SMAR TT481W Manual

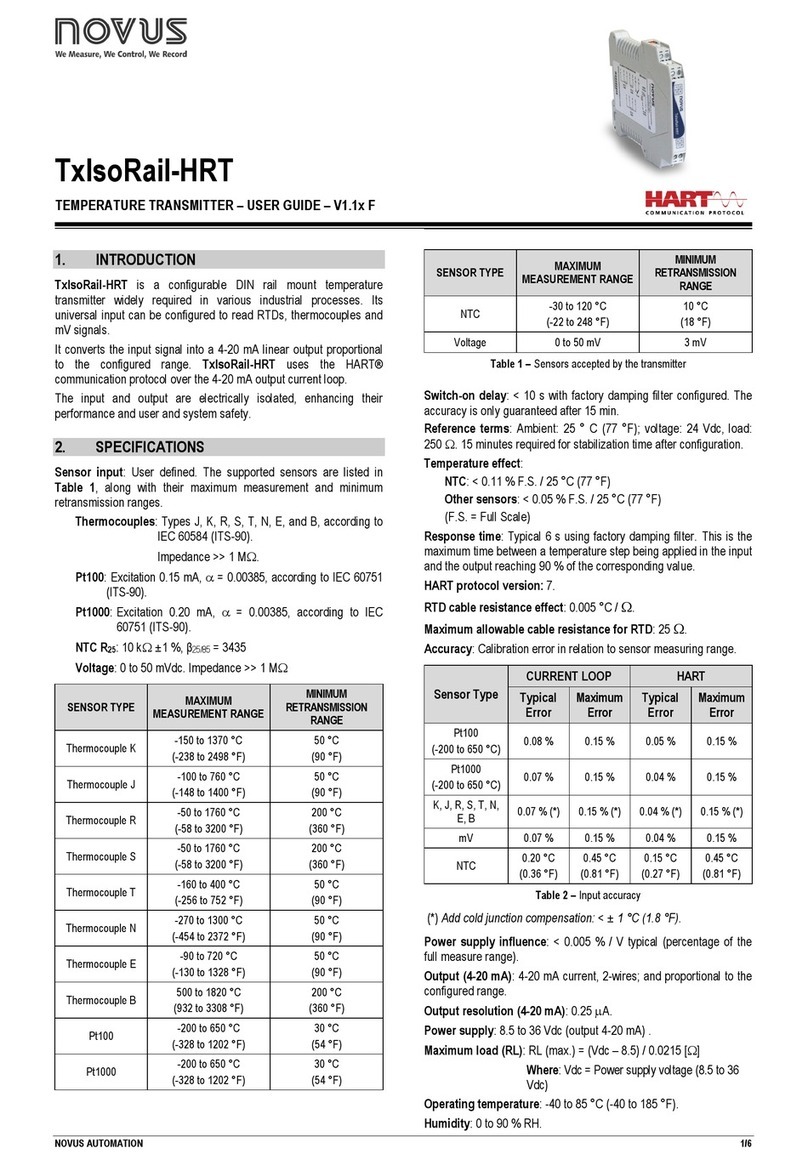

Introduction

III

NOTE

This manual is compatible with version 1.XX, where 1 denote software version and XX software

release. The indication 1.XX means that this manual is compatible with any release of software

version 1.

Waiver of responsibility

The contents of this manual abides by the hardware and software used on the current equipment

version. Eventually there may occur divergencies between this manual and the equipment. The

information from this document are periodically reviewed and the necessary or identified corrections

will be included in the following editions. Suggestions for their improvement are welcome.

Warning

For more objectivity and clarity, this manual does not contain all the detailed information on the

product and, in addition, it does not cover every possible mounting, operation or maintenance

cases.

Before installing and utilizing the equipment, check if the model of the acquired equipment complies

with the technical requirements for the application. This checking is the user’s responsibility.

