SolarEdge SMI-180 User manual

Installation Guide

Safety and Monitoring

Interface (SMI-180)

For Europe and APAC

Version 1.1

Disclaimers

Important Notice

Copyright © SolarEdge Inc. All rights reserved.

No part of this document may be reproduced, stored in a retrieval system or

transmitted, in any form or by any means, electronic, mechanical, photographic,

magnetic or otherwise, without the prior written permission of SolarEdge Inc.

The material furnished in this document is believed to be accurate and reliable.

However, SolarEdge assumes no responsibility for the use of this material. SolarEdge

reserves the right to make changes to the material at any time and without notice. You

may refer to the SolarEdge web site (www.solaredge.com) for the most updated version.

All company and brand products and service names are trademarks or registered

trademarks of their respective holders.

Patent marking notice: see http://www.solaredge.com/patent

The general terms and conditions of delivery of SolarEdge shall apply.

The content of these documents is continually reviewed and amended, where

necessary. However, discrepancies cannot be excluded. No guarantee is made for the

completeness of these documents.

The images contained in this document are for illustrative purposes only and may vary

depending on product models.

Emission Compliance

This equipment has been tested and found to comply with the limits applied by the

local regulations.

These limits are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, you are encouraged to try to correct

the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and the receiver.

Disclaimers 1

SMI-180 Installation Guide MAN-01-00157-1.1

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by the party responsible for

compliance may void the user’s authority to operate the equipment.

SMI-180 Installation Guide MAN-01-00157-1.1

2 Emission Compliance

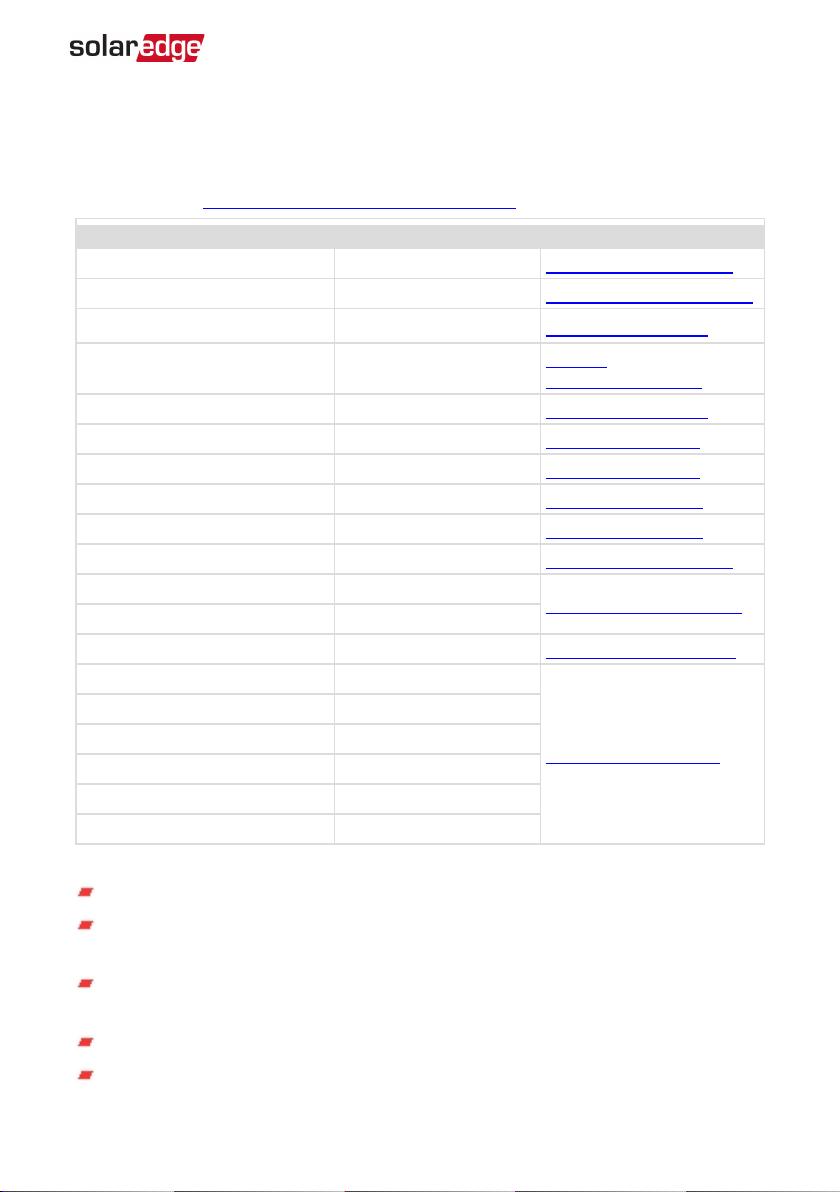

Support and Contact Information

If you have technical problems concerning SolarEdge products, please contact us:

Support Center: https://www.solaredge.com/service/support

Country Phone E-Mail

Australia (+61) 1800 465 567 support@solaredge.net.au

APAC (Asia Pacific)(+972) 073 240 3118 support-asia@solaredge.com

Belgium (+32) 0800-76633 support@solaredge.be

China (+86) 21 6212 5536 support_

china@solaredge.com

DACH & Rest of Europe (+49) 089 454 59730 support@solaredge.de

France (+33) 0800 917410 support@solaredge.fr

Italy (+39) 0422 053700 support@solaredge.it

Japan (+81) 03 6262 1223 support@solaredge.jp

Netherlands (+31) 0800 7105 support@solaredge.nl

New Zealand (+64) 0800 144 875 support@solaredge.net.au

Republic of Ireland (+353) 1800 901 575 support-uk@solaredge.com

United Kingdom (+44) 0800 028 1183

US & Canada (+1) 510 498 3200 ussupport@solaredge.com

Greece (+49) 89 454 59730

support@solaredge.com

Israel (+972) 073 240 3122

Middle East &Africa (+972) 073 240 3118

South Africa (+27) 0800 982 659

Turkey (+90) 216 706 1929

Worldwide (+972) 073 240 3118

Before contact, make sure to have the following information at hand:

Model and serial number of the product in question.

