Sollatek AVR User manual

The Sollatek Three Phase

Automatic Voltage Regulator (AVR)

Instruction Manual

Issue: July 2021

Important: This manual contains important safety instructions.

Keep this manual handy for reference.

www.sollatek.com

www.sollatek.com

the power to protect

the power to protect

1. Unpacking and Inspection

It is possible that the unit will have sustained damage during transit. The following procedure

should be followed immediately upon receipt of the unit.

1.1 Crate/Packaging - Check for transit damage.

1.2 Cabinet/Casework - Check for visible signs of damage to exterior panels, doors and fittings. If cracks,

scratches or dents are visible there is a chance of internal damage. Particular attention should be paid

to the terminal panel.

1.3 Internal components - Unlock the door using the key provided. Inspect for damage to the

transformers, PCBs and other components. All mountings should be tight and there should be no sign

of movement of the transformers.

1.4 Internal wiring - All wiring connections should be checked to ensure that transit vibration has not

loosened screw terminals.

If inspection reveals problems in the above or other areas, the carrier should be notified as

soon as possible in writing.

2. Installation

2.1 Safety

Under no circumstances should any work be carried out on the unit unless the supply is isolated.

2.2 Positioning

The unit should be sited indoors on a firm, level, dry surface, away from sources of heat, dust, vibration

or moisture. A position allowing access on all four sides to permit preventative maintenance would be

advantageous.

2.3 Ventilation

The unit should be positioned such that a free flow of air is available. It is especially important to

ensure that cooling fan outlets are free from obstruction. A free space of at least 300mm should be

left in all directions around the AVR.

2.4 Cable and terminals

Before any connections can be made the incoming and outgoing cable sizes have to be selected and,

on 200A units and above, the appropriate ring terminals fitted. (See Table 2.4.1). Cable size may be

selected using values of current given in table 2.4.1 bearing in mind the usual limiting factors such as

volt drop, heating, etc. The appropriate breaker sizes are also given. Note that the input and output

currents can differ by 40%. This means that a larger cable size may have to be employed on the input

than the output.

THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021 ENGLISHENGLISH THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021

Output kVA (415V) kVA Input A Input Output Ring

Amps/ph (240V) (Max) MCCB MCCB Size mm

10 7.2 4.2 14 16 10 8

20 14 8.1 28 32 20 8

30 21 12 41 50 32 8

50 36 21 69 80 50 8

75 54 31 103 100 80 8

100 72 42 138 160 100 8

150 108 62 207 200 160 8

200 144 83 275 320 200 16

300 216 125 413 400 320 16

400 288 166 550 630 400 16

500 360 208 690 800 630 16

600 431 249 830 1000 630 16

Table 2.4.1

Page 2 Page 3

Table of Contents

SECTION PAGE

1. Unpacking and Inspection 3

2. Installation 3

2.1 Safety

2.2 Positioning

2.3 Ventilation

2.4 Cables and Terminations

2.5 Circuit Breakers

2.6 Incoming Connections

2.7 Outgoing Connections

3. System Power-up 5

4. Functional Description 5

4.1 General Function

4.2 AVR Function

4.3 AVS Function

4.4 –HA Function

4.5 Bypass Function

4.6 Surge Arrester

5. Maintenance 8

6. Trouble Shooting 9

6.1 Safety

6.2 False Starting

6.3 Shut Down

6.4 Common Troubleshooting Points

6.5 Error Mode

7. Specification 10

8. Appendix 1: General Arrangement 21

9. Appendix 2: Bypass Installation 22

10. Appendix 3: Circuit topology 24

11. Appendix 4: On-site test procedure 32

On-site test/acceptance form

On-site repair and test procedure

12. Appendix 5: Circuit diagrams 41

3. System power-up

Before the system is powered-up for the first time the following checks should be carried

out by qualified personnel only.

Inspect the input and output terminations for tightness, correct wiring and phase rotation.

1. Check that the building electrical service is of sufficient capacity to supply the input current of the AVR,

remembering that this can be 40% higher than the output current to the load.

2. Check building electrical service is of correct nominal voltage and wiring configuration and that main circuit

breakers are suitable for the inductive nature of the load represented by the AVR.

3. Ensure that the load equipment is ready to be energised. Once the above conditions have been verified,

input power may be applied to the AVR. Once input power is applied the three digital voltage meters on

the door of the AVR should indicate a valid output voltage. If this is not the case switch off the power

immediately and refer to the troubleshooting section of this manual. The AVS indicators on the door (if

fitted) should show ‘on’ (after the wait time of 3 minutes).

Once input power is applied the three digital voltage meters on the door of the AVR should indicate a valid

output voltage. If this is not the case switch off the power immediately and refer to the troubleshooting section

of this manual. The AVS indicators on the door should show ‘on’ (after the wait time of 3 minutes). When it has

been verified above that the AVR is functioning correctly, the incoming power should be switched off and the

output circuit breaker set to the on position. If power is now re-applied, the load will be automatically supplied

when the 3 minute delay time has elapsed.

4. Functional Description

4.1 General Function

This three phase AVR is made up from three identical single phase regulator units. Each of these

monitors its own output voltage and adjusts for variations in mains supply voltage so as to maintain

an output voltage within close limits. When the AVS function is fitted the outputs from the regulators

are connected through a contactor to the load. The contactor is controlled by a three phase Automatic

Voltage Switcher PCB which monitors the AVR outputs. This connects the load only when all the

phase voltages are within acceptable limits. There is a delay between the time when all voltages come

within limits and the contactor switching on. This is so as to allow the supply to stabilise and to avoid

repeated switching of the load on and off should the mains supply be exceptionally erratic. The state

of the AVS circuit is indicated on the front panel by three large LEDs, Green for On, Yellow for Wait and

Red for Off.

4.2 AVR Function

This is based on an auto transformer with tap changing on the output. There are seven taps to

each transformer giving an accurate output voltage for a wide range of input voltage. The taps are

switched by generously rated Triac banks to cope with motor start loads. Low value resistors are fitted

with each Triac to ensure that high currents are shared equally between the Triacs within each bank.

This technique results in a voltage stabiliser which has no moving parts, responds quickly to voltage

fluctuations and is not as large or heavy as other AVRs utilising different regulation techniques.

A micro-controller forms the heart of the control system. It measures the AVR output voltage and

turns on the appropriate Triac bank to select the correct tap. A potentiometer is provided for fine

adjustment of the output voltage. The micro-controller also measures the frequency of the mains

supply and compensates accordingly. This also means that the AVR will work over a frequency range

of 45 - 88Hz automatically and down to as low as 30Hz for short periods to help cope with diesel

generator loading problems.

