IMPORTANT SAFETY INSTRUCTIONS

PREPARATION (Continued)

4. Be familiar with the area in which the machine

will be operated. Inspect area for objects and

hazards that could cause loss of control.

5. Keep people and pets clear of machine and

work area.

6. Inspect shields, guards, switches, brakes and

other safety devices frequently for proper

operation and keep them in place.

7. Inspect headlights and repair as required before

operating machine. Keep headlight lenses and

rear reflectors clean to provide maximum

visibility.

8. Make sure all safety signs are clearly legible.

Replace if damaged.

9. Protect yourself; dress appropriately for the

conditions and the work being performed.

Protective equipment, such as helmet, safety

glasses or face shield , substantial footwear,

long pants, is recommended.

10. Know how to STOP the machine quickly and

safely in preparation for emergencies.

11. Use extra care when loading or unloading

machine into a truck or trailer.

12. Make sure accelerator, brake, steering, and shift

lever function properly before operating

machine.

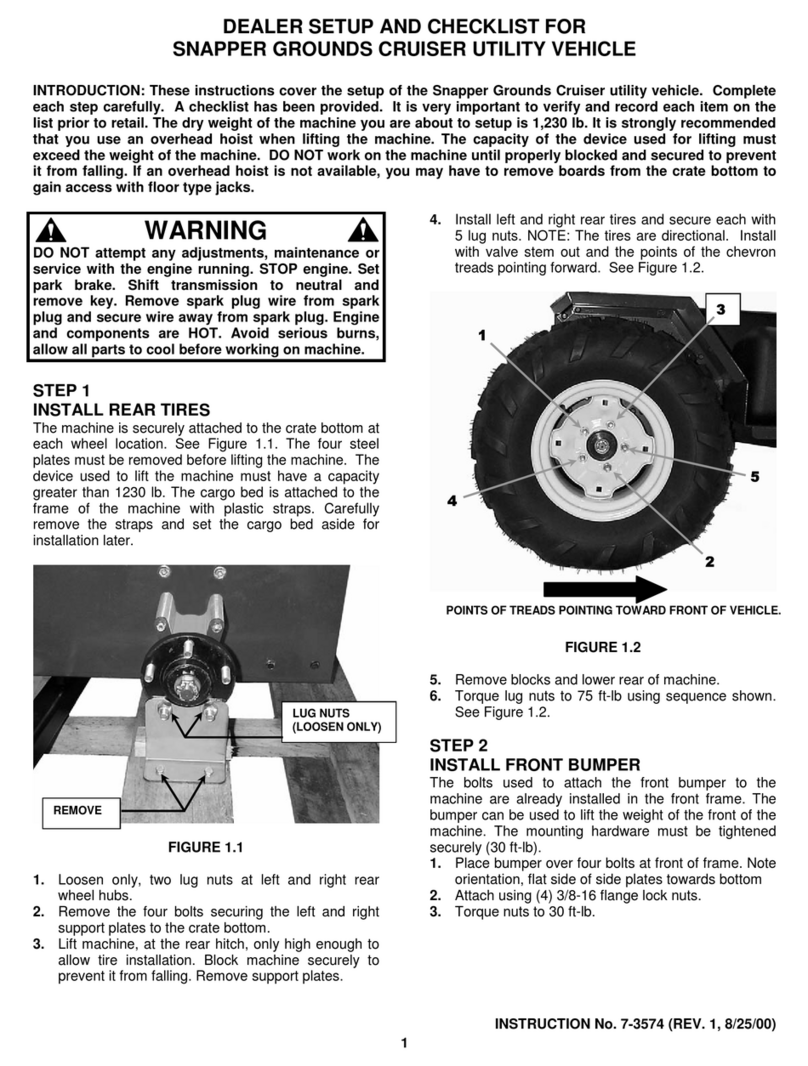

13. Adjust tire inflation pressure to the

specifications listed on the machine and in this

manual.

14. Inspect condition of tires and replace worn or

deteriorated tires before operating machine,

using only tires of the same size, type and

construction approved by SNAPPER.

15. Obey all local ordinances and laws governing

the operation of off-road vehicles. Drive

responsibly and respect private property.

SAFE HANDLING OF GASOLINE

To avoid personal injury or property damage, use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive

1. Extinguish all cigarettes, cigars, pipes and

other sources of ignition.

2. Use only an approved fuel container.

3. DO NOT remove fuel cap or add fuel with the

engine running. Allow the engine to cool before

refueling.

4. DO NOT refuel the machine indoors.

5. DO NOT store the machine or fuel container

inside where there is an open flame, spark or

pilot light such as on a water heater or other

appliances.

6. DO NOT fill fuel containers inside a vehicle or

on a truck or trailer bed with a plastic liner.

Always place the containers on the ground

away from the vehicle before filling.

SAFE HANDLING OF GASOLINE

(Continued)

7. Remove gas-powered equipment from the

vehicle or trailer and refuel it on the ground. If

this is not possible, then refuel equipment

using a portable container, rather than a

gasoline dispenser nozzle.

8. DO NOT start gas powered equipment in

enclosed vehicles or trailers.

9. Keep the nozzle in contact with the rim of the

fuel tank or container opening at all times until

fueling is complete. DO NOT use a nozzle lock-

open device

10. If fuel is spilled on clothing, change clothing

immediately.

