Z_ISE80-TF2Z045EN

Page 2 of 3

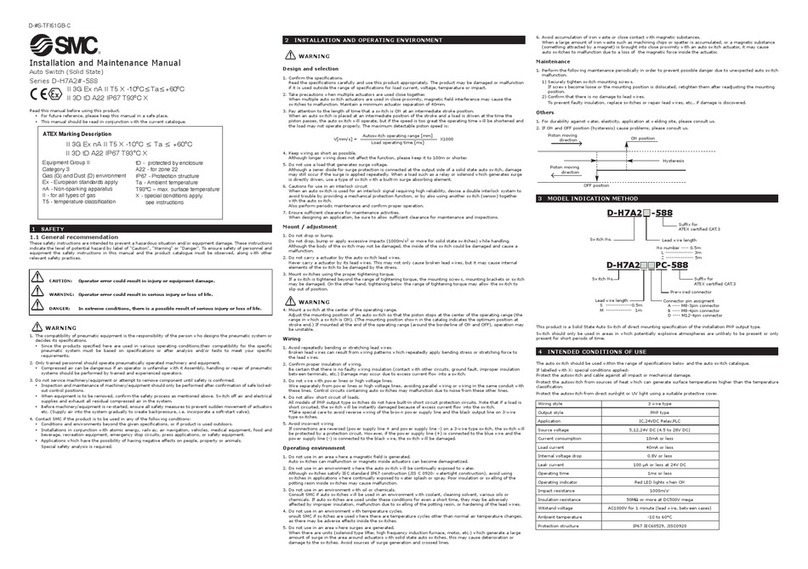

4 Installation (continued)

4.2 Environment Warning

Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

Do not use in an explosive atmosphere.

Do not expose to direct sunlight. Use a suitable protective cover.

Do not install in a location subject to vibration or impact. Check the

product specifications.

Do not mount in a location exposed to radiant heat.

Do not use the product in a place where electrical static charge will be

a problem. It can cause the error and damage to the system.

4.3 Piping Caution

Before piping make sure to clean up chips, cutting oil, dust etc.

When installing piping or fittings, ensure sealant material does not

enter inside the port. When using seal tape, leave 1 thread exposed

on the end of the pipe/fitting.

Tighten fittings to the specified tightening torque.

4.3.1 Connection using screw type fitting

Connect suitable piping to the port.

To connectthe hexagon socket head plugor fitting tothe pressure port,

hold the hexagon part of the pressure port with a suitable spanner.

The required tightening torque is 12 to 14 N•m.

4.4 Vent Tube attachment

When the product is used in a place where water and dust splashes

may occur, insert a tube into the atmospheric vent port, and route the

other end of the tube to a safe place away from water and dust.

Insert the tube into the atmospheric vent port until it bottoms out.

SMC TU0425 (polyurethane, O.D 4, I.D 2.5) is a suitable tubing.

4.5 Lubrication Caution

SMC products have been lubricated for life at manufacture, and do not

require lubrication in service.

If a lubricant is used in the system, use turbine oil Class 1 (no additive),

ISO VG32. Once lubricant is used in the system, lubrication must be

continued because the original lubricant applied during manufacturing

will be washed away.

5 Wiring

5.1 Wiring connections

Connections should be made with the power supply turned off.

Use a separate route for the product wiring and any power or high

voltage wiring. Otherwise, malfunction may result due to noise.

If a commercially available switching power supply is used, be sure to

ground the frame ground (FG) terminal. If the switching power supply is

connected for use, switching noise will be superimposed and it will not

be able to meet the product specifications. In that case, insert a noise

filter such as a line noise filter/ferrite between the switching power

supplies or change theswitching power supply to a series power supply.