Frequency and voltage measurements are filtered by the circuit and software to remove noise and so

prevent spurious tap changes.

THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021 ENGLISH

2.5 Circuit breakers

The recommended input and output breaker ratings are given in table 2.4.1. Values not shown may be

interpolated. Due to the fact that breaker ratings jump in large steps it is strongly recommended that

adjustable trip level MCCBs are used. In this way a high degree of protection may be achieved. The

input MCCB should be of a type suited for use with inductive loads (with a high initial surge current).

The output breaker should be chosen to suit the nature of the load.

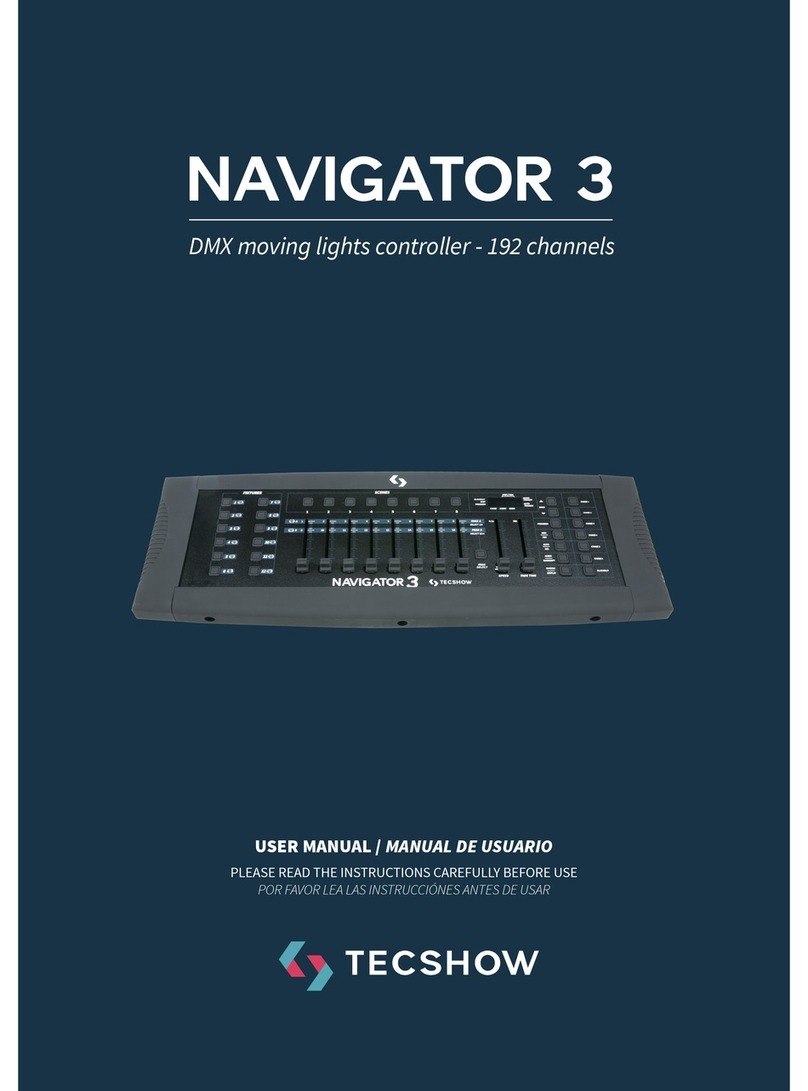

2.6 Incoming connections

The three incoming lines should be connected to the terminals marked R1 S2 T3 on the terminal panel

in the section marked INCOMING MAINS. The incoming neutral is connected to the N terminal and the

system earth is connected to the E terminal. N.B. The AVR must be supplied with an incoming neutral

which should be fully rated. Care should be taken to ensure that all terminals are securely tightened.

See diagram 2.6.1

2.7 Outgoing connections

The three outgoing lines should be connected to the terminals marked R1 S2 T3 on the terminal panel

in the section marked OUTGOING MAINS. The outgoing neutral should be connected to the N terminal

and the load earth to the E terminal. N.B. All neutrals should be fully rated. Care should be taken to

ensure that all terminals are securely tightened. See diagram 2.6.1 Ensure phase rotation continuity

from input to output.

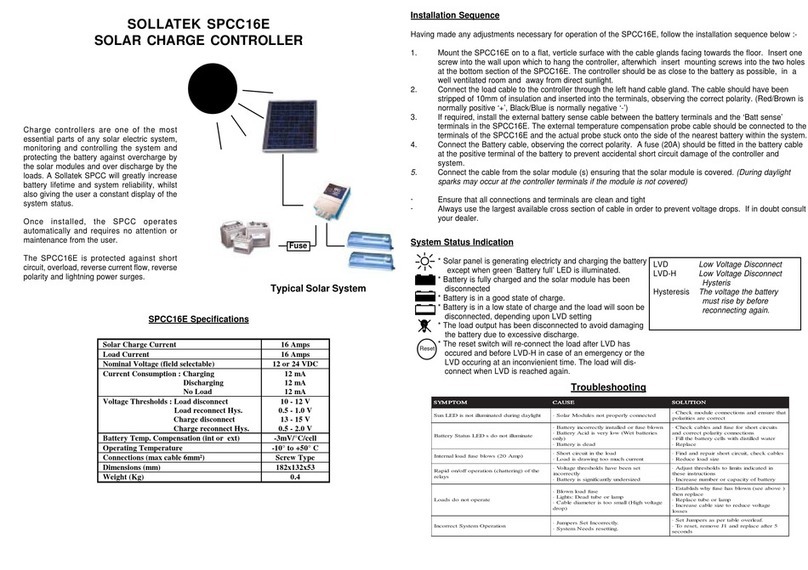

INCOMING MAINS

R1 = Phase 1 in

S2 = Phase 2 in

T3 = Phase 3 in

N = Fully rated neutral in

E = Supply earth

OUTGOING MAINS

R1 = Phase 1 out

S2 = Phase 2 out

T3 = Phase 3 out

N = Fully rated neutral out

E = Load Earth

Connections should be made using ring terminals

or using the screw terminals provided.

Ensure connections are tight.

R1 S2 T3

EEN

T3

S2R1

N

http://www.sollatek.com

N

R1 S2

EE

Sollatek UK Ltd.

T3

N

R1 S2 T3

SOLLATEK U.K. LTD.

