Battery Replacement on Previous Page)

7. Problem: i.q. - doesn’t function (-IC models only)

Cause: Button is not working properly.

Solution: Replace sensor throat plate; see parts breakdown on next page

for correct sensor throat plate replacement (item #2B).

8. Problem: The water temperature is too hot or too cold on a

Faucet connected to hot and cold supply lines.

CAUSE: Supply Stops are not adjusted properly.

SOLUTION: Adjust Supply Stops.

CAUSE: For models with integral mixing valve - Mixing valve is

set improperly for the water temperature desired.

SOLUTION: Rotate mixing valve handle clockwise to decrease water

temperature or counterclockwise to increase water temperature.

TROUBLESHOOTING GUIDE

Prepare for operation

(A) When activating a new faucet

(or new sensor replacement)

for the first time, after removing

protective label from sensor window,

press sensor button one (1) time,

then place hand or installation

instructions within 1 to 2 inches

in front of sensor until faucet

activates water flow, remove hand

or instructions,

water flow stops, red LED flashing

ends followed with one (1) Green

LED flash (approximately 12

seconds) Test faucet.

If waterflow DOES NOT start

after removing the sticker and

the RED LED within the sensor

flashes continue with the

following procedure!!

place installation instructions within

1 to 2 inches in front of sensor

until faucet activates water flow,

then remove instructions, water

flow stops, red LED flashing ends

followed with one (1) Green LED

flash (approximately 12 seconds).

Test faucet.

SERVICE OPERATION

1x

1x

4 Sec.

4 Sec.

10 Sec.

10 Sec.

4 Sec.

10 Sec.

1x

1x

4 Sec.

4 Sec.

10 Sec.

10 Sec.

4 Sec.

10 Sec.

A

B

C

A

B

C

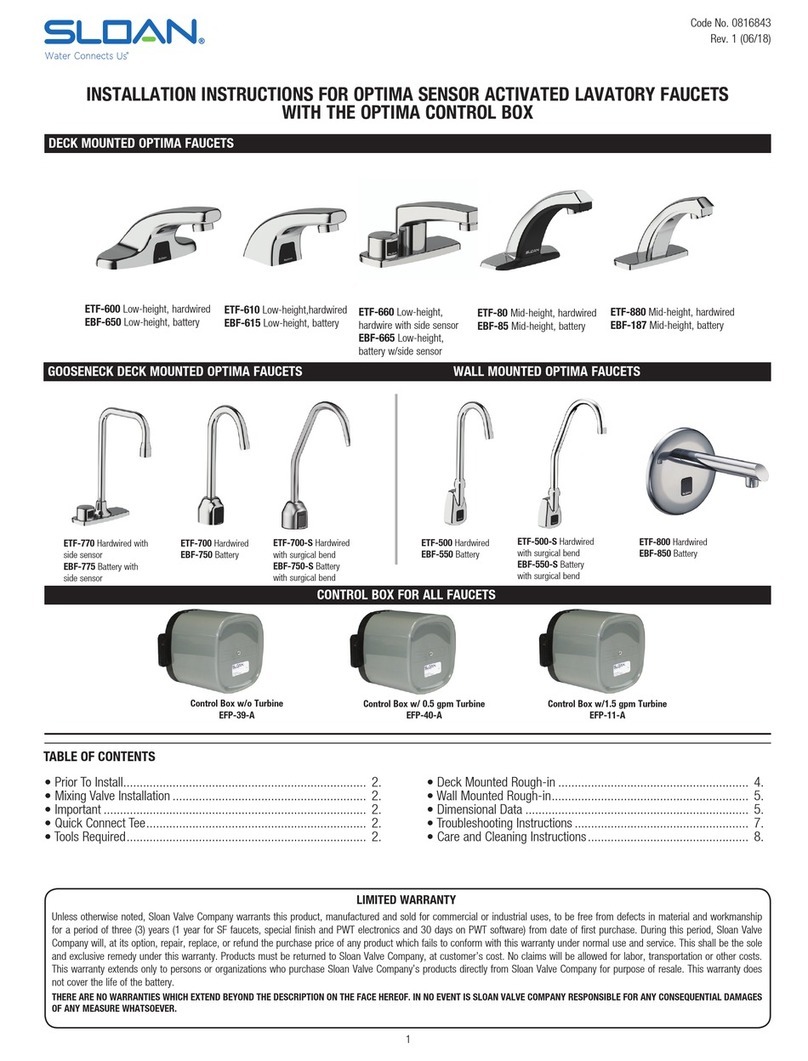

Optima®EAF-150 Faucet