JXCL1-SMW16EN

Page 2 of 2

3 Installation - continued

+24 VDC power supply for IO-Link

communication.

IO-Link communication starts when the power

supply L+/L- and C24V control power are supplied

to the JXC controller.

0 VDC power supply f or IO-Link communication

Phoenix Contact product number: FMC1,5/4-STF-3,5 or equiv alent.

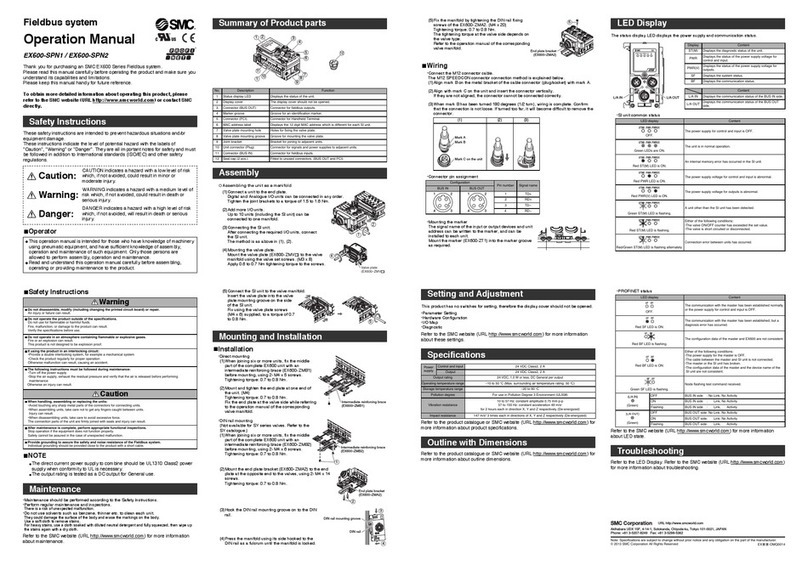

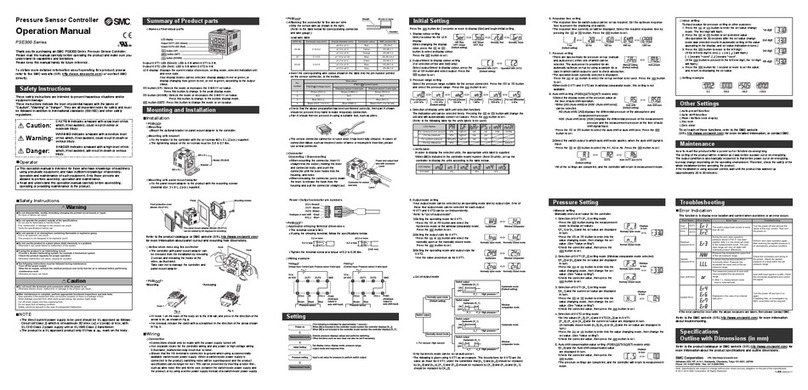

•Electric Wiring Specifications

Prepare the wiring according to the follow ing specifications (to be

prepared by the user).

Single wire, stranded wire AWG24-16 (0.2-1.5 mm2)

The rated temperature of theinsulation coating should be

60oC or more. The O.D. should be ø2.5 mm or less.

Conductor resistance 3 ohms or less

Conductor capacitance 3 nF or less

After wiring the IO-Link communication plug, connect it to the IO-Link

connector onthecontroller.

IO-Link communication plug

3.2 Environment Warning

Do not use in an environmentwhere corrosive gases, chemicals, salt

w ater or steamare present.

Do notuse in an explosiveatmosphere.

Do notexpose to direct sunlight.Use a suitable protective cover.

Do not install in a location subject to vibration or impact. Check the

productspecifications.

Do notmount in a location exposedtoradiant heat.

4 Settings

Initial Setting

•IO-Link master configuration

IODD file

The IODD file is used for mapping the JXC controller to the IO-Link

master.

The IODD file is a device definition file which provides all properties

and parameters requiredfor establishing operation and communication

of the JXC controller.

