SODECA KIT BOXPDS User manual

PL

Dokumentacja Techniczno-Ruchowa

User Manual

Wersja 1.1

ys.. Przykady montau

ys.. Elementy zestawu OXPDS

ys.. Schemat tablicy sterownicej OXPDS Rys Prepustnica

R DAWNICY

KA LOWEJ PIS YJANIENIE RZEKRJ KA LA

5 ael sieci asilaceRZ1-K 5G4

1 Kael ccy silni wentylatora

RC4C1-K

4G2,5

2-3-12 K 3G1

6-7-13

przepustnicy Z1Z1-K (AS) 0 6/1kV 6G1

8-11

$%y DEVICENET 1x2xAWG18 +

1x2xAWG15

4 K$ 3G1,5

10 K%

$ 3G1,5

9 K&' RJ45 cat.6 -

RC4C1-K

RC4C1-K

RC4C1-K

ys . Dawnice kablowe w tablicy sterowniczej OXPDS

Rys

Zewntrzny panel sygnalizacyjny

Zasilanie

A

poarowy

waria

a s o w a n i e

u

Sterowanie

p r z e p u s t n i c a m i

LEWA- PRAWA

ym w

instalacji

10 K%

$ 3G1,5

9 K&' RJ45 cat.6 -

RC 4C 1- K

R DAWNICY

KA LOWEJ OPIS YJANIENIE RZEKRJ KA LA

Sterowanie

AUT. - MAN.

NR TKIETA ZALECAN TP I PRZEKRJ PRZEWODU

230V 50Hz z

z

1L, N and ground 3

0,75 … 1,5mm²

Z

/

BATTERY rzewody dostarczane przez producenta.

Z

OUT 1, OUT 2 2

1 or 2,5mm²

W

BAT FLT

2

1x2x0,8mm²

W

MAINS FLT

W

EXT FLT

LED –

OWER

LED – z

O ERATION

LED – c

BAT (BATTERY)

