Sonel MZC-310S User manual

OPERATING MANUAL

SHORT-CIRCUIT LOOP

IMPEDANCE METER

MZC-310S

SONEL SA

ul. Wokulskiego 11

58-100 Świdnica

Version 3.6

3

TABLE OF CONTENTS

1PREFACE ......................................................................................................5

2INTRODUCTION............................................................................................6

3SAFETY .........................................................................................................6

4DEVICE DESCRIPTION AND ITS FUNCTIONALITY...................................6

4.1 MZC-310S CHARACTERISTICS....................................................................6

4.2 STANDARD ACCESSORIES...........................................................................7

4.3 OPTIONAL ACCESSORIES ............................................................................7

4.4 TERMINALS AND KEYS LAYOUT....................................................................8

4.4.1 Terminals .......................................................................................................8

4.4.2 Keyboard........................................................................................................9

4.5 GRAPHICAL DISPLAY PANEL (LCD)............................................................10

4.6 BUZZER....................................................................................................11

4.7 TEST LEADS .............................................................................................12

5STORAGE....................................................................................................13

6BEFORE YOU START.................................................................................13

7OPERATIONS..............................................................................................14

7.1 PREPARING THE DEVICE FOR WORK..........................................................14

7.2 POWER SUPPLY VOLTAGE MONITORING ....................................................15

7.3 BATTERY REPLACEMENT...........................................................................15

7.4 CONDITIONS FOR PERFORMING TESTS AND OBTAINING CORRECT RESULTS 16

7.5 DEVICE CONNECTION DIAGRAMS...............................................................17

7.6 MEASUREMENT OF ALTERNATING VOLTAGE ...............................................22

7.7 SHORT-CIRCUIT LOOP MEASUREMENT ......................................................22

7.7.1 Measurement of Network Voltage and Frequency .......................................23

7.7.2 Changing The Network Rated Voltage.........................................................23

7.7.3 Displaying All Measurement Results Or The Main Result Only....................24

7.7.4 Displaying The Measurement Results In Terms of Impedance or Short-

Circuit Current..............................................................................................24

7.7.5 Measurement of Touch Voltage UST And Touch Shock Voltage UT.............25

7.7.6 Selection of Test Cables Length (For Measurements Using Two-Pole

Method)........................................................................................................25

7.7.7 Results Display ............................................................................................26

7.7.8 Measurement of Short-Circuit Loop Parameters Using Two-Pole Method...26

7.7.9 Measurement of Short-Circuit Parameters By the Four-Pole Method ..........26

7.8 MEASUREMENT OF EARTHING RESISTANCES..............................................27

7.9 SAVING THE MEASUREMENT RESULTS.......................................................28

7.9.1 Storing Measurement Results In The Memory.............................................29

7.9.2 Memory Browsing ........................................................................................30

7.9.3 Erasing the memory.....................................................................................30

4

7.10 MENU.......................................................................................................31

7.10.1 Display Contrast Adjustment........................................................................31

7.10.2 Data Transmission .......................................................................................31

7.10.3 Display settings............................................................................................31

7.10.4 Loop Measurement Settings ........................................................................32

7.10.5 Language Selection .....................................................................................32

7.10.6 Advanced Functions.....................................................................................32

7.10.6.1 Expected Dispersion of Results ...................................................................32

7.10.6.2 Upgrading The Software ..............................................................................33

7.10.7 Information About The Manufacturer And The Software..............................34

7.11 SENDING DATA TO A COMPUTER................................................................34

7.11.1 Communications Kit .....................................................................................34

7.11.2 Connecting The Meter To A Computer.........................................................34

8TROUBLE SHOOTING................................................................................35

8.1 WARNINGS AND INFORMATION DISPLAYED BY THE METER.........................35

8.1.1 Exceeding The Measurement Range...........................................................35

8.1.2 Battery Status Display..................................................................................35

8.2 SELF-TEST ERROR MESSAGES..................................................................35

8.3 BEFORE YOU SEND THE DEVICE FOR REPAIRS...........................................35

9CLEANING AND MAINTENANCE..............................................................36

10 DECOMMISSIONING AND RECYCLING...................................................36

11 APPENDICES..............................................................................................37

11.1 TECHNICAL SPECIFICATIONS .....................................................................37

11.2 MANUFACTURER.......................................................................................39

5

1 Preface

Thank you for purchasing our short-circuit loop impedance meter. MZC-310S is a state-of-the-art,