R1 S2 T3 N

R1 S2 T3 N

R1 S2 T3 N

T3 N

R1 S2

Diagram 2.6.1 Terminal Arrangement

ISOLATE BEFORE HANDLING CONNECTIONS

OUTGOING MAINS

INCOMING MAINS

ENGLISH THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021

Page 4 Page 5

c) Phase Rotation [optional]

The AVS can detect a phase rotation error of the three phase mains supply. Detection of parameters

c) and d) above is not standard, but are obtained by an optional plug-in board. On this board, it is

possible to select by a d.i.l. switch whether abnormality is indicated only, or it causes disconnection

also.

4.3.2 Principle of Operation

The frequency and phase rotation detection circuits are explained in a separate section. The detailed

operation of the AVS in detecting the other parameters is given under CIRCUIT DESCRIPTION below.

Basically, however, the AVS compares the peak of the mains AC sinusoid of each phase with two

references, one corresponding to the lower or undervoltage limit of the window, and the other to the

upper or over-voltage limit. If the mains is normal, so that the peaks lie between the two limits and

also within a time not exceeding T/3 (T is the period of one cycle), a monostable is triggered which,

after the wait time, switches the power to the equipment. If any one or more of the peaks are below

the lower limit, above the upper limit or the separation between two consecutive peaks exceeds T/3,

the AVS is reset to disconnect the equipment.

4.3.3 Checks and adjustments

a) Window Limits

P1 and P2 are adjusted to equalise the three phases, so that P1 adjusts the peak at the junction of

P1 and R12, and P2 at the junction of P2 and R20 to make them equal to the peak at the junction of

R2 and R3. For measurement, an ordinary multi-meter or digital multi-meter may be used on the

AC range, since these give readings proportional to peak.

P3 and P4 adjust the limits of the window. Start with these around the centre of their travel.

Connect the normal three phase supply to the AVS with one phase via a Variac and monitor voltage

with voltmeter. Adjust Variac to the under-voltage limit. Adjust P4 so that indication goes from

Red to Amber. Adjust Variac to over-voltage limit. Adjust P3 so that indication fluctuates between

Amber and Red.

If the Variac is set so that the voltage is within the window, with Amber indicating, after the wait

time (nominal 1 minute) Green will indicate and the contactor is energised.

For a complete check, three Variacs should be used, one on each phase, and the various

combinations of under- and over-voltage on each phase with the others tested.

b) Wait Time

The wait time is given by 0.7xR37xC6. With R37 = 820K and C6 = 100uF, the wait time is around 60

sec. to within the tolerance of the components.

4.4 -HA Option

This option is available on all ratings of the AVR (Automatic Voltage Regulator) three phase units larger

than 21kVA.

The standard Three Phase AVR provides an output which is stable to within + 4% given an input

voltage variation of + 27% from a defined nominal. Although it is likely that voltage stability of + 4%

will meet most customers’ requirements, higher accuracy can be provided by incorporating a further

‘fine’ resolution stage beyond the standard AVR system.

The standard AVR incorporates a fully electronic (static) 7-tap changing system providing an output

regulated to + 4%. This is fed to the -HA option which utilises a further 7 taps, again fully electronic, to

achieve an output stability of + 2.0%.

THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021 ENGLISHENGLISH THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021

A watchdog function is implemented in the micro controller. This independently monitors the operation

of the micro-controller and its software. If it detects a malfunction, it will reset the micro and

re-initialise the control system.

The low voltage DC supply to the control circuit is also protected by a fuse.

Additionally, a hardware reset circuit is included which monitors the supply rail for the control circuit.

If the mains is so low that the control circuit will not function correctly, the monitor circuit will put the

micro-controller into the reset state and turn off all Triacs.

When the mains supply increases to a usable level, the monitor circuit will restart the micro and the

system will re-initialise. This ensures an orderly and controlled restart from a brownout or blackout

condition. The circuit is designed with a large hysteresis so that the unit will not attempt to turn

on again until the supply voltage is sufficient to withstand possible starting surges. This avoids the

possibility of such a surge of current causing the supply to dip sufficiently to turn the unit off again.

Additional protection is provided by temperature sensors fitted to each transformer. If the AVR is

used at full load and either the ambient temperature is excessively high or the ventilation grills have

been obstructed, the temperature of the transformer may increase beyond reasonable limits. In such

an event, the temperature sensor will disconnect the supply to the corresponding control board and

thereby turn the output off. When the transformer has cooled sufficiently, the sensor will restart the

AVR.

When restarting after the above condition the AVR may cause equipment to begin to operate suddenly.

Steps should be taken to ensure that this does not expose persons to risk.

4.3 AVS Function [Optional - has to be ordered separately at time of purchase]

4.3.1 General Description

The Automatic Voltage Switcher (AVS) is a device for the protection of electrical equipment against

fluctuations, interruptions and other abnormalities in the electricity mains supply.

The Three Phase AVS monitors various parameters of the mains supply, and keeps it connected to

the equipment so long as all the parameters are within defined acceptable limits. This is the normal

condition and it is indicated by a Green LED (light emitting diode). If the mains voltage goes outside

these limits, the AVS disconnects the equipment from the mains and this is indicated by the Red LED

(In some options, it is possible to select indication only without disconnection's.) When the mains

supply returns within the acceptable limits, indicated by an Amber LED, the mains remain disconnect

from the equipment during the wait time, set to a nominal 1 minute by factory selected components. If

during the wait time the mains again goes outside the limits, the wait time starts from the beginning

At the end of the wait time, when the mains supply has been continuously within the limits for its

duration, normal condition returns indicated by the Green LED, and the equipment is re-connected to

the mains.

The parameters monitored by the Three Phase AVS are:

a) Value of the Mains Voltage

The normal condition is when the values of the mains voltage of all the phases are within certain

preset limits referred to as the "window". The AVS detects when the voltage of any one or more

phases goes outside the window, either over- or undervoltage.

b) Phase Relationship (timing)

The AVS monitors the phase relationship between the three phases of the supply. The normal

condition is when the phase difference between the three phases is 120 degrees, corresponding to

T/3 where T is the period of one cycle.

Page 6 Page 7

6 Troubleshooting

6.1 Safety

Under no circumstances should any work be carried out on the unit unless the supply is isolated.

6.2 False Starting

If it is found that the AVR keeps trying to start but turns off immediately, this is most likely to be due

to poor wiring to the AVR or in the building. This could be:

1. Cabling is not thick enough.

2. Cabling is too long for its thickness leading to excessive volt drop.

3. Poor joints or connections.

Any such problems should be corrected, so that the supply can deliver the high currents necessary to

run the load.

6.3 Shut Down

If it is found that the unit switches off after some time even when the mains voltage is good, it may be

that the AVS is detecting some bad condition of the mains supply that is not apparent without the use

of test equipment.