The error indicated on the Inverter LCD screen or on the monitoring platform or by

the LEDs, if there is such an indication.

System configuration information, including the type and number of modules

connected and the number and length of strings.

The communication method to the SolarEdge server, if the site is connected.

The software version as appears in the ID status screen.

Support and Contact Information 3

SMI-180 Installation Guide MAN-01-00157-1.1

Contents

Disclaimers 1

Important Notice 1

Emission Compliance 1

Support and Contact Information 3

HANDLING AND SAFETY INSTRUCTIONS 6

Safety Symbols Information 6

IMPORTANTSAFETYINSTRUCTIONS 6

Chapter 1: Introducing the SMI-180 Safety and Monitoring Interface for Large

Scale Installations 7

The SMI External Interfaces 8

The SMI Internal Interfaces 9

Chapter 2: Installing the SMI 11

SMI Package Contents 11

Identifying the SMI 11

Installation Workflow 11

Mounting the SMI 12

Connecting PV Strings to the SMI 15

Connecting to a DC Power Supply 18

Chapter 3: Commissioning the Installation 21

Step 1: Activating the System 21

Step 2: Pairing Power Optimizers to the SMI 22

Step 3: Verifying Proper Activation 23

Step 4: Reporting and Monitoring Installation Data 24

Chapter 4: SMI Connections 27

Connecting the DC Out Cables to the SMI 27

Connecting the Inverter to the SMI 28

Verifying Proper Operation 29

Chapter 5: User Interface 30

LCD User Buttons 30

SMI Configuration – Setup Mode 31

Configuration Menu Options 35

Status Screens - Operational Mode 39

Chapter 6: Setting Up Communication to the Monitoring Platform 44

Communication Options 44

Communication Connectors 46

Creating an Ethernet (LAN) Connection 47

Creating an RS485 Bus Connection 51

Verifying the Connection 55

Additional Connection Options 57

SMI-180 Installation Guide MAN-01-00157-1.1

4 Support and Contact Information

Appendix A: Errors and Troubleshooting 58

Troubleshooting Communication 58

Troubleshooting SolarEdge Systems, Addendum (Europe & APAC) 60

Error Codes 60

Appendix B: SMI Specifications 63

Mechanical Specifications 63

Technical Specifications 65

Support and Contact Information 5

SMI-180 Installation Guide MAN-01-00157-1.1

HANDLING AND SAFETY INSTRUCTIONS

During installation, testing and inspection, adherence to all the handling and safety

instructions is mandatory. Failure to do so may result in injury or loss of life and

damage to the equipment.

Safety Symbols Information

The following safety symbols are used in this document. Familiarize yourself with the

symbols and their meaning before installing or operating the system.

WARNING!

Denotes a hazard. It calls attention to a procedure that, if not correctly

performed or adhered to, could result in injury or loss of life. Do not proceed

beyond a warning note until the indicated conditions are fully understood and

met.

CAUTION!

Denotes a hazard. It calls attention to a procedure that, if not correctly

performed or adhered to, could result in damage or destruction of the

product. Do not proceed beyond a caution sign until the indicated conditions

are fully understood and met.

NOTE

Denotes additional information about the current subject.

IMPORTANTSAFETYFEATURE

Denotes information about safety issues.

Disposal requirements under the Waste Electrical and Electronic Equipment (WEEE)

regulations:

NOTE

Discard this product according to local regulations or send it back to SolarEdge.

IMPORTANTSAFETYINSTRUCTIONS

WARNING!

Do not remove the SMI cover before five minutes have elapsed after

disconnecting all sources of power.

WARNING!

Before operating the SMI, ensure that the has been grounded properly.

SMI-180 Installation Guide MAN-01-00157-1.1

6 HANDLING AND SAFETY INSTRUCTIONS

WARNING!

Opening the SMI and repairing or testing under power must be performed

only by qualified service personnel familiar with the SMI.

WARNING!

The SMI is designed to work in conjunction with non-SolarEdge inverters and

with SolarEdge power optimizers equipped with the IndOp™ technology. It

will NOT work with the SolarEdge fixed string voltage mode. Therefore, string

lengths and system design must comply with the inverter design guidelines.

SolarEdge extended string lengths are not applicable. Designing outside of

the inverter design rules may result in permanent damage to the SMI.

WARNING!

If the photovoltaic array is exposed to light, it supplies DC voltage to the

power optimizers.

CAUTION!

This unit must be operated under the specified operating conditions as

described in the

Technical Specifications

, or the latest technical specification

datasheet, available on the SolarEdge website at

http://www.solaredge.com/groups/products/overview.

NOTE

The following warning symbols appear on the SMI warning label:

Risk of electric shock

Risk of electric shock from energy stored in the

capacitor. Do not remove cover until 5 minutes after

disconnecting all sources of supply.