high-quality measuring instrument that is easy and safe to operate. However, familiarising with this

manual will let you avoid measurement errors and will prevent possible problems that might occur

while operating the device.

In this instruction we use three types of warnings. They are shown as a framed text and describe

possible hazards for either the user of the device. Texts that start with the word “WARNING:” describe

a life threatening or hazardous situation that can result if the instructions are not followed. Wherever a

“CAUTION!” exclamation opens the framed text, it describes a situation where non-adherence to the

manual can result in damage to the meter. Possible problems that may occur are preceded with the

word “Note:”.

WARNING:

Before starting to use the device, please read carefully this manual, always follow all health

and safety rules and comply with manufacturer’s recommendations.

WARNING:

MZC-310S meter is designed to measure short-circuit loop impedance and alternating volt-

ages. Using the device for purposes other then described in this manual can cause an injury

to the operator and/or can damage the device.

WARNING:

MZC-310S may be used only by qualified personnel who is certified to work with electrical

installations. Operating the instrument by a person who is not qualified, can result in a haz-

ardous situation and/or can cause damage to the meter.

WARNING:

Using this manual does not exclude the need to comply with occupational health and safety

regulations and with other relevant fire regulations required during the performance of a par-

ticular type of work. Before starting the work with the device in special environments, e.g.

potentially fire-risk/explosive environment, it is necessary to consult it with the person re-

sponsible for health and safety.

Note:

An attempt to install drivers in 64-bit Windows 8 may result in displaying "Installation failed"

message.

Cause: Windows 8 by default blocks drivers without a digital signature.

Solution: Disable the driver signature enforcement in Windows.

6

2 Introduction

This manual describes the MZC-310S short circuit loop meter. We recommend that you familiarize

yourself thoroughly with the contents of this manual in order to avoid errors that can result in a safety

hazard or in an incorrect assessment of tested installations. More information related to safety issues

can be found in chapter 3 –Safety. Before you use the device for the first time, read carefully chapter

6 –Before You Start. If the device causes any problems, refer to chapter 8 –Trouble Shooting. All

information on how to use the device is located in chapter 7 –Operations.

3 Safety

MZC-310S device is intended for testing electric shock protection and grounding in AC power net-

works. Results obtained from readings determine the safety status of installations. Therefore, to en-

sure correct operations of the device and reliability of measurements, you need to adhere to the fol-

lowing rules:

Before starting to use the meter, you have to become thoroughly familiar with this manual.

The device should be operated only by persons holding appropriate qualifications and who at-

tended appropriate occupational health and safety training.

It is not acceptable to:

oUse the meter that is damaged in any way

oUse leads with damaged insulation

oUse a meter stored in inappropriate conditions (e.g. high humidity) for a prolonged pe-

riod of time

Before commencing a measurement, select the desired mode and make sure that the test leads

are connected to the appropriate terminals.

Repairs can be performed by an authorised service agent only.

Additional points to remember:

The text BAT! appearing in the right upper corner of the display (instead of the battery symbol) in-

dicates insufficient power supply voltage and signals a need to replace the batteries.

Measurements made with the meter with the supply voltage being too low are burdened with some

additional errors that are impossible for the user to evaluate and therefore must not be relayed up-

on when assessing if the installation tested is sufficiently protected.

4 Device Description and Its Functionality

4.1 MZC-310S Characteristics

MZC-310S is designed to measure short-circuit loop impedance and alternating voltages.

Main features of MZC-310S.