Alternatively, it may be that the temperature overload is operating, in which case the following points

should be checked:

1. The output current is not above that stated on the serial label at the rear of the AVR.

2. The AVR is not subject to excessive ambient temperature due to a poor location near a source of

heat.

3. The ventilation grills on the side of the AVR case have not been covered or blocked.

4. That there is room for free movement of air around the outside of the AVR casework.

6.4 Common Troubleshooting Points

THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021 ENGLISHENGLISH THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021

4.5 Bypass Option

4.5.1 Manual Bypass

This is used to take the AVR out of circuit, bypassing the supply straight to the load. A fully rated, in

line, mechanical switch is used to achieve this, as opposed to a relay or electronically based system.

This ensures that the supply to the AVR cannot be re-connected unintentionally by component failure

or supply disruptions. This is particularly important if the bypass is used to enable maintenance to be

carried out.

4.5.2 Automatic Bypass

This facility operates to bypass the supply directly to the load in the event of a problem associated

with the AVR. If the temperature sensors built into the transformers detect that overheating is taking

place due to overloading, poor ventilation or high ambient, the bypass operates. Similarly, if the

microprocessor detects that a problem has occurred within the AVR itself, the supply is bypassed to the

load.

4.6 Surge Arrester

4.6.1 Function

The unit is designed to prevent high voltage spikes and surges from causing damage either to the AVR

or to equipment down the line from the AVR. These spikes are commonly caused by lightning, sub-

station load switching or heavy motor load switching.

4.6.2 Operation

The unit is connected in parallel with the supply incoming to the AVR, forming a spur. If built in to

the AVR it will be situated above the connection terminals at the rear. Two indicators per phase are

provided to give warning of reduced protection level, in order that the surge arrester may be replaced

before protection is lost. The unit incorporates multi-stage MOV protection circuits.

5 Maintenance

This is a fully solid state AVR with no moving parts and therefore requires only the minimum of maintenance.

You can expect many years of trouble-free service with the AVR completely unattended.

Isolate the incoming mains supply before carrying out any maintenance.

The only maintenance required is to clean any dust and dirt from the outside and inside of the casework which

could be restricting the free ventilation of the equipment. If there is a build up of dust on the PCB then this

should also be carefully removed with a soft brush. It is also wise on any equipment periodically to check the

security of the electrical connections and the condition of the cabling. Again ensure the power is turned off

before starting work.

If the AVR is damaged for any reason, or you suspect a fault, contact your nearest Sollatek

agent or Sollatek (UK) Ltd Head office for advice.

Sollatek UK Limited

Sollatek (UK) Ltd. Sollatek House, Waterside Drive, Langley, Slough SL3 6EZ UK

Tel: +44 (1753) 214 500

www.sollatek.com

Problem Cause/Solution

AVR trips main breaker at switch on. 1. Check that input and output wiring is not shorted out.

2. Check that input circuit breaker is suitable for

inductive loads.

AVR shuts down after a period of 1. Check that load does not exceed rated output.

normal operation. 2. Check that ventilation ducts/fan outlets are not

blocked.

3. Incoming voltage may be too low to drive AVR

electronic systems.

AVR shuts down immediately upon 1. Check terminal joints and connections

switch on. satisfactorily made.

2. Check incoming cable is of sufficient capacity.

3. Check that cable run not too long causing

excessive volt drop.

Input power is present but there is no output. 1. Check that AVS indicators (if fitted) show ‘on’

2. Check that circuit breakers (if fitted) are in the ‘on’

position.

Three phase equipment rotates Phase rotation problem. Check incoming and outgoing

backwards. mains wiring

Page 8 Page 9

ENGLISH THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021

6.5 Error Modes

If the AVR has shut down it is possible to observe the LEDs on the PCBs within the unit. These can

display two different error modes.

This procedure should be carried out by qualified personnel only.

The main door to the unit may be opened whilst the supply is still connected. It is then possible to see

the PCBs. There are a number of LEDs visible down one edge of each of the three PCB groups. One of

the following two error indications may be observed.

1. The square LEDs in a group scan in a cyclical pattern starting at the top moving to the bottom

repeatedly. This indicates that a fault has occurred in the voltage measurement feedback circuit.

Contact your nearest Sollatek agent or Sollatek (UK) for advice.

2. The green and red undervoltage LEDs in the same group flash. This indicates that an AVR system

fault has occurred. Again, contact Sollatek for advice.

These indications may be observed on any or all of the three PCB groups.

7. Specifications

Model : Three Phase Automatic Voltage Regulator

Input voltage : 230/400V +22% -30% (Other voltages available)

Output voltage : 230/400V +/- 4% (+/- 2.0% with HA Option)

Correction time : within 15 m sec

Frequency range : 45Hz to 88Hz

Voltage protection : Automatic under voltage protection

THD : < 0.25%

Max. amb. Temp. : 40 C

Acoustic Noise : < 45 dB

Expected Service Life : > 25 years

Technology : All solid state (static) switching

Bypass modes : Manual bypass for maintenance. Automatic bypass on

(Optional) AVR fault and overload.

Restart modes : Supply to output is automatically disconnected when

(optional AVS) supply outside preset limits and re-connected when

voltage becomes good. Built-in 3 minute delay.

Filtering (Optional) : Input and output noise and spike filtered

Standards : Manufactured to comply with :-

EN60065

EN60555

BSEN50081

BSEN50082

Page 10

SollatekSollatek

))AVRAVR

2021

www.sollatek.com

www.sollatek.com

the power to protect

11

PCBs

22

AVR

200A

2021

kVAkVA

))((

AA

MCCBMCCB

MCCBMCCB

1016108

2028208

21128

2169808

100808

100721601008

108622072001608

20020016

21616

28816616

20869080016

600100016

13

2021

2

AVR

AVR

HA

18

19 6

20 7

12

MCCBs

MCCB

INCOMING MAINS

E N

AVR

E

N

R1

1

R1

2

S2

N

E

1

R1

2

S2

N

E

R1 S2 T3

EEN

T3

S2R1

N

http://www.sollatek.com

N

R1 S2

EE

Sollatek UK Ltd.

T3

N

R1 S2 T3

SOLLATEK U.K. LTD.