4 Settings - continued

The IODD includes the main IODDfile and a set of image files such as

vendor log, device picture and device icon.

Refer to the operation manual for the IO-Link master for installing the

IODD file.

The IODD file for the JXCL1 can be downloaded from the SMC Web

site.

•URL:http://www.smcworld.com

Documents / Download→Instruction Manuals →

SMC-JXCL17JXCL18_ .zip

•Contents of SMC-JXCL1_v.zip

IODD file: SMC-JXCL17JXCL18- -IODD1.1.xml

Device symbol: SMC-JXCL17JXCL18-pic.png

Device icon: SMC-JXCL17JXCL18-icon.png

Vendor logo: SMC-logo.png

5 How to Order

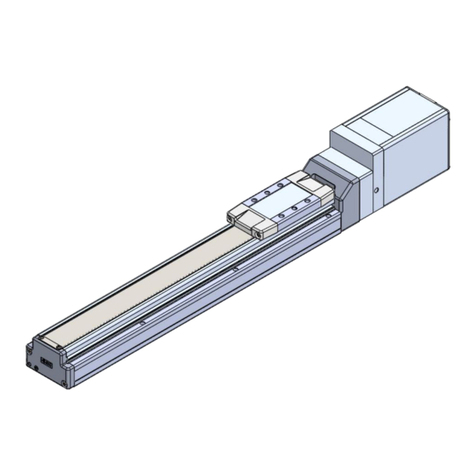

6 Outline Dimensions (mm)

1) Direct mounting(JXCL17-#)

6 Outline Dimensions (mm) - continued

2) DIN rail mounting(JXCL18-#)

7 Maintenance

7.1 GeneralMaintenance Caution

Not follow ing proper maintenance procedures could cause the

product tomalfunction and lead to equipment damage.

If handled improperly, compressed air can be dangerous.

Maintenance of pneumatic systems should be performed only by

qualified personnel.

Before performing maintenance, turn off the power supply and be

sure to cut off the supply pressure. Confirmthat the air is released to

atmosphere.

After installation and maintenance, apply operating pressure and

pow er to the equipment and perform appropriate functional and

leakage teststo make suretheequipment is installed correctly.

If any electrical connections are disturbed during maintenance,

ensure they are reconnected correctly and safety checks are carried

out as required to ensure continued compliance with applicable

national regulations.

Do notmake any modification tothe product.

Do not disassemble the product, unless required by installation or

maintenance instructions.

8 Limitations of Use

8.1 Limited warrantyand Disclaimer/Compliance Requirements

The product used is s ubject to the following “Limited warranty

and Disclaimer” and “Compliance Requirements”. Read and

accept them before usingthe product.

Limited warrantyand Disclaimer

1) Thew arranty period of the product is 1 year in service or 1.5years

after the product is delivered, whichever is first (1). Also, the product

may have specified durability, running distance or replacement parts.

Please consult your nearest sales branch.

2) For any failure or damage reported within the warranty period

which is clearly our responsibility, a replacement product or

necessary partswillbe provided.

This limited warranty applies only to our product independently, and

not to anyotherdamage incurreddueto the failureof theproduct.

3) Prior to using SMC products, please read and understand the

warranty terms and disclaimers noted in the specified catalogue for

the particular products.

(1) Vacuumpads are excludedfromthis 1 year w arranty.

A vacuumpad is aconsumable part, so it iswarrantedfor ayear after

it is delivered. Also, even within the warranty period, the wear of a

product due to the use of the vacuum pad or failure due to the

deterioration of rubber material are not covered by the limited

warranty.

Compliance Requirements

1) The use of SMC products with production equipment for the

manufacture of weapons of mass destruction (WMD) or any other

w eapon is strictly prohibited.

8 Limitations of Use - continued

2) The exports of SMC products or technology fromone country to

another are governed by the relevant security laws andregulations of

the countries involved in the transaction. Prior to the shipment of a

SMCproduct to another country, assure that all local rules governing

that exportareknownandfollowed.

Caution

SMC products are not intendedfor use as instrumentsfor legal

metrology.