Measurement of very low short-circuit loop impedances with a current of 150A at 230V, maximum

280A at 440V (Rzw = 1,5)

Touch voltage and touch shock voltage measurement

Ability to perform a measurement with a current of 23A at 230V, maximum 42A at 440V (Rzw =

10)

Measurements in installations with rated voltages between 220/380V and 230/400V and frequen-

cies 45...65Hz

Selection of rated voltage: 220V/380V or 230V/400V

Ability to perform measurements in short-circuit system: phase-phase, phase-protective, phase-

neutral

Automatic calculation of the short-circuit current

Differentiation between the phase voltage and the inter-phase voltage while calculating the short-

circuit current

7

Automatic choice of measurement range

Ability to change the length of measurement cables without a need to re-calibrate the instrument

Measurement of alternating voltages

Memory to store 990 measurement results with an ability to transfer them to PC via an

RS-232C connection

Large, legible LCD with a backlit option

Monitoring battery’s charge status

Automatic switch-off when the instrument is not used (AUTO-OFF)

Ergonomic design

4.2 Standard Accessories

The device is supplied in a kit that contains:

MZC-310S meter –WMPLMZC310S

Set of measuring conductors:

1.2 m black conductor with pin plugs –WAPRZ1X2BLBB

1.2 m yellow conductor with pin plugs –WAPRZ1X2YEBB

Black test prod with a female connector –WASONBLOGB1

Yellow test prod with a female connector –WASONYEOGB1

3-m two-wire cable (2 pcs.) –WAPRZ003DZBB

Black crocodile clip K03 (4 pcs.) –WAKROBL30K03

Kelvin’s crocodile clip (2 pcs.) –WAKROKELK06

High current prod with a female connector –WASONSPGB1

Carrying case L1 for the meter and its accessories –WAFUTL1

Serial transmission cable RS-232 –WAPRZRS232

Meter carrying harness –WAPOZSZE1

Service manual

Calibration certificate –LSWPLMZC310

5 R14 batteries

Note:

In order to measure touch voltage use the 20 m cable included among the accessories.

4.3 Optional Accessories

Additional accessories that are not a part of the standard kit can be purchased from the manufac-

turer or from suppliers:

USB/RS232 adapter–WAADAUSBRS232

Yellow cables with pin plugs for measurements of loop impedance by means of the bipolar method

(2 pcs):

- Length: 5m –WAPRZ005YEBB

- Length: 10m –WAPRZ010YEBB

- Length: 20m –WAPRZ020YEBB

SONEL “Electric measurements” software aiding preparation of complete measurement documen-

tation –WAPROSONPE3

Software generating drafts, electric installation schematic diagrams SONEL Schematic –

WAPROSCHEM

Measurement calculation software SONEL PE Calculations –WAPROKAL

8

4.4 Terminals and Keys Layout

232

U2

MZC-310S

RS

U

2p (I =42A)

max 4p (I =280A)

max

MEM

4p

2p UB

232

U2

MZC-310S

RS

U

2p (I =42A)

max 4p (I =280A)

max

MEM

4p

2p UST/T

8

7

10

15

911 12

1

3

14

6

2

4

5

13

MAX 440V MAX 440V

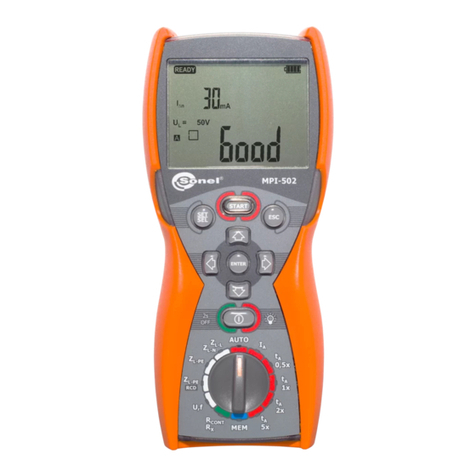

Fig.1. MZC-310S front panel layout

4.4.1 Terminals

CAUTION!

MZC-310S is designed to operate at rated phase voltages of 220V and 230V and inter-

phase voltages of 380V and 400V.