If the user needs more information, or on the event of specific problems not specified or treated in

this manual, the information should be sought from Smar. Furthermore, the user recognizes that the

contents of this manual by no means modify past or present agreements, confirmation or judicial

relationship, in whole or in part.

All of Smar’s obligation result from the purchasing agreement signed between the parties, which

includes the complete and sole valid warranty term. Contractual clauses related to the warranty are

not limited nor extended by virtue of the technical information contained in this manual.

Only qualified personnel are allowed to participate in the activities of mounting, electrical connection,

startup and maintenance of the equipment. Qualified personnel are understood to be the persons

familiar with the mounting, electrical connection, startup and operation of the equipment or other

similar apparatus that are technically fit for their work. Smar provides specific training to instruct and

qualify such professionals. However, each country must comply with the local safety procedures,

legal provisions and regulations for the mounting and operation of electrical installations, as well as

with the laws and regulations on classified areas, such as intrinsic safety, explosion proof, increased

safety and instrumented safety systems, among others.

The user is responsible for the incorrect or inadequate handling of equipments run with pneumatic

or hydraulic pressure or, still, subject to corrosive, aggressive or combustible products, since their

utilization may cause severe bodily harm and/or material damages.

The field equipment referred to in this manual, when acquired for classified or hazardous areas, has

its certification void when having its parts replaced or interchanged without functional and approval

tests by Smar or any of Smar authorized dealers, which are the competent companies for certifying

that the equipment in its entirety meets the applicable standards and regulations. The same is true

when converting the equipment of a communication protocol to another. In this case, it is necessary

sending the equipment to Smar or any of its authorized dealer. Moreover, the certificates are

different and the user is responsible for their correct use.

Always respect the instructions provided in the Manual. Smar is not responsible for any losses

and/or damages resulting from the inadequate use of its equipments. It is the user’s responsibility to

know and apply the safety practices in his country.

TT481 WirelessHARTTM –Operation & Maintenance, Instruction Manual

IV

Table of Contents

V

TABLE OF CONTENTS

INTRODUCTION .............................................................................................................................................VII

INSTALLATION FLOWCHART.....................................................................................................................XIII

SECTION 1 - INSTALLATION....................................................................................................................... 1.1

GENERAL....................................................................................................................................................................1.1

MOUNTING.................................................................................................................................................................1.1

BATTERY MODULE WIRING.....................................................................................................................................1.4

INSTALLATION IN HAZARDOUS LOCATIONS.........................................................................................................1.6

INTRINSICALLY SAFE................................................................................................................................................1.6

SECTION 2 - OPERATION............................................................................................................................ 2.1

FUNCTIONAL DESCRIPTION-HARDWARE..............................................................................................................2.1

TEMPERATURE SENSOR .........................................................................................................................................2.2

THERMOCOUPLES...................................................................................................................................................................2.2

THERMORESISTANCES (RTDS)..............................................................................................................................................2.3

CURRENTS (4 TO 20MA)..........................................................................................................................................................2.4

THE DISPLAY .............................................................................................................................................................2.4

WRITTING PROTECTION..........................................................................................................................................2.5

SECTION 3 - MAINTENANCE....................................................................................................................... 3.1

GENERAL....................................................................................................................................................................3.1

DIAGNOSTICS WITH THE DISPLAY.........................................................................................................................3.1

PROBLEMAS E SOLUÇÕES......................................................................................................................................3.1

DISASSEMBLY PROCEDURE ...................................................................................................................................3.1

REASSEMBLY PROCEDURE ....................................................................................................................................3.3

RETURNING MATERIALS..........................................................................................................................................3.4

SECTION 4 - TECHNICAL CHARACTERISTICS......................................................................................... 4.1

ORDERING CODE......................................................................................................................................................4.4

APPENDIX A - SRF –SERVICE REQUEST FORM FOR TEMPERATURE TRANSMITTER.....................A.1

APPENDIX B –BATTERY SAFETY DATASHEET......................................................................................B.1

TT481 WirelessHARTTM –Operation & Maintenance, Instruction Manual

VI

Installation Flowchart

VII

INTRODUCTION

WirelessHART technology overview

The WirelessHART technology is based on a wireless mesh network communication protocol used in

process automation applications. It adds wireless capabilities to the HART protocol, while maintaining

compatibility with existing HART devices, commands and already known and used tools.