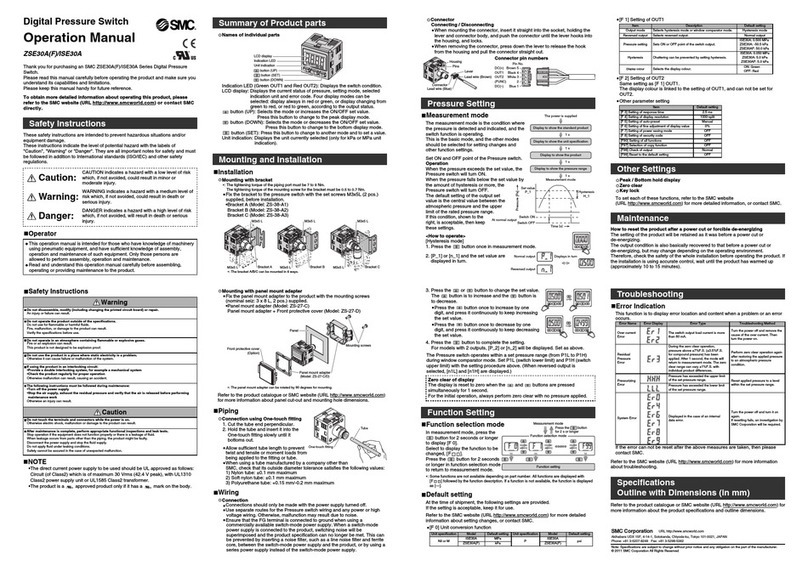

6 Pressure Setting

6.1 Measurement mode

The measurement mode is the condition where the pressure is detected

and displayed, and the switch function is operating.

This is the basic mode, and other modes should be selected for setting

changes and other function settings.

Setting the ON and OFF points of the Pressure switch.

Operation

When the pressure exceeds the set point, the Pressure switch will be

turned ON.

When the pressure falls below theset point bythe amount of hysteresis

or more, the Pressure switch will be turned OFF.

The default setting of the Pressure switch is adjusted to be turned on

at the central value between atmospheric pressure and the upper limit

of rated pressure range, and turned off when the pressure decreases

by 5% of the span between atmospheric pressure and the upper limit

of rated pressure range.

If this condition, shown below, is acceptable, then keep these settings.

6.2 Operation

[Hysteresis mode]

1, Press the button once in measurement mode.

2, [P_1] or [n_1] and the set value are displayed in turn.

6 Pressure Setting (continued)

3, Press the or button to change the set value.

The button is to increase and the button is to decrease.

Press the button once to increase by one digit, and press it

continuously to keep increasing the set value.

Press the button once to decrease by one digit, and press it

continuously to keep decreasing the set value.

4, Press the button to finish the setting.

For models with 2 outputs, [P_2] or [n_2] will be displayed. Set as

above.

The Pressure switch operates within a set pressure range (from P1L to

P1H) during window comparator

mode. Set P1L (switch lower limit) and P1H (switch upper limit) with the

setting procedure above.

(When reversed output is selected, [n1L] and [n1H] are displayed.)

Zero clear of Display

The display is reset to zero when the and buttons are pressed

simultaneously for 1 second. For the first operation, always perform zero

clear with no pressure applied.

7 Function Setting

In measurement mode, press the button for 2 seconds or longer to

display [F 0]. Select to display the function to be changed, [F ## ].

Press the button for 2 seconds or longer in function selection mode

to return to measurement mode.

*: Some functions are not available depending on part number. All functions are

displayed with [F ##] followed by the function description.

If a function is not available, the function is displayed as [---].

7 Function Setting (continued)

7.1 Default Function settings

At the time of shipment, the following settings are provided.

If this condition is acceptable, then keep these settings.

To change the settings, enter function selection mode.

[F 0] Unit selection function.

[F 1] Setting of OUT1

Select hysteresis mode or

window comparator mode.

Set the ON or OFF point of

the switch output

ISE80: 0.500 MPa

ZSE80: -50.5 kPa

ZSE80F: 50.0 kPa

ISE80H: 1.000 MPa

Set the hysteresis to prevent

chattering.

ISE80: 0.050 MPa

ZSE80: 5.1 kPa

ZSE80F: 5.0 kPa

ISE80H: 0.100 MPa

Select the display colour.

[F 2] Setting of OUT2 is the same setting as [F 1] OUT1.

The display colour is linked to OUT1 and cannot be set for OUT2.

Other parameter settings

8 Other Settings

Peak/bottom value display

The maximum (minimum) pressure when the power is supplied is

detected and updated.

Zero clear function

The displayed value can be adjusted to zero when the measured

pressure is within 10% of the spanbetween atmospheric pressure and

upper limit of rated pressure range, from the default value of pressure.

Key-lock function

The key-lock function is used to prevent errors occurring due to

unintentional changes of the set values.

For further details refer to the operation manual on the SMC website

(URL: https://www.smcworld.com).

9 How to Order

Refer to the operation manual on the SMC website (URL:

https://www.smcworld.com) for How to order information.

10 Outline Dimensions

Refer to the operation manual or catalogue on the SMC website (URL:

https://www.smcworld.com) for Outline Dimensions.

[F 4] Analogue output / Auto-shift input

[F 5] Display resolution(not set ISE80H)

[F 7] Fine adjustment of display value

[F 8] Auto-preset function

[F98] Setting of all functions

[F99] Reset to the default setting