Applying voltages higher than those specified to any of the test terminals can damage the

device.

1 Test terminal I1(Imax 280A)

Terminal to connect the phase current cable in the four-pole method of the short-circuit loop impedance

measurement using current not exceeding 280A.

2 Test terminal I1(Imax 42A)

Socket to connect the phase current cable in the two-pole method of the short-circuit loop impedance

measurement using current not exceeding 42A.

3 Test terminal I2

Terminal (common for both methods) to connect the neutral cable N, protective cable PE/PEN (current

cable in the four-pole method) or another phase cable in a case of a short-circuit loop impedance meas-

urement in the phase-phase configuration.

4 Test terminal U1

Terminal to connect the voltage phase cable in the four-pole method of short-circuit loop impedance

measurement or a cable to measure alternating voltage.

9

5 Test terminal U2

Terminal to connect the voltage neutral cable N or the protective cable PE (PEN) in the four-pole meth-

od of short-circuit loop impedance measurement or the cable to measure alternating voltage.

6 Test terminal UST/T (UB)

Terminal to connect the protective cable PE (PEN) in the function of touch voltage UST measurement or

an electrode (probe) in the touch shock voltage UTmeasurement mode.

7 Test terminal RS-232C

Terminal to connect a serial communications cable (RS-232C).

4.4.2 Keyboard

8 Key

Switching the device power supply on and off.

9 Rotary mode switch

Selection of measurement function:

U- measurement of alternating voltage

2p (Imax=42A) –measurement of short-circuit loop impedance by the two-pole method using a cur-

rent not exceeding 42A (short-circuit resistor Rzw = 10)

4p (Imax=280A) –measurement of short-circuit loop impedance by the four-pole method using a cur-

rent not exceeding 280A (short-circuit resistor Rzw =1.5) and touch voltage measurement

MEM –memory browsing

10 Key

Starting the measurement of short-circuit loop impedance or short-circuit current.

11 Keys

Set of cursor keys with auto-repetition function activated by holding the key depressed:

, - Selection of an option vertically, change of the bank number

, - Selection of an option horizontally, change of the cell number

12 Key

Confirmation of selected option

On completing of the measurement:

Start of the memory write mode

In the memory write mode –storing the measurement result in the selected cell

13 Key

Selection of additional functions:

Display contrast adjustment

Starting the data transmission mode

Setting the measurement and display parameters

Language selection

Advanced functions

Manufacturer and software info

10

14 Key

Exit from selected option

Return to the previous screen

15 Key

Switching the LCD illumination on and off.

4.5 Graphical Display Panel (LCD)

16 - Device overheating (symbol replaces “READY” flag)

17 - Battery status

18 - Battery low –needs replacement.

19 - Sending results to the memory.

Measurement function Battery status

Value of voltage

being measured

Frequency of voltage

being measured

Fig.2. Screen layout in alternating voltage measurement mode

Measurement function

Length of measurement cables for “2p”

Battery status

Bank and cell number (in store-in-memory mode)

or the text “ ” advising about

the capability to make the measurement

or the temperature

excess symbol

READY

Main result or

messages Current value of U and I

or messages

Complementary results

Fig.3. Screen layout in short-circuit loop impedance measurement mode (all results)

11

Measurement function

Length of measurement cables for “2p”

Battery status

Main result

or messages

Current value of U and f

or messages

Text “READY” advising

about the capability

to make the measurement

or the temperature

excess symbol

Fig. 4. Screen layout in short-circuit loop impedance measurement mode (main result only)

Network rated voltage

Bank and

cell numbers

Main result

Function

Complementary results

Measurement

method

Fig.5. Screen layout in the memory browse mode

Fig.6. Screen appearance after switching the meter on (loop impedance measurement –all

results)

4.6 Buzzer

Warning signals:

Continuous beep

The voltage applied to meter’s terminals exceeds 440

12

CAUTION!

Applying voltage that is higher than the permissible value can damage the device.