11. DO NOT overfill a fuel tank. Replace fuel cap

and tighten securely.

OPERATION

It is extremely important that the operator of this

machine understand that it is not a toy, an ATV or

recreation vehicle. Engaging in horseplay, joy

riding, racing, jumping, hill climbing and similar

activities greatly increases the likelihood of

accidents, which may result in damage, serious

injury and death.

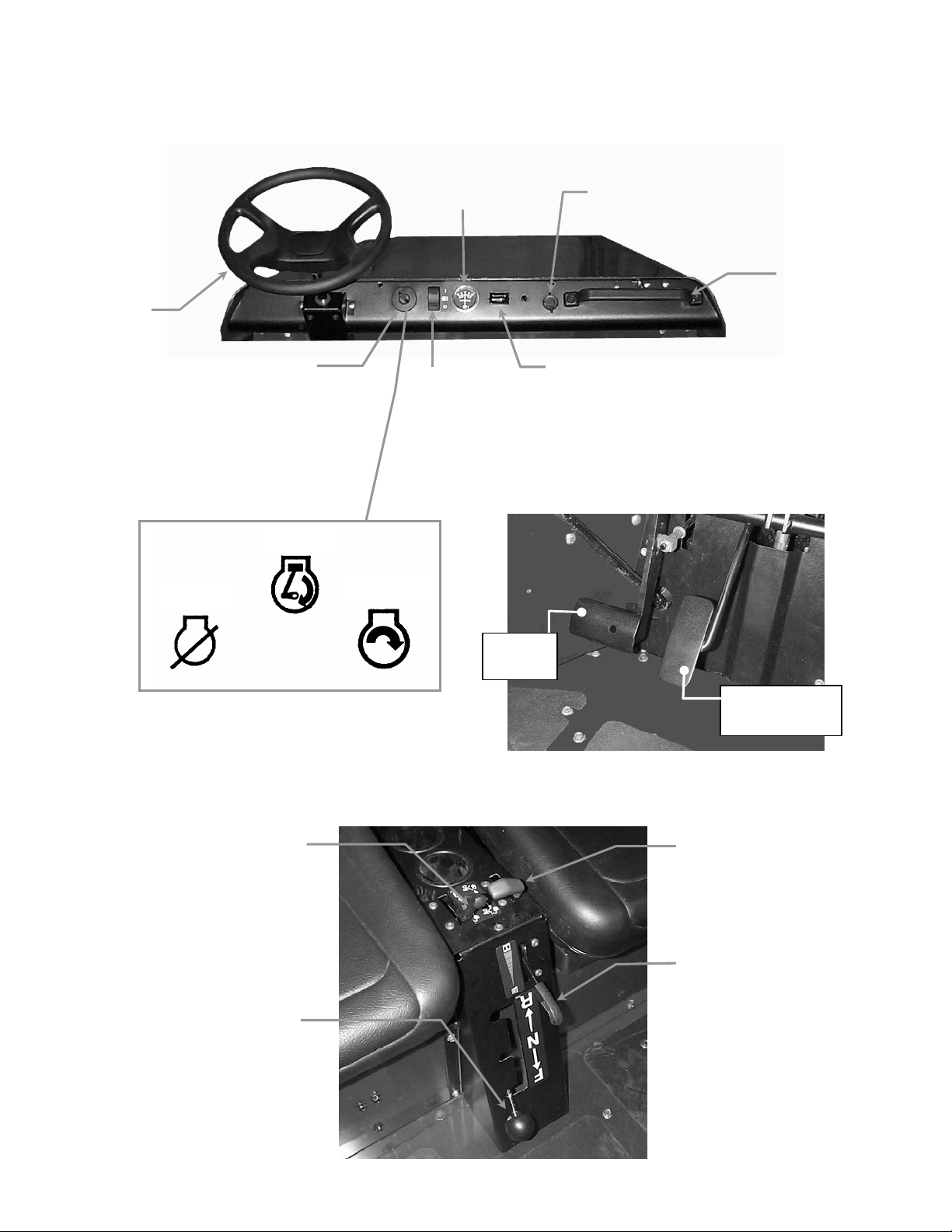

1. Operator must mount and dismount the

machine from the left side. The passenger must

mount and dismount the machine from the right

side.

2. DO NOT attempt to start engine unless properly

seated in the operator’s seat.

3. DO NOT leave the machine with the engine

running. Stop engine, set park brake, shift to

neutral and remove key before leaving the

machine for any reason.

4. Operator must be properly seated with the seat

belt buckle securely latched and the seat belt

adjusted to a snug fit before operating machine.

5. Seating is restricted to only one operator and

one passenger. The passenger must be

properly seated in the passenger seat with the

seat belt buckle securely latched and the seat

belt adjusted to a snug fit before starting and

operating the machine. DO NOT carry more

than one passenger.

6. DO NOT shift transmission when machine is in

motion. Machine must be fully stopped before

shifting.

7. DO NOT operate machine on or near highways

or public roadways. This machine is designed

for off-road use only and is not licensed for use

on public roads.

8. Keep hands and feet inside machine at all

times.

9. DO NOT stand up in machine while machine is

in motion.