R1 S2 T3 N

R1 S2 T3 N

R1 S2 T3 N

T3 N

R1 S2

2021

14

.1 AVR

.2

AVR

.3AVR

AVR

AVS

AVR

AVS

AVR

(

AVR

AVS

AVRPCB

LEDs

AVS

AVRAVR

(

AVRs

AVR

AVR

2021

15

DC

AVR

AVR

AVR

AVSAVS

AVS

AVS

LED

AVS

LED

LED

1

LED

AVS

a

AVS

2021

16

b

AVS

120

T

d

AVS

AVS

AC

AVS

T

AVS

a

R12P1

P1

P2P1

R2

R20P2

P2

AC

AVS

1

b

60

21kVA

AVR

+ 27%

AVR

AVR

2021

17

7

AVR

7

AVR

AVR

AVR

AVR

AVRAVR

AVR AVR

MOV

AVR

AVR

PCB

Sollatek

AVR

Sollatek UK Limited

Sollatek (UK) Ltd. Sollatek House, Waterside Drive, Langley, Slough SL3 6EZ UK

+44 (1753) 214 500 :

www.sollatek.com

2021

18

66

AVR

AVR

.1

.2

.3

AVS

.1

AVR

.2

AVR

.3

AVR

.4

AVR

AVR

1

2

AVR

1

2

AVR

AVR

1

2

AVS

1

2

2021

19

APPENDIX 1: General Arrangement

2021

20

LEDs

PCBs AVR

PCB

PCBs

LEDs

LEDs

1

Sollatk

AVR

LEDs

2

Sollatek

PCB

77

THDTHD

AVR

AVS

THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021

Page 21

Model Weight Dims (mm)

kg W x D x H

AVR3x20-22 100 450 x 635 x 850

AVR3x30-22 150 450 x 635 x 850

AVR3x50-22 210 500 x 685 x 1060

AVR3x75-22 285 600 x 735 x 1110

AVR3x100-22 400 500 x 835 x 1280

AVR3x150-22 450 500 x 835 x 1280

AVR3x200-22 575 680 x 1200 x 2070

AVR3x250-22 675 680 x 1200 x 2070

AVR3x300-22 735 680 x 1200 x 2070

AVR3x400-22 790 680 x 1200 x 2070

AVR3x700-22 1200 1360 x 1200 x 2070

AVR3x800-22 1590 1360 x 1200x 2070

AVR3x900-22 1700 1360 x1200 x 2070

AVR3x1000-22 1850 2040 x1200 x 2070

Up to 3000A per phase available

APPENDIX 2

Bypass installation procedure

1. Positioning

The bypass should be installed directly next to the AVR to allow wiring between the two units. Both

units should be positioned as closely as possible to the incoming supply access. See AVR manual for

further positioning requirements.

Fig 1. Bypass positioned close to AVR and utility access point

2. Interconnection

In the standard bypass connection configuration, the main incoming supply and load output are

connected at the bypass. Connections are then made to and from the AVR using the terminals provided

on the bypass terminal panel. The AVR and bypass should be connected together using the cable kit

provided. This kit consists of nine identical cables two meters in length (three phases and neutral in

and out plus one earth connection). The bypass terminal panel shows connection information. See AVR

manual for further information on cable connection. NB Ensure all connections are tight.

The bypass is fitted with a terminal cover to prevent accidental contact

with the terminals. It is necessary to remove this cover and feed the

cables through before replacing it after the connections have been

made.

3. Bypass operation

When the AVR is required to be in circuit, during normal operation, the

operation handle on the top of the bypass case should be in the ‘normal’

position. This takes the incoming supply via the AVR to the load.

When the AVR needs to be taken out of circuit, for instance to perform

maintenance, the operation handle should be moved to the ‘bypass’

position. This takes the incoming mains directly to the load and the AVR

is isolated.

4. Alternative bypass connection

There is an alternative bypass/AVR connection method that may be

employed if desired. In this case, the bypass is used to select between

the regulated supply from the AVR and the incoming mains supply as

the feed to the load. Connections are as indicated on the terminal panel

with the exception the terminals marked ‘TO AVR’ are not used. (See

Diagram)

N.B. This arrangement does not allow the bypass to be used to isolate the AVR for maintenance.

THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021

R1 S2 T3

EEN

T3

S2R1

N

http://www.sollatek.com

N

R1 S2

EE

Sollatek UK Ltd.

T3

N

R1 S2 T3

SOLLATEK U.K. LTD.

R1 S2 T3 N

R1 S2 T3 N

R1 S2 T3 N

T3 N

R1 S2

R1 S2 T3

EEN

T3

S2R1

N

http://www.sollatek.com

N

R1 S2

EE

Sollatek UK Ltd.

T3

N

R1 S2 T3

SOLLATEK U.K. LTD.

R1 S2 T3 N

R1 S2 T3 N

R1 S2 T3 N

T3 N

R1 S2

Fig 2. Bypass terminal panel

marking

AVR

BY-PASS

TERMINALS

TERMINALS

AVR INPUT AND OUTPUT CABLES

INCOMING SUPPLY AND

OUTGOING LOAD CABLES

INCOMING SUPPLY

OUTPUT TO LOAD

TO AVR

FROM AVR

EARTH

Page: 21

Fax: 01753 685306

Tel: 01753 688300

Slough, Berks. SL3 0AX.

Blackthorne Road, Poyle,

Units 4/5, Trident Ind. Est.,

DWG. No.

Title:

Edition Sheet

Scale

Date

Filename

Approved by - date

Checked by

Designed by

1198

nts

15/2/01

183501

1835.01

AVR & Bypass switch wiring

rgb

Quantity Material-

Finish-

Size Article No./Reference

Date

Revision note

RevNo

Page 22 Page 23

APPENDIX 3

System topology diagrams

1. Main AVR

2. Main power PCBs

3. Cooling fans

4. LCD Display

5. Distribution surge protection

6. Fuse PCB

7. Automatic Voltage Switcher

THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021

Page: 24

Slough, Berks. SL3 0AX.

Blackthorne Road, Poyle,

Units 4/5, Trident Ind. Est.,

1211

nts

13/3/01

184501

1845.01

AVR block diagram

rgb

Filename

Approved by - date

Tel: 01753 688300

Fax: 01753 685306

DWG. No.

Title:

Scale

Date

Edition Sheet

Article No./Reference

Date

Revision note

RevNo

Designed by Checked by

Quantity

Size

Finish-

Material-

Page 24 Page 25

Page: 25

THREE PHASE AUTOMATIC VOLTAGE REGUL ATOR Issue: Feb 2002

1217

nts

14/3/01

185101

1851.01

AVR PCB/xfmr connection

rgb

Filename

Approved by - date Scale

Date

Edition Sheet

Article No./Reference

Date

RevNo Revision note

Designed by

Size

Units 4/5, Trident Ind. Est.,

Blackthorne Road, Poyle,

Slough, Berks. SL3 0AX.

Checked by

Tel: 01753 688300

Fax: 01753 685306

Material-

Quantity

Finish-

Title:

DWG. No.

THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021

Page: 26

THREE PHASE AUTOMATIC VOLTAGE REGUL ATOR Issue: Feb 2002

DWG. No.

1216

nts14/3/01185001

1850.01

AVR cooling fans

rgb

Approved by - date

Units 4/5, Trident Ind. Est.,

Blackthorne Road, Poyle,

Slough, Berks. SL3 0AX.

Tel: 01753 688300

Fax: 01753 685306

Material-

Finish-

Checked by

Designed by

Size Quantity

Title:

Revision noteRevNo

Edition

Article No./Reference

Date

Sheet

Scale

Date

Page 26 Page 27

Page: 27

THREE PHASE AUTOMATIC VOLTAGE REGUL ATOR Issue: Feb 2002

Revision note

RevNo Date

1215

nts

14/3/01

184901

1849.01

AVR - LCD V & I displays

rgb

Approved by - date

DWG. No.

Tel: 01753 688300

Designed by

Quantity

Size

Slough, Berks. SL3 0AX.

Units 4/5, Trident Ind. Est.,

Blackthorne Road, Poyle,

Checked by

Material-

Finish-

Title:

Fax: 01753 685306

Article No./Reference

Date

Filename Scale

Edition Sheet

THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021

Page: 28

THREE PHASE AUTOMATIC VOLTAGE REGUL ATOR Issue: Feb 2002

Revision note

RevNo Date

1214

nts

13/3/01

184801

1848.01

AVR3¿suppressorPCB's

rgb

Approved by - date

Slough, Berks. SL3 0AX.

Blackthorne Road, Poyle,

Units 4/5, Trident Ind. Est.,

Fax: 01753 685306

Quantity Material-

Finish-

Designed by

Size

Checked by

Tel: 01753 688300

Edition

Article No./Reference

DWG. No.

Filename

Title:

Date Scale

Sheet

Page 28 Page 29

Page: 29

THREE PHASE AUTOMATIC VOLTAGE REGUL ATOR Issue: Feb 2002

1213

nts13/3/01184701

1847.01

AVR fuse distribution PCB's

rgb

DWG. No.

Tel: 01753 688300

Fax: 01753 685306

Slough, Berks. SL3 0AX.

Blackthorne Road, Poyle,

Units 4/5, Trident Ind. Est.,

Checked by

Material-

Finish-

Designed by

Size Quantity

Approved by - date

Title:

RevNo Revision note

Edition

Article No./Reference

Filename Date

Sheet

Scale

Date

THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021

Page: 30

THREE PHASE AUTOMATIC VOLTAGE REGUL ATOR Issue: Feb 2002

1212

nts

13/3/01

184601

1846.01

AVSoptionfor3¿AVR

rgb

Filename

Edition Sheet

Date

Article No./Reference

Scale

Date

Revision note

RevNo

Units 4/5, Trident Ind. Est.,

Slough, Berks. SL3 0AX.

Blackthorne Road, Poyle,

Fax: 01753 685306

Tel: 01753 688300

Checked by

Material-

Finish-

Designed by

Size Quantity

DWG. No.

Approved by - date

Title:

Page 30 Page 31

Final Test Procedure Document Number: QP07

Product Name: Installed Large AVR Variants: All ST165 based

Inspection Checklist

1. Check PCBs for damage, poor alignment, comb positioning and general condition.

2. Ensure that all internal nuts, bolts and fixings are secure and that nothing has come loose during

installation.

3. Examine all wiring, paying particular attention to power cable terminal tightness. If Bypass is fitted, check all

power connections. Check crimp joints have not loosened.

Check all pink/grey connections are correct and that ribbon cable connectors have not been dislodged.

4. Clean all exterior panel work and check for damage.

Function Test

1. Note all results on form QF07.

2. Using a variac on input of one phase at a time, with a test lamp at the output, increase voltage until ST165

master switches on (reset LED goes off). Note input voltage. This should be in the range 140V to 170V.

3. Reduce input voltage and note voltage at which reset LED lights. This should be between 120V and 135V.

4. Increase input voltage from 160V and note output voltage at which tap down occurs on each tap. This should

be at 240V +/- 1V.

5. From 270V reduce input voltage and note output voltage at which tap up occurs on each tap. This should be

at 220V +/- 1V.

6. Set output voltage to 220V on brown tap. Input voltage should be less than 161V.

7. Set output voltage to 240V on violet tap. Input voltage should be greater than 280V.

8. Set input voltage to 230V. Compare measured input voltage to displayed input voltage. Difference should

not exceed 2%.

9. Compare measured output voltage to displayed output voltage. Difference should not exceed 2%. AVS must

be operational for this test.

10. Compare measured output current to displayed output current. Difference should not exceed +/- 10% at

20% full load. AVS must be operational for this test.

11. Connect two phases to the input of the AVR. Connect the third phase via the variac. Adjust the variac voltage

to 230V. Time the delay before AVS switches on. This should 10 seconds +/- 5%. Ensure AVS amber LED

illuminates during wait.

12. Increase variac voltage until AVS cuts out. Note AVS input voltage. This should be 260V +/- 3 V. Ensure Red

overvoltage LED is illuminated.

13. Reduce input voltage to 230V. Ensure AVS amber LED is illuminated. Once AVS has re-connected reduce

input voltage until AVS cuts out. Note AVS input voltage. This should be 190V +/- 3 V. Ensure red

undervoltage LED is illuminated.

14. Note AVS HVD, LVD and Time delay settings.

THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021

Inspection and Test Document Number: QF07

Product Name: Installed Large AVR Variants: All ST165 based

Inspection Checklist

1. PCBs

2. Assembly

3. Wiring

4. Exterior

Function Test

Tick for pass and enter value

R1 (value) S2 (value) T3 (value) Limit

Switch on voltage c ——— c ——— c ——— 140V – 170V

Switch off voltage c ——— c ——— c ——— 120V – 135V

Tap down voltage c ——— c ——— c ——— 240+/-1V

Tap up voltage c ——— c ——— c ——— 220+/-1V

I/P V @ 220V out (brown) c ——— c ——— c ——— < 161V

I/P V @ 240V out (violet) c ——— c ——— c ——— > 280V

I/P V meter % acc. c ——— c ——— c ——— +/- 2%

O/P V meter % acc. c ——— c ——— c ——— +/- 2%

Current meter % acc. c ——— c ——— c ——— +/- 10%

AVS Switch on time _______________________________________ 3 min +/- 5%

AVS HVD operates _______________________________________ 190V +/- 3V

AVS LVD operates _______________________________________ 260V +/- 3V

AVS LED function _______________________________________

AVS HVD setting _______________________________________

AVS LVD setting _______________________________________

AVS delay setting _______________________________________

Inspected by (SUKL Engineer) _______________________________________

Accepted by (Facilities Engineer) _______________________________________

Date _______________________________________

Page 32 Page 33

AVR on-site repair guide

Power PCB replacement procedure (Single PCB per Stack)

Ensure the AVR is isolated from the supply and load before commencing

1. Remove neutral sense cable (Single cable connected to J5)

2. Remove ribbon cable (connected to J2) if fitted.

3. Remove Pink/Grey cables (twisted pair to J6)

4. The PCB is fixed to the metalwork by means of 7 screws into nylon pillars. Removing these gives access to

the back of the PCB.