Long beep (0.5 sec)

Key, that is inactive for the selected function, has been pressed.

Device overheating (after the key 10 has been pressed)

Two long beeps (after starting a measurement by pressing the 10 key)

Network frequency outside of the permissible range (45..65 Hz).

Supply power voltage too low UX<Umin

Test leads connected incorrectly

Voltage fading or measurement error.

Short-circuit loop faulty.

Measurement range exceeded

Confirmation and miscellaneous sounds:

Short sound

Confirmation of a key being pressed and of a function being performed by the device.

Transition from the greeting screen to a screen appropriate for the mode selected.

Return to the home screen after displaying an error message.

In MEM mode –return to the main menu after erasing a cell, a memory bank or the entire

memory.

Ready to perform a measurement (displaying READY)

Long sound (0.5 sec)

Signals turning the device ON

Signals that the meter has automatically switched off

Three short sounds

Measurement result stored in the memory

Confirmation of new MENU settings

Cell, bank or the entire memory erasure confirmation

4.7 Test Leads

MZC-310S short-circuit loop meters using a 2p method are factory calibrated to compensate for

the resistance of the proprietary test leads that are supplied in the following lengths:

cable L:

1.2m

cable PE/N:

1.2m

5m

10m

20m

Cables used for measurements using the four-pole method do not require calibration. However,

they have to ensure an undisturbed flow of high currents.

13

WARNING:

Connecting unsuitable or faulty cables can cause an electrical shock.

Note:

The manufacturer guarantees correct readings only if the original leads supplied with the

device are used and if the correct length (for 2p method) has been selected in the MENU.

Extension leads or third party cables can be a source of additional errors.

Note:

Symbol “CAT III 1000V” shown on accessories is equivalent to the symbol “CAT IV 600V”

5 Storage

When storing the device you should:

Disconnect all leads from the meter

Ensure that the device and all accessories are dry

Ensure that the batteries are removed if the device is not going to be used for a prolonged period

of time

Storage should conform to the PN-85/T-06500/08 standard. Storage temperatures listed in the

technical specification are acceptable

6 Before You Start

After the purchase:

Check the contents of the packaging

Insert batteries

Verify and if necessary modify instrument’s configuration (method of displaying results, network

rated voltage, measurement of touch voltage, length of cables in the 2 p method)

14

7 Operations

You need to get familiar with this chapter as it describes test diagrams, testing methods and basic

rules of interpreting obtained results.

7.1 Preparing the Device For Work

Before commencing the measurements:

Make sure that the battery condition will allow you to complete the task

Check if the meter’s housing and leads’ insulation are not damaged

WARNING:

Using test leads with damaged insulation can cause electrocution.

WARNING:

Do not use a device that was stored for a prolonged period of time in unsuitable (e.g. hu-

mid) conditions.

WARNING:

You must not use the device with open or partially closed battery compartment and you

must not use any power source other than specified in this manual.

WARNING:

You must not leave disconnected leads while some of them remains connected to the test-

ed installation.

You must not leave the device unattended while it is connected to the tested installation.

You must not touch appliances connected to the tested installation.

WARNING:

You must not use the device if you notice that a loose object is present inside (the device

is rattling when shaken).

Do not insert any objects into the device through the fan mesh nor use the device if an ob-

ject was placed inside.

Note:

If the display is totally illegible, press down the keys 13 and 12 and adjust the

contrast using the keys and .

15

7.2 Power Supply Voltage Monitoring

The battery charge is shown by the indicator located in the upper right corner of the display as

shown in Fig.7.

Function name

Measurement results

From to

Charged batteries Discharged batteries

next

Replace batteries!

Fig.7. Battery charge indicator

7.3 Battery Replacement

MZC-310S meter is supplied with five R14 batteries (alkaline batteries are recommended) that

should be placed in the battery compartment located in the bottom part of the meter’s housing.

WARNING:

Leaving the leads attached to the terminals can result in a life threatening electrocution.

CAUTION!

If the batteries leaked inside the compartment, the device should be sent to an author-

ised service agent.