WirelessHART network

Basically, a WirelessHART network, defined in the HART specifications, consists of a host, a

WirelessHART Gateway and one or more field devices and/or WirelessHART adapters. Together they

compose a mesh network where the host and devices can communicate.

Host

The host, usually connected to the control network, is a workstation in which, e.g., can be installed an

Human Machine Interface application, which allows an operator to interact with the process. Through

the WirelessHART Gateway, the host can gather data from devices connected to the WirelessHART

network. The host communicates with the WirelessHARTGatewayusingacommunicationprotocol,for

example, HSE, H1, Profibus or Modbus.

WirelessHART Gateway

It is a "translator" equipment. Thus it converts data from the host to the WirelessHART protocol, used

by the devices connected to the WirelessHART network, and converts data from the devices to the

host. In general, the WirelessHART Gateway incorporates the features of Network Manager and

Access Point. Roughly, the access point can be understood as the WirelessHARTradioinstalledatthe

gateway to communicate with devices connected to the wireless network.

TT481 WirelessHARTTM –Operation & Maintenance, Instruction Manual

VIII

Network Manager

The Network Manager is an application that can be embedded in the WirelessHART Gateway. On a

WirelessHART network is only allowed to have one Network Manager. Among its responsibilities, the

Network Manager distributes network identity (advertisement) publishing its existence, manages and

authenticates the addition (joining) of devices to the network. It also distributes individual securitykeys

(static or rotating) to the devices to ensure secure communication between it and the devices. The

Network Manager assigns communication band to the devices already connected to the network that

requested services to it, as well as manages the routes between the devices on the mesh network.

Specifically about the joining process of a WirelessHART device to the network, the Network Manager

validates the Network ID and the Join Key attributes which are configured in the WirelessHART

Gateway and WirelessHART devices.

The Network ID identifies a WirelessHART network in unique way. It is an unsigned integer attribute

and must be configured on the WirelessHART Gateway and all WirelessHART devices. Considering a

WirelessHART network installed in a plant, the permitted values for the Network ID ranges from 0 (hex

0x0000) to 32767 (0x7FFF hexadecimal).

The Join Key is a security key used to encrypt joining requests from WirelessHART devices that

receive the advertisement with the Network Id identical to theirs. It may be single or each

WirelessHART device may be configured with an individual Join Key. In the first case, the

WirelessHART Gateway and all WirelessHART devices must be configured with the same JoinKey.In

the second case, which provides higher communication security level, (a) must be configured in the

WirelessHART Gateway a list with individual Join Keys, i.e., a key for each WirelessHART device, and

(b) you must configure each WirelessHART device with its individual Join Key. The Join Key is a

hexadecimal string of 16 bytes. There is no restriction to the hexadecimal value of each byte. Thetable

below shows examples of some join keys.

JOIN KEYS

16-BYTES HEXADECIMAL STRING

00000000000000000000000000000000

0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00,

0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00

00000000000000000000000000000302

0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00,

0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x03, 0x02

00000000FFFFFFFF0000000000000000

0x00, 0x00, 0x00, 0x00, 0xFF, 0xFF, 0xFF, 0xFF,

0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00

550000000000000000000000000000AA

0x55, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00,

0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0xAA

WirelessHART device

The WirelessHART field device is the device that connects to the process, being able to receiveand/or

transmit data on the WirelessHART network. It is a WirelessHART router (repeater) by nature, i.e., it is

able to retransmit messages to/from other devices on the WirelessHART network.