OWER

FAULT

C

1400 2.32 1.1 19750 75 188

1430 3.44 1.5 21100 75 191

1445 4.83 2.2 23950 78 200

1445 4.83 2.2 28000 79 208

1445 6.33 3 32700 80 210

1440 8.12 4 37200 81 215

Rys. Panel zasilacza

OPIS

LED –

LED – z

Rys1. Waciwoci techniczne

OXPDS-900-7.5

1440 11.60 5.5 47000 89 254

OXPDS-900-10

1455 13.90 7.5 53000 109 265

OXPDS-1000-10

1455 13.90 7.5 58500 112 273

OXPDS-1000-15

1460 20.90 11 68000 113 296

OXPDS-1000-20

146027.90 15 71850 114 315

W2

- ROFIBUS

-x0.75mm2 +

W1

3x2.5 mm2

W2

400 V

W1

5x6 mm2

400V

Silnik wentylatora 400V 4kW

Zasilanie 400V + neutralny (3 +N) + uziemienie

Cz

stotliwo

50Hz

GY

BN

BK

BL

E

SH

GY

BK

BN

Zasilanie i sygna

magistrali CAN BUS

RD

GR

SH

E

BL

BN

Zasilanie 230V (1 + N) + uziemienie

Cz

stotliwo

50 Hz

ZASILACZ

BN

BL

E

Rys. Schemat podczenia zewntrznego panelu sygnalizujcego

Rys. Podczenie zasilania i sterowania tablicy sterowniczej OXPDS

GY BN BK BL E

L1 L2 L3 N E

BN BK GY SH

U V W E

4x4mm2 + OSONA

W10

3x1.5 mm2 + OSONA

W9

5x1.5 mm2

W7

3x1.5 mm2 +OSONA

W6

4x1 mm2 + OSONA

W5

4x1 mm2 + OSONA

W4

3x1 mm2 + OSONA

W3

2x0.75 mm2 +OSONA ROFIBUS

W8 -

3x1.5 mm2 + OSONA

Rys. Pocenie MOD US

PILOT POCZENIA

MAISTRALI CAN US

WKRCIE ONIA

CZUJKA DMU 1

SNA

PRZEPUSTN 1

SIONIK

PRZEPUSTNIC 1

CZUJKA DMU 2

SNA

PRZEPUSTN 2

SIONIK

PRZEPUSTNIC 2

OPCJONALNIE

PRZEKANIK STATUSU

HORNER AP RCC VSD3/A-RFT-5,5 DPT POACZENIE Z PC

ROZANIK ROZANIK

Rys . Erany sterownia PLC

AWARIA

KONFIGURACJA REGULATORA ID

ARAMETRY ROBOCZE

ARAMETRY ROBOCZE SYSTEMU

Cinienie rnicowe

w czasie poaru

ARAMETRY TRANSFERU

BD TRANSFERU

RECZNE STROJENIE ID

WYCZONE RECZNE STROJENIE

Czas prby

asmo przejciowe ID

asmo przejciowe ID

RZE USTNICA OWIETRZA

CZAS OTWARCIA RZE USTNIC

O OZNIENIE REAKCJI NA DYM

LICZBA KLA

WENTYLATOR

MAKS. CISNIENIE ROZNICOWE

MIN. CISNIENIE ROZNICOWE

CISNIENIE ROZNICOWE

CISNIENIE ROZNICOWE

Opnienie bezpiecznej prdkoci

Opnienie zatrzymania

SYGNA OZARU RZE USTNICA

OWIETRZA

WENTYLATOR

SYGNA

OZARU

LOGIKA SYGNAU

OZARU

O OZNIENIE SYGNAU

OZARU

EZPIECZNA PREDKO

ZMIANA HASLA

ASO

WENTYLATOR

% RZETEZENIA

CZAS RZETEZENIA

% NISKIEGO R

DU

KONFIGURACJA

REGULATORA PID

SYGNA

POARU

EZPIECZNA

PRDKO

PRZEPUSTNICA

POWIETRZA

WENTYLATOR

KONFIGURACJA

STEROWANIA

ys. Scemat LC

Wstp

wand a l e j m oraz ama

tandardami wzakresie ami ami

ymi

bowizujcych

normy

!

"

#

pis

$estaw wyrobwBOX DS do rnicowaniaia achprzedsionkach i

N-& '(')'%*

!

!"#"

rzemiennik czstotliwoci

"rzetwornik

%

#

+." ,+, +-,

+./rzepustnice

$ "%!&'(#)*+"#

0$,-./

0"

0! 1

0

0" pewni by

0 &".12#'34-4&"5#52#".2#"5#

0$ &

0"

6 #25#'2# .4

0&

0& 2

0&rzewodu zasilajcego

0&

0& urzdzenia 3

o1

o

Zewntrzny p anel s terujcy do wywietlania wartoci cinienia w czasie rzeczywistym, owania

w za pomoc lampe k oraz r cznej aktywacji systemu.

Z !

"#!$tosuje

zajce " $

zabezpieczpone na etapie prodkucji$ $

%!#$osiadajcego wiedz i

dowiadczenie z zakresie montau, przegldwi$#

&

si odpowiednich $

czcego kanau

Zestaw$#

'an wentylacyjnych#estawu

($ekablicy czej

(estaw$##

$elementy zestawu.

$

estaw

(gnalizacyjny, w

pobliu wejcia do budynku, w pomieszczeniu obsugi budynku lub przy wejsciu dla stray poarnej.

)

!*

o +!

o ,!(

#$$

$#

D estawu astosowa certyfikowany przewd,

$ m u$ m ,

urzdzenie

!"*" terowany bnienie $

$arametry elektryczneabliczce znamionowej

#$

$ %-. % ablicy zej ,

"$!#$$

&'

!"(

)*+,,,*$*,-$+*.$

#/$!$

$0$

12$!

3 .4

12

! $

#

aley

Naleu s

i

!"#

$

%&

!"'

(

)*+,(-%)-%

-. !"

/ -. 0 +++FIRE SIGNAL” (SNA POARU) DAM ER”

(PRZEPUSTNICA POWIETRZA) FAN” ( ENTLATOR) ! SAFTY S EED” ("EZPIECZNA PRDKO)

#ekranie 16 FIRE SIGNAL”#$%OAR)$%0

FIRE SIGNAL LOGIC” (LOGIKA SGNAU POARU) umoliwia skonfigurowanie stycznika (NO, NC).