Refer to the product documentation

General hazard

NOTE

Use PV modules rated according to IEC 61730 class A.

NOTE

The symbol appears at grounding points on the SolarEdge equipment.

This symbol is also used in this manual.

HANDLING AND SAFETY INSTRUCTIONS 7

SMI-180 Installation Guide MAN-01-00157-1.1

Chapter 1: Introducing the SMI-180 Safety and

Monitoring Interface for Large Scale

Installations

When connecting SolarEdge power optimizers to a non-SolarEdge inverter, the

SolarEdge safety and monitoring interface for large scale installations (SMI) enables the

following features:

1. Safety functions of the power optimizers

2. Communication of the module-level data sent from the power optimizers to the

SolarEdge monitoring platform.

SolarEdge offers also the monitoring interface (MI) , which includes only the second

feature above.

The SMI supports the SolarEdge optimizer SafeDC™ feature. The SafeDC™ mechanism

automatically shuts down module voltage whenever the grid power is shut down, thus

providing greater safety during installation, maintenance and firefighting.

The SMI is installed between the SolarEdge power optimizers and a non-SolarEdge

inverter, and is compatible with any on-grid inverter.

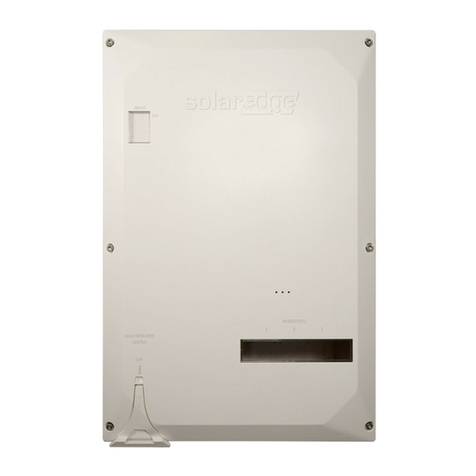

Figure 1: The SolarEdge safety and monitoring interface for large scale installations (SMI)

connected in a PV system

Figure 2: The SolarEdge safety and monitoring interface (SMI) for large scale installations