Measurement instruments that SMC manufactures or sells have not

been qualified by type approval tests relevant to the metrology

(measurement) law s of eachcountry.

Therefore, SMC productscannot be usedfor business or certification

ordained by the metrology (measurement) law s of each country.

9 Contacts

SMC Pneumatik GmbH,Girakstrasse 8, AT-2100 Korneuburg

SMC Pneumatics N.V. ⁄ S.A. Nijverheidsstraat 20, B-2160

Wommelgem

SMC Industrial Automation Bulgaria EOOD, Business Park Sofia,

Building 8-6th f loor, BG-1715 Sofia

SMC IndustrijskaAutomatikad.o.o. ZagrebačkaAv enija 104,10

000 Zagreb

SMC Industrial Automation CZ s.r.o. Hudcov a 78a, CZ-61200

Brno

SMC Pneumatik A ⁄ S,Egeskov vej 1, DK-8700 Horsens

SMC Pneumatics EstoniaOü,Laki 12, EE-10621 Tallinn

SMC Automation Oy , PL72, Tiistinniity ntie 4, SF-02031 Espoo

SMC France, 1, Boulevard de Strasbourg, Parc Gustave Eiffel,

Bussy Saint Georges, F-77607 Marne La ValleeCedex 3

SMC Deutschland GmbH, Boschring 13-15, 63329 Egelsbach

SMC Italia Hellas Branch, Anagenniseos 7-9-P.C. 14342

N.Philadelphia, Athens

SMC Hungary IpariAutomatizálásiKft.Torbágy u. 19, HU-2045

Törökbálint

SMC Pneumatics (Ireland) Ltd.2002 Citywest Business Campus,

Naas Road, Saggart, Co. Dublin

SMC Italia S.p.A.Via Garibaldi 62, I-20061Carugate, (Milano)

SMC Pneumatics Latv iaSIA, Dzelzavas str. 120g, Riga, LV-

1021,

UAB “SMC Pneumatics”, Oslo g. 1, LT-04123 Vilnius

SMC Pneumatics B.V.De Ruyterkade 120, NL-1011 AB

Amsterdam

SMC Pneumatics Norway AS, Vollsv eien13 C,

GranfosNæringspark, N-1366 Lysaker

SMC Industrial Automation, Polska Sp z o.o.

02-826 Warszawa, ul. Poloneza 89

SMC Sucursal Portugal, S.A.Rua De Eng Ferrerira Dias 452

4100-246, Porto

SMC Romania S.r.l. StrFrunzei 29, Sector 2, Bucharest

SMC Pneumatik LLC. Business centre, building 3, 15

Kondratjev skij prospect, St.Petersburg, 195197

SMC PriemyselnáAutomatizáciaSpols.r.o. Fantranská 1223,

Teplickanadv ahom, 01301

SMC IndustrijskaAv tomatikad.o.o. Mirnskacesta 7, SLO-8210

Trebnje

SMC España S.A. Zuazobidea 14, 01015 Vitoria

SMC Pneumatics Sweden AB,Ekhagsv ägen 29-31, SE-141 71

Segeltorp

SMC Schweiz AG,Dorf strasse 7, Postf ach, 8484 Weisslingen,

SMC PnömatikSanay iTicaretv eServ is A.Ş. GülbaharCaddesi,

Ay dın Plaza, No: 9 ⁄ 4 Güneşli – 34212 , Istanbul

SMC Pneumatics (U.K.) Ltd. Vincent Avenue, Crownhill, Milton

Keynes, Buckinghamshire MK8 0AN

http// www.smcworld.com (Global) http// www.smceu.com (Europe)

'SMC Corporation, Akihabara UDX15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo

101 0021

Specif ications are subject to change without prior notice f rom the manuf acturer.

© 2018SMC Corporation All Rights Reserved.

Template DKP50047-F-085G

Number of axis/

Pow er supply type

(Enter the actuator model and

include "stroke"

E.g. LEFS16B-100B-S1CL17,

1 axis, Pow ersupply

(24VDC)