5. Undo the 8 nuts/bolts securing the transformer connections to the rear of the PCB. NB - the order in which

these cables are connected should be noted for replacement. The Correct cable colour connections are

marked on the PCB.

6. Remove faulty PCB. Ensure that the replacement PCB is exactly the same type as the removed PCB ie slave,

master, 3 way, 5 way etc.

7. Fitting replacement PCB is a reversal of the above procedure.

8. It is essential that the On Site AVR Test Procedure following Maintenance/Repair for replaced power PCBs is

followed before the AVR is put back on-line.

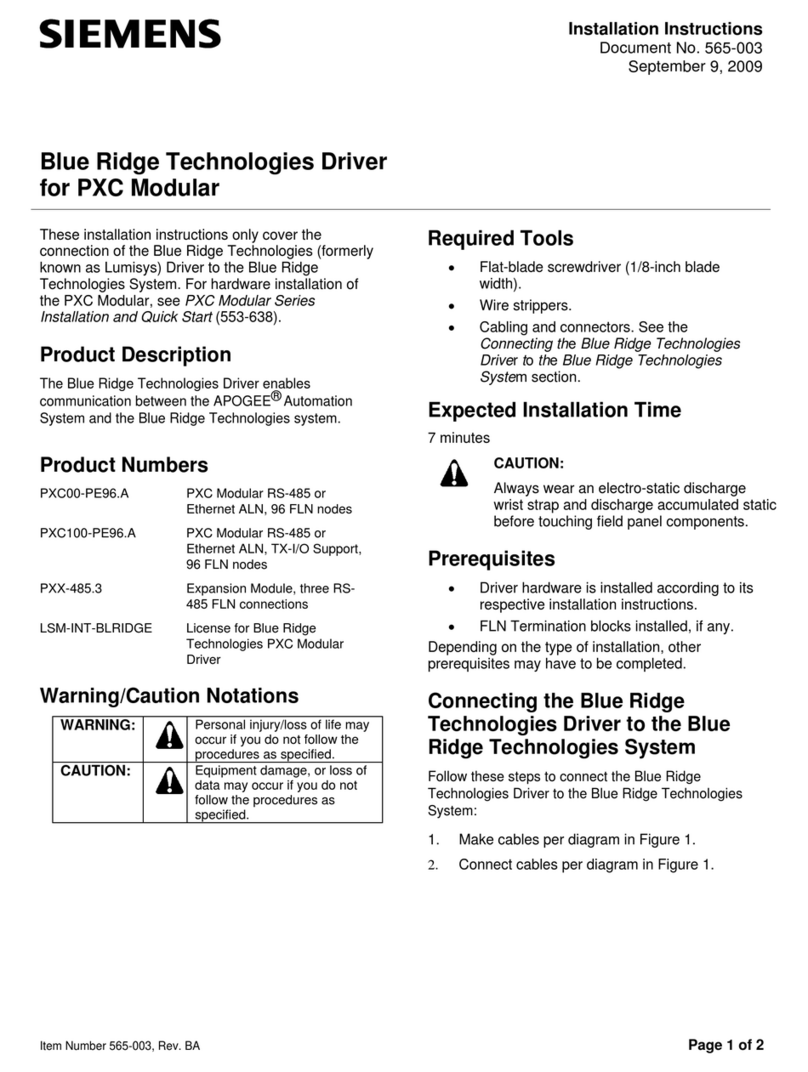

Power PCB replacement procedure (Multiple PCBs per Stack – see Photo)

Ensure the AVR is isolated from the supply and load before commencing

1. Remove front PCB neutral sense cable (Single cable connected to J5)

2. Remove front PCB ribbon cable (connected to J2)

3. Remove Pink/Grey cables (twisted pair to J6)

4. The front PCB is fixed to those behind by hexagonal brass pillars and nuts. To remove the the front PCB

remove these nuts.

5. The same procedure should be repeated until the faulty board is outermost.

6. Replace faulty PCB. If this is the PCB with the transformer cables attached then the above procedure for

single PCB per stack should be followed here. Ensure that the replacement PCB is exactly the same type as

the removed PCB ie slave, master, 3 way, 5 way etc.

7. Re-assembling the PCB stack is the reverse of this procedure.

8. It is essential that the On Site AVR Test Procedure following Maintenance/Repair for replaced power PCBs is

followed before the AVR is put back on-line.

THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021

In the large AVRs the main circuit boards are type ST165. There is one master PCB per phase and several slaves.

In the picture below of an AVR3x400, there is one master and 7 slave PCBs.

Notes.

1. The Pink/grey wire brings low voltage ac from a small winding on the main transformer to power the circuit

boards. It connects first to one PCB, and then links to all the rest.

2. The ribbon cable takes the control signals from the maser PCB and links it to all the slave PCBs.

3. There are seven round input LEDs on each PCB. These should all be on the same position for the PCBs on any

one phase.

4. The Reset LED will only be on when the mains power is too low to operate the circuit boards correctly.

7 Slave PCBs (ST165)

Pink/Grey fuse (in

line on older units).

Brass pillars

with sleeving

1 Master PCB

(ST165)

Neutral

Connection

Output LEDs

Micro

Input LEDs

Live-Out

Screw

Ribbon Cable

Reset LED (one

on every PCB)

Triacs on

heatsinks

ST163 Resistor

PCBs

Pink/Grey Wires

Page 34 Page 35

5. DSP replacement procedure

Ensure the AVR is isolated from the supply and load before commencing

1. Remove AVR back panel by undoing securing screws.

2. Remove cable access cover by undoing securing screws. The screws are covered by plastic inserts which must

be removed.