SMI-180 Installation Guide MAN-01-00157-1.1

7 Chapter 1: Introducing the SMI-180 Safety and Monitoring Interface for

Large Scale Installations

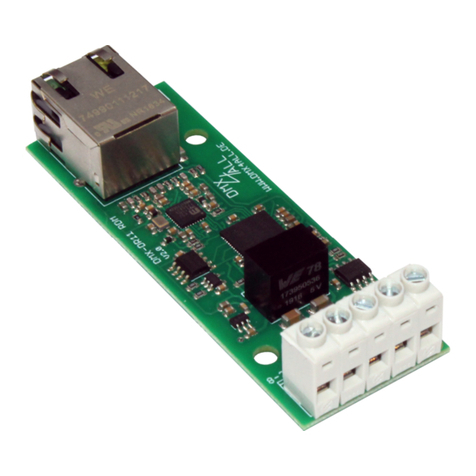

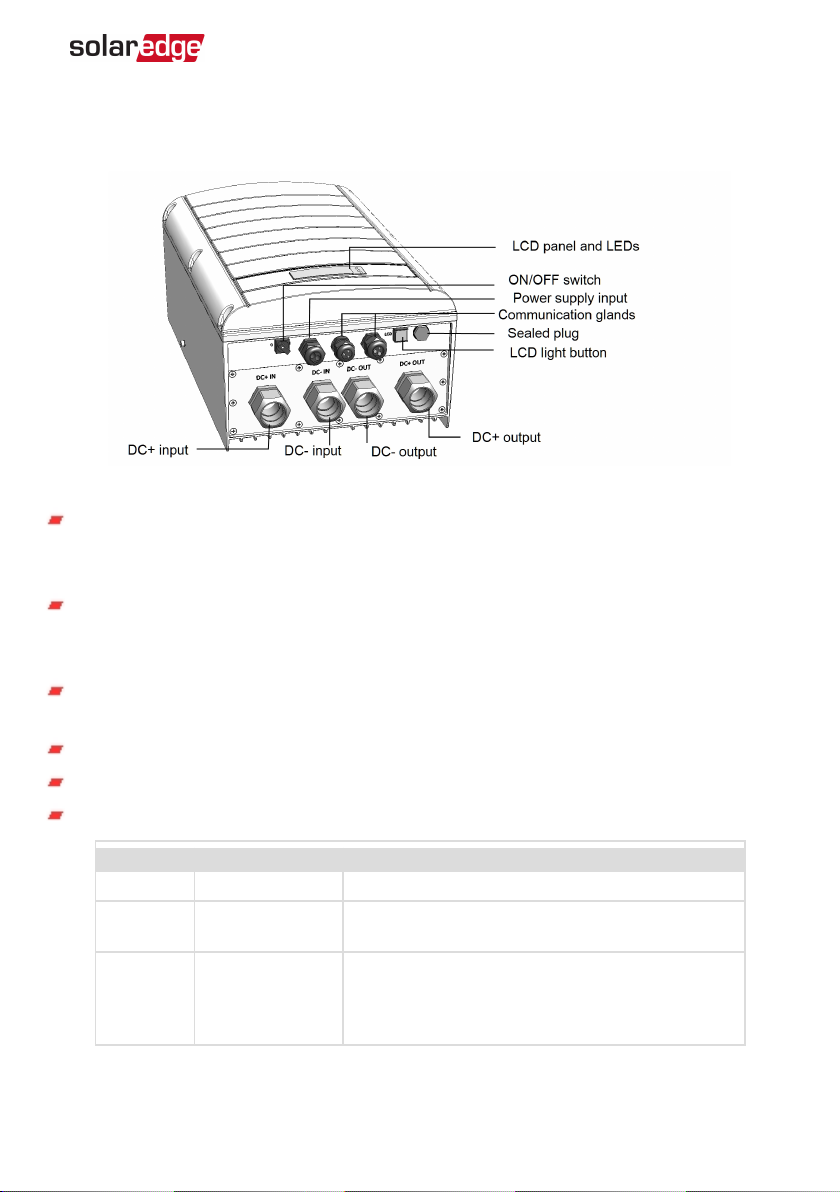

The SMI External Interfaces

The following shows the SMI connectors and interfaces:

Figure 3: SMI interfaces

ON/OFF Switch: Turning this switch ON (1) starts the operation of the power

optimizers. Turning it OFF (0) reduces the power optimizer voltage to a low and safe

value. In the MIthis functionality is disabled.

LCD Light Button: Pressing this button lights up the LCD for 30 seconds. In addition,

you can press this button to access configuration menu options, as described in

Configuring the SMI Using the LCD Light Button

on page 33.

Two Communication Glands, for connection of communication options. Refer to

Setting Up Communication to the Monitoring Platform

on page 44.

Power Supply Input: Used to connect the SMI to an auxiliary power supply unit.

LCD Panel: displays SMI information and configuration parameters

LCD LEDs: Three LEDs indicate the following SMI statuses:

Color Description Functionality

Green Power OK Indicates whether the SMI is connected to power.

Yellow Module

Communication

Blinking when monitoring information is received

from a power optimizer.

Red Fault

Indicates that there is an error. Refer to

Errors and

Troubleshooting

on page 58 for more

information. In addition, this LED blinks while the

SMI is being shut down.

All LEDs are on while the SMI is being configured.

Chapter 1: Introducing the SMI-180 Safety and Monitoring Interface for Large

Scale Installations 8

SMI-180 Installation Guide MAN-01-00157-1.1

The SMI Internal Interfaces

As part of the installation and configuration process, accessing the internal

components of the SMI may be required. This involves removing the cover of the SMI.

Opening and Closing the SMI Cover

To remove the SMI cover:

1. Turn the ON/OFF switch to OFF.

2. Disconnect the power to the SMI:

a. Turn OFF the inverter

b. Turn OFFthe PSU. Wait 5 minutes for the inverter and SMI capacitors to

discharge.

3. Open the cover’s six Allen screws and carefully remove the cover.

CAUTION!

When removing the cover, make sure not to damage internal components.

SolarEdge will not be held responsible for any components damaged as a

result of incautious cover removal.

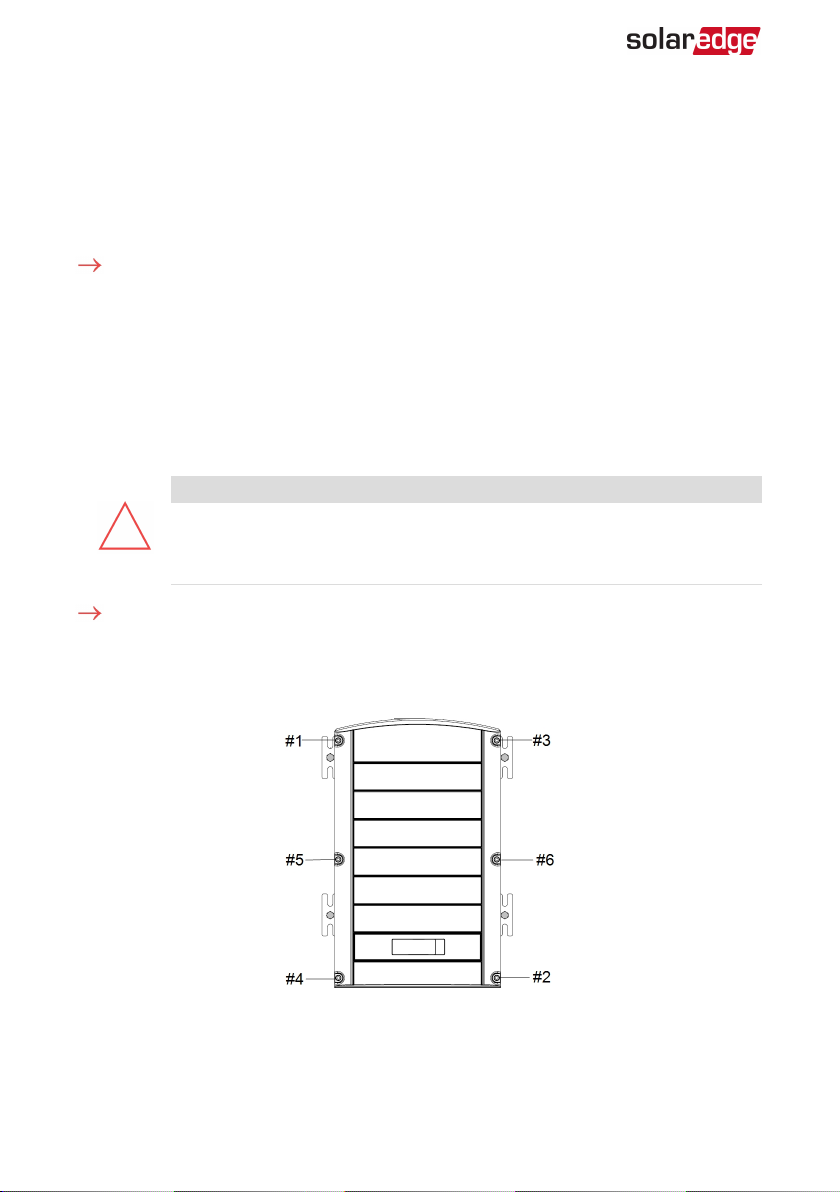

To close the SMI cover:

Attach the cover and secure it by tightening the screws with a torque of 4.0 N*m/ 2.9

lb*ft. For proper sealing, first tighten the corner screws and then the two central screws.