WirelessHART Adapter

It is a bridge-type device, because it is able to provide data of HART + 4 to 20mA field device, legacy,

to the host via WirelessHART. The adapter uses HART FSK standardcommunication,wired,to access

data from HART field devices. And the adapter also uses the WirelessHARTcommunicationtoprovide

data of the field device to the host. The adapter thus enables a HART field device to work on

WirelessHART network.

We recommend a visit to the HART Communication Foundation website for additional information

about the WirelessHART protocol such as WirelessHART project planning, positioning of devices,

commissioning and verification tools, and practices.

TT400 WirelessHARTTM - Manual de Instrução, Operação e Manutenção

IX

Planning an WirelessHART network

The planning of a WirelessHART network is a task that is very similar to the activities that currently we

perform with conventional wired devices. Furthermore, due to the simplicity of a mesh WirelessHART

network, is exempt, in general, detailed field surveys, which areusuallyneededwhenweplannetworks

based on other wireless technologies.

Basically, a WirelessHART network involves planning, design, installation and commissioningphases.

Planning

This phase requires the execution of the steps below:

Scope definition

Clearly define the scope of the network. Answer the question: why do we need the wireless network?

To monitor process variables or to implement a non-critical control? The answer to this question will

facilitate the understanding between the team members responsibleforthenetworkand determine one

or more process units in the plant. For each process unit, allocate a gateway with unique and specific

Network ID. Outline the main field devices.

Identify potential sources of interference

Are there radio communications or other wireless networks in the plant? What protocols and

frequencies do they use? Use high power? Although unlikely, given the robustness of the radios used

by the WirelessHART technology, prior knowledge of the answers to these questions may identify

potential sources of interference and to indicate the taking of preventive and/or limiting actions even

before installation. For example, you can select a frequency channel as unavailable, adding it to the

black list of frequencies that is under the WirelessHART Network Manager control.

Integration with the host

The gateway connects the WirelessHART field devices to the host system.Planwhatdevicesand what

data are needed. Also, the stations or applications which will process the data have to be clearly

defined. From this set, among the protocols in the system, define which one will be used for integration

with the host and with the existing tools for configuring the devices. After defining the protocol for

integration, the user has to choose the gateway on the market that best meets your requirements.

Project

In the project phase, it is recommended the adoption of the practices below. Although conservative,

these practices ensure robustness and scalability to the network.

oDefine the Network ID that will be used for all devices in the process unit;

oDefine if the Join Key will be common to all devices or individual and dedicated ;

oDefine the policy to be used for the definition of devices (Long) Tags;

oUse a scale drawing of the process unit;

oPlace the gateway in a strategic position in the process unit ;

oPlan networks with at least five devices;

oInstall at least five devices within the gateway coverage area;

oEnsure that 25 % of the devices are within the gateway coverage area;

TT481 WirelessHARTTM –Operation & Maintenance, Instruction Manual

X

oReposition the gateway as needed ;

oCheck the coverage area of each device;

oEnsure that each device has three neighbors within its coverage area;

oPlace the repeaters as needed.

Installation

As mentioned before, WirelessHART devices should be connected to the process and configured the

same way as conventional wired HART devices.

Handheld terminals can be used normally. Just be sure of having it properly uploaded with the latest

DD files of the devices. However, it is known that the WirelessHART devices have characteristics

inherent to the technology. Because of this, it is recommended the adoption of practices mentioned

below for positioning the gateway and devices.

oInstall the gateway and the devices so that their antennas are vertical;

oEnsure that the antennas are at 0.5 m minimum distance of large obstacles or surfaces ;

oEnsure that the antennas of gateway and repeaters are 2 m above most obstacles within their

coverage areas;

TT400 WirelessHARTTM - Manual de Instrução, Operação e Manutenção

XI

oIf there are high devices, does not exceed 45 ° viewing angles between them;

oMake sure that the gateway is integrated to the host system as planned.