FIRE SIGNAL DELAY” (OP&NIENIE SGNAU POARU), umoliwiajcy wybranie czasu opnienia sygnau

alarmowego.

#ekranie 17DAM ER”RZEPUSTNICA POWIETRZA$.0

DAM ER TRAVEL TIME” (CZAS OTWARCIA PRZEPUSTNIC) to czas opnienia alarmu przepustnicy. Jeli po

upywie tego czasu nie nastpi otwarcie przepustnicy, zostanie wyzwolony alarm.

SMOKE DELAY” (OP&NIENIE REAKCJI NA DM) to czas opnienia od momenty wykrycia dymu do czasu

uaktywnienia alarmu.

NUMBER OF DAM ERS” (LICZ A PRZEPUSTNIC) suy do okrelenia, czy system jest wyposaony w 1 czy w

2 przepustnice.

#ekranie 22FAN” '$(#%()$0

DIFF. RESSURE MAX”*%+,-$-'NIE R&NICOWE $,

DIFF. RESSURE MIN”*-$C-$-' R&NICOWE $

DELAY DIFF. RESSURE, safety speed”,INIENIE &$-,)WEOpznienie ./!/0j123ci

$

$+12334/54/67,

DELAY DIFF. RESSURE, stop” CINIENIE R&NICOWE Opznienie//0!8

+,

+1233 4/54/ 62#, # $

# 18 +3#,(WENTLATOR)$.:

+9 :;/4"544/#8, (999 PRZETENIA)

+826/:;/4"544/#8,(CZAS PRZETENIA)rzetenie

* przepustnicy

ae

+9 !:* "544/#8, (999 NISKIEGO PRDU) #

$

#ekranie 19 SAFETY S EED”"'4-',4$%+)9-

$<&

ZASILANIE

y

ALARM POZARO

DM W INSTALACJI

AWARIA”

KASOWANIE ALARMU” znajduje

AUTO-MAN

zestaw

! " #

"

"

STEROWANIE PRZEPUSTNICAMI LEWA-PRAWA

$#

!" "#

bsugi technicznej

"

%"

&

'()*

&

'+

&

&,(-...

& $"

