-2-

Doc.DOC1069999

Table of Contents

Safety Instructions 3

Precautions regarding the Radio Law8

EXW1-A11# 8

Precautions for Handling10

Important Instructions concerning the Wireless System 12

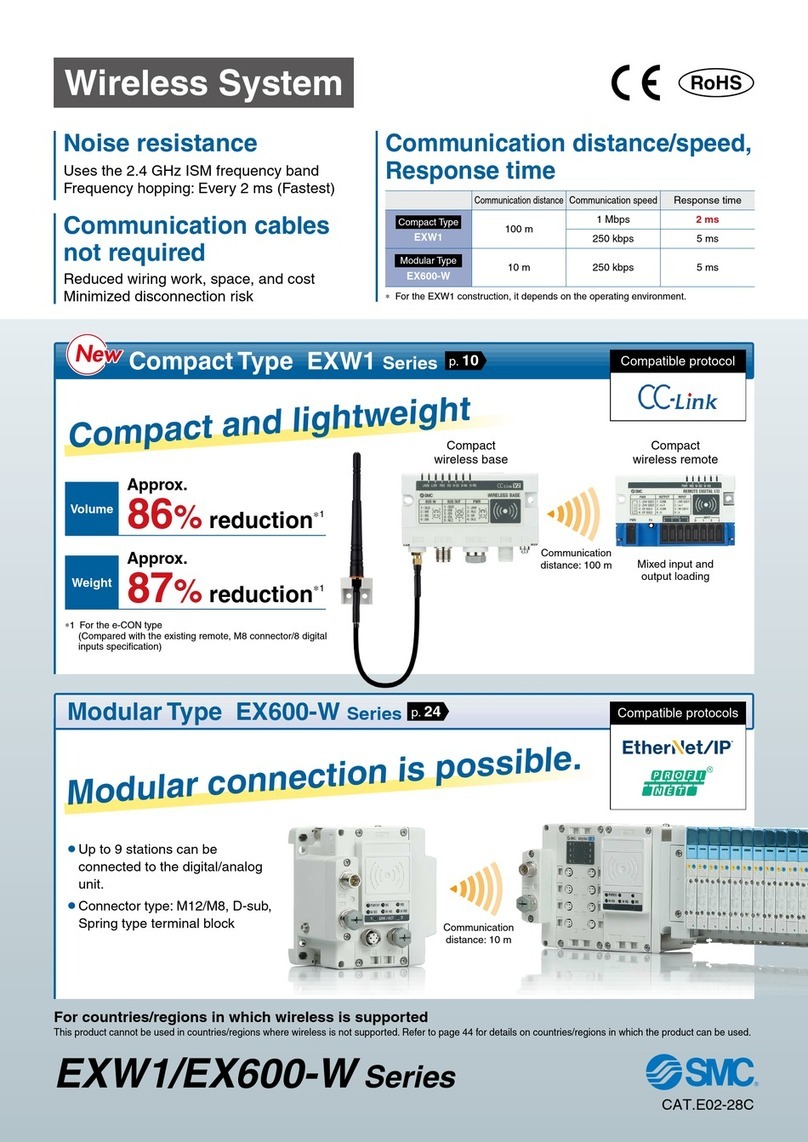

SMC Wireless System 13

Features and Summary 13

System Configuration 14

System compatibility 15

How to Order 22

Summary of Product parts23

EXW1-BPNAC123

EXW1-A11*(Option) 27

Setting and Adjustment28

Flow chart for operating the wireless system 28

I/O Configurator (NFC version) 29

Preparation30

Installation of the software 30

Before starting the software31

Download the I/O Configurator (NFC version) 34

Start the I/O Configurator (NFC version) 35

Screen Layouts of the I/O Configurator (NFC Version) 36

Setting up 38

Setting/Adjustment of the Wireless Unit39

Parameter settings of the Base 39

System setting 39

OPCUA 42

Events 43

Wireless 45

Pairing and Unpairing Procedures47

Pairing Procedure 47

Unpairing Procedure 55

Mounting and Installation of Units57

EXW1-BPNAC157

Troubleshooting 61

Technical Information67

I/O Map 67

I/O Mapping

69

I/O mappingorder of base/remote 70

D

iagnostics map details72

Frequency channel select function( F.C.S.80

Number of pairing remotes82

Detail of Parameters 83

Hardware configuration97

Acyclic communication 108

Web server 130

OPC UA 131

Specifications 138

Dimensions138

specification 140

Accessories 142

Accessory List 142