Commissioning

Commissioning consists of testing the device and verifying its configuration data. The TT481

WirelessHARTTMcan be commissioned both before and afterinstallation. Thedevicecommissioncan

be performed through some configurator that interprets DD,for example,the DEVCOMDROIDsoftware

(Android DDL interpreter), which can be used in conjunction with the HI331 (Bluetooth interface) to

configure the Hart equipment.

TT481 WirelessHARTTM –Operation & Maintenance, Instruction Manual

XII

To turn the transmitter on / off, use the SW1 (ON / OFF) terminal, as shown in Figure 1.4.

To connect the handheld configurator to the equipment, use the communication terminals "CN1 and

CN2" on the terminal block. See Figure 1.4.

WirelessHART devices commissioning

a. Install and power on the gateway.

B. If not specified by the customer at the time of ordering, the Network ID and Join Key values for the

gateway and devices should be according the factory default value. Note: It is strongly recommended

that both be changed! To change these parameters install the gateway and all the devices on the

network following the steps below. Once the network is fully functional it will be more practical to

change them.

c. The device configuration must be carried out individually, starting with those closest to the gateway

and moving away to the most distant so that the communication is being established correctly.

d. Always install the equipment with the antenna in the vertical direction. If the device is installed

horizontally, consult Smar to purchase the antenna for horizontal assemblies, in order to be 90 ° with

the equipment. No WirelessHART device should be located at the highest point of theplant,preventing

it from lightning;

e. Turn on the device using the key on the left of the display and wait until it connects to the network

(this time can vary from 2 minutes to up to 20 minutes, depending on the size of the network). The

status of the device on the network can be checked via the display (section - Status indication on the

display), maintenance port or gateway.

ATTENTION

If the device was not purchased together with the gateway, that is, if the gatewayalreadyhas Network

ID and Join Key values different from the factory values, it is necessary to configuretheseparameters

on the device so that it connects correctly to the network : first configure Network ID and then Join

Key, resetting the device after the settings.

f. As soon as these steps are performed for all devices in the network and theyareconnectedcorrectly,

itis time to change the values of Network ID and Join Key following the instructions according previous

(e) step (if they have not already been changed). Network ID is any number between 0 and 32767 and

identifies the network among others. Join Key is a key of 32 hexadecimal characters (0-9 or A-F) and

enable the device to the configured network.

g. Configure the LongTAG parameter that identifies the equipment on the network.

H. Check that the engineering units of the equipment are in accordance with those required by the

process.

i. Configure Burst mode parameters to publish desired measurements and status:

• Burst message: up to 3 messages can be configured with different commands and times;

• Minimum Time: is the time for publication of the variables;

• Maximum Time: must be longer than the minimum time and is only used in trigger mode (check the

operation of the trigger mode in the device manual;

• Command: HART command which sends the variables desired by the user (for example,command3

sends the values of PV, SV, TV and QV, when available);

• Burst mode: once all the above parameters have been configured, activate Burst mode.

• Acquisition based on Burst time: parameter that reduces equipment consumption by making only one

acquisition immediately before the Burst transmission. If this parameter is disabled, the equipment will

make an acquisition every two seconds, regardless of the Minimum Burst Time.

j. After some negotiation time with the gateway, the device will begin to publish the configured

command at a minimum configured time rate. The ACK icon is shown on the display (if available)when

the device enters Burst mode and the F (t) icon flashes when the Burst command is sent (see section -

Status indication on the display).