3. Remove cables from terminals, noting cable order.

4. Pull cables out of DSP case.

5. Remove DSP from AVR by undoing two securing screws in cable access area.

6. Lift DSP off rear of AVR.

7. To fit new DSP, reverse the above procedure.

8. Test according to instructions in AVR Site Test Procedure

9. Replace back panel

Meter PCB replacement procedure

Ensure the AVR is isolated from the supply and load before commencing

1. Undo fixing nuts on rear of faulty meter PCB.

2. Remove PCB gently and disconnect ribbon connector.

3. Fit ribbon connector on replacement PCB.

4. Set replacement PCB in place on studs and replace nuts.

5. Ensure jumper on rear of PCB is set to the same setting as the removed PCB.

6. Test according to instructions in AVR Site Test Procedure.

7. If new meter PCB is out of adjustment, it can be re-calibrated using P1 on rear of replaced PCB. P1 should be

adjusted until displayed voltage agrees with measured voltage.

AVS PCB replacement procedure

Ensure the AVR is isolated from the supply and load before commencing

1. On certain AVR models it will be necessary to remove the rear panel to access the AVS PCB.

2. Note all wiring colours and positions and AVS settings.

3. Remove all wiring.

4. Remove PCB by undoing screws

5. Place replacement PCB in position and fix.

6. Replace wiring in the same order as previously connected.

7. Ensure all voltage and delay setting knobs are set to the same positions as they were on the old PCB.

8. Test according to instructions in AVR Site Test Procedure

9. Replace back panel

THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021

AVS Contactor replacement procedure

Ensure the AVR is isolated from the supply and load before commencing

1. Remove AVR back panel by undoing securing screws.

2. Note all wiring positions.

3. Remove all wiring.

4. Undo securing bolts carefully. Larger contactors are heavy!

5. Remove old contactor and fix replacement in position.

6. Replace all wiring in the same order as previously connected.

7. Test according to instructions in AVR Site Test Procedure

8. Replace back panel

Page 36 Page 37

On Site AVR Test procedures following maintenance/repair

Items Required:

Single Phase Variac (Variable Transformer)

Multimeters

Clamp-on Current Meter

Test lamp

‘Safebloc’ Safety Mains Connector

Following Master PCB Replacement

The AVR should be disconnected from Mains and Load before commencing this test.

1. Connect the Variac input to a mains supply but do not switch on.

2. Connect Test Lamp across Neutral and output of phase under test.

3. Connect the Variac Neutral to the AVR incoming Neutral terminal

4. Connect Variac Live output to the Incoming Mains connection of the phase under Test.

5. UNITS WITH AVS ONLY Using Safebloc, connect (but do not switch on) mains supply live to terminal

marked ‘Test Use Only’, situated bottom right of the rear panel. This will supply power to operate the AVS

contactor, switching on the lamp at the output.

6. Reduce Variac output voltage setting to zero.

7. Connect Multimeter # 1 (indicating AC Voltage 600V scale) across variac output.

8. Connect Multimeter # 2 (indicating DC 20V scale) between TP1 (0V), and TP2 (5V).

9. Fit clamp-on current meter around variac live out cable (set to 200A)

10. Switch on power to variac and increase output voltage slowly observing current measurement.

11. Current should rise slowly and be no more than a few amps at 100V input.

12. Switch on supply to AVS Test Terminal. A loud thump will be heard as the contactor pulls in.

13. Set Master PCB Potentiometer P2 fully anti clock wise. Increase variac and check that TP2 reaches about

4.8V and stabilises when the mains reaches about 120V. Reset LED LD8 should be on, as should the green

output LED LD13, but no others. Adjust P2 for 5.00Vdc.

14. Move meter positive lead to TP4 (7V). Check this stabilises between 6.8V and 7.2V when the variac is

increased to 140V.

15. Continue to increase the variac and the Reset LED (LD8) should go off at approx. 140 to 150V mains in.

The green tap LED (LD5) should come on and then move to the end (LD1). Check the lamp on the output

comes on.

16. Turn P1 fully clockwise (indicates 240V). Turn the variac to 160V in). Check the output is between 210 and

230V ac and that the end red LED (LD1) is on.

17. Increase the variac until the AVR output is 241Vac +/- 0.5V. SLOWLY turn P1 anticlockwise until the output

voltage drops (to approx. 222V). LED LD2 should now be on.

18. Reduce the variac until LD1 comes back on. SLOWLY increase the variac and check that the AVR output

reaches 239 to 241V before dropping. (If not repeat steps 16 and 17 above). Keep increasing the variac and

check that the voltage rises and drops in the same way a further 5 times. The round LEDs should move step

THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021THREE PHASE AUTOMATIC VOLTAGE REGULATOR Issue: July 2021

at a time to the end. Check P1 points to 230V on the PCB ident, +/-5V.

19. Slowly reduce the variac and check the output voltage goes down to 220V before rising again. This should

happen a total of 6 times.

20. Increase and decrease the variac several times and check that all LEDs (LD1 to 7) light in turn. Check also

that there is no ‘thudding’ noise made by either the transformer or the variac. (A faint ‘click’ may be heard

from the PCB but this is normal.)

21. Switch the variac off and remove the neutral connection from J5 on the ST165. Turn the variac on again and

check that the output lamp and green LED (LD5) come on for about 1 second and then go off, followed by the

four rectangular LEDs lighting in a scanning pattern.

22. Switch off, reconnect the neutral and switch on. Check the output lamp comes on again.

23. Reduce the variac and check the output switches off at 130 to 135 V input.

24. Switch off and disconnect all mains power

25. Repeat the above procedure for the other phases if required.

26. The AVR is now ready for re-connection on-line.

Following Slave PCB Replacement

The AVR should be disconnected from Mains and Load before commencing this test.

1. Connect the Variac input to a mains supply but do not switch on.

2. Connect Test Lamp across Neutral and output of phase under test.

3. Connect the Variac Neutral to the AVR incoming Neutral terminal

4. Connect Variac Live output to the Incoming Mains connection of the phase under Test.

5. UNITS WITH AVS ONLY Using Safebloc, connect (but do not switch on) mains supply live to terminal

marked ‘Test Use Only’, situated bottom right of the rear panel. This will supply power to operate the AVS

contactor, switching on the lamp at the output.

6. Reduce Variac output voltage setting to zero.

7. Connect Multimeter #1 (indicating AC Voltage 600V scale) across variac output.

8. Fit clamp-on current meter around variac live out cable (set to 200A)

9. Vary input volts between 160 and 280V a number of times to ensure the replaced PCB is functioning

properly. Lamp on output should be lit.

10. Leave on soak test for 1 hour.

11. Switch off and disconnect all input and output connections.

12. The AVR is now ready for re-connection on-line

Digital Meter Function Check

The AVR should be disconnected from Mains and Load before commencing this test.

1. Connect Variac as in PCB test procedure above.

2. Connect Multimeter #1 to variac output

3. Connect Multimeter #2 to AVR output

Page 38 Page 39

Table of contents

Other Sollatek Controllers manuals