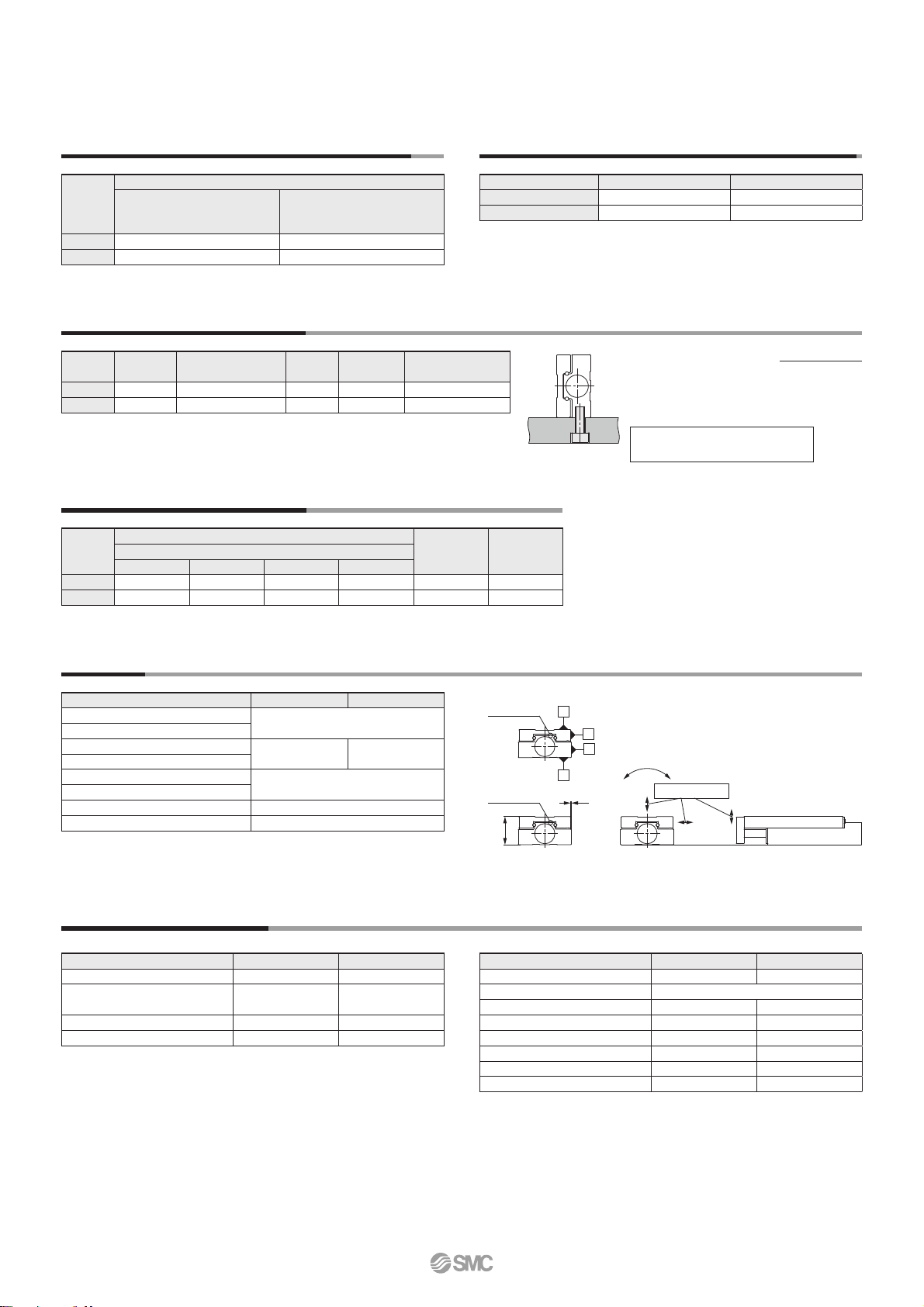

Air Slide Table MXJ Series

Maximum Allowable Load Mass: m max

Maximum Allowable Moment (Reference Values)

Allowable Kinetic Energy: J

Accuracy

Adjuster Specifications/Refer to page 11 for adjuster models and dimensions.

Stroke 10, 20, 30 50

B side parallelism to A side 0.03 mm

E side parallelism to D side

B side traveling parallelism to A side

0.005 mm 0.008 mm

E side traveling parallelism to D side

M dimension tolerance ±0.05 mm

W dimension tolerance

End deflection ±0.003 mm

Non-rotating table accuracy (deg) at the retracted end

±0.02

∗ The table displays the values for an unloaded, unpressurised cylinder

without deflection. The values are recorded at 20°C ±5°C.