The following figure illustrates the recommended order:

Figure 4: Tightening order of the screws

SMI-180 Installation Guide MAN-01-00157-1.1

9 The SMI Internal Interfaces

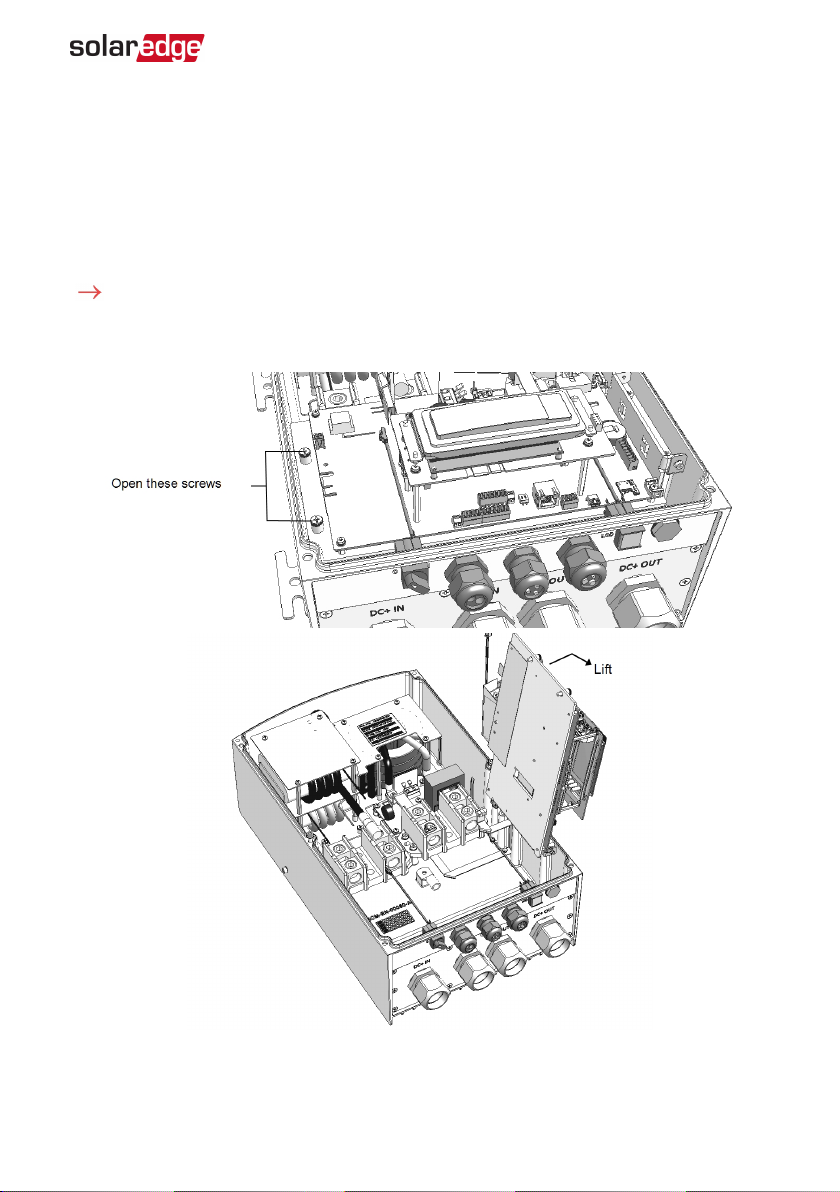

Accessing the Internal Compartments

The SMI is divided into two compartments by a plate. The top compartment on the

plate includes the communication board, the LCD screen and user buttons, the power

supply connector and communication connectors. The lower compartment includes

the DC input and output connections. The lower compartment is accessed by lifting the

plate which is hinged to the SMI enclosure.

To access the lower compartment:

1. Loosen the two screws on the left side of the internal plate.

2. Carefully lift the internal plate.

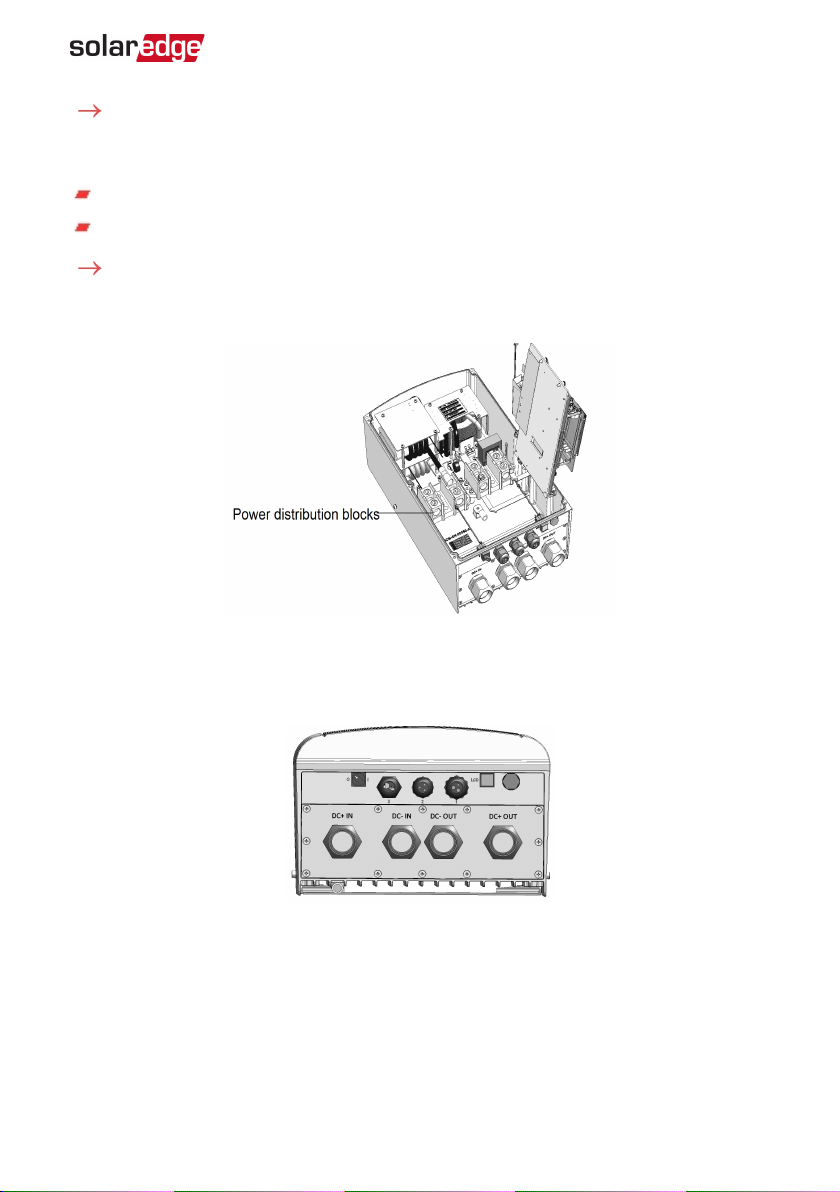

Figure 5: Accessing the SMI lower compartment

Chapter 1: Introducing the SMI-180 Safety and Monitoring Interface for Large

Scale Installations 10

SMI-180 Installation Guide MAN-01-00157-1.1

Chapter 2: Installing the SMI

CAUTION!

Do not rest the connectors at the bottom of the SMI on the ground, as it may

damage them. To rest the SMI on the ground, lay it on its back, front or side.

SMI Package Contents

One SMI

One mounting bracket

Two Allen screws for fastening the inverter to the mounting bracket

Installation guide (with activation card and instructions)

Optional (for wireless communication to monitoring platform) - RF antenna and

mounting bracket

AC ferrite bead kit

Identifying the SMI

Refer to the sticker on the SMI that specifies its Serial Number and its Electrical Ratings.

Provide the serial number when contacting SolarEdge support. The serial number is also

required when opening a new site in the monitoring platform.

Installation Workflow

1. Mounting the SMI, page 12

2. Accessing the Internal Compartments, page 10

3. Connecting PV Strings to the SMI, page 15

4. Connecting to a DC Power Supply, page 18

5. Pairing Power Optimizers to the SMI, page 22

6. SMI Connections, page27

7. Setting Up Communication, page 44

SMI-180 Installation Guide MAN-01-00157-1.1

11 Chapter 2: Installing the SMI

Mounting the SMI

This chapter describes how to mount the SMI. At this stage, power optimizers are

already installed and connected in strings. For more information on power optimizer

installation, refer to the IndOP™ power optimizers installation guide available on the

SolarEdge website at http://www.solaredge.com/files/pdfs/products/power-optimizers/se_

power_optimizers_installation_guide_indop.pdf.

The SMI can be mounted either vertically or horizontally. Each of these installation

options is described below. The SMI is supplied with two brackets pre-assembled for

vertical mounting. When choosing the horizontal mounting option, remove these

brackets and use the four floor anchoring brackets supplied in the package.