When the symbol 18 is displayed, it signals that the batteries are discharged. Re-

placement of the batteries is then necessary. To do it you need to:

Disconnect all leads from the terminals

Remove the battery compartment lid

Replace all batteries. The batteries (5xR14) should be inserted as shown on the diagram inside

the compartment. Incorrectly installed batteries will not damage the device or the batteries but will

prevent the meter from functioning

Replace the lid and secure it with screws.

16

Fig. 8. Opening the battery compartment

7.4 Conditions for Performing Tests and Obtaining Correct Results

To start a test sequence a number of conditions have to be fulfilled. The device will automatically

prevent a test from commencing (except for voltage measurement) if any of the conditions listed below

is not satisfied:

Situation

Displayed symbols

and warning signals

Remarks

The voltage applied to meter’s ter-

minals exceeds 440V.

Text: U> 440V! and a continuous

beep produced.

Immediately disconnect the meter

from the tested installation!

The voltage frequency in the instal-

lation is outside of the range

45..65Hz.

Texts: Error! and:

f<45Hz or

f>65Hz

Two long beeps

The text appears and a sound sig-

nal is produced when the key 10

is pressed

The voltage applied to meter’s ter-

minals is too low to measure the

impedance.

Texts: Error! and:

U<180V or

U<190V

Two long beeps

The text appears and a sound sig-

nal is produced when the key 10

is pressed.

Improperly connected cable I1: in

4p method to socket I1(42A) or in

2p method to socket I1(280A)

Texts: Cables connected improp-

erly! and:

Terminal I1(42A)! or

Terminal I1(280A)!

Two long beeps

The text appears and a sound sig-

nal is produced when the key 10

is pressed

Cables I1 or I2 are not connected

(in the 4p method).

Text: No voltage on terminals I1,

I2!

Two long beeps

The text appears and a sound sig-

nal is produced when the key 10

.

In the 4 p method, cables U or I

swapped, or connected to different

phases

Text: Different voltage phases on

terminals U and I!

Two long beeps

The text appears and a sound sig-

nal is produced when the key 10

is pressed

Improperly connected cable UBwith

the set option of touch voltage

measurement

Texts: Incorrectly connected ca-

ble! and:

Terminal UB!

Two long beeps

The text appears and a sound sig-

nal is produced when the key 10

is pressed

While measuring the loop imped-

ance a voltage drop below Umin

took place.

Text: Voltage failure while meas-

uring!

Two long beeps

While measuring the loop imped-

ance a situation preventing com-

pletion of the measurement oc-

curred.

Text: Error while measuring!

Two long beeps

17

Situation

Displayed symbols

and warning signals

Remarks

While measuring the loop imped-

ance the fuse was burnt or another

emergency situation in the current

circuit occurred.

Text: Short circuit loop faulty!

Two long beeps

Thermal protection prevents the

measurement.

Displayed symbol 16 .

Long beep

A sound signal is produced when

the key 10 is pressed

Exceeded measurement range

Inscription: OFL

Two long beeps

Discharged batteries

Displayed symbol 18

Making the measurements is still

possible, however, the user should

take into account some additional

errors.

Note:

Displayed warnings stay on the screen for 3 seconds.

7.5 Device Connection Diagrams

CAUTION!

The meter is connected to the tested installation as shown in Figures 9 -19. Attention

should be paid to the correct selection of test terminals since the precision of the meas-

urements being performed depends upon the quality of connections made. They have to

provide a good contact and allow for undisturbed flow of high current measured. For in-

stance, it is unacceptable to clip the crocodile connectors onto oxidized or corroded points

–they have to be either cleaned beforehand, or the test needle tip probe should be used for

measurements.

The device is to be connected to a tested installation or appliance in the way shown in fig. 9-19.