TT400 WirelessHARTTM - Manual de Instrução, Operação e Manutenção

XIII

ATTENTION

The Burst mode settings will remain even after the device is turned off. After turned on, the device will

automatically connect to the network in Burst mode with the sameconfiguredtimeand command.The

higher the refresh rate, the shorter the battery life and vice versa. Set a refresh rate which allows the

device keep running for a few years.

k. After the general configuration of the network, wait a period of about 1 hour for the network to start

operating in a 100% optimized way. Attention: There is a parameter for estimating battery life that

indicates the expected life, in days, of the equipment. This parameter is recalculated every 60 minutes

and its value should only become valid after two or three hours of operation of the device on the

network (time needed to optimize consumption). When this value is close to the end, the user will

receive an alarm on the device status and on the display (when available). When replacing the Battery

Module (Smar code 400-1273), the replacement must beconfiguredusing aconfiguratorthatwill cause

the equipment to reset the estimated lifetime count for the new module. (Search for “Battery Life

Remaining”).

ATTENTION: do not dispose the Battery Module in ordinary waste. Use asuitabledisposal forbatteries

or chemical waste.

Checking Equipment Range

Identify what distance may be considered according the kind of environment where the device is

installed:

• Strong obstruction - about 30 meters. Very dense environments in relation to the device, pipes,

cables, etc. A place where you would normally are not able to walk.

• Medium obstruction - about 75 meters. Environments where devices are located in a good distance

from others equipaments in the factory floor.

• Light obstruction -150 meters. Consider an open environment that hassomekindof obstructionlikea

silo or a tank. There is plenty of free space around for RF waves to propagate.

• No obstruction - up to 225 meters. Consider that the antenna of the device "sees"directlytheantenna

of other devices or gateway in the network, without any obstacle between them. In addition, the

difference in height between them should not cause an angle greater than 5 degrees.

Conditions that significantly reduce the range of thedeviceincludemountingthe equipmentcloseto the

ground, below ground level or under water, as the RF signal is absorbed by the ground or water and

does not propagate. In addition, mounting the equipment outside the network area (gateway), for

example, considering a network in an open environment, installing the equipmentinsidea closedroom

also contributes to signal attenuation, after all the signal will not propagate very well under concrete,

wood, etc.

Gateway commissioning

Gateways can have a remote antenna connection, allowing them to be installed indoors and only the

antenna installed outdoor.

a. Make sure that the gateway is available to the host system;

b. Check the gateway and make sure that it has at least five (05) devices directly connected to it;

c. Check that 25% of the devices are connected directly to the gateway. If necessary, add repeaters;

d. The gateway connects the devices to the host system. Therefore, check that the device data is

reaching the applications that subscribe to it.

TT481 WirelessHARTTM –Operation & Maintenance, Instruction Manual

XIV

INSTALLATION FLOWCHART

Yes

Was the transmitter

configured on the bench

to match the application?

Configure the engineering unit

Simule the value(s)

of the work range in the sensor(s)

conection terminal(s)

mV or Ohm

Start

No

No OK

Yes

Configure the sensor type

Configure the sensor connection

Configure the measurement range

0% and 100%

Configure the alarm

See manual

(Section 5 - )Maintenance

Is the reading correct?

Check the area classification

and its practices

Install the transmitter preferably

on weather- protected areas

Power the transmitter properly.

Configure Network ID and Join Key

for HARTWireless

Install the transmitter according

with the application, verifying the

the most appropriate position

indicator and the antenna is

pointing upwards

Section 1

1.1

INSTALLATION

General

The overall accuracy of temperature and other measurements depends on severalvariables. Although

the transmitter has an outstanding performance, proper installation isessential, in order tomaximizeits

performance.

Among all factors, which may affect transmitter accuracy, environmental conditions are the most

difficult to control. There are, however, ways of reducing the effects of temperature, humidity and

vibration.

Temperature fluctuation effects can be minimized bylocating thetransmitterinareasprotectedfromex-

treme environmental changes.

In warm environments, the transmitter should be installed to avoid, as much as possible, direct expo-

sure to the sun. Installation close to lines and vessels subjected to high temperatures should also be

avoided. For temperature measurements, sensors with cooling-neck can be used or the sensor canbe

mounted separated from the transmitter housing.