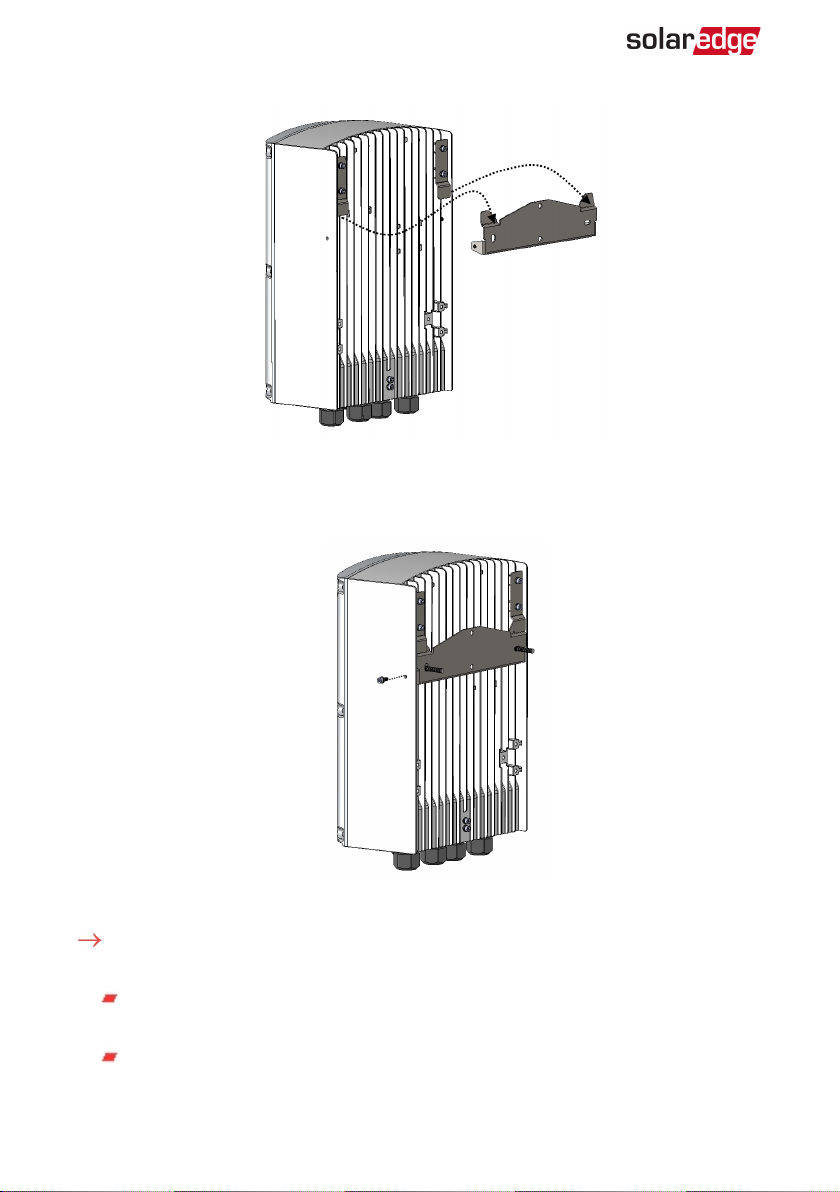

To Mount the SMI vertically:

1. Determine the SMI mounting location, on a wall or pole, as follows:

To allow proper heat dissipation, maintain 2'' / 5 cm minimum clearance areas

between the SMI and other objects.

Make sure the mounting surface or structure can support the weight of the SMI.

2. Position the mounting bracket against the wall and mark the drilling hole locations.

Ensure that the flat side of the bracket is at the bottom.

Figure 6: Wall mounting bracket

3. Use at least two bracket holes. Additional holes can be used to fix the

bracket.Determine which and how many holes to use according to mounting

surface type and material.

4. Drill the holes and mount the bracket. Verify that the bracket is firmly attached to

the mounting surface.

5. Hang the SMI on the bracket:Align the two assembled brackets on the SMI

enclosure with the two triangular protrusions of the mounting bracket, and lower

the SMI until it rests on the bracket.

Chapter 2: Installing the SMI 12

SMI-180 Installation Guide MAN-01-00157-1.1

Figure 7: Hanging the SMI on the bracket

6. Insert the two supplied screws through the outer heat sink fin on both sides of the

and into the bracket. Tighten the screws with a torque of 4.0 N*m / 2.9 lb.*ft.

Figure 8: Inserting the bracket screw

To mount the SMI horizontally:

1. Determine the SMI mounting location, on a rail or on the floor, as follows:

To allow proper heat dissipation, maintain 2'' / 5 cm minimum clearance areas

between the SMI and other objects.

Make sure the mounting surface or structure can support the weight of the SMI.

SMI-180 Installation Guide MAN-01-00157-1.1

13 Mounting the SMI

2. Remove the two vertical mounting brackets that are attached to the unit and used

for vertical mounting.

Figure 9: Vertical mounting brackets

3. Assemble the four horizontal mounting brackets (supplied in the package) to the

SMI rear side. Make sure the floor anchoring holes are facing out.

Figure 10: Horizontal mounting brackets

4. Mount the unit on the rail or structure: Use 5/16" screws or bolts (8.0 mm diameter)

for anchoring to the surface.

Figure 11: Horizontal anchoring screws

Functional earthling is required to enable the over-voltage protection. To earth the SMI,

connect a grounding cable to the grounding location at the rear of the SMI. The

grounding cable must be at least 1.5mm2. You may use a cable of up to 50mm2.

Chapter 2: Installing the SMI 14

SMI-180 Installation Guide MAN-01-00157-1.1

Figure 12: Grounding point

Connecting PV Strings to the SMI

The following procedure describes how to connect the DC cables from the power

optimizer strings to the SMI. A typical installation has up to 18 strings connected to an

SMI through a combiner box.

Figure 13: String connection

SMI-180 Installation Guide MAN-01-00157-1.1

15 Connecting PV Strings to the SMI

To determine how many strings can be connected to the SMI:

Verify that the cumulative short circuit current (Isc) of all parallel-connected strings is

below:

The rated maximum input current of the inverter

The rated maximum input current of the SMI

To connect DC strings to the SMI:

1. Open the lower compartment of the SMI as described in

Accessing the Internal

Compartments

on page 10.

Figure 14: Connection area

2. Use an Allen key to loosen the 5/16” screws of the SMI DCpower distribution blocks.

3. Remove the seal from the glands labeled DC+ IN/DC- IN.

Figure 15: SMI - bottom view

4. If the cables from the combiner box are 18-25 mm in diameter, insert the wires

through the opening.