L1

PE

N

L3

L2

U1

U2

Fig.9. Alternating voltage measurement

18

L1

PE

N

L3

L2

I max42A

1

I2

Fig.10. Measurement of impedance in working circuit (L-N) using two-pole method

L1

PE

N

L3

L2

I max42A

1

I2

Fig.11. Measurement of impedance in protective circuit (L-PE) using two-pole method

L1

PE

N

L3

L2

I max42A

1

I2

Fig.12. Measurement of impedance in working circuit (L-L) using two-pole method

Table of contents

Other Sonel Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

NorthStar

NorthStar NS3100 Multi Instrument user manual

PBI Dansensor

PBI Dansensor MAP Check 9000 user manual

GE Digital Energy

GE Digital Energy Kelman MINITRANS installation manual

BES

BES MDU12i Modular unit

Badger Meter

Badger Meter LM-OG-P2 Advanced user manual

Seneca

Seneca T203PM100-MU installation manual

Elecsys

Elecsys WATCHDOG II MESH Installation and operation manual

brennenstuhl

brennenstuhl PM 231 E operating instructions

Mitutoyo

Mitutoyo MDH user manual

MADDALENA

MADDALENA microCLIMA U Installation and operating instructions

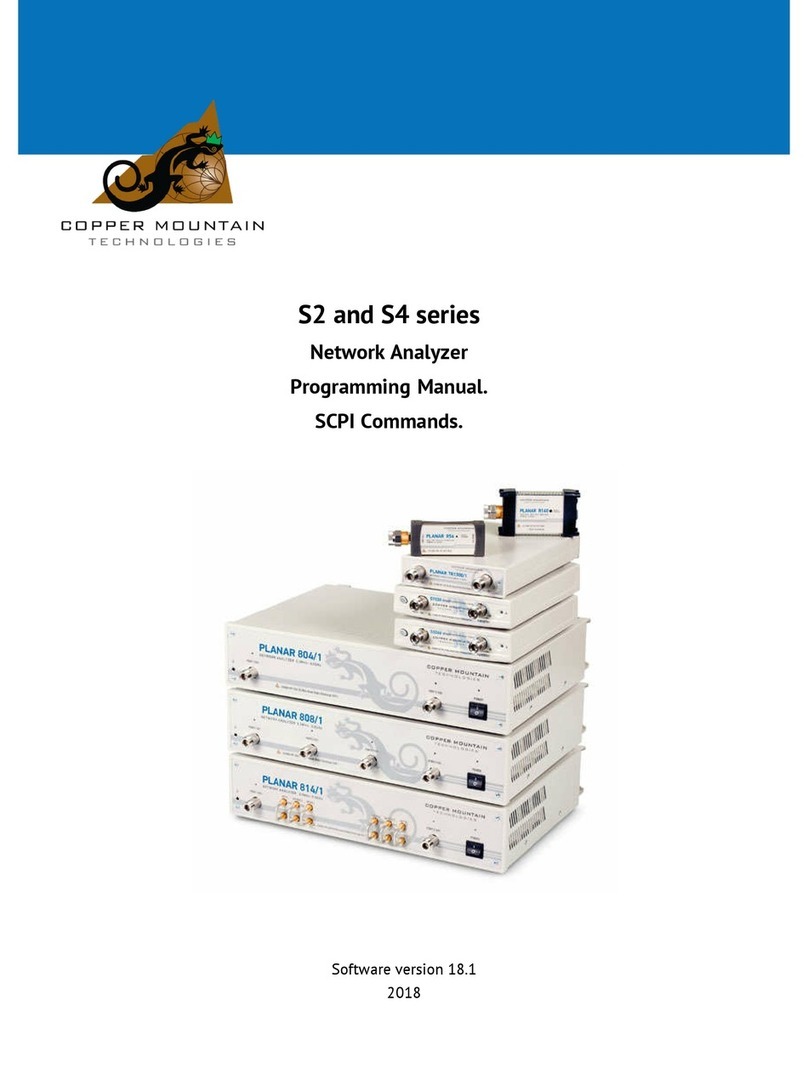

Copper Mountain Technologies

Copper Mountain Technologies S2 Series Programming manual

ECD

ECD DO82 Instructional manual