&

& ,

&

,

,

EN

1. Start

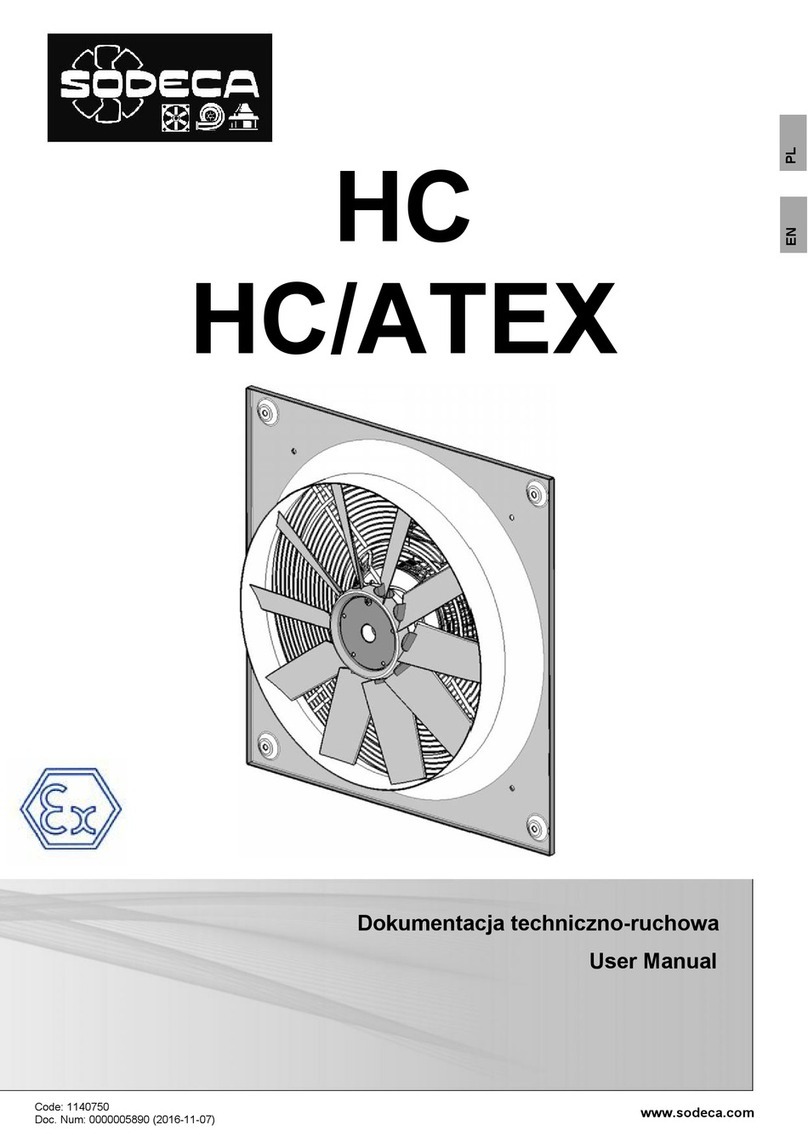

All fans produced by SODECA, hereinafter the manufacturer, and the full line of accessories, have been manufactured under

the most rigorous standards of quality assurance, systems and production processes.

Their project, testing, manufacture and control structure has been configured in line with EU standards and regulations,

especially as regarding current safety standards.

The materials used in our fans, and the standardised components of which they are made meet the same standards and, when

so required, are backed up by the corresponding quality certificates.

The Original Manual was written in Spanish

The manufacturer reserves the right to make modifications without prior notice

All the documentation in this manual is the property of the manufacturer, and its total or partial reproduction is prohibited.

2. Product Definition

KIT OXPDS: ressurisation equipment for stairwells, escape routes and lobbies, compliant with European Standard EN

12101-6.

IMPORTANT: This product is not suitable for use in explosive environments.

FEATURES OF THE KITS

Component

Variable Frequency Inverter

High precision differential pressure probe

Electrical switchboard with magneto-thermal circuit-breakers and mains power cut indicator

Certified battery-powered power source to guarantee supply to the control equipment if there is a mains

power failure

Electronic control for managing alarms maintenance. ModBUS port for connection to BMS (Building

management systems) and Damper based control

3. General Information

• Always check the products received (Fig. 2).

• After unpacking the equipment, it must be checked to make sure that it is not damaged. Damaged products must never

be installed.

• This equipment must not be used for purposes other than those for which it was designed; it must only operate under

the conditions described in this manual.

• In the event of a defect or malfunction, this must be reported to the authorised representative, with a description of the

problem, in order to coordinate its return or possible repair.

• Before starting up the equipment, it is important to ensure that the safety and installation instructions in this document

have been read

4. Transportation, storage and handling

• Always hold the equipment at the points provided for this. Do not lift it by the electrical cables, connection boxes, or the

air inlets or outlets.

• Before installation, store the equipment in a clean, dry place, protected from inclement weather.

5. Safety

• Do not disassemble or modify the equipment. This could negatively affect the equipment or even cause accidents.

• Do not put fingers or any objects into the protective grilles on ducts, inlets or outlets. If this were to occur, immediately

disconnect the equipment's power supply.

• Never use a damaged power cable.

• Do not operate the equipment if it has been forcibly installed on a curved or unstable surface.

• Do not perform equipment inspection or maintenance without first checking the following:

o That the equipment has been disconnected from the electrical supply.

o That all its components are at rest.

• The equipment must not be operated unless it has been properly installed and the inlets and outlets have been

protected, if necessary.

EN

In designing and manufacturing the various Series of the manufacturer's Fans and Extractors, Hazard Elimination has been

taken into account, in order to meet the conditions for Integrated Safety.

When their configuration and manufacturing processes permit this, the manufacturer directly incorporates the most appropriate

Safety Devices. If the conditions for installation or use mean that these devices cannot be incorporated at source, all additional

safety accessories are available for implementation when the equipment is installed and before it comes into service.

6. Installation and Assembly

This equipment may only be installed by a qualified technician who is familiar with the installation, monitoring and maintenance

of this type of equipment, and uses suitable tools.

Mechanical

• To ensure safe operation, the equipment must be firmly fixed.

• The installation must prevent contact with the fan's impeller, through the use of grilles, accessories, or by installing a

connecting tube of a suitable length.