If the cables are less than 18 mm in diameter, replace the rubber seals in the gland

with the rubber seals supplied in the SMI package, and insert the wires through the

opening.

Chapter 2: Installing the SMI 16

SMI-180 Installation Guide MAN-01-00157-1.1

NOTE

Do not insert more than one wire through each gland: Insert the DC+ wire

through the gland marked DC+ and the DC- through the gland marked

DC-. Seal all the glands after installation.

5. Connect the cables to the DC+ and DC- input terminal blocks.

If your local regulations require using cable lugs, use the lugs and screws supplied

in the package: Fasten the cable ring terminal to the lug (apply torque 17 N*m / 12.5

Lb*ft) and insert the lug into the input terminal blocks.

Figure 16: Using cable lugs

6. Fasten the Allen screws of the power distribution blocks. Apply a torque of 30 N*m /

22 lb.*ft.

Figure 17: DC INcables connected

7. Seal all glands.

SMI-180 Installation Guide MAN-01-00157-1.1

17 Connecting PV Strings to the SMI

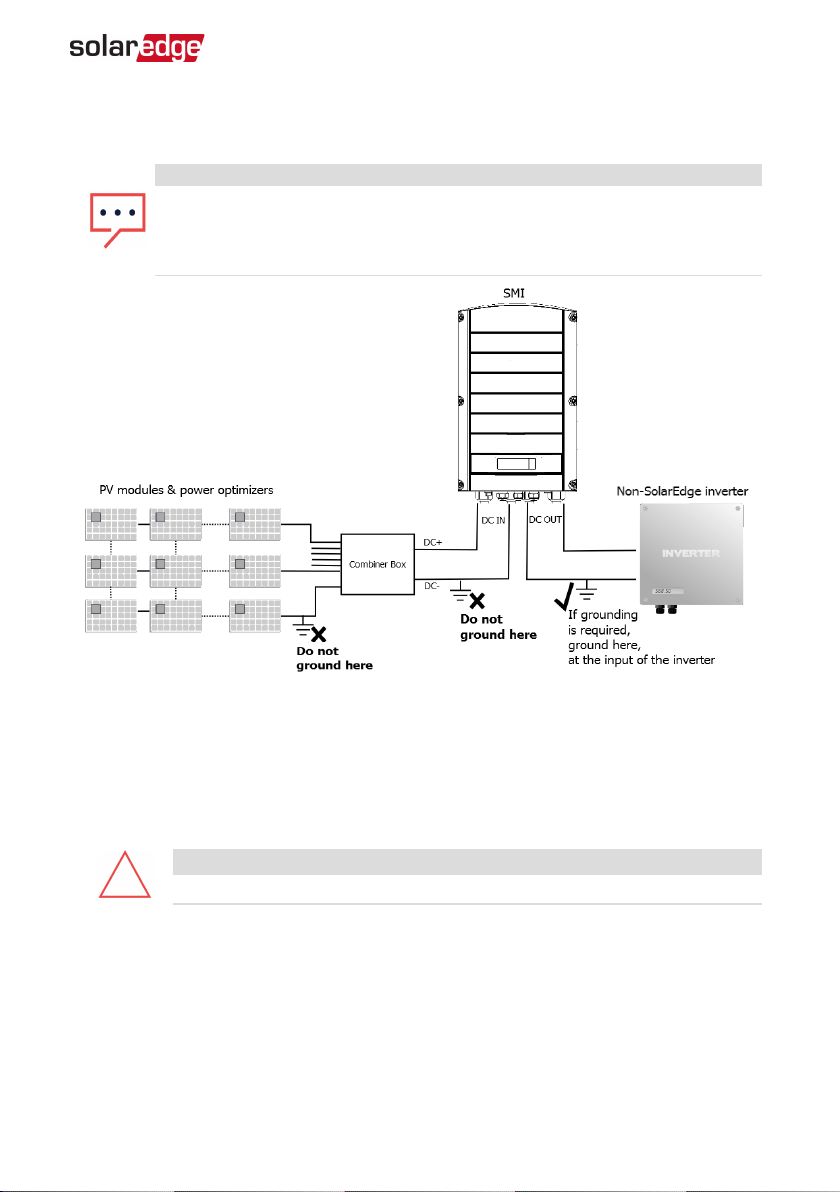

If grounding of the DC wires is required, refer to the following figure that demonstrates

proper and improper grounding locations (marked aand ×).

NOTE

When connecting the SMI to a grounded array, the grounding must not be

between the SMI and the power optimizers. All grounding should be at the

inverter or between the SMI output and the inverter. The SMI allows both

positive and negative grounding.

Figure 18: Example - Grounding locations

Connecting to a DC Power Supply

The SMI is powered from a separate DC power supply unit (PSU, not provided by

SolarEdge). Use a PSU with 48V nominal voltage. The input of the SMI can be connected

to voltages 30-55 VDC, and each SMI will consume 12W.

CAUTION!

The PSU must be limited or fused to 50A .

Up to 10 SMIs can connect to a single PSU.

Refer to the following table for selecting the PSU wiring and the DC wiring, depending

on the number of SMIs connected to the same PSU:

Chapter 2: Installing the SMI 18

SMI-180 Installation Guide MAN-01-00157-1.1

Other manuals for SMI-180

1

Table of contents

Other SolarEdge Recording Equipment manuals