Weight of Moving Parts: m1

Model

Weight of moving parts Additional

weight of

magnet

Additional weight

of adjustment

block

Stroke [mm]

10 20 30 50

MXJ12 96 99 115 147 0.61 16

MXJ16 138 147 168 211 0.61 30

Model

Maximum load mass

Without adjuster

Rubber stopper

Shock absorber

Metal stopper with bumper

Metal stopper

MXJ12 0.8 0.5

MXJ16 1.5 1

Model Pitch, Yaw Roll

MXJ12 4.5 5.3

MXJ16 6.4 9.2

∗ A model cannot be selected with the maximum allowable moment.

Select a model according to the model selection steps on page 19.

Model Without

adjuster

Metal stopper

with bumper

Rubber

stopper

Shock

absorber Metal stopper

MXJ12 0.05 0.015 0.05 0.245 0.012

MXJ16 0.069 0.023 (0.017)∗10.069 0.49 0.02 (0.014)∗1

Kinetic energy E [J] =

m1: Weight of cylinder moving parts

kg

m2: Load mass kg

V: Piston speed at the end m/s

(m1 + m2)V2

2

V = 1.4 Va

Va: Average piston speed

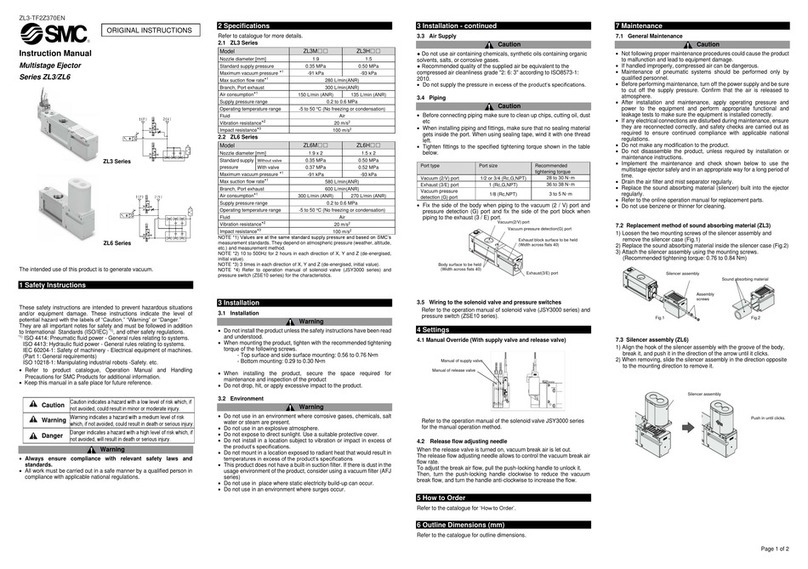

Side mounting

E

D

B

A

Non-rotating accuracy

End deflection

M

W

Groove for

reference

Groove for

reference

[kg] [N·m]

[J]

[g]

Shock Absorber/RJ

Model MXJ12 MXJ16

Stroke absorption [mm] 4 6

Collision speed [mm/s] 50 to 500

Max. operating frequency [cycle/min]

20 42

Max. allowable thrust [N] 150 245

Spring force (Extended) [N] 1.3 2.8

Spring force (Compressed) [N] 3.9 5.4

Mounting screw size M6 x 0.75 M8 x 1

Shock absorber part number RJ0604N RJ0806LN

Metal Stopper with Bumper

Model MXJ12 MXJ16

Stroke absorption [mm] 2 2.8

Min. operating pressure of metal

stopper with bumper∗

1

[MPa]

0.3 0.3

Full compression force of bumper [N]

20 42

Mounting screw size M6 x 0.75 M8 x 1

∗1 Minimum operating pressure required to fully compress the protrusion

of the bumper to get in contact with the metal part

When using the metal stopper with bumper for positioning, use it at a

pressure level exceeding the minimum operating pressure. For vertical

mounting, the workpiece mass should be taken into consideration. For

details, refer to Specific Product Precautions on page 24.

∗1 When the MXJ16 is side mounted and used with metal stoppers or metal stoppers

with bumper, keep the kinetic energy below the value shown in brackets ( ).

∗Average piston speed: Speed that the stroke

is divided by a period

of time from starting

the operation to reach-

ing the end.

6