• The equipment may be installed in different ways, depending on each need. (Fig. 1)

• Do not connect the elbows close to the equipment's connecting flanges or clamps.

•

Leave sufficient room to be able to open the control panel door.

• The equipment must be installed in such a way that the whole of its surface area is stuck to the surface on which it is

installed.

• The installation must be such that the weight of the system of ducts is not supported by the equipment.

• When connecting the ducts, ensure that the direction of airflow is correct in accordance with the arrows indicating flow

direction through the equipment.

• The external control panel must be installed in the access inside the area to be pressurised.

• The air connection must be executed with a 4mm diameter tube, and it must be located at the end of each tube in the

following position or zone:

o (+) Leave the tube in the zone to be pressurised in the event of a fire.

o (-) Leave the tube in the benchmark pressure zone. rotect it to prevent contact with water.

• Once the mechanical assembly is complete, it is important to check that the impeller turns freely, with no friction or

tension

Electrical

• Make sure the equipment is connected to a power supply as per the instructions with the connection diagram at the

beginning of this document (Fig. 7, 8, 12 and 13)

• For the electrical supply connection for this fan, special cable certified as compliant with fire regulations must be used,

of a suitable cross-section for the current the fan uses.

• IMPORTANT: When the equipment is controlled by reducing the voltage, the motor's current may be higher than the

rated value.

• Check that the electrical characteristics stated on the plate correspond to the power supply.

• The equipment's earth connection must be connected.

Start-up

• After installing the equipment, check that there are no alarm signals in the box BOX DS (Fig. 5) inside the control

panel. If this is not the case, turn one of the power input phases to ensure the equipment functions correctly.

• After starting up the motor, it is important to check that the motor is turning correctly, without vibrations, and is not

making unusual noises.

• A check must be made to ensure that the motor's actual power consumption does not exceed the level stated on the

equipment's label and that it does not heat up excessively.

IMPORTANT:

This operation must only be performed by the authorised installer or the manufacturer.

Before start-up, check the correct operation of the equipment in the case of fire. To do this, first verify that there are no failure pilot

lamps lit on the control panel. Once this has been done, activate the manual selector switch, after first closing the doors of the area

that is to be pressurised. The next step is to check that the necessary 50 a in the pressurised area have been reached, and then

configure the Safety Speed parameter, with the frequency value indicated by the Frequency Converter (VSD1) for pressurisation

at 50 a.

After verifying the correct operation of the equipment, change the position of the selector switch from Manual to Automatic to start

up the equipment.

EN

• The machine must not be switched on and off intermittently, as this could damage the winding of the motor or the

insulation, due to overheating.

Parameter adjustment

To see the activated alarms go to screen 4 (Fig. 15). To access it, follow the steps in the LC diagram (Fig. 16).

Screen 4 shows the different alarms inside the device and whether they are activated.

The system status can be seen by accessing screen 20 (Fig. 15). To access it, follow the steps in the LC diagram

(Fig. 16). If the fan figure is green, this means it is on. arameters SD2 and SD1 indicate the presence of smoke or a

sensor failure (in this case a wiring failure). Depending on the number of “dampers” the system has (1 or 2) number 1

or number 2 will appear on the screen with a warning of whether they are open or closed.

To access screen 13 (Fig. 15) follow the steps set out in the LC diagram (Fig. 15). The 13 screen provides access

to different parameters: “FIRE SIGNAL”, “DAMPER”, “FAN” and “SAFETY SPEED”.

In the “FIRE SIGNAL” screen (P 16) 2 parameters can be configured: “FIRE SIGNAL LOGIC” allows you to configure

the contactor (NO, NC). The other parameter to be configured is “FIRE SIGNAL DELAY” which allows you to choose

the alarm signal delay time.

In the “DAMPER” screen (P 17) 3 parameters can be configured: “DAMPER TRAVEL TIME” is the “DAM ER” alarm

delay time. If after this time the “DAM ER” does not open, an alarm will be triggered in the equipment. “SMOKE

DELAY” is the delay time from the time the smoke is detected to the time the alarm is activated. “NUM ER OF

DAMPERS” is used to determine whether the system has 1 or 2 “”DAM ERS”.

