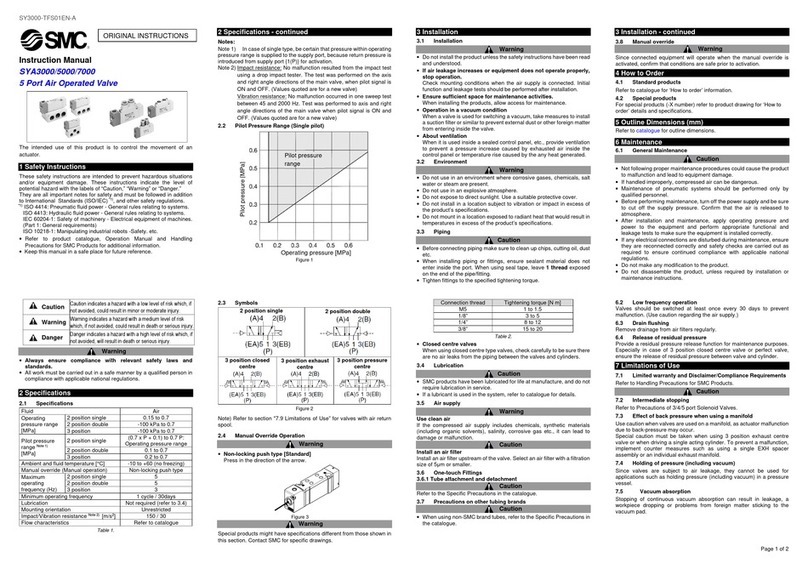

3 Port Air Operated Valve

Precautions 1

Be sure to read this before handling products.

1. Confirm the specifications.

This product is designed only for use in compressed air

systems. Do not operate at pressures, temperatures, etc.,

beyond the range of specifications, as this can cause damage

or malfunction.

Please contact SMC when using a fluid other than

compressed air.

We do not guarantee against any damage if the product is

used outside of the specification range.

2. Actuator drive

When an actuator, such as a cylinder, is to be driven using a

valve, take appropriate measures (such as the installation of a

cover or the restricting of access to the product) to prevent

potential danger caused by actuator operation.

3. Intermediate stops

Due to the compressibility of air, it is difficult for this product to

make a piston stop at the required intermediate position

accurately and precisely.

Furthermore, since valves and cylinders are not guaranteed

for zero air leakage, it may not be possible to hold a stopped

position for an extended period of time.

Please contact SMC if it is necessary to hold a stopped

position for an extended period of time.

4. Effects of back pressure when using a

manifold

Use caution when valves are used on a manifold because

actuators may malfunction due to back pressure.

When a single acting cylinder is operated, take appropriate

rmeasures to prevent malfunction by using an individual EXH

manifold.

5. Holding pressure

Since valves are subject to air leakage, they cannot be used

for applications such as holding pressure in a pressure vessel.

6. Not suitable for use as an emergency shutoff

valve, etc.

The valves presented in this catalog are not designed for

safety applications (e.g. emergency shutoff valve). If the valves

are used in such applications, additional safety measures

should be adopted.

7. Release of residual pressure

For maintenance and inspection purposes install a system for

releasing residual pressure.

8. Ventilation

Provide ventilation when using a valve in a confined area,

such as in a closed control panel. For example, install a

ventilation opening, etc., in order to prevent pressure from

increasing inside of the confined area and to release the heat

generated by the valve.

9. Do not disassemble the product or make any

modifications, including additional machining.

Doing so may cause human injury and/or an accident.

1. Operation in low temperature conditions

It is possible to operate the valve in extreme temperatures, as

low as 5oC. Take appropriate measures to avoid the freezing

of drainage, moisture, etc. in low temperatures.

2. Mounting orientation

Mounting orientation is not specified.

3. Initial lubrication of main valve

Grease has been applied to the main valve as initial lubricant.

1. Operation manual

Install the products and operate them only after reading the

operation manual carefully and understanding its contents.

Also, keep the manual where it can be referred to as

necessary.

2. Ensure sufficient space for maintenance

activities.

When installing the products, allow access for maintenance

and inspection.

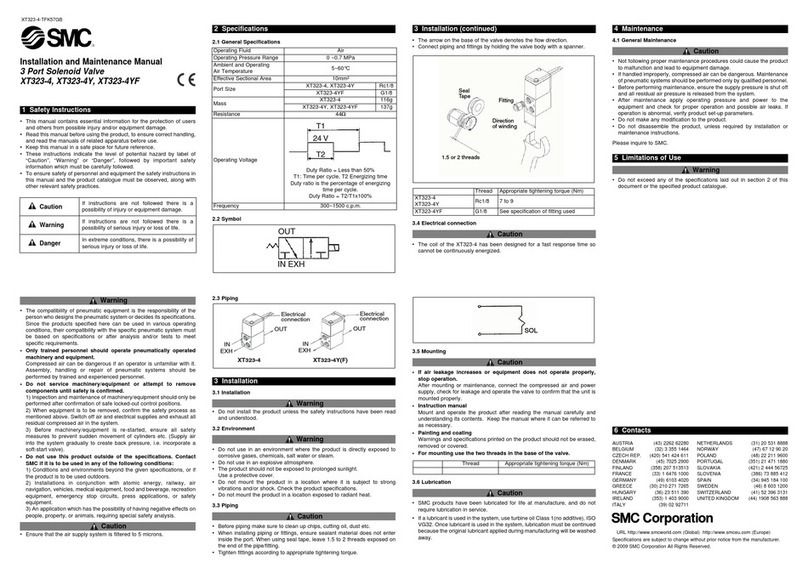

3. Tighten threads with the proper tightening

torque.

When installing the products, follow the listed torque

specifications.

4. If air leakage increases or equipment does not

operate properly, stop operation.

Check mounting conditions when air and power supplies are

connected. Initial function and leakage tests should be

performed after installation.

5. Painting and coating

Warnings or specifications printed on or affixed to the product

should not be erased, removed, or covered up.

Please consult with SMC before applying paint to resinous

parts, as this may have an adverse effect due to the solvent in

the paint.

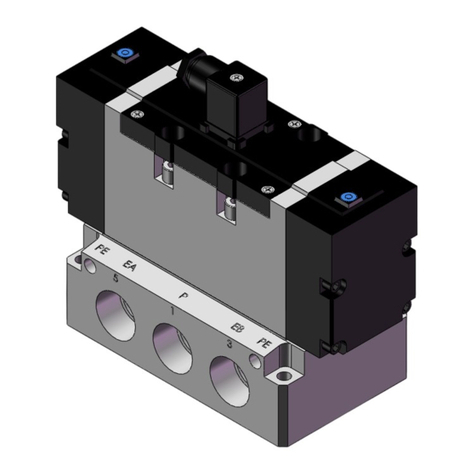

1. Preparation before piping

Before piping is connected, it should be thoroughly blown out

with air (flushing) or washed to remove chips, cutting oil, and

other debris from inside the pipe.

2. Winding of sealant tape

When screwing piping or fittings

into ports, ensure that chips

from the pipe threads or sealing

material do not enter the piping.

Also, if sealant tape is used,

leave 1 thread ridge exposed at

the end of the threads.

- 4 -No.VT325∗∗-OMF0002-B