Use of sunshades or heat shields to protect the transmitter from external heat sources should be

considered, if necessary.

Humidity is fatal to electronic circuits. In areas subjected to high relative humidity, the O’Rings for the

electronics cover must be correctly placed. Removal of the electronics cover in the field must be

reduced to the minimum necessary, since each time it is removed the circuits are exposed to the

humidity. The electronic circuit is protected by a humidity proof coating, but frequent exposures to

humidity may affect the protection provided. It is also important to keep the covers tightened in place.

Every time they are removed, the threads are exposed to corrosion, since these parts can not be

protected by painting. Code-approved sealing methods on conduit entering the transmitter should be

employed.

Measurement error can be decreased by connecting the sensor as close to the transmitter as possible

and using proper wires (see Section 2, Operation).

WARNING

Random, frequent or common cause failures must not damage the equipment´s work or result in

death or serious injure, must not harm to the environment or equipment, and must not loss

of equipment or production.

Electrical shock can result in serious injury.

Mounting

The transmitter may be mounted according to the Figure 1.1.

To access the electronic board, terminal block, battery and display module, open the cover of the

gear box by unscrewing the four front screws.

TT481 WirelessHARTTM –Operation & Maintenance, Instructions Manual

1.2

70

100

MOUNTING BRACKET FOR TUBE 2"

153

207

180

180

214

Figure 1.1 (a) –Dimensional Drawing - TT481 WirelessHARTTM with 4 Channels

Installation

1.3

70

100

153

180

207

234

180

214

MOUNTING BRACKET FOR TUBE 2"

Figure 1.1 (b) –Dimensional Drawing - TT481 WirelessHARTTM with 8 Channels

WARNING

The TT481 WirelessHARTTM should always be installed with the antenna positioned upward.

TT481 WirelessHARTTM –Operation & Maintenance, Instructions Manual

1.4

Minimum

0.5 m

Minimum

1.5 m

Legend:

1 - Vertical Obstacle

2 - Floor

3 - Minimum of three neighboring equipment

4 - Advised five neighboring transmitters

Figure 1.2 –Wiring Diagram for Wireless Transmitters

Battery Module Wiring

The device go out of factory with battery module off, for safety and standard shipping. To turn it is

necessary to previously connect the Battery Module connector to circuit board and flip the switch SW1

to the ON position (Figure 1.3).

Installation

1.5

Figure 1.3 –Connecting the Battery Module to Electronic Board

The maintenance port allows initial configuration of the transmitter. To do this, it must connect a HART

configurator in communication terminals "CN7" and "CN8", shown in Figure 1.4..

Figure 1.4 –Maintenance Port

TT481 WirelessHARTTM –Operation & Maintenance, Instructions Manual

1.6

The sensor connection on the input plate of the equipment shall be performed according to Figure 1.5,

considering the type and number of sensors to be connected.

Figure 1.5 –Sensors Wiring

Installation in Hazardous Locations

WARNING

Explosions could result in death or serious injury, besides financial damage. Installation of this

transmitter in explosive areas must be carried out in accordance with the local standards and the

protection type adopted. Before continuing the installation make sure the certificate parameters are

in accordance with the classified area where the equipment will be installed.

The instrument modification or parts replacement supplied by other than authorized representativeof

Smar is prohibited and will void the certification.

The transmitters are marked with options of the protection type. The certification is valid onlywhenthe

protection type is indicated by the user. Once a particular type of protectionis selected,anyothertype

of protection can not be used.

Intrinsically Safe

WARNING

In hazardous zones with intrinsically safe or non-incendive requirements, the circuit entity

parameters and applicable installation procedures must be observed.

For free access to the HART bus in the explosive environment, ensure the instruments in the

loop are installed in accordance with intrinsicallysafe or non-incendive field wiring practices.

It is not recommended to remove the transmitter cover when the power is ON.

Table of contents

Other SMAR Transmitter manuals