In the “FAN” screen (P 22) 4 parameters can be configured: “DIFF. PRESSURE MAX” is the maximum configurable

safety pressure and “DIFF. PRESSURE MIN” is the minimum configurable pressure. “DELAY DIFF. PRESSURE,

safety speed” allows you to configure the time period for the equipment to change to the SAFETY S EED if the

maximum pressure configured in “DIFF. RESSURE MAX” is exceeded. “DELAY DIFF. PRESSURE, stop”. This

parameter will stop the equipment if after entering the “safety speed” option and after this time, the pressure fails to fall

to the minimum determined in “DIFF RESSURE MIN.” It is recommended not to modify the parameters established

by the manufacturer.

On the “FAN” screen (P 18) 3 parameters can be configured. “% OVERCURRENT” indicates the “OVERCURRENT”

intensity level with respect to the motor nominal current. “TIME OVERCURRENT” indicates the time during which

“overcurrent” is present. Once this time has passed, the alarm is activated. In this case the “DAM ER” status must be

checked as if it is closed it will lead to an increase in motor consumption. “% LOW CURRENT” indicates whether the

motor is connected. It is recommended not to modify the parameters established by the manufacturer.

In the “SAFETY SPEED” screen (P 19) the % value shown on screen 1 must be configured (Fig. 15) when the

pressure reaches 50 A with the system activated.

External control panel parameters (Fig.8)

The “READY” pilot lamp indicates whether the equipment is ready to operate. The pilot lamp will be on when the main

panel is supplied with power and no alarms are activated.

The “FIRE ALARM” pilot lamp is activated when the equipment receives a fire alarm signal.

The “SMOKE IN DUCT” pilot lamp indicates the presence of smoke in the aspiration duct.

The “COMMON FAULT” pilot lamp is activated when an alarm is activated.

When set to position 1, the “RESET ALARM” selector switch will reset the fire alarm.

For the equipment to function correctly, the “AUTO-MAN” selector switch must be on automatic. The manual position

activates the equipment without the need for the fire alarm to be activated, either to force the system activation or to

perform maintenance checks. In this position, the equipment does not take smoke detection in the aspiration duct into

consideration. This function must only be used by authorised personnel. In the event of smoke entering the pressurised

zone, the responsibility will be that of the fire fighting staff or the maintenance staff who activate this function.

The “MAN.DAMPER” selector switch must be used when the equipment is in the automatic operation mode. If the

system stops due to the presence of smoke in the aspiration duct, the fire brigade may force the manual activation of

the equipment, ignoring the alarm indicating the presence of smoke in the duct. This function must only be used by

authorised personnel. In the event of smoke entering the pressurised zone, the responsibility will be that of the fire

fighting staff or the maintenance staff who activate this function.

EN

7. Maintenance

Maintenance must be performed by qualified technicians.

•

Replacing the batteries with different powered batteries is not recommended. They should always be 12V and 18Ah.

•

We recommend checking the batteries at least once a year and replace them each 4 years.

•

If there is a failure or problem check the operation of the control panel with the indicators.

• The bearings are greased and sealed for life. Nevertheless, changing them about every 25.000 hours effective running

time is recommended.

• If the fan is not equipped with an air filter, the only maintenance required is to clean the impeller; this must be carried

out at least once every six months.

• Care must be taken when cleaning the impeller, in order not to affect its balance.

• Use of chemical cleaners or aggressive substances is not advisable, as they could damage the equipment.

• If a part must be replaced, consult the distributor.

8. Disposal

Careless or negligent disposal of the equipment may cause contamination. The disposal process must be carried out in

compliance with the standards and regulations applicable in that country.

9. Warranty

Incorrect use of the equipment and failure to observe the instructions in this manual may result in cancellation of the warranty.

Table of contents

Other SODECA Fan manuals

SODECA

SODECA HC User manual

SODECA

SODECA CBDT 9/9-4T User manual

SODECA

SODECA HGT User manual

SODECA

SODECA CJTHT-40-2/4T-1,5 User manual

SODECA

SODECA HCT/IMP Series User manual

SODECA

SODECA CMP User manual

SODECA

SODECA THT/WALL-40-2T-1 User manual

SODECA

SODECA CJBD User manual

SODECA

SODECA WALL/DUCT User manual

SODECA

